Understanding Jacking Trolleys: Your Vehicle Lifting Solution

Ever been stuck with a flat tire or needed to peek underneath your car for that mysterious rattle? That's where a jacking trolley comes to the rescue! This wheeled wonder is your ticket to safely lifting your vehicle for all those DIY maintenance tasks that make car ownership more affordable.

A jacking trolley is essentially a wheeled hydraulic lifting device that's designed to raise one corner of your vehicle with minimal effort. For those who like their information neatly packaged:

| Feature | Description |

|---|---|

| Purpose | Vehicle lifting for maintenance, tire changes, and repairs |

| Capacity | Typically 1.5-3 tons (suitable for most passenger vehicles) |

| Lift Range | 10-15 inches on average |

| Safety Note | Always use with jack stands - never work under a vehicle supported only by a jack |

Unlike those flimsy scissor jacks that come with your car (you know, the ones that make you break a sweat just thinking about using them), jacking trolleys provide a stable, secure lifting solution. The magic happens through hydraulic power – fluid pressure amplification between two connected cylinders multiplies the force you apply, letting you lift thousands of pounds with just a few pumps of the handle.

Most weekend mechanics don't realize that a jacking trolley is designed to lift just one corner of a vehicle at a time. That's why you typically only need a jack with about 75% of your vehicle's total weight capacity. Your family sedan? A 2-ton capacity jack should do the trick. Got a beefy SUV or 4x4? Step up to at least a 3-ton model for peace of mind.

What makes these tools so handy is their mobility. The wheeled design lets you easily roll your jacking trolley right under the proper lifting points of your vehicle. But remember – convenience should never trump safety. Always pair your jack with proper jack stands before sliding underneath your vehicle for any reason.

Here at American Mortuary Coolers, we understand lifting equipment inside and out. While our specialty is helping funeral professionals select the right equipment for their unique needs, our expertise extends to all types of lifting solutions, including jacking trolleys. We're committed to durability and reliability – whether it's for a funeral home or your home garage.

Want to learn more about specialized lifting equipment? Check out our resources on cremation oven systems, mark iv table 2 specifications, and tug for racks equipment – where we apply the same attention to detail and safety considerations as we discuss here with jacking trolleys.

What Is a Jacking Trolley & How It Works

A jacking trolley (also known as a trolley jack or floor jack) is a hydraulic lifting device that transforms a little bit of your effort into enough power to lift a vehicle weighing thousands of pounds. Unlike those flimsy scissor jacks that come with most cars, a jacking trolley gives you stability, ease of use, and safety features that make vehicle maintenance much less stressful.

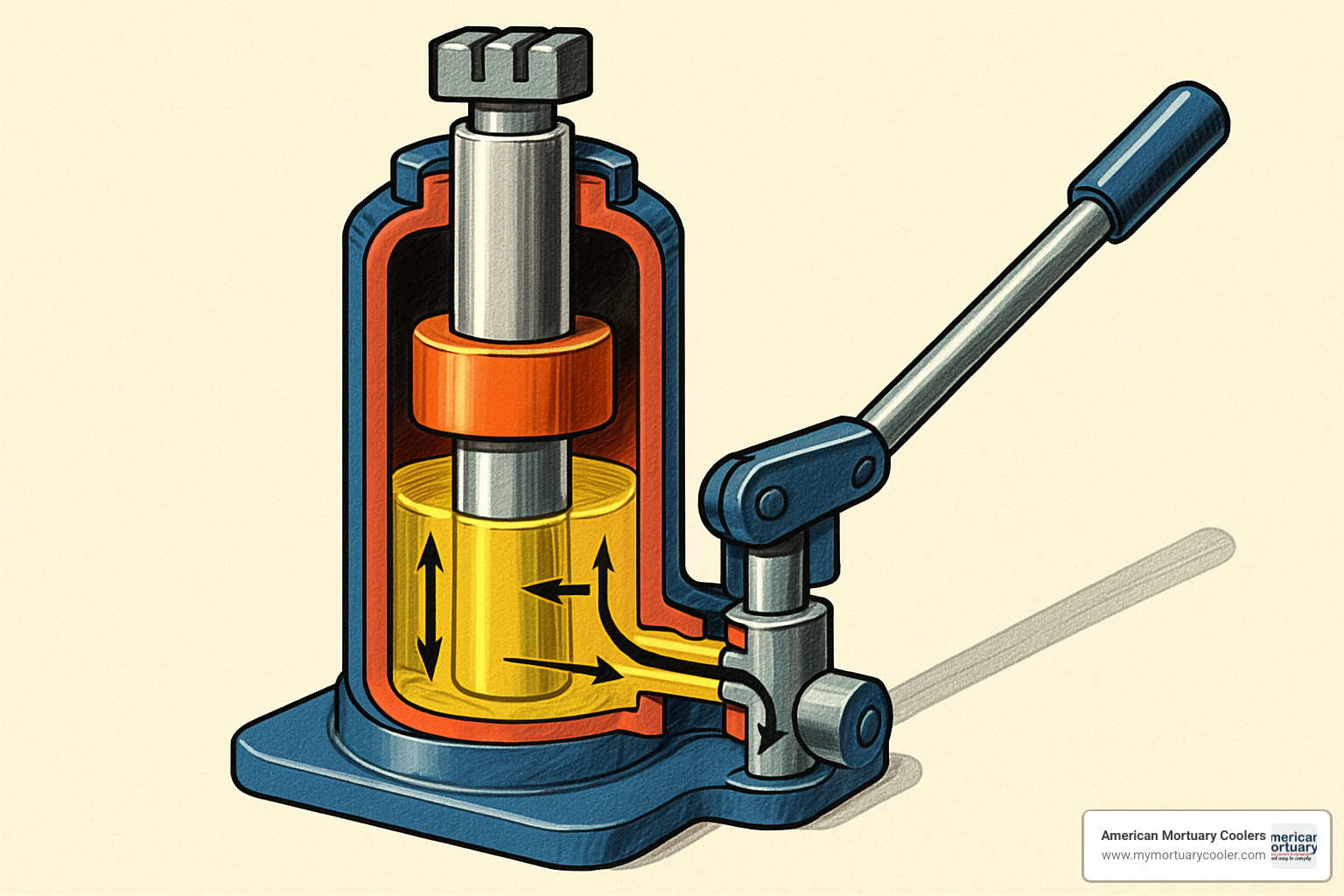

The Hydraulic System

The magic behind a jacking trolley lies in its hydraulic system. Think of it as a mechanical multiplier that turns your modest arm strength into vehicle-lifting power. When you pump the handle, you're moving a small piston that pushes hydraulic fluid (usually oil) into a much larger cylinder. The pressure stays the same throughout the system, but because the larger cylinder has more surface area, the force gets multiplied dramatically. It's like turning a garden hose into a fire hose!

The system consists of several key parts working together. The hydraulic cylinder contains the fluid that transfers your force. The pump handle is what you work to create pressure. The saddle & lift arm makes contact with your vehicle and does the actual lifting. And when it's time to lower your vehicle, the release valve lets you control a smooth, gradual descent.

Key Components and Their Functions

Your jacking trolley comes with several features designed for safety and convenience. The swivel casters let you easily wheel the jack into position under your vehicle, even in tight spots. An overload valve acts as a safety feature that prevents you from trying to lift more than the jack is rated for – potentially saving you from dangerous situations.

Most jacking trolleys offer a lifting range of about 10-15 inches from their lowest to highest position. This range works for most vehicles, though low-profile sports cars might need specialty jacks. The saddle is the part that makes direct contact with your vehicle's designated lifting points, often padded to prevent damage to your vehicle.

"Hydraulic jacks use pressure amplification between two connected cylinders to lift vehicles with minimal effort." - AutoZone

The One-Corner Lift Principle

Here's an important point that's often misunderstood: a jacking trolley is designed to lift just one corner of a vehicle at a time, not the entire thing. This is why you'll typically see recommendations for a jack with a capacity of around 75% of your vehicle's total weight.

For example, if you own a 2,800-pound car, a 2-ton (4,000-pound) capacity jack would be more than sufficient since you're only lifting approximately 700 pounds (one corner) at a time. This principle helps explain why most home mechanics can get by with a 2-ton or 3-ton jack for most passenger vehicles.

At American Mortuary Coolers, we understand the importance of reliable lifting equipment. While our specialty is mortuary equipment, the hydraulic principles in our body lifts and mortuary trolleys mirror those in automotive jacking trolleys. Whether lifting a vehicle or handling more sensitive cargo, the priorities remain the same: safety first, reliability always, and ease of use as a bonus.

Main Types & Comparisons

Shopping for a jacking trolley can feel overwhelming with so many options available. Let's break down the different types so you can find the perfect match for your garage or workshop needs.

Common Jack Types

The world of vehicle jacks offers something for every situation. The standard floor jack or trolley jack is what most home mechanics prefer – it rolls easily into position and has that long handle that gives you plenty of leverage without breaking your back.

If you're working with trucks or higher vehicles, a bottle jack might be your best friend. These compact powerhouses provide impressive lifting capacity in a vertical design, though they're not quite as stable as their wheeled cousins.

Most cars come with a scissor jack tucked away with the spare tire. They're handy in emergencies but require more elbow grease and wobble more than I'd like when I'm working underneath my vehicle.

For those beautiful low-riding sports cars, a low-profile race jack is essential – some can slide under vehicles with as little as 3 inches of clearance. And if you're tired of lugging around heavy steel jacks, an aluminum racing jack offers the same strength at a fraction of the weight (though your wallet might feel a bit lighter too).

Hate pumping that handle? An electric jack might be worth the investment, especially if you have strength or mobility limitations. And for those monster trucks and SUVs, a high-lift jack provides the extra height you need to get those big wheels off the ground.

Trolley Jack vs. Floor Jack: What's the Difference?

I often hear these terms used interchangeably, and while they're similar, there are some noteworthy differences:

| Feature | Trolley Jack | Floor Jack |

|---|---|---|

| Construction | Usually smaller with swivel wheels | Larger with a wide steel base |

| Weight Capacity | 500 lbs to 3 tons | 1 to 12 tons |

| Lift Range | 10-15 inches | Up to 21 inches |

| Mobility | Full directional with swivel casters | Two-wheel directional movement |

| Best For | Quick, light-duty vehicle lifts | Heavy-duty lifts of larger vehicles |

| Price Range | $40-$200 | $100-$500+ |

As Martin, who recently purchased an electric floor jack, happily shared: "Great value for price. As advertised. It did what it was supposed to and did it well... Easy peasy."

Hydraulic vs Mechanical Jacking Trolley

The debate between hydraulic and mechanical jacks often comes down to your specific needs and preferences.

Hydraulic Jacking Trolleys

Hydraulic jacking trolleys harness the power of fluid pressure to do the heavy lifting. Standard single-piston models typically need 10-15 pumps to reach full height, but if you're impatient like me, you might appreciate a dual-piston model that gets there faster. For the ultimate in efficiency, rocket-lift designs can reach full height in just 3-5 pumps – perfect for busy shops.

The beauty of hydraulic systems is how they transform a modest arm workout into enough force to lift a vehicle. They offer smoother operation, greater lifting capacity, and that wonderfully controlled lowering with the release valve that prevents heart-stopping sudden drops.

Mechanical Jacking Trolleys

On the other hand, mechanical jacks like the scissor variety use a simple screw mechanism instead of hydraulic wizardry. They'll give you more of a workout, but they're typically more compact, lighter, and less expensive. Plus, you'll never have to worry about hydraulic fluid leaks – a nice bonus if you're storing it in your trunk.

At American Mortuary Coolers, we've found that hydraulic lifting systems provide the reliability and ease of use that funeral professionals demand. While our day-to-day focus is on mortuary equipment rather than vehicle maintenance, the principles of safe, efficient lifting remain the same. For those in the funeral industry seeking specialized lifting solutions, our comprehensive guide to comparing mortuary lifting trolleys offers detailed information specific to mortuary applications.

Sizing, Features & Buying Criteria

Choosing the right jacking trolley for your needs doesn't have to be complicated. Think of it like buying a good pair of shoes – you need the right fit, quality materials, and features that match your specific needs. Let's walk through what matters most when shopping for one of these handy garage tools.

Determining the Right Capacity

First things first – can the jack actually lift your car? This is the most important question to answer.

Start by checking your vehicle's curb weight in your owner's manual or with a quick online search. Here's where many folks get confused: you don't actually need a jack rated for your entire vehicle's weight. Since you're only lifting one corner at a time, the standard advice is to follow the 75% rule – a jack rated at about 75% of your vehicle's total weight will typically do the job safely.

For most vehicles, this breaks down pretty simply:

- Your compact car will usually be fine with a 1.5-ton capacity jack

- The family sedan typically needs a 2-ton capacity model

- Bigger vehicles like SUVs, trucks and 4x4s generally require at least a 3-ton capacity

As one automotive expert puts it: "A full-size family saloon will probably only need a jack with a 2-ton capacity to lift it, while an SUV or 4x4 may need a capacity of at least 3 tons."

Key Features to Consider

Physical Dimensions

The size of your jacking trolley matters more than you might think. If you've got a lowered sports car, the minimum height becomes crucial – some low-profile jacks start at just 3 inches off the ground. Meanwhile, the maximum height determines how high you can lift your vehicle for comfortable access underneath.

The chassis length affects both stability and storage – longer jacks generally provide better stability but take up more space in your garage. And don't overlook the saddle diameter (that's the part that actually contacts your vehicle). Larger saddles distribute pressure better and reduce the risk of damaging your car's frame.

Safety Features

When it comes to lifting thousands of pounds over your body, safety isn't optional. Look for jacks with an overload protection valve that prevents lifting beyond the rated capacity. A good bypass valve stops over-extension of the hydraulic ram, while some premium models include a built-in safety lock as an additional mechanical backup.

I always recommend models with a rubber saddle pad to protect your vehicle's lifting points from damage. These small features make a big difference in both safety and preventing costly damage.

Construction Materials

The age-old tradeoff between weight and strength applies to jacking trolleys too.

Steel jacks offer superior durability and tend to cost less, but they're significantly heavier to move around. Aluminum models weigh about 50-60% less than comparable steel jacks, making them much easier to position, but you'll pay a premium for that convenience.

Some manufacturers offer the best of both worlds with hybrid designs – steel frames for stability with aluminum lifting arms to reduce overall weight.

As Edward C., a satisfied jack owner, noted in his review: "This jack is well made. It's heavy and solid." That heft is often a sign of quality construction that will last for years.

Performance Features

Little conveniences can make a big difference when you're working in your garage. Rapid-lift technology gets your vehicle up with fewer pumps, while dual-piston designs provide faster lifting action overall. A long handle offers better leverage for easier pumping, and 360° swivel casters make positioning under tight spots much simpler.

Price Considerations

Like most tools, jacking trolleys come in a range of price points that generally reflect their quality and features:

Entry-level models ($40-$80) offer basic 1.5-2 ton capacity suitable for occasional home use, but may lack durability and extra features.

Mid-range options ($80-$200) provide better build quality with additional safety features and typically 2-3 ton capacity – a sweet spot for most home mechanics.

Professional-grade jacks ($200-$500+) feature heavy-duty construction, higher capacities, rapid lift features, and extended warranties for those who use them frequently.

At American Mortuary Coolers, we understand quality lifting equipment as an investment in both safety and efficiency. While our specialty is the mortuary industry, we apply these same principles of durability and reliability to all our hydraulic equipment. For specialized applications, our guide on lift standards with hydraulic mortuary trolleys provides additional insights.

For those looking for a reliable automotive option, the TEQ Correct 2 Ton Floor Jack strikes a good balance between quality and value for most passenger vehicles.

Safe Operation, Vehicle Support & Maintenance

Let's face it – a jacking trolley is only as safe as the person using it. I've seen too many DIYers take shortcuts that made me wince! Proper technique isn't just about getting the job done; it's about making sure you go home with all your fingers and toes intact.

Safe Operation Procedures

Before you even think about lifting your vehicle, park it on a flat, level concrete surface – never on gravel, dirt, or an incline. Trust me, I've heard horror stories about jacks sinking into soft ground mid-job! Always engage your parking brake first, then place wheel chocks on the opposite wheels from where you're lifting.

Your vehicle's owner manual is your best friend here – it shows the exact jack points designed to support your car's weight. Using random spots can damage components or create dangerous instability. Position your jacking trolley so the saddle centers perfectly under that jack point before you start pumping.

Weight rating on your jack? It's not a suggestion – it's a safety limit determined through engineering and testing. A 2-ton jack trying to lift a 3-ton truck is a recipe for disaster.

Vehicle Support with Jack Stands

Here's my number one rule that I'll shout from the rooftops: Never, ever get under a vehicle supported only by a hydraulic jack!

A jacking trolley is a lifting tool, not a support system. Hydraulic systems can fail, and when they do, they don't give warning. Always use properly rated jack stands placed under designated support points (usually frame rails or subframe components). Lower your vehicle onto these stands gradually – don't just drop it! – and ensure the locking mechanisms fully engage.

Before you slide underneath, give your vehicle a gentle rock test. If there's any movement or instability, start over. As Hovig Manouchekian, who has 30+ years of experience with lifting equipment, puts it: "Never work under a vehicle supported only by a jack; use jack stands." Words to live by, literally.

Step-by-Step Jacking Trolley Procedure

Let me walk you through the safest way to use your jacking trolley:

First, prepare your vehicle by applying the parking brake and chocking the wheels that will remain on the ground. Next, ensure the release valve is closed by turning it clockwise until finger-tight – no need to channel your inner Hulk here!

Position your jack with the saddle centered under the proper lifting point, then pump the handle using smooth, full strokes. Once you've reached the desired height, place your jack stands under appropriate support points, then slowly open the release valve (turning counterclockwise) until the vehicle gently settles onto the stands.

With your vehicle securely supported, you can remove the jack completely. When your work is finished, the process reverses: jack up slightly, remove the stands, then gradually lower by slowly opening the release valve.

Maintenance for Longevity

A well-maintained jacking trolley can last decades. I've seen treasured jacks passed down through generations of mechanics! Regular inspection is key – check for hydraulic fluid leaks (those small puddles under your stored jack aren't normal), make sure wheels and casters roll freely, and examine the lifting arm for any bending or damage.

The hydraulic system needs love too. If lifting performance decreases, you might need to top off the fluid or bleed air from the system. That "spongy" feeling when pumping usually means trapped air. I recommend replacing the hydraulic oil annually or whenever performance declines – it's cheap insurance against failure.

Storage matters more than you might think. Keep your jacking trolley in an upright position in a dry location to prevent rust. Slightly opening the release valve when stored prevents seal damage, and wiping it clean before storage keeps debris from damaging the sensitive components.

The most common mistakes I see are using jacks on uneven surfaces (disaster waiting to happen), lifting at improper points (goodbye, oil pan!), overloading beyond capacity (physics always wins), working without jack stands (please don't), and leaving the release valve open while pumping (it'll never lift properly).

At American Mortuary Coolers, we understand hydraulic lifting principles deeply – they're critical in our mortuary equipment. While our specialty is serving the funeral industry with reliable hydraulic body lifts and stretchers, the same safety principles apply whether you're lifting a vehicle or handling more sensitive cargo.

Scientific research from Trail-a-mate confirms what experienced mechanics already know: proper use of hydraulic equipment dramatically reduces injury risk while improving efficiency. When it comes to working under thousands of pounds of metal, there's simply no room for shortcuts.

Conclusion & FAQs

Conclusion

After spending time with a jacking trolley, you'll wonder how you ever managed without one. These remarkable tools transform what used to be a sweaty, frustrating job into something almost enjoyable. Throughout this guide, we've walked through everything from hydraulic principles to safety procedures, hoping to make your vehicle maintenance both safer and more efficient.

Remember these key points as you shop for and use your jacking trolley:

First, always select a jack with enough muscle for your vehicle – that 75% rule (picking a jack rated for at least 75% of your vehicle's total weight) isn't just a suggestion, it's your safety net.

Second, match your jack to your specific needs. If you're working on a lowered sports car, that standard jack might leave you frustrated – go for a low-profile model instead. Similarly, SUV owners will appreciate the extra height and capacity of heavy-duty options.

Third, those safety features aren't just fancy selling points – the overload valves and stable bases might just save you from a trip to the emergency room. And please, never, ever rely solely on a jacking trolley to hold your vehicle while you're underneath it. Jack stands aren't optional – they're essential.

At American Mortuary Coolers, we understand quality lifting equipment because reliability is non-negotiable in our industry. While we focus on crafting custom mortuary coolers and equipment from our Tennessee workshop, we apply the same durability standards to everything we touch. There's something satisfying about equipment built to last, whether it's supporting a vehicle or serving funeral professionals across the country.

For those curious about our primary business, our guide on mortuary coolers provides a comprehensive look at our custom solutions.

FAQ #1: What size jacking trolley do I need?

This is the question I hear most often, and thankfully, it has a straightforward answer. Start by finding your vehicle's weight in the owner's manual or through a quick online search. Once you have that number, you're typically lifting just one corner at a time, so a jacking trolley rated for 75% of your vehicle's total weight is usually perfect.

For most regular cars and sedans, a 1.5-2 ton capacity jack handles the job beautifully. If you're driving an SUV or light truck, bump up to a 2.5-3 ton model. Those with heavy trucks or commercial vehicles should look at 3+ ton capacity options.

I always tell friends that when it comes to jacks, it's better to have a little more capacity than you need rather than cutting it close. The peace of mind is worth the small additional cost.

FAQ #2: Can I work under a car held only by a jacking trolley?

I can't stress this enough: absolutely not. This mistake can be fatal, and sadly, it happens all too often. Your jacking trolley is designed to lift, not support. Hydraulic systems can fail, seals can leak, and jacks can slip – often without warning.

Always pair your jack with quality jack stands rated for your vehicle's weight. Position them at the manufacturer-recommended support points, and fully lower the vehicle onto these stands before sliding underneath. Never try to save time by using makeshift supports like cinder blocks or stacked wood – they can crumble without warning.

Before getting underneath, give the vehicle a firm push to test its stability on the stands. That extra five seconds could save your life.

As a mechanic friend once told me, "A jacking trolley is like an elevator – great for getting you where you need to go, but you wouldn't remove the cables once you reached your floor."

FAQ #3: How often should I service my jacking trolley?

Your jacking trolley needs regular attention to stay safe and reliable. I recommend changing the hydraulic oil annually – this keeps the lifting action smooth and prevents internal corrosion. Every few months, take a moment to check the seals for any signs of leaking or damage.

If your jack starts feeling "spongy" when you pump it, that's a sign you need to bleed air from the system – a simple procedure detailed in most owner's manuals. Don't forget to lubricate the moving parts and pivot points every 3-6 months with a quality grease.

When you're not using it, store your jack in a dry place, upright with the ram lowered and the release valve slightly open. This simple habit prevents unnecessary pressure on the seals when not in use.

At American Mortuary Coolers, we've learned that preventive maintenance saves both money and headaches, whether we're talking about a garage jacking trolley or specialized mortuary equipment. A little care goes a long way toward years of reliable service.

With these guidelines in mind, your jacking trolley will be ready whenever you need it, making your DIY vehicle maintenance safer and more enjoyable for years to come.