Understanding the Core of Cremation Operations

When families choose cremation, they rarely see the technology that makes this dignified process possible. At the heart of every crematory lies the cremation retort – a specially designed furnace that transforms human remains into the ashes families eventually receive.

A cremation retort isn't your average industrial furnace. It's a carefully engineered system that balances technical precision with deep respect for the deceased. These remarkable machines operate at temperatures between 1,400-2,000°F, hot enough to efficiently reduce human remains to bone fragments and ash in a matter of hours.

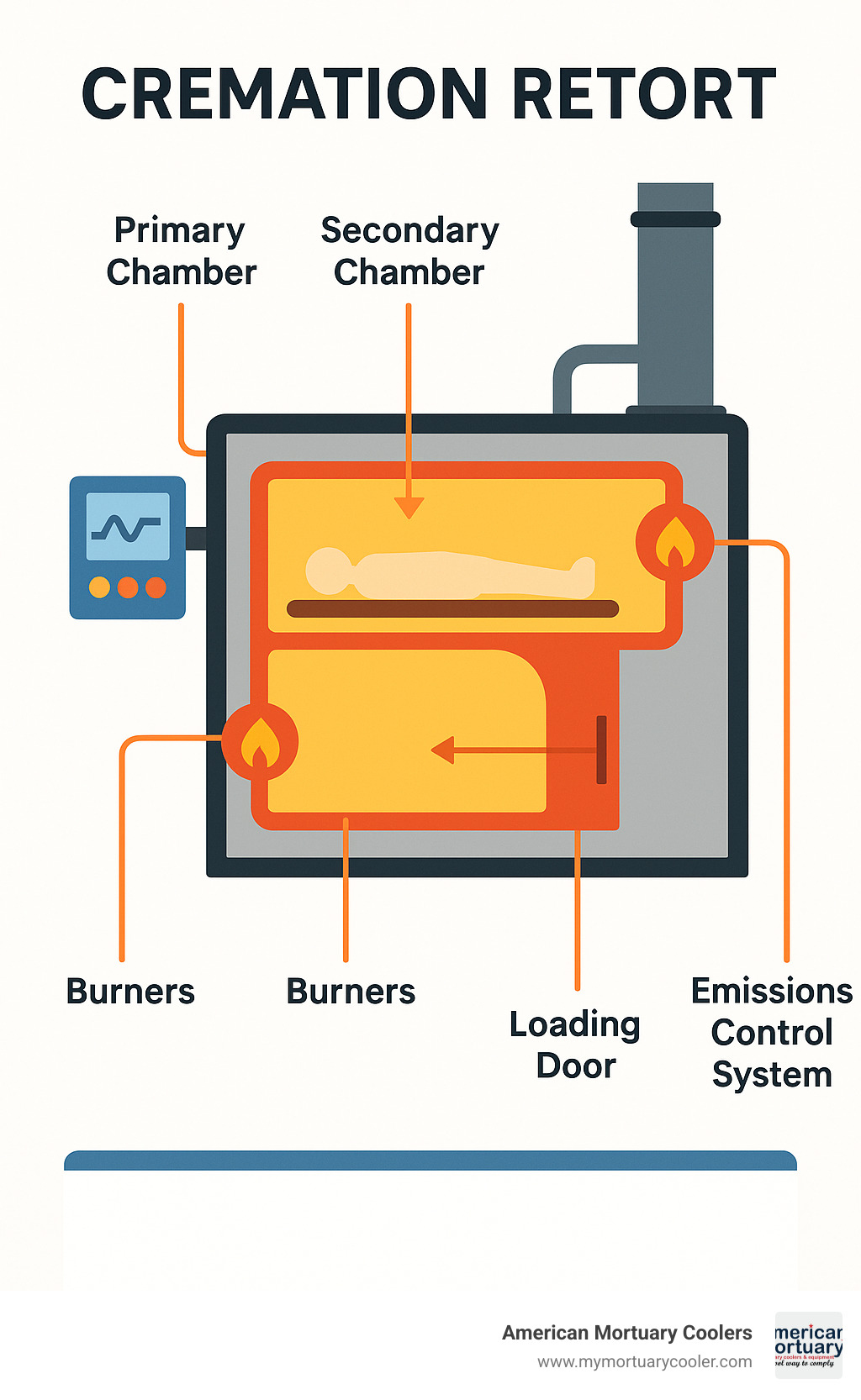

What makes these systems special is their thoughtful design. Each cremation retort features fire-resistant brick lining capable of withstanding the intense heat generated during operation. They contain both primary and secondary chambers to ensure complete combustion, minimizing environmental impact while maximizing efficiency.

The growing preference for cremation makes these systems increasingly important. According to the National Funeral Directors Association, cremation rates are projected to reach 78% in the U.S. by 2035. As this trend continues, funeral homes across America are investing in quality equipment to meet this rising demand.

I've seen how the right equipment transforms a funeral home's operations. At American Mortuary Coolers, we regularly work alongside crematory operators to provide complementary equipment that integrates seamlessly with their cremation retort systems. Our Tennessee-based team has finded that proper equipment selection dramatically impacts both operational efficiency and the quality of service families receive.

Modern cremation retorts integrate sophisticated technology – from precision burners and intuitive control systems to advanced air filtration and cooling mechanisms. But they're more than just technical marvels. These systems represent our industry's commitment to providing dignified end-of-life care while respecting environmental responsibilities.

For funeral professionals looking to expand their knowledge, here are some related terms worth exploring:

- cremation oven (another common term for these systems)

- jacking trolley (equipment used in the loading process)

- tug for racks (helps move remains safely within the facility)

Every cremation retort requires certified professionals to operate it safely and effectively. These dedicated individuals undergo specialized training to ensure they can manage the system while maintaining compliance with strict regulatory oversight. Their expertise ensures each cremation is conducted with the utmost respect, technical precision, and environmental consideration.

Cremation Retort Basics: Definition & Primary Function

When funeral directors talk about the equipment they use, there's one piece that stands at the center of modern cremation services: the cremation retort. While you might hear people casually say "cremation oven" or "cremation chamber," those of us in the industry know that "retort" is the proper technical term.

A cremation retort isn't just any furnace—it's officially classified as a Type IV incinerator specifically engineered for the respectful change of human or animal remains through carefully controlled heat. Its primary job is to apply intense, regulated temperatures that reduce the body to inorganic bone fragments while minimizing environmental impact through proper combustion and filtration systems.

The term "retort" actually carries some meaningful history in our industry. Originally, it described furnaces heated from below, which prevented fuel ash from mixing with human remains—a thoughtful design feature that showed respect for the deceased even in the technical aspects of the equipment.

In our years of service at American Mortuary Coolers, we've noticed that funeral professionals who truly understand their equipment make better operational decisions. A cremation retort is far more than a simple furnace—it's a carefully engineered system built with specific parameters to ensure every cremation is handled with dignity, efficiency, and environmental responsibility.

More info about cremation chambers

What Is a "Cremation Retort"?

Think of the cremation retort as the heart of the entire cremation process. It's a specialized thermal processing unit with one specific purpose: to reduce human remains to bone fragments through the application of intense heat. Unlike general industrial furnaces you might find in manufacturing, a cremation retort is engineered exclusively for this solemn purpose.

In our industry, the term "retort" specifically refers to the chamber where the actual cremation takes place. Environmental regulations classify this equipment as a Type IV incinerator, meaning it's specifically designed and approved for processing human or animal remains.

One of the most important aspects of a proper cremation retort is what we call the "one-body rule"—both a legal requirement and ethical standard that ensures only one person is cremated at a time. This fundamental principle preserves the dignity of each individual and maintains the integrity of the entire process.

In our work with crematoriums from coast to coast—from busy facilities in New York to family-owned operations in Los Angeles—we've seen how all proper identification protocols and processing procedures are built around this essential aspect of retort operation.

Core Temperatures & Fuel Sources

What makes a cremation retort work effectively is its ability to generate and maintain extremely high temperatures. Modern retorts operate between 1,400 and 2,000 degrees Fahrenheit (760 to 1,093 degrees Celsius)—hot enough to melt aluminum and some types of steel.

These extreme temperatures aren't just for show—they serve several critical purposes. They ensure complete combustion of organic materials, reduce the body to its basic mineral components, minimize emissions and particulates, and complete the process efficiently within a reasonable timeframe.

Most cremation retorts today run on one of three main fuel sources:

Natural Gas is the most common choice across America, typically consuming between 700-1,000 cubic feet per hour during operation. It's popular for its clean-burning properties and relative affordability in urban areas.

Propane often powers retorts in areas where natural gas lines aren't readily available, using approximately 10 gallons per hour. Many of our rural Tennessee clients and those in remote areas choose this option for its reliability.

Bio-Fuel Options are emerging alternatives in environmentally conscious markets, particularly in regions focused on reducing dependency on fossil fuels.

The energy needs vary based on the size and efficiency of the retort, but typically, a cremation requires about 100 MJ of thermal energy (roughly equivalent to 3 cubic meters of natural gas) before combustion can properly begin for an average adult.

In our experience at American Mortuary Coolers, we've found interesting regional preferences. Our clients in rural areas and throughout the Rocky Mountain Region often prefer propane systems, while our urban customers in Chicago and New York typically choose natural gas for its operational efficiency and lower long-term costs. These practical considerations make a big difference in day-to-day operations and the bottom line.

Anatomy & Operation: Components, Temperatures, Step-by-Step Process

When you step into a modern crematorium, the cremation retort stands as the centerpiece of operations. It's not just a piece of equipment—it's a carefully engineered system designed to perform its solemn duty with respect and efficiency. Let me walk you through what makes these remarkable machines tick.

I've visited dozens of crematoriums across America while helping funeral directors choose complementary equipment, and I'm always struck by how much thoughtful engineering goes into each cremation retort.

Main Components & Features

The heart of any cremation retort is its primary chamber—a carefully constructed space where the actual cremation takes place. This chamber is lined with specialized fire bricks that can withstand the intense heat and repeated heating-cooling cycles. Some of our clients in the Southwest have shown me bricks that have endured thousands of cremations, a testament to their durability.

Behind the scenes, the secondary chamber (often called the afterburner) works its magic. Operating at temperatures above 900°C, this component ensures that gases and particles are fully combusted before leaving the system. As one crematorium director in Ohio told me, "The afterburner is what keeps our neighbors happy—they never see smoke from our stack."

The loading door might seem simple, but it's actually a marvel of engineering. Heavily insulated and equipped with safety interlocks, it creates a perfect seal to maintain internal temperatures while keeping operators safe. We've noticed facilities in colder climates like Minnesota especially appreciate well-designed doors that minimize heat loss.

Modern cremation retorts feature sophisticated control panels that would make any tech lover smile. These programmable logic controllers (PLCs) manage everything from temperature profiles to air flow patterns. Many now include touchscreens and data logging capabilities that create digital records of each cremation—important for both quality control and regulatory compliance.

The opacity sensor might be small, but it plays a mighty role in environmental protection. By continuously monitoring exhaust for particulates, it helps ensure the facility stays within air quality guidelines. One crematorium manager in California proudly showed me their perfect environmental record, thanks in part to this critical component.

Preparation & Loading Procedures

Before a cremation retort begins its work, careful preparation is essential. The process starts with meticulous identification verification—a step that can never be rushed or overlooked. The ID tag stays with the deceased throughout the entire process, ensuring the right remains are returned to the family.

The container selection matters more than you might think. Whether it's a simple cardboard container or an neat cremation casket (depending on whether a viewing took place), it needs to be both combustible and sturdy enough to support the weight during transfer.

Medical device removal is another critical step that sometimes surprises people new to the industry. Pacemakers and implantable defibrillators must be removed before cremation since they can explode when heated—potentially damaging the retort and disrupting the process. I once spoke with a crematory operator in Texas who described the sound of an overlooked pacemaker exploding as "like a shotgun going off in the chamber."

For larger individuals, many facilities use what's known as a "hot hearth" approach. By pre-heating the floor of the retort above 1,000°F, they ensure immediate evaporation of excess fluids upon contact. This thoughtful adaptation helps maintain dignity while addressing practical considerations.

The loading process itself is handled with remarkable care. Using specialized loading tables or hydraulic systems, the body is transferred into the cremation retort with respect and precision. Proper positioning ensures even heat distribution and efficient combustion.

Inside the Cremation Retort – Complete Cycle

Once the door closes, the cremation retort begins its carefully orchestrated cycle. It starts with gentle ignition and gradual temperature increase—not unlike warming up a car engine before a long drive. This measured approach prevents thermal shock to the expensive refractory materials.

As temperatures climb to between 1,400-1,800°F, primary combustion begins in earnest. It's fascinating to realize that a typical body, being about 65% water, requires around 100 MJ of thermal energy just to begin the combustion process. The physics behind cremation is quite remarkable.

While the primary chamber does its work, gases flow upward into the secondary chamber. Here, temperatures above 1,650°F ensure complete oxidation of organic compounds. This two-stage approach dramatically reduces emissions—something that makes modern cremation much more environmentally friendly than many people realize.

Throughout the process, sophisticated systems continuously monitor and adjust conditions. Modern cremation retorts process about 100 pounds per hour on average, with capacity to handle up to 150 pounds per hour at maximum efficiency.

The active cremation typically takes 2-3 hours, followed by a cooling period of 15-30 minutes. Once temperatures drop to safer levels, the cremated remains—primarily bone fragments—are carefully swept from the chamber into a cooling pan.

The final step involves processing the cooled bone fragments in a separate machine called a cremulator. This reduces them to the consistent, fine ash that families receive. As a crematorium director in Seattle explained to me, "We take great care with this final processing step—it's the last service we provide before returning the remains to the family."

More info about tools of the trade

At American Mortuary Coolers, we've designed our cooling and preparation equipment to integrate seamlessly with the cremation retort workflow. After all, a well-designed facility considers the entire process, not just individual pieces of equipment. That's the difference that comes from working with specialists who understand the unique needs of the funeral profession.

Safety, Environmental & Regulatory Controls

When it comes to operating a cremation retort, safety isn't just a checkbox—it's a fundamental responsibility. Today's cremation equipment operates within carefully structured frameworks that protect operators, respect the environment, and maintain compliance with an array of regulations. Let's explore how these critical controls work together in modern cremation facilities.

Emission Control & Air Quality Standards

The days of billowing smoke from crematorium chimneys are long behind us. Modern cremation retorts incorporate sophisticated emission controls that make the process virtually invisible to neighboring communities.

The magic happens in the secondary chamber, where temperatures must stay above 900°C (1,650°F). At this intense heat, gases and particulates undergo complete combustion before ever reaching the atmosphere. It's like having a second chance to capture anything that didn't fully combust the first time around.

Many of our clients have upgraded to systems with baghouse filtration—essentially giant vacuum cleaners for smoke particles. And with growing awareness about mercury from dental fillings, some forward-thinking facilities have added activated carbon systems that specifically target and capture mercury emissions.

"Getting your state air permit is just the beginning," as one of our Pennsylvania customers told us. "Keeping it requires constant vigilance." That's why opacity sensors have become standard equipment, monitoring emission density and alerting operators before small issues become big problems.

In our work installing complementary equipment from coast to coast, we've noticed a clear trend: newer cremation retorts are dramatically cleaner than their predecessors. The EPA agrees that proper secondary combustion is the critical factor in minimizing environmental impact. For more in-depth research, the Cremation Association of North America offers excellent scientific resources on emissions standards.

Operator & Facility Safety Measures

The people operating cremation retorts deserve to go home safely every day, which is why modern equipment incorporates multiple safety systems that work together seamlessly.

Temperature interlocks prevent accidents by making it physically impossible to open the loading door when chamber temperatures are dangerously high. Door sensors ensure cremation can't begin until everything is properly sealed. These aren't just good ideas—they're essential protections.

The workplace environment matters too. Modern retorts operate at around 55 decibels—about as loud as a normal conversation—compared to older models that could reach a ear-damaging 96 dB. Proper room ventilation pulling in at least 2,500 cubic feet of fresh air per minute prevents overheating and maintains comfortable working conditions.

Proper training remains the cornerstone of safety. As one of our Tennessee crematory operators put it: "The equipment can have all the safety features in the world, but nothing replaces a well-trained operator who understands what they're doing."

The exterior of a properly functioning cremation retort should never feel dangerously hot to the touch. Safety codes mandate that the exterior temperature shouldn't exceed the ambient room temperature by more than 60 degrees—a simple test that tells you a lot about equipment condition and installation quality.

Governing Codes & Certifications

Navigating the regulatory landscape can feel like working through a maze, but understanding these requirements is essential for trouble-free operation.

The Environmental Protection Agency sets the baseline for emissions standards nationwide, though day-to-day enforcement typically happens at the state or local level. Meanwhile, professional organizations like the National Funeral Directors Association provide ethical guidelines that go beyond legal minimums.

Most quality cremation retorts carry UL-listing—a certification from Underwriters Laboratories confirming they meet rigorous safety standards. This isn't just a nice-to-have feature; many insurance companies require it.

Local zoning requirements often dictate where cremation equipment can be installed, sometimes requiring special permits or hearings. Once operational, detailed record-keeping becomes mandatory, tracking everything from case identification to operating parameters.

Annual inspections have become standard practice in most jurisdictions. These check-ups, typically conducted by manufacturer representatives or certified technicians, help catch small issues before they become expensive problems or safety hazards.

At American Mortuary Coolers, we've guided funeral homes across the country through these complex requirements. Whether you're in Boston or Baton Rouge, we understand how local regulations impact your equipment choices and installation options. Our experience with complementary equipment gives us valuable perspective on how these systems work together in real-world settings.

More info about essential maintenance tips can help you keep your equipment running safely and efficiently for years to come.

Ownership Essentials: Fuel, Costs, Maintenance & Human vs Animal Differences

When you're considering a cremation retort for your funeral home, there's much more to think about than just the upfront purchase. Let's talk about what ownership really means – from the day-to-day costs to keeping your equipment running smoothly for decades.

Fuel Consumption & Operating Expenses

Every time you fire up your cremation retort, you're making an investment in serving families. Understanding the fuel costs helps you plan your business operations more effectively.

Natural gas is the most common fuel choice across America, with typical retorts consuming between 700 and 1,000 cubic feet per hour during active cremation. For our funeral homes in rural areas without natural gas infrastructure, propane serves as an excellent alternative, though it runs at about 10 gallons per hour (sometimes peaking at 16 gallons during maximum operation).

When budgeting, think about $0.16 per pound of body weight as a general rule of thumb for fuel costs. That means cremating someone weighing 180 pounds would cost around $29 in fuel – an important figure when calculating your service pricing.

"We upgraded to a modern cremation retort last year," shared one of our Columbia, SC customers. "The better insulation and more efficient burners cut our fuel bills by almost a third, and we can serve more families each week. The machine paid for itself faster than we expected."

Some of our forward-thinking clients have installed heat recovery systems that capture waste heat from the secondary chamber to warm other areas of their funeral home – a smart way to reduce overall energy costs, especially in colder regions like the Northeast.

Don't forget about the electrical requirements either. Your retort will typically need 208/240V, single-phase, 60-amp electrical service on 6 AWG wiring to power the control systems and blowers.

Purchase Price, Installation & Customization

Investing in a cremation retort is a significant decision that extends beyond the equipment itself.

New human cremation retorts typically range from $80,000 to $150,000 depending on capacity and features. But the equipment is just the beginning. You'll need to budget for proper installation, which includes crane and rigging services (usually $5,000-$10,000), a substantial concrete slab (minimum 4 inches thick, though we recommend 6 inches for longevity), plus all the necessary gas and electrical connections.

Your retort doesn't have to be a utilitarian eyesore, either. Modern units offer various customization possibilities to match your facility's aesthetic – from color and finish options to different control interfaces ranging from basic systems to sophisticated touchscreens. We've helped funeral homes from Los Angeles to New York select complementary equipment that integrates seamlessly with their cremation retort installations.

Space planning matters too. You'll need to dedicate approximately 20' x 15' with at least 12' ceiling clearance for proper installation and operation. At American Mortuary Coolers, we specialize in helping you maximize your available space for optimal workflow.

Maintenance & Repair Best Practices

A well-maintained cremation retort is like a trusted employee – reliable, efficient, and capable of serving your community for decades.

The smartest owners follow a routine maintenance schedule, scheduling annual tune-ups or maintenance every 500 cremations, whichever comes first. This includes regular inspection of the refractory materials for cracks or wear, burner cleaning and adjustment, and control system testing.

The most significant maintenance expense you'll face is refractory replacement. A complete relining of a cremation chamber typically costs between $15,000 and $20,000 and is generally needed after approximately 8,000 hours of operation. Savvy funeral directors establish a maintenance fund by setting aside about $10 per cremation to cover these predictable future expenses.

"Preventative maintenance isn't an expense—it's an investment," as one of our Johnson City, TN clients put it. "Our cremation retort is approaching 20 years of service because we've followed the manufacturer's maintenance recommendations religiously."

Modern "Quick Change" modular hearth systems can be replaced in a single day, minimizing downtime – a crucial consideration when serving families on tight timelines. With proper care, your quality retort can remain in service for over 30 years, though you might need to update control systems and burners during this period.

For more detailed guidance, check out our Essential maintenance tips resource.

Human vs. Animal Retorts

As pet cremation services continue to grow in popularity, many funeral homes are considering whether to offer both human and animal services. The equipment, while similar in principle, has important differences.

Capacity considerations vary significantly between the two types. Human retorts typically accommodate bodies up to 750-1,000 pounds, while pet cremation units range dramatically in size – from small chambers for pets under 50 pounds to specialized equine units capable of handling animals over 1,500 pounds.

Perhaps the most fundamental difference involves multi-load capabilities. Human cremation requires one body per cremation by both law and ethical standards. In contrast, animal retorts often come in two varieties: those designed for "segregated" cremations with partitioned chambers keeping pets separate, and others built for "communal" cremations of multiple animals together.

The design differences reflect these distinct purposes. Animal retorts frequently feature multiple smaller chambers rather than one large one, with loading systems custom to the size and weight of remains. The control systems may also be simplified compared to those required for human cremation.

Regulatory requirements also differ substantially. Human cremation faces stricter oversight in most jurisdictions, while animal cremation often falls under different permitting categories.

We've noticed increasing interest in pet cremation services particularly across the Southwest and Pacific regions, with many funeral homes expanding their offerings to include both human and animal cremation. At American Mortuary Coolers, we're happy to discuss how our complementary equipment can support either or both types of services.

Innovations & Future-Ready Customization

The world of cremation retorts isn't standing still. Today's innovations are changing these essential machines into smarter, cleaner, and more efficient systems that better serve both funeral professionals and the families they help.

Digital Controls & Remote Diagnostics

Gone are the days of operators constantly monitoring dials and making manual adjustments. Modern cremation retorts now feature intelligent control systems that practically think for themselves.

The most impressive advancement might be the weight-based algorithms that automatically customize each cremation. Simply input the deceased's weight, and the system calculates the optimal temperature, timing, and fuel usage—no guesswork required. As one Chicago crematorium manager told us with a smile, "It's like upgrading from a flip phone to a smartphone. What used to require constant babysitting now happens with a few taps."

These smart systems also create digital breadcrumbs of each cremation. Every temperature change, timing adjustment, and emission reading gets recorded automatically, making regulatory compliance more straightforward than ever. When something does need attention, cloud-based alerts can ping an operator's phone immediately—even if they're in another part of the building.

Perhaps most valuable is the remote diagnostic capability. Systems like Tek Marshal allow manufacturers to peek under the hood from hundreds of miles away. A crematorium director in Minneapolis recently shared how this saved their operation: "Our retort started acting up on a Friday afternoon. Instead of waiting until Monday for a technician, the manufacturer connected remotely, walked us through a simple fix, and we were back running in 30 minutes."

Sustainability & Green Options

Environmental consciousness is reshaping cremation retort design, with manufacturers racing to reduce ecological impacts while maintaining respectful, efficient operation.

Electric retorts represent perhaps the boldest step forward. While still relatively uncommon, these systems eliminate direct fossil fuel combustion entirely. In regions blessed with clean electricity generation, this can dramatically reduce the carbon footprint of each cremation.

Waste heat recovery systems are gaining popularity as well. Rather than letting valuable heat escape up the stack, these clever systems capture it to warm facility spaces or water. A funeral director in Portland told us, "The heat recovery system on our cremation retort now handles about 60% of our building's heating needs during winter. It's both environmentally responsible and budget-friendly."

Bio-gas compatibility is another frontier. Modern retorts can increasingly operate on renewable fuel sources, further reducing their environmental impact. And some manufacturers are even exploring supplemental solar heating systems to reduce fossil fuel consumption during the initial heating phase.

At American Mortuary Coolers, we've noticed our clients in the Pacific and Rocky Mountain regions are particularly interested in these eco-friendly options. As one Colorado funeral home owner put it, "Families increasingly ask about our environmental practices. Having a greener cremation retort gives us a meaningful answer."

Facility-Specific Engineering

Today's cremation retorts can be custom to fit your specific facility needs like a custom-made suit.

Stack height optimization has become surprisingly scientific. Using computational fluid dynamics (CFD) simulations, manufacturers can now determine the perfect stack height for your specific location. This ensures proper emission dispersion based on surrounding buildings and prevailing winds—particularly valuable in urban settings where neighbors might be close by.

For facilities in noise-sensitive areas, improved soundproofing options can reduce operational noise below the standard 55 dB to create an even more peaceful environment. Color customization has also evolved beyond basic options, with manufacturers offering finishes that complement your facility's aesthetic or even incorporate branding elements.

Space constraints? No problem. Today's manufacturers offer custom configurations for facilities with unusual room layouts or limited square footage. A funeral home director in downtown Atlanta shared how this flexibility saved their expansion plans: "When we installed our new cremation retort, we were working with a challenging basement space. The manufacturer designed a system that fit perfectly while still meeting all our operational needs."

Integration capabilities have improved dramatically as well. New retorts can be designed to work seamlessly with your existing ventilation, monitoring, or facility management systems, creating a unified operational approach rather than disconnected equipment islands.

More info about cremation furnace evolution

At American Mortuary Coolers, we understand that every funeral home has unique needs and spaces. That's why we ensure our coolers and related equipment integrate perfectly with modern cremation retorts, creating efficient workflows that serve both your staff and the families counting on you.

Frequently Asked Questions about Cremation Retorts

How long does a cremation take inside a retort?

When families ask about cremation timing, I always explain that a cremation retort typically completes the process in about 2–3 hours. This timeline isn't set in stone though—it varies based on several important factors.

Body mass plays a significant role. Larger individuals naturally require more time due to greater tissue volume and higher water content. I've seen cases where a person weighing over 300 pounds might take nearly twice as long as someone half that size.

The starting temperature of the retort makes a difference too. When a cremation retort has been used recently and still retains heat from previous cremations, the process moves along more quickly than with a cold start. That's why many crematoriums schedule cremations back-to-back when possible—it's both more efficient and environmentally responsible.

Modern equipment simply works faster than older models. The newer cremation retorts with advanced insulation and optimized burner placement can achieve higher temperatures more quickly and maintain them more consistently.

After the active cremation finishes, we always allow a cool-down period of 15–30 minutes before processing the remains. This waiting period is necessary for both safety and proper handling of the cremated remains.

In terms of efficiency, today's modern cremation retorts process about 100 pounds per hour on average, though they can reach up to 150 pounds per hour under ideal conditions. This helps crematoriums plan their daily schedules with reasonable accuracy.

What happens to metal implants after cremation?

One question that frequently surprises families is what happens to metal implants during cremation. The truth is, metals like hip replacements, dental work, and surgical hardware remain intact after the cremation retort completes its cycle.

After cremation, we carefully separate these metals from the cremated remains. For ferrous metals (those containing iron), we often use magnetic separation techniques. Non-ferrous metals like titanium joint replacements or gold dental work require manual identification and removal by trained staff.

Most crematoriums today participate in responsible recycling programs for these recovered metals. Specialized companies collect and process them, with many programs donating the proceeds to charitable causes. Some facilities receive rebates that help offset operational costs, ultimately benefiting the families they serve.

The handling of these post-cremation metals is subject to regulations that vary by location. Some states require disclosure to families about what happens to metal implants, while others have specific guidelines for recycling or disposal. At American Mortuary Coolers, we've worked with crematoriums nationwide and seen various approaches to handling this aspect of the process.

It's worth mentioning that very small metal items like surgical staples, pins, or tiny screws may oxidize during the intense heat of the cremation retort and become indistinguishable from the cremated remains themselves.

Can one person safely operate a retort from start to finish?

Yes, modern cremation retorts are specifically designed for safe, efficient operation by a single person. This is a significant improvement over older equipment that often required multiple staff members working together.

Today's retorts feature fully automated cremation cycles with straightforward controls. Rather than constantly monitoring and adjusting temperatures manually, operators can rely on preset programs for different case types, automatic temperature regulation, and a main timer that tracks the process from start to finish.

Safety is paramount in modern design. Multiple built-in safety systems prevent dangerous operations—door interlocks make it impossible to open the chamber during high-temperature operation, temperature monitors prevent overheating, and emergency shutdown capabilities ensure quick response to any unusual situation.

That said, proper training remains essential. Operators must complete specialized certification courses, typically provided by the manufacturer. These certifications generally last for five years, though annual refresher training is highly recommended to stay current with best practices and safety protocols.

As a crematorium director in Dallas once told me: "Our modern cremation retort has such comprehensive automation and safety features that a properly trained individual can confidently manage the entire process alone, which wasn't possible with the equipment we used even a decade ago."

At American Mortuary Coolers, we've found that this single-operator efficiency is especially valuable for smaller funeral homes where staff often wear multiple hats throughout the day.

Conclusion and Next Steps

The cremation retort represents the beating heart of modern cremation services – a remarkable fusion of engineering excellence and compassionate care. As more Americans choose cremation (with rates projected to reach 78% by 2035), understanding this specialized equipment becomes essential for forward-thinking funeral professionals.

Throughout this exploration, we've uncovered the fascinating world of these specialized furnaces and what makes them tick. From the intense heat that transforms human remains with dignity to the sophisticated controls that ensure environmental compliance, cremation retorts embody both technical precision and respectful service.

Investing in quality cremation equipment involves more than just the initial purchase price. Smart funeral directors recognize the ongoing partnership they're forming – with considerations for fuel efficiency, routine maintenance schedules, and eventual refractory replacement all playing crucial roles in the total cost of ownership. As one of our clients in Nashville put it, "Buying a retort isn't just an equipment decision; it's a business relationship that lasts decades."

The future looks bright for cremation retort technology. Today's innovations – from cloud-connected diagnostic systems to eco-friendly designs that slash carbon footprints – are changing what's possible. These advancements don't just benefit your bottom line; they reflect your commitment to environmental stewardship and technical excellence.

Here at American Mortuary Coolers, we understand that successful cremation operations depend on more than just the retort itself. The supporting equipment – from body coolers to preparation tables – creates the workflow foundation that makes your daily operations smooth and efficient. Our custom mortuary coolers are specifically designed to integrate seamlessly with modern cremation retorts, creating a harmonious system rather than disconnected pieces of equipment.

From our home base in Tennessee, we've helped funeral homes across America – from the sandy beaches of Florida to the mountains of Colorado – build cremation systems that truly work. Our team's practical experience with installations nationwide gives us unique insight into what actually works in real-world funeral homes, not just what looks good on paper.

Whether you're adding cremation services for the first time or upgrading aging equipment, understanding the fundamentals of cremation retort technology empowers you to make choices that will serve both your business and your community for decades to come. The right equipment doesn't just perform a technical function – it enables you to provide families with the dignified, efficient service they deserve during life's most difficult moments.