Everything You Need to Know About Choosing a Prep Table With Sink

Essential Guide to Modern Kitchen Workstations

A prep table with sink is a specialized workstation that combines a flat working surface with an integrated sink basin, providing an all-in-one solution for food preparation and cleaning tasks in both commercial and residential kitchens.

| What is a Prep Table with Sink? | Key Features | Common Materials | Standard Sizes |

|---|---|---|---|

| A workstation combining a flat surface with an integrated sink | • Stainless steel construction • Backsplash (5-10" high) • Undershelving • Adjustable legs |

• 304 stainless steel (16/18 gauge) • Poly tops for knife work • Solid wood for aesthetics |

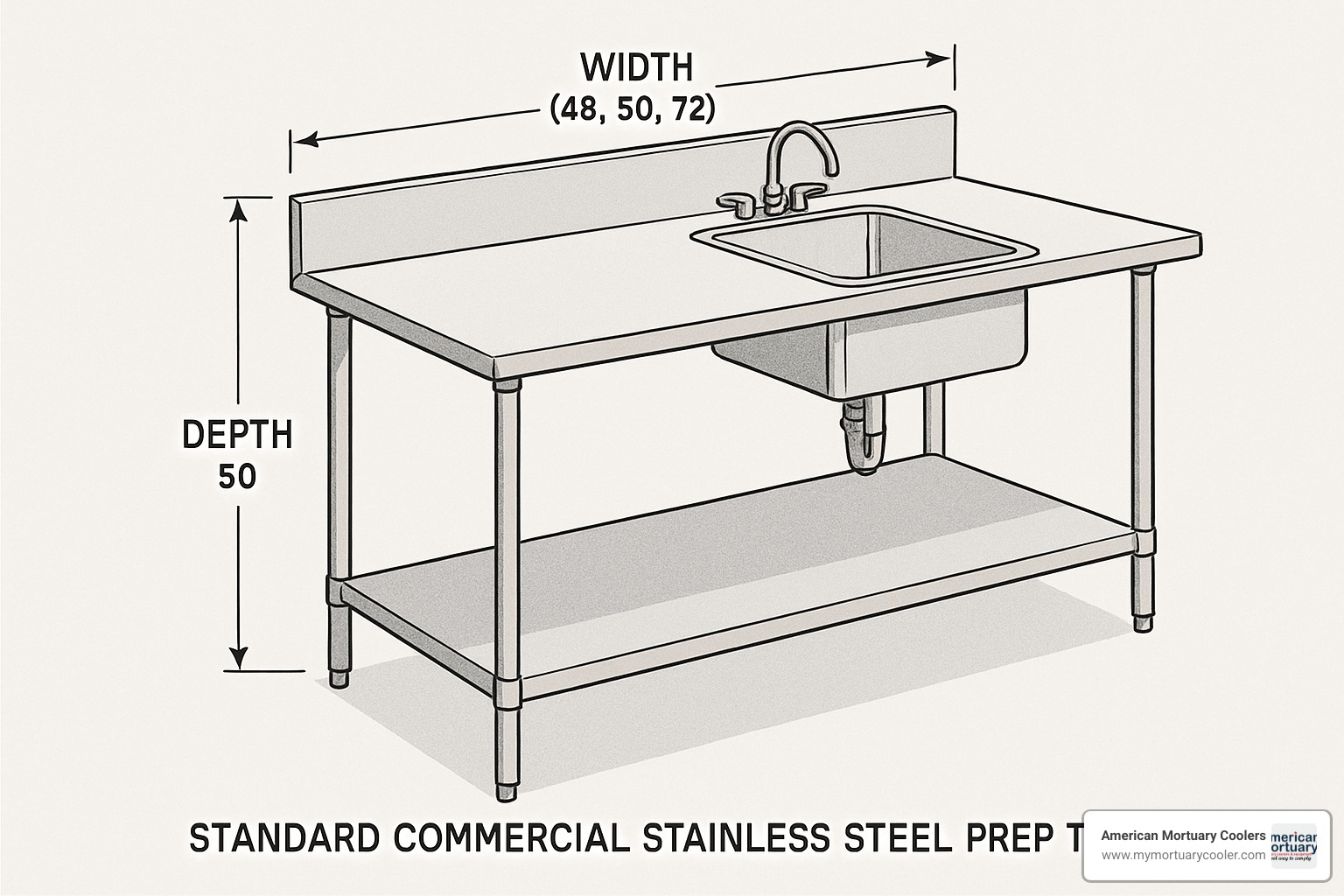

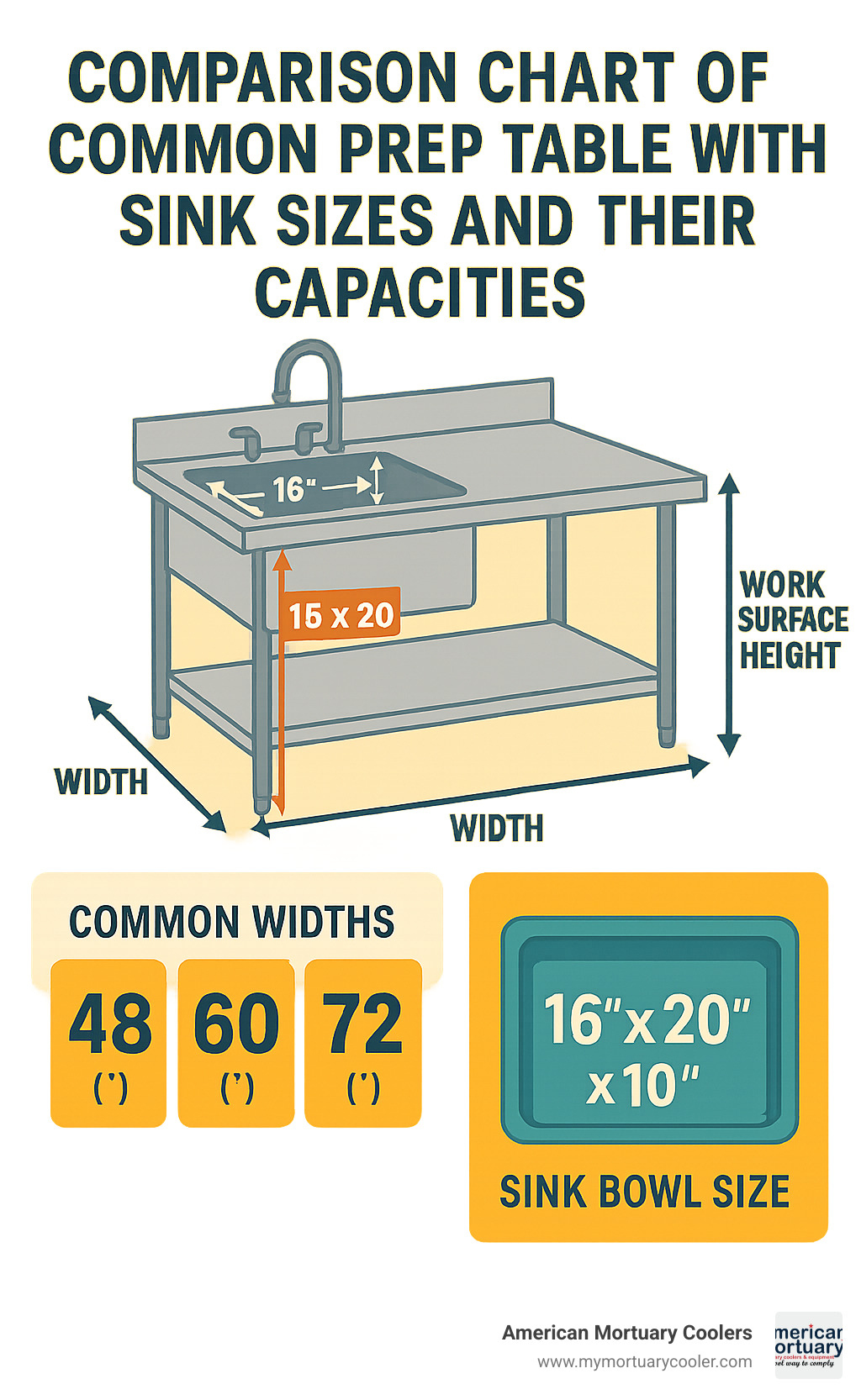

• Widths: 48-72" • Depths: 30" • Standard sink bowl: 16"x20"x10" |

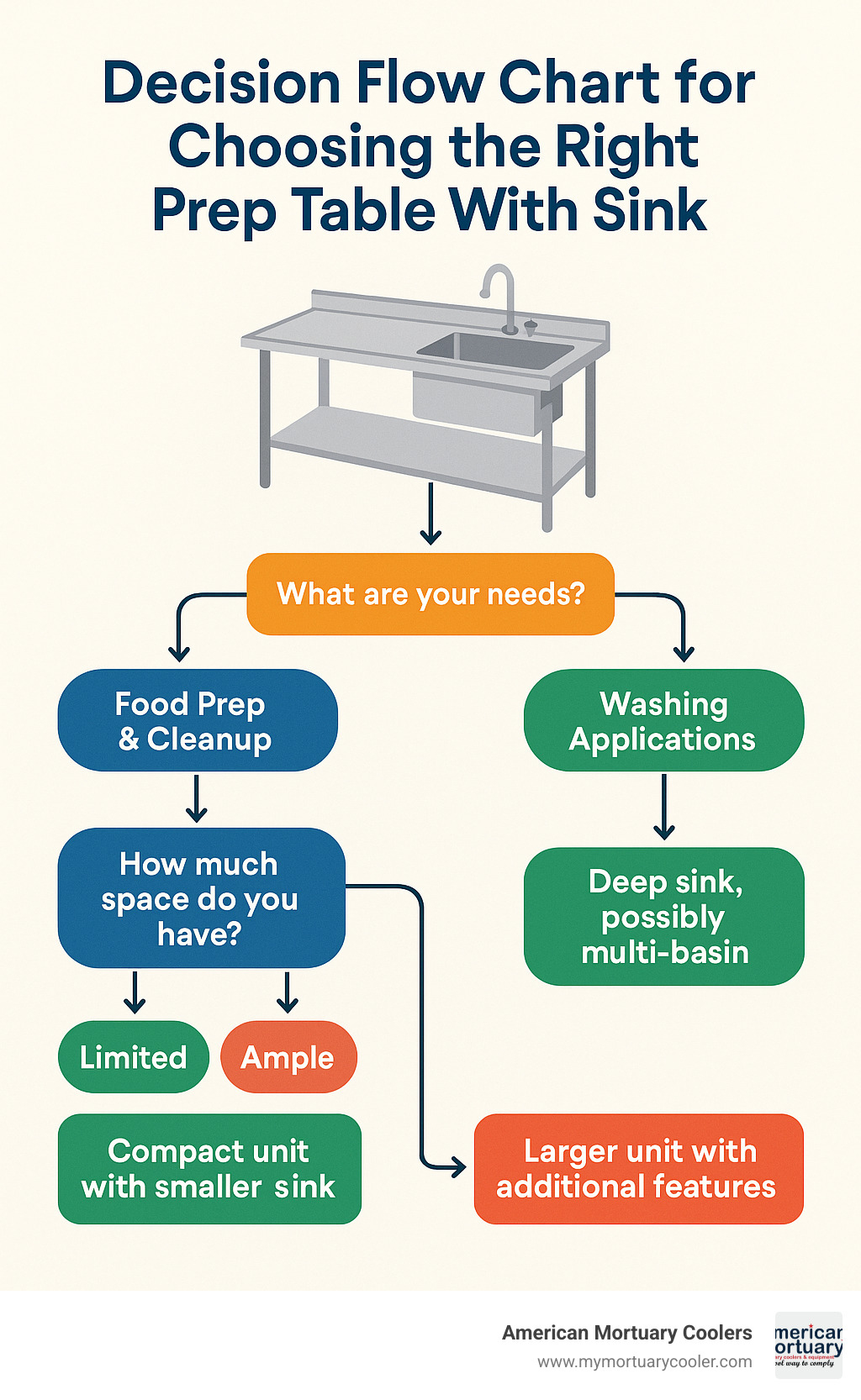

When selecting the perfect prep table with sink for your needs, consider these key factors:

- Space requirements - Measure your available area carefully

- Material durability - 18-gauge stainless steel for standard use, 16-gauge for heavy duty applications

- Sink configuration - Left, right, or center placement depending on your workflow

- Storage needs - Undershelves, drawers, and customizable accessories

- Compliance requirements - NSF certification for commercial applications

The integrated sink design eliminates unnecessary movement between workstations, creating an efficient workflow that saves time and reduces cross-contamination risks. This is especially valuable in busy commercial kitchens where space optimization and food safety are paramount concerns.

Stainless steel models dominate the market due to their durability, ease of cleaning, and compliance with health regulations. Most commercial-grade options feature NSF certification, ensuring they meet strict public health standards.

Residential models tend to focus more on aesthetics and may incorporate different materials like wood bases with stainless tops to blend with home décor while maintaining functionality.

I'm Mortuary Cooler, a national supplier of specialized preparation equipment including prep tables with sinks for funeral homes and commercial kitchens across America. My experience has shown that the right prep table with sink can dramatically improve workflow efficiency while maintaining the highest standards of sanitation.

Explore more about prep table with sink:

Prep Table With Sink 101: Definition, Uses & Benefits

If you've ever watched professional chefs at work, you've probably noticed how smoothly they move between tasks. A big part of that efficiency comes from having the right equipment – and a prep table with sink is one of those game-changing workstations that can transform how you work in the kitchen.

Think of a prep table with sink as your kitchen's multitasking hero. It combines a sturdy work surface with an integrated water source, creating a single station where you can wash, chop, and prepare ingredients without running back and forth across the kitchen. This simple combination makes an enormous difference in commercial kitchens and is increasingly finding its way into serious home cooks' spaces too.

In busy restaurant kitchens, these workstations become the heart of food preparation. Chefs use them for washing and prepping fresh vegetables, rinsing seafood, thawing frozen ingredients under cool running water, and cleaning tools between tasks. The beauty is having everything you need within arm's reach.

"I tell my staff that our prep table with sink is like having an extra pair of hands in the kitchen," says Chef Miguel, who runs a popular taco restaurant in Austin. "It's where all our fresh ingredients start their journey to the plate."

One of the biggest benefits of these tables is how they support food safety. By providing a dedicated station for washing produce, commercial kitchens can more easily comply with health department regulations that require separate areas for different types of food preparation. The vegetable prep sink component becomes a crucial tool in preventing cross-contamination.

In smaller kitchens where space comes at a premium, a prep table with sink is practically magical – it eliminates the need for separate fixtures, freeing up valuable floor space for other essential equipment. It's like getting two workstations while only using the footprint of one.

Residential vs. Commercial Prep Table With Sink

While they serve the same basic purpose, the prep tables with sinks you'll find in professional kitchens differ significantly from those designed for homes.

Commercial models are built like tanks. They typically feature NSF-certified 304 stainless steel construction with heavier 16-gauge (or even 14-gauge) thickness that can withstand years of intense daily use. They come standard with commercial-grade plumbing fixtures, standardized heights for standing work, and practical features like marine edges that contain spills. Everything about them is designed for durability, sanitation, and efficiency rather than aesthetics.

Home versions, by contrast, often balance function with form. They might incorporate decorative wood elements or designer finishes alongside stainless steel components. They typically use lighter 18-gauge steel, feature smaller sink bowls, and may have adjustable heights for comfort. Many are designed to blend beautifully with home décor while still providing professional-level functionality.

Sarah, a home baker from Portland who recently upgraded her kitchen, told me: "After years of dreaming about it, I finally installed a prep table with sink in my kitchen renovation. Now I wonder how I ever lived without it. Kneading dough, washing fruits, and prepping ingredients all happen in one spot. It's changed how I cook entirely."

Why a Prep Table With Sink Improves Workflow

The magic of a prep table with sink lies in how it transforms kitchen workflow through thoughtful design.

First, there's the time savings. A study in commercial kitchens found that chefs saved about 30 minutes per shift when using an integrated prep station compared to separate areas. Those minutes add up quickly in a busy restaurant – or even in your home kitchen when you're trying to get dinner on the table after work.

Then there's the food safety angle. By keeping washing and cutting activities at the same station, you dramatically reduce the risk of spreading bacteria from one food to another. No more dripping raw chicken juice across the kitchen as you move from sink to cutting board!

The ergonomic benefits are substantial too. A well-designed prep table with sink creates a natural workflow that reduces physical strain. Commercial models typically stand between 34¾ and 41¾ inches tall – the sweet spot for comfortable standing work. Everything is positioned to minimize reaching, twisting, and unnecessary movement.

"In culinary school, they taught us that efficiency starts with how you arrange your workspace," explains home chef Marcus from Chicago. "My prep table with sink creates what professionals call a 'work triangle' where everything I need is within easy reach. I'm less tired after cooking a big meal now, and I actually enjoy the prep process instead of seeing it as a chore."

Whether you're running a busy restaurant kitchen or simply want to bring professional efficiency to your home cooking, a prep table with sink represents one of the smartest investments you can make in your culinary workspace. It's where functionality meets convenience – the perfect marriage of two essential kitchen elements.

Key Features, Materials & Accessories Checklist

Shopping for a prep table with sink can feel overwhelming with all the options available. Let me walk you through what really matters when making this important kitchen investment.

When I talk with chefs about their prep table with sink preferences, material quality always tops the list. Most commercial models feature Type 304 stainless steel, which stands up beautifully to daily use while resisting corrosion. The thickness matters too – 18-gauge works well for normal kitchen duties, while 16-gauge provides that extra durability when things get hectic. Many of our customers appreciate this difference when they're prepping for hours on end.

The backsplash might seem like a minor detail, but it's actually a major sanitation feature. Those 5-10 inch walls behind your prep table with sink prevent water splashes from damaging your walls and creating potential mold issues. Commercial kitchens typically opt for taller backsplashes – and for good reason! I've seen many a kitchen wall saved by this simple feature.

Don't overlook the importance of a marine edge – that slightly raised rim around your work surface. It's a small detail that makes a huge difference when you're dealing with liquids. Rather than running onto the floor creating slip hazards, spills stay contained on your prep table with sink where they belong. Your maintenance staff will thank you!

The sink configuration deserves careful thought based on your specific needs. A standard commercial bowl typically measures about 16" x 20" x 10" deep, but I've worked with clients who needed specialized dimensions for particular tasks. Think about what you'll be washing most frequently when deciding on size and depth.

Stability matters tremendously in a busy kitchen. Look for adjustable legs with bullet feet that can be precisely leveled even on uneven floors. The best commercial models feature 1⅝" diameter stainless steel legs that won't wobble during intense prep sessions. Many of our prep tables with sinks include a patented stability system with recessed gusset design that dramatically reduces side-to-side movement.

Storage considerations should factor into your decision too. An adjustable undershelf transforms wasted space into valuable storage for equipment and supplies. Most models position this shelf 4-7 inches less than the table width to accommodate the legs while maximizing usable area.

Faucet options vary widely, from basic models to pre-spray versions that make cleaning stubborn food residue much easier. While some prep tables with sinks come with faucets installed, others require separate purchase – an important detail to confirm before ordering.

For a deeper dive into stainless steel options and benefits, check out our detailed guide on stainless steel tables.

Material Pros & Cons

The material you choose for your prep table with sink affects everything from maintenance requirements to knife blade longevity. Let me break down your options.

Stainless steel dominates commercial kitchens for good reason. Its non-porous surface resists bacteria growth, making it ideal for food safety. It stands up to heat without warping and cleans up beautifully after even the messiest prep sessions. The 304-grade stainless we recommend meets all NSF requirements for commercial kitchens and resists both rust and corrosion.

"I've had my stainless prep table with sink for over a decade of daily use, and it still looks almost new," one restaurant owner told me recently. "Just a quick wipe-down and it's ready to go again."

The downsides? Stainless can be noisy when pots and pans are set down firmly. It does show water spots and fingerprints, especially in high-humidity environments. And knife enthusiasts should note that stainless surfaces will dull your blades faster than softer alternatives.

For serious knife work, many chefs prefer a poly-top surface made from high-density polyethylene. These surfaces are much gentler on knife edges while resisting stains and odors effectively. They're particularly good for acidic food preparation where reactivity might be a concern. The trade-off comes in heat resistance – you'll need to be careful with hot pans – and they do eventually show cutting marks over time.

Solid wood brings warmth and beauty to residential kitchens where aesthetics matter. A well-maintained wooden prep table with sink provides a good cutting surface and operates much more quietly than metal alternatives. The natural look blends beautifully with home décor, and minor damage can often be sanded and refinished.

However, wood requires regular maintenance with food-grade oils or sealants to prevent moisture damage. It's more susceptible to bacterial growth if not properly maintained and typically won't meet NSF approval for commercial applications. In high-volume environments, wood simply won't last as long as more durable alternatives.

Must-Have Accessories

The right accessories transform a basic prep table with sink into a workflow powerhouse custom to your specific needs.

Storage solutions make a tremendous difference in efficiency. Adjustable undershelves keep frequently used equipment within reach but out of the way. Drawer assemblies – typically around 20" x 20" x 5" – provide organized storage for smaller tools and utensils. I've had clients rave about the difference dedicated cutting board storage makes, keeping these essential tools accessible without cluttering valuable work surfaces.

Backsplash additions maximize your vertical space. Integrated knife racks keep cutting tools safely accessible, while utensil hooks ensure your most-used items remain within easy reach. Some chefs swear by adding spice shelves to their backsplashes, keeping seasonings visible and immediately available during intense cooking sessions. For tech-forward kitchens, electrical outlets incorporated into the backsplash allow for small appliance use without stretching cords across workspaces.

Faucet upgrades often provide the biggest functional improvements. Pre-spray faucets make quick work of stubborn food residue, while foot pedal controls allow hands-free operation when your hands are covered in food. Water filtration systems ensure that everything you prepare benefits from clean, pure water. Temperature control through proper mixing valves means you'll always have the right water temperature for the task at hand.

Mobility considerations matter too. Heavy-duty casters with reliable locking mechanisms provide flexibility to reconfigure your kitchen as needed while ensuring stability during use. Proper leveling feet guarantee a wobble-free work surface even on uneven floors. Don't forget bumper guards if you'll be moving your prep table with sink regularly – they protect both your investment and your walls during repositioning.

Cutting surface options deserve careful thought. Integrated poly cutting boards (typically 16" x 24" x ½") provide knife-friendly work surfaces that can be easily sanitized. Removable inserts allow for quick swapping when switching between meat and produce preparation, reducing cross-contamination risks.

Health & Safety Certifications

For commercial kitchens, proper certification of your prep table with sink isn't just recommended – it's essential for compliance and peace of mind.

NSF certification represents the gold standard for food service equipment. When you see that NSF mark on a prep table with sink, you know it's been rigorously tested for food safety. The certification confirms the table is constructed from food-safe materials, designed to prevent bacteria harboring, can be effectively cleaned, and meets structural standards for commercial use. Always look for the permanent NSF tag or etching when evaluating commercial options.

"I learned the hard way during my first health inspection that uncertified equipment can lead to violations," a cafe owner shared with me. "Now I wouldn't dream of purchasing any food prep equipment without proper NSF certification."

Beyond NSF, your prep table with sink needs to comply with FDA Food Code requirements and local health department regulations. These typically specify minimum sink depths for proper utensil immersion, require smooth surfaces without hard-to-clean crevices, mandate non-absorbent materials, and prefer rounded corners that prevent food particle accumulation. A compliant table makes health inspections much less stressful.

For establishments serving staff or customers with disabilities, ADA considerations become important. ADA-compliant prep tables with sinks feature lower height profiles (typically maxing out at 34 inches), provide proper knee clearance beneath the sink area, include accessible controls and faucets, and have properly insulated pipes to prevent contact burns.

At American Mortuary Coolers, we understand these certifications aren't just about avoiding fines – they're about protecting your business reputation and ensuring the highest standards of food safety. That's why all our prep tables with sinks meet or exceed NSF standards, giving you one less thing to worry about in your busy kitchen.

Size, Configuration & Budget Guide

Finding that "just right" size for your prep table with sink is a bit like Goldilocks tasting porridge – too small and you'll constantly feel cramped, too large and you're wasting valuable kitchen real estate. Let me walk you through the standard dimensions that most kitchens work with.

Most commercial prep tables with sinks come in widths of 48", 60", or 72" inches. Think of these as your small, medium, and large options. The standard depth is typically 30 inches – deep enough to give you plenty of workspace but not so deep that you're stretching uncomfortably to reach across.

For height, most tables stand between 34¾ and 41¾ inches tall, with 36 inches being the sweet spot for most commercial kitchens. This height works well for most adults to work comfortably without hunching over.

The sink bowl itself generally measures around 16" x 20" with a 10" depth – plenty of room to wash produce or soak utensils without water splashing everywhere.

When it comes to sink placement, you've got options that can make a surprising difference in your workflow:

Left-side sink configurations work beautifully for right-handed folks who naturally work from left to right. The sink sits ready to receive unwashed items, with clean workspace extending to the right.

Right-side sink placements better serve lefties or kitchens with specific workflow patterns that move from right to left.

Center sink designs offer balanced access from either side – perfect for shared workstations where multiple people might be prepping at once.

Some kitchens benefit from double bowl configurations, allowing separate washing and rinsing stations. The Eagle Group SMPT30108 model, for instance, features impressive dual 24" × 18" × 12" sink bowls with lever drains and overflows – a serious setup for serious prep work.

Smart chefs think about their workflow zones when planning their prep table with sink configuration:

- A receiving zone for unwashed items

- The washing zone (your sink)

- A clean, dry prep zone for cutting and preparation

- A finished product zone where your beautifully prepped items wait for cooking

Matching Size to Space & Volume

Ever tried squeezing into pants that are a size too small? That uncomfortable feeling is exactly what you'll experience with a prep table with sink that's mismatched to your space or prep volume.

Start by measuring your available space carefully. Remember to account for wall clearances (you'll want at least 2-3 inches), comfortable passage space around the table (minimum 36 inches so people aren't bumping into each other), and don't forget about ceiling height if you're planning a backsplash or overhead storage.

A kitchen design consultant I know has a brilliant tip: "Tape out the footprint of your planned prep table with sink on the floor before purchasing. This simple step helps visualize the impact on your space and workflow better than any drawing could." It's like test-driving a car before buying it.

Your anticipated prep volume should directly influence your size choice:

- Small operations serving under 50 meals daily can usually manage well with a 48" width

- Medium-sized kitchens handling 50-150 meals will appreciate the extra room of a 60" width

- Large operations cranking out 150+ meals should consider 72" or larger to keep up with demand

When possible, plan for growth. It's better to have a little extra space than to outgrow your setup in six months. Some forward-thinking manufacturers offer prep tables with sinks featuring modular or adjustable components, giving you flexibility as your needs evolve.

Price Ranges & Cost Drivers

Let's talk money – what can you expect to pay for a quality prep table with sink, and what drives those costs?

In the economy range ($300-$800), you'll find basic 18-gauge stainless steel construction with standard sink dimensions. These are perfectly functional for light-duty applications or home use, but may lack the durability needed for high-volume commercial settings.

The mid-range ($800-$1,500) offers 16-18 gauge stainless steel construction with NSF certification for commercial use. These tables typically include quality fixtures and basic undershelf storage – solid workhorses for most standard commercial kitchens.

At the premium end ($1,500-$3,000+), you're investing in heavy-duty 14-16 gauge stainless steel construction with custom sink configurations and specialized features. These tables often include improved stability features like the uni-lok gusset design, multiple storage options, and specialized accessories for high-volume environments.

Several factors can significantly impact the price of your prep table with sink:

The material gauge makes a big difference – heavier gauge (lower number) stainless steel costs more but offers superior durability. Moving from 18-gauge to 16-gauge construction typically adds 15-25% to the price, but that investment often pays off in longevity.

Size dimensions naturally affect cost – larger tables require more materials and are more expensive to ship. A 72" table may cost 30-40% more than a comparable 48" model, so be sure you truly need that extra space.

Sink configuration choices like double bowls or specialized shapes will bump up the price. Adding a second bowl typically increases the cost by 20-30%, but can dramatically improve workflow efficiency.

Don't forget about shipping weight – most commercial prep tables with sinks are heavy (200-500 pounds), making delivery a substantial cost factor. That Eagle Group model I mentioned earlier? It weighs a whopping 480 pounds!

As one restaurant supply expert told me, "The initial price difference between economy and premium prep tables with sinks often pays for itself within a year in busy commercial environments through reduced maintenance and longer service life." Sometimes the cheapest option ends up being the most expensive in the long run.

Popular Brands & Models

The market offers several trusted manufacturers, each with their own strengths and specialties. Let me walk you through the major players:

John Boos tables are like the luxury cars of the prep table with sink world – known for exceptional quality and craftsmanship. Their commercial models feature 18-gauge Type 300 stainless steel with a beautiful #4 polish finish. They offer customizable sink orientation and optional upgrades like pre-sprayer faucets. Their Commercial Economy Prep Worktable exemplifies their approach – offering customization while maintaining commercial-grade quality.

Eagle Group specializes in heavy-duty equipment designed for high-volume environments. Think of them as the tanks of the kitchen world. Their tables typically feature robust 14-gauge type 304 stainless steel construction and a patented uni-lok gusset system for rock-solid stability. Their SMPT30108 model showcases their premium approach with dual sink bowls, drawer assembly, and integrated cutting board – serious equipment for serious kitchens.

Advance Tabco offers versatility with unique material options, including their poly-top series. Their tables often feature 5/8" thick Poly-Vance cutting surfaces that are friendlier to your knife blades than stainless steel. With stainless steel understructures and adjustable undershelves, they've found a nice balance between functionality and durability.

BK Resources provides cost-effective options without compromising essential commercial features. Their tables typically include 18-gauge 304 stainless steel construction, standard NSF certification, and adjustable undershelf storage – solid quality at approachable prices.

"Each brand has its sweet spot," as a restaurant equipment specialist explained to me. "John Boos excels in craftsmanship and detail, Eagle Group in heavy-duty applications, Advance Tabco in specialized surfaces, and BK Resources in value-conscious commercial solutions."

At American Mortuary Coolers, we carefully evaluate these manufacturers and others to ensure we offer prep tables with sinks that meet the specific needs of our customers across various industries. Whether you're preparing food or working in a mortuary setting, we can help you find the perfect table for your unique requirements.

Installation, Compliance & Maintenance Roadmap

Setting up your prep table with sink isn't just about dropping it in place and connecting a few pipes. Think of it as creating the foundation for years of smooth kitchen operations. While I always recommend professional installation for commercial settings, understanding what goes into the process helps you make informed decisions and ensures you get exactly what you need.

When I visit kitchens to consult on installations, I focus on four key areas that make or break a successful setup. First, the plumbing connections need careful attention – from proper water supply lines (typically ½" for both hot and cold) to correctly configured drainage with a standard 1½" P-trap. Don't forget about backflow prevention devices, which many local codes require to keep your water supply safe.

If you're placing your prep table with sink near electrical connections, safety becomes even more important. GFCI outlets are a must to prevent shock hazards in wet areas, and proper grounding of metal components helps prevent electrical issues down the road.

"I once saw a beautiful new prep station ruined within months because it was installed on an uneven floor without proper leveling," a restaurant owner told me recently. This highlights why structural requirements matter so much. These units can weigh anywhere from 200-500 pounds when fully loaded, so your floor needs to handle that weight without sagging or shifting.

Local building codes aren't just bureaucratic red tape – they're there to protect you, your staff, and your customers. Different jurisdictions have varying requirements for commercial kitchen installations, from specific plumbing configurations to health department regulations. Taking the time to understand these requirements before installation can save you headaches and expensive modifications later.

Interestingly, your prep table with sink isn't just a practical tool – it could actually improve your health! Research highlighted in a study on standing workstation benefits shows that standing work configurations like these tables can reduce back pain, boost energy levels, and potentially lower health risks associated with sitting all day.

Step-by-Step Installation

Whether you're a DIY enthusiast or just want to understand what your contractor will be doing, here's how a proper prep table with sink installation unfolds:

The journey begins when you unpack and inspect your new equipment. This isn't just about checking for shipping damage – it's your opportunity to verify all components are present before your installer arrives. I always recommend laying out all parts according to the manufacturer's diagram and checking them off one by one.

Next comes positioning the table in its new home. This step requires careful thought about workflow – will staff have enough room to move around it comfortably? Is it close enough to water connections without stretching pipes too far? Does it align sensibly with other kitchen elements?

"The most important thing I learned after installing dozens of these tables is that perfect leveling makes all the difference," shares a kitchen equipment specialist I work with regularly. Using the adjustable bullet feet, your installer should check the level across multiple points on the work surface, ensuring a slight slope toward the sink (about ¼" per foot) to prevent water pooling.

When it's time to connect water supply, professional installers always install dedicated shutoff valves if they're not already present. This seemingly small detail makes future maintenance infinitely easier. Flexible supply lines with appropriate plumber's tape or thread compound ensure watertight connections, and thorough leak testing before proceeding prevents water damage down the road.

The drainage installation is where many DIY attempts go wrong. Beyond simply connecting the P-trap, proper slope in the drain line (minimum ¼" per foot) is essential for preventing clogs and backups. In commercial settings, local codes may require an air gap or backflow prevention device to protect the water supply from contamination.

One step that's often overlooked is sealing seams and edges properly. Food-grade silicone sealant where the backsplash meets the wall prevents moisture from seeping behind the unit, while ensuring all seams are watertight protects your investment from water damage and prevents sanitation issues in hidden spaces.

Before the job is complete, your installer should make final adjustments – checking level once more, securing any loose components, and performing a thorough leak check with running water. This attention to detail during installation pays dividends in years of trouble-free operation.

Cleaning & Care for Longevity

Your shiny new prep table with sink deserves proper care to stay in top condition for years to come. I've developed this maintenance approach after seeing what works best in busy kitchens:

Daily cleaning isn't just about appearances – it's your first line of defense against contamination and premature wear. At the end of each shift, a thorough wipe-down with food-safe sanitizer prevents bacterial growth, while flushing the drain with hot water keeps pipes clear. Don't forget those faucet handles and spouts – they're high-touch areas that need special attention.

Once a week, set aside time for deeper cleaning that reaches the spots daily maintenance might miss. Remove and thoroughly clean any detachable components like cutting boards or inserts, which can harbor bacteria in microscopic cracks. This is also the perfect time to polish stainless steel surfaces, which not only keeps them looking great but actually helps maintain their corrosion resistance.

"Monthly maintenance is what separates kitchens that replace equipment every few years from those where equipment lasts decades," explains a chef I worked with who maintained the same prep table with sink for over 15 years. This monthly ritual includes checking and tightening fasteners that vibration may have loosened, descaling faucets to prevent mineral buildup that can restrict water flow, and inspecting all plumbing connections for slow leaks that might not be immediately obvious.

Every three months, take maintenance a step further with a quarterly service check. This more thorough inspection examines welds and joints for integrity, verifies the sink seal remains watertight, and includes a deep clean of drain lines with appropriate cleaners to prevent stubborn buildup.

Different materials require specific care approaches. Stainless steel surfaces should always be cleaned with the grain using dedicated stainless cleaner – never chlorine bleach or abrasive pads that can damage the protective oxide layer. If your unit has poly tops, mild detergent and soft brushes are ideal, while avoiding exposure to high heat that could warp the surface. For the less common wood components, a damp cloth with mild soap works best, with periodic re-oiling to prevent drying and cracking.

Staying Compliant

For commercial kitchens, health department compliance isn't optional – it's essential for staying in business. Your prep table with sink plays a central role in meeting these requirements.

The NSF certification tag on your equipment isn't just a selling point – it's documentation that your equipment meets specific design and material standards for food safety. Keep records of this certification accessible for inspections, and remember that any modifications or repairs should maintain this compliance. Even something as simple as replacing a component with a non-NSF-approved part could jeopardize your certification status.

"The kitchen managers who sail through health inspections are the ones who maintain detailed records," notes a former health inspector I consulted with. Beyond just cleaning regularly, maintaining logs that document when and how equipment is sanitized demonstrates your commitment to food safety. These records, along with documentation of regular maintenance, can make a significant difference during inspections.

Water temperature is another compliance factor that's often overlooked. Most health codes require minimum water temperatures of 100°F for handwashing stations and 120°F for cleaning and sanitizing. Your prep table with sink should deliver water at these temperatures consistently, which may require adjustments to your water heater or the addition of thermostatic mixing valves.

Staff training completes the compliance picture. Everyone who uses the prep table with sink should understand proper cleaning procedures and appropriate use of the equipment. This knowledge isn't just about passing inspections – it protects your investment by preventing damage from improper use or cleaning methods.

At American Mortuary Coolers, we understand that compliance requirements vary across industries and regions. Whether you're setting up a commercial kitchen, mortuary preparation area, or other specialized workspace, our prep tables with sinks are designed to meet or exceed relevant standards throughout our service areas, including Tennessee, Georgia, Illinois, South Carolina, Texas, California, New York, Pennsylvania, and regional coverage throughout the Midwest, Northeast, Rocky Mountain, Southeast, Southwest, and Pacific regions.

Frequently Asked Questions about Prep Table With Sink

You've got questions about prep table with sink options, and we've got answers! After helping hundreds of customers find their perfect workstation, these are the most common questions we hear.

How do I pick the right gauge stainless steel?

Choosing between 18, 16, or 14-gauge stainless steel for your prep table with sink comes down to how hard you'll be using it and your budget comfort zone.

Most home chefs find that 18-gauge stainless steel hits the sweet spot between affordability and durability. It's lighter (about 10-15% less weight than 16-gauge), more budget-friendly, and perfectly adequate for residential kitchens or commercial settings with lighter prep needs.

If you're running a busy restaurant or commercial kitchen, investing in 16-gauge stainless steel makes good business sense. It resists denting better, dampens noise more effectively, and generally offers a longer service life. As Maria, one of our restaurant customers, told us: "The extra I spent on 16-gauge paid for itself in the first year - no dents despite my prep cooks banging sheet pans on it daily!"

For truly high-volume operations, 14-gauge steel represents the premium choice. Yes, it costs 30-50% more than 18-gauge, but its exceptional durability makes it the go-to choice for kitchens that never seem to close.

With stainless steel gauges, the lower the number, the thicker the steel. Think of it as an investment decision - match the gauge to how hard you'll work the table over its lifetime.

Can I retrofit a prep table with sink into an existing counter run?

Yes, you absolutely can integrate a prep table with sink into your existing counter setup, though it requires some careful planning. I recently helped a customer in Georgia do exactly this in his home kitchen renovation.

First, check your plumbing situation. You'll need accessible water supply lines and drainage connections with enough room for the P-trap and supply lines. Sometimes this means cutting into flooring or walls, so having a plumber assess the situation before you purchase can save major headaches.

Next, consider structural support. That beautiful counter might not be designed to hold the additional weight of a commercial-grade sink. Most prep tables with sinks weigh between 200-500 pounds, so verify your existing cabinetry and floor can handle it.

The trickiest part is often matching dimensions. Standard prep tables with sinks might not align perfectly with your existing counter heights, which can create awkward workflow issues. Measure your current counter height and depth precisely, then look for modular options or consider custom fabrication if standard sizes won't work.

As Tom, a home chef from California who completed this type of project, shared: "The hardest part wasn't finding the right table - it was convincing my plumber that yes, I really did want commercial-grade equipment in my home kitchen!"

What routine maintenance keeps my prep table sanitary?

Keeping your prep table with sink clean isn't just about appearances - it's essential for food safety and longevity of your investment. After years of working with commercial kitchens, I've seen how proper maintenance prevents expensive repairs and health code violations.

For daily cleaning, develop a simple routine: clear everything off, rinse with hot water, apply food-safe detergent, and scrub all surfaces thoroughly. Don't forget the often-missed spots like the underside of the sink rim, backsplash corners, and table legs. These hidden areas can harbor bacterial growth if neglected. Finish with proper sanitizer and allow everything to air dry.

Once a week, go deeper by removing any accessories like cutting boards or inserts, checking drain strainers, and inspecting for any developing issues. This is also a good time to polish stainless steel surfaces to maintain that professional shine.

Different materials require specific approaches. For stainless steel, always clean with the grain and avoid chlorine bleach that can cause pitting. If you have a poly-top surface, stick with mild detergents and soft brushes to prevent scratching. Wood components need minimal moisture and occasional food-grade mineral oil treatment.

"The single best thing I did for my prep table with sink was creating a laminated cleaning checklist for my staff," says Roberto, a restaurant owner from Tennessee. "Having a visual reminder of all the spots to clean means nothing gets missed, and my health inspections have been spotless since."

For stubborn cleaning challenges, try these simple solutions: use a vinegar solution (1:3 with water) for water spots, stainless steel polish for fingerprints, baking soda paste for food stains, and straight vinegar for descaling faucets. These gentle approaches maintain your surfaces without harsh chemicals that might damage them over time.

At American Mortuary Coolers, we understand that whether you're preparing food or handling more specialized tasks, sanitation is non-negotiable. That's why our prep tables with sinks are designed with cleaning in mind, featuring seamless construction and materials that stand up to regular sanitizing.

Conclusion

I've spent years helping kitchen professionals select the right equipment, and if there's one thing I've learned, it's that a prep table with sink isn't just another piece of kitchen furniture – it's the heart of your preparation workflow. Whether you're running a busy restaurant or creating a dream home kitchen, your choice will impact your daily operations for years to come.

Throughout this guide, we've walked through everything you need to know to make an informed decision. Let me summarize the key points that will guide you to the perfect choice:

First, be honest about your specific needs. The perfect prep table with sink for a high-volume restaurant might be completely wrong for a home chef. Consider your space constraints, workflow patterns, and budget realistically before making your decision.

Quality construction isn't just about appearance – it's about longevity and performance. That 16-gauge stainless steel might cost more upfront than 18-gauge, but in a busy kitchen, that investment often pays for itself through years of trouble-free service and easier cleaning.

Never underestimate the importance of proper installation. I've seen beautiful, expensive prep tables with sinks rendered nearly useless by poor installation that created drainage problems or workflow bottlenecks. Whether you're hiring a professional or tackling it yourself, proper planning prevents headaches down the road.

Regular maintenance isn't optional – it's essential. Your prep table with sink will only remain food-safe and functional if you commit to consistent cleaning and preventative maintenance. Those few minutes of daily attention can extend your equipment's life by years.

Finally, think of accessories as workflow improvers, not just add-ons. The right cutting board insert, undershelf configuration, or specialized faucet can dramatically improve your specific preparation process. Choose accessories thoughtfully based on your actual needs.

At American Mortuary Coolers, we understand the importance of quality preparation equipment. While our specialty lies in mortuary coolers and related funeral industry equipment, we apply the same principles of durability, customization, and attention to detail to everything we offer, including prep tables with sinks.

We're proud to provide direct delivery across the contiguous 48 states from our locations in Johnson City TN, Atlanta GA, Chicago IL, Columbia SC, Dallas TX, Los Angeles, New York NY, Pittsburgh PA, with comprehensive regional coverage throughout the Midwest, Northeast, Rocky Mountain, Southeast, Southwest, and Pacific areas.

I've seen how the right prep table with sink can transform a kitchen's efficiency. One restaurant client cut their prep time by nearly 25% after upgrading to a properly configured workstation. For a home chef I worked with, their new prep table with sink turned a cramped cooking experience into a joyful one with plenty of space for washing, chopping, and assembling meals.

Whether you're outfitting a commercial kitchen, upgrading your home cooking space, or equipping a specialized facility, I hope this guide helps you find the perfect solution for your unique needs.

For more information about professional preparation equipment, including specialized applications like mortuary tables, check out our resource on professional prep & embalming tables.