Why American-Made Walk-In Coolers Are the Smart Choice

American-cooler systems represent the gold standard in commercial refrigeration, offering superior construction, energy efficiency, and customization options that mass-produced alternatives simply can't match. These walk-in coolers and freezers are manufactured by companies like American Cooler Technologies (ACT) in Lawrence, Michigan, delivering reliable temperature control solutions across multiple industries.

Quick Answer for American-Cooler Buyers:

- What: Custom-designed walk-in coolers and freezers manufactured in the USA

- Who: American Cooler Technologies (ACT) and similar domestic manufacturers

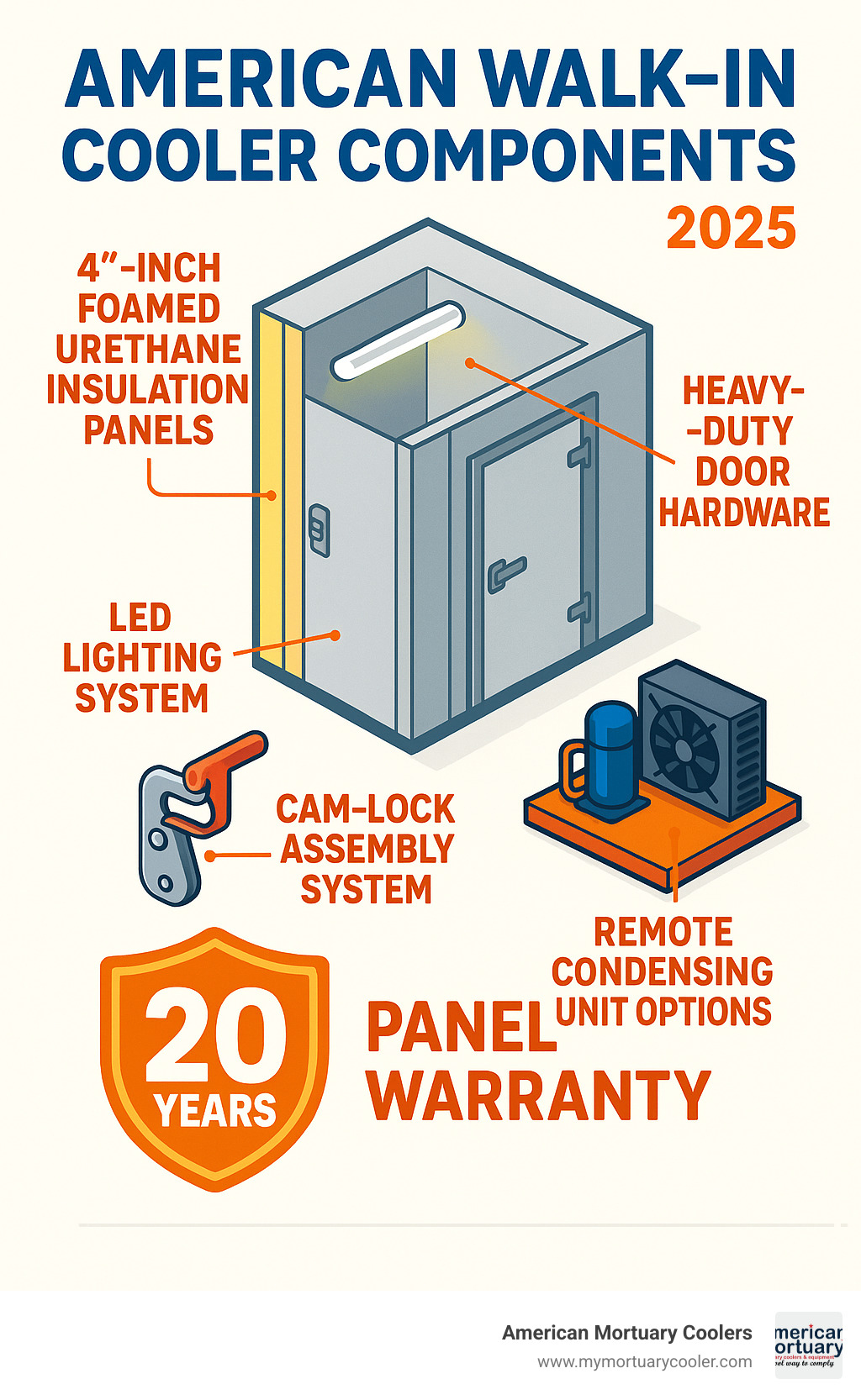

- Key Features: 4" foamed-in-place urethane insulation, R-29/R-32 ratings, 20-year panel warranties

- Industries: Food service, breweries, scientific labs, mortuaries, clean rooms

- Benefits: Direct manufacturer pricing, custom sizing, DOE compliance, nationwide installation

- Typical Cost: Starting around $7,956 for a 10'×10'×8' unit (shipping included)

The difference between American-made coolers and imported alternatives goes far beyond patriotic preference. Domestic manufacturers offer direct customer service, custom engineering for local building codes, and the ability to modify designs for specific applications - something particularly crucial for specialized industries like mortuary services where precise temperature control can't be compromised.

American Cooler Technologies has earned an impressive 5-star rating from 2,394 Google reviews, demonstrating the reliability and customer satisfaction that comes with buying direct from the manufacturer rather than through dealers or distributors.

I'm Mortuary Cooler, a national-level mortuary cooler supplier specializing in American-cooler solutions for funeral homes and related industries. My experience working directly with funeral directors has shown me how critical it is to choose equipment that combines durability, customization, and reliable support - qualities that define the best American-made cooling systems.

Easy American-cooler glossary:

Why Coolers Matter All Year

Cold storage isn't just about keeping things chilly - it's about maintaining precise temperature control that directly impacts your business operations and bottom line. Whether you're preserving perishable food inventory, maintaining laboratory specimens, or ensuring proper storage conditions for sensitive materials, the right cooling system becomes the backbone of your operation.

Energy efficiency plays a massive role in long-term operating costs. A properly insulated American-cooler with R-29 cooler panels or R-32 freezer panels can significantly reduce your monthly utility bills compared to poorly insulated alternatives. We've seen businesses cut their refrigeration energy costs by 30-40% simply by upgrading to properly designed American-made units.

Understanding the American Cooler Landscape

When you're shopping for commercial refrigeration, you'll quickly find that American-cooler manufacturers operate in a completely different league than mass-market alternatives. Companies like American Cooler Technologies (ACT) have spent decades perfecting their craft, building walk-in coolers and freezers that actually solve real-world problems instead of just checking boxes on a spec sheet.

ACT represents the gold standard in this industry - they're the folks who've been quietly revolutionizing commercial refrigeration from their headquarters in Lawrence, Michigan. What makes them special isn't just their 20-year panel warranty (though that's pretty impressive). It's their approach to treating every project like it matters, whether you're a small restaurant owner or running a large mortuary facility.

The American-cooler landscape includes walk-in coolers, walk-in freezers, and specialized units like mortuary coolers. But here's where it gets interesting - these aren't cookie-cutter products pulled from a warehouse. Each unit gets customized based on your specific needs, space constraints, and industry requirements.

Direct manufacturer relationships change everything about how you buy refrigeration equipment. Instead of dealing with pushy salespeople who don't understand your business, you work directly with engineers who've solved similar challenges hundreds of times before. No dealer markups, no miscommunication, no wondering if the person on the phone actually knows what they're talking about.

| Panel Thickness | Cooler R-Value | Freezer R-Value | Best Applications |

|---|---|---|---|

| 4" Standard | R-29 | R-32 | Most commercial applications |

| 6" Premium | R-35+ | R-38+ | Extreme temperature environments |

R-values matter more than most people realize. That R-29 rating on 4-inch panels means your cooler will maintain temperature efficiently for decades, not just the first few years. Cheaper alternatives often start strong but lose insulation effectiveness as inferior materials break down over time.

What is American Cooler Technologies (ACT)?

American Cooler Technologies started in 2002 with a simple but powerful idea - what if a refrigeration company actually listened to what customers needed instead of just pushing whatever was easiest to manufacture? Based in Lawrence, Michigan, this 11-50 employee company has built something special by staying focused on custom solutions rather than chasing volume.

ACT's custom-design approach means they're not trying to sell you the same cooler they sold to the restaurant down the street. Your mortuary has different needs than a brewery, which has different requirements than a scientific laboratory. ACT gets this, and their entire business model revolves around creating the right solution for each specific situation.

What Sets American-Made Coolers Apart

Customization capabilities represent the biggest difference between American-made coolers and imported alternatives. When a funeral director calls needing a mortuary cooler that fits through a narrow doorway, American manufacturers don't just say "sorry, that's not a standard size." They figure out how to make it work.

Made-in-USA quality goes deeper than patriotic marketing. American manufacturers use superior materials because they can source them locally and maintain quality control throughout the supply chain. That foamed-in-place urethane insulation creates a seamless thermal barrier that maintains its performance for decades.

Energy-efficiency improvements in quality American-cooler units often pay for themselves through reduced utility costs. DOE-compliant designs ensure maximum thermal performance while meeting federal energy standards. We've seen businesses cut their refrigeration energy costs by 30-40% simply by upgrading from poorly insulated imported units to properly designed American-made systems.

American-cooler Buying Considerations & Customization

Buying an American-cooler isn't like picking up a refrigerator at the appliance store. These are serious pieces of equipment that need to match your exact needs, and honestly, that's where the magic happens. The best part about working with American manufacturers is how they treat every project like a custom puzzle to solve.

Temperature range is your starting point. Most coolers keep things between 35°F and 41°F, while freezers run from -10°F to 0°F. But here's where it gets interesting - mortuary applications often need different ranges entirely. That's exactly why customization matters so much.

Sizing goes way beyond measuring your space with a tape measure. You need to think about future growth, how you'll move products in and out, and what your daily workflow looks like.

Many manufacturers now offer Insta-Quote systems that give you instant pricing. It's pretty slick - you enter your specs and get real numbers, often including shipping to anywhere in the lower 48 states.

DOE compliance isn't something you can ignore. Federal law requires certain energy efficiency standards, and quality American-cooler manufacturers make sure you're covered.

Regional building codes can throw curveballs, especially in places like California, Florida, Oregon, and Washington. These states often require special engineering documents for things like seismic codes, wind loads, or snow loads. American manufacturers know these local quirks and handle the paperwork for you.

For specialized guidance, check out the Ultimate Guide to Choosing a Walk-In Mortuary Cooler for detailed sizing and customization considerations.

Key Construction & Insulation Explained

The secret sauce in any quality American-cooler is the foamed-in-place urethane insulation. This isn't your typical insulation job - they inject liquid urethane between the panel walls, where it expands and hardens into one solid piece. No gaps, no thermal bridges, no weak spots.

Those 4" panels might not look thick compared to your house insulation, but they pack serious performance. We're talking R-29 for coolers and R-32 for freezers - numbers that easily beat federal energy standards.

Cam-lock assembly is pretty clever engineering. These systems let panels connect rock-solid without permanent fasteners. The cam-locks also squeeze gaskets between panels, creating vapor barriers that keep moisture where it belongs - outside your cooler.

American-cooler Compliance & Certifications

Certifications might seem like alphabet soup, but each one protects you in different ways. NSF-7 certification confirms your panels meet National Sanitation Foundation standards for food equipment - absolutely essential if you're handling anything consumable.

UL approval covers electrical safety and overall system integrity. DOE compliance ensures your cooler meets federal energy efficiency standards. Beyond being environmentally responsible, non-compliant equipment might disqualify you from energy rebates or tax incentives.

Choosing the Right American-cooler for Your Industry

Different industries have wildly different cooling needs, and the best American-cooler manufacturers get that. Foodservice applications need easy cleaning, NSF compliance, and rock-solid temperature control.

Brewing applications demand precise temperature control during fermentation and storage. Floral cold storage requires gentle air circulation to prevent flower damage while maintaining optimal humidity.

Mortuary facilities represent one of the most demanding applications, where temperature stability and reliability are absolutely non-negotiable. For detailed insights, read Precision and Performance: Why American Mortuary Coolers Lead the Industry.

Laboratory and clean room applications require specialized features like stainless steel construction, filtered air systems, and precise temperature and humidity control.

Getting an American-cooler Installed Seamlessly

Proper site preparation can make or break your installation experience. Indoor installations on ground floors are usually straightforward, but outdoor installations require extra planning for weather protection and access.

Wind load and snow load calculations become critical for outdoor installations or areas with extreme weather. American manufacturers provide engineered drawings that account for local conditions and building codes.

Line sets connect your indoor evaporator to the outdoor condensing unit. Standard installations include up to 35 feet of copper line sets, with longer runs available for additional cost.

For applications requiring ultra-precise temperature control, Advanced Thermoelectric options provide alternative cooling technologies that work alongside traditional refrigeration systems.

Industry Applications & Real-World Success Stories

Nothing tells the story of American-cooler quality quite like real customer experiences. When a company maintains a perfect 5-star rating across 2,394 Google reviews, you know they're doing something right. These aren't just numbers - they represent thousands of businesses that depend on American-made cooling systems every single day.

The beauty of working with American manufacturers lies in their ability to solve unique challenges. Take the craft brewery that called us last month - they needed a cooler that could fit through a narrow basement door, make a 90-degree turn, and still provide enough capacity for their growing operation. Try getting that level of customization from an overseas manufacturer.

Food & Beverage Distribution

Large-scale food distribution demands cooling systems that can handle serious workloads while keeping energy costs manageable. Bulk inventory storage requires precise temperature control across massive spaces, often with different zones for various product types.

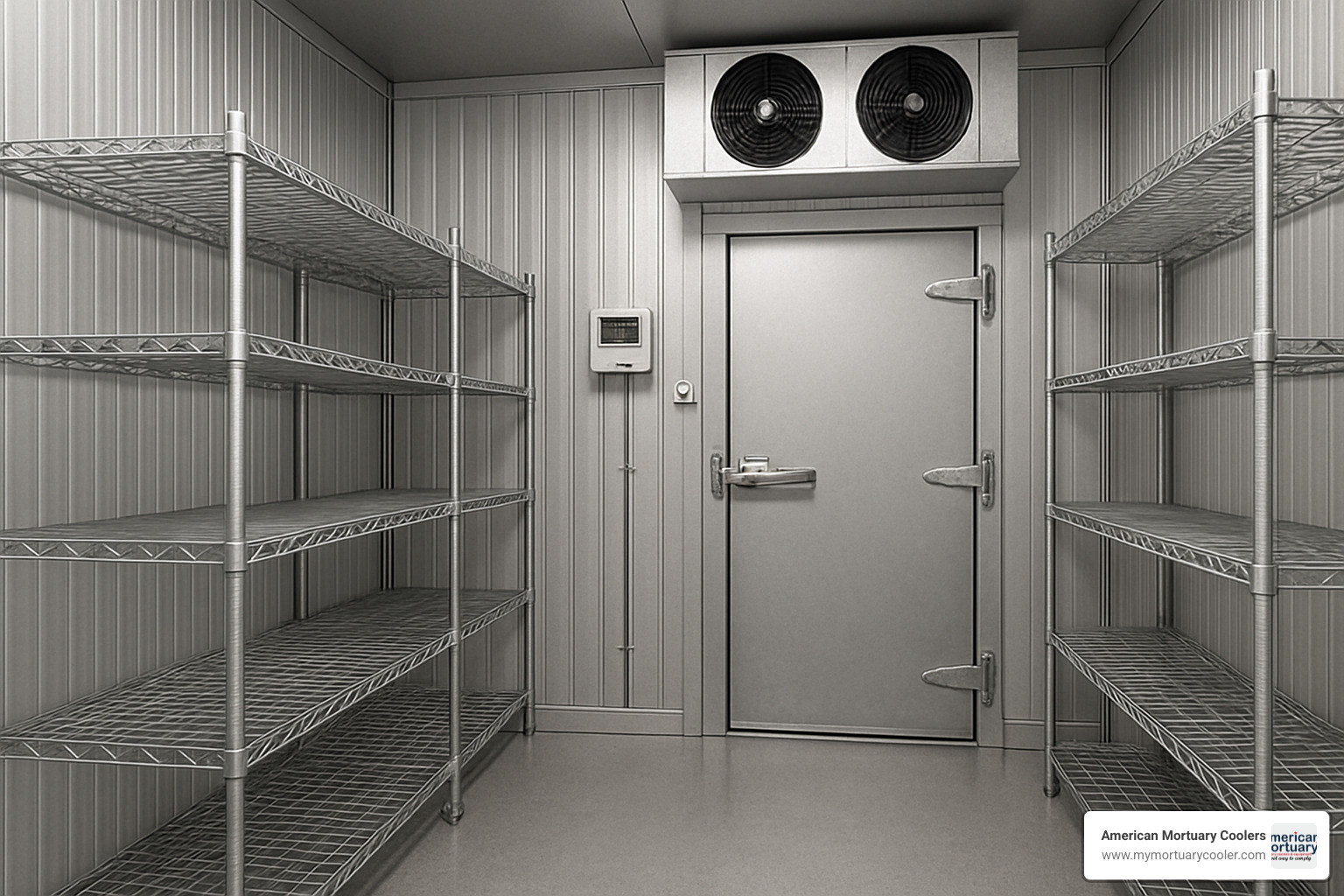

Remote condensing units solve a common problem in these facilities - noise. By locating the compressor equipment outside or in mechanical rooms, workers can focus on their jobs without constant mechanical noise.

Energy savings in distribution centers can be dramatic. We've seen facilities cut their refrigeration costs by thousands of dollars monthly just by upgrading to properly designed American-cooler systems. LED lighting plays a bigger role than most people realize - those old fluorescent fixtures generate heat that the cooling system has to work against.

Scientific & Medical Storage

CMM labs and precision manufacturing facilities need cooling systems that most people would consider overkill. When you're measuring parts to thousandths of an inch, even tiny temperature changes can throw off your equipment calibration.

Temperature stability becomes more important than the actual temperature in these applications. A lab might need their space held at exactly 68°F ± 0.5°F, which requires specialized controls that standard commercial systems simply can't provide.

Mortuary & Forensic Facilities

Morgue coolers represent the most critical application we handle. There's no room for error when families are trusting you with their loved ones. Temperature control isn't just about preservation - it's about maintaining dignity and meeting strict legal requirements.

Body storage regulations vary by state, but most require maintaining temperatures between 35-40°F with minimal fluctuation. The reliability of your cooling system becomes absolutely paramount because equipment failures create serious legal and ethical problems.

We've worked with funeral homes across the country, from small family operations to large metropolitan facilities. Each has unique requirements, whether it's fitting equipment into historic buildings or designing systems that operate silently out of respect for grieving families.

Our comprehensive guide on Features of Effective Mortuary Coolers Explained covers the specific requirements that make mortuary cooling different from standard commercial applications.

Maintenance, Warranty & Lifetime Support

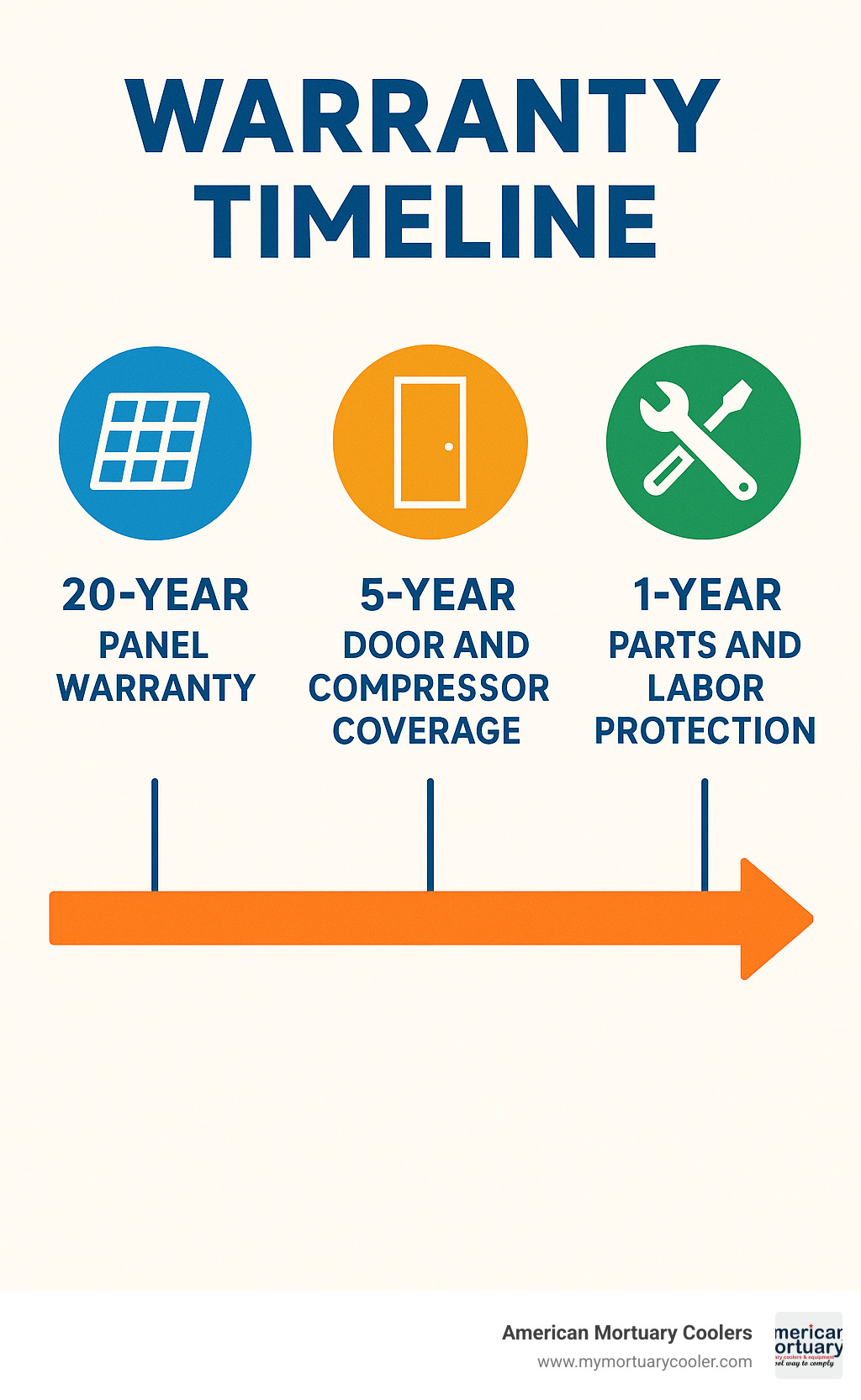

One of the biggest advantages of investing in a quality American-cooler is the peace of mind that comes with exceptional warranty coverage. When American Cooler Technologies offers a 20-year panel warranty, they're putting their money where their mouth is. That's two decades of protection on the most expensive part of your cooling system.

The warranty structure makes sense when you break it down. Panels get 20 years because they're built to last that long with proper care. Doors and compressors get 5 years - these are mechanical components that work harder but are still built for longevity. Parts and labor get 1 year to cover you during those critical first months when any manufacturing defects would show up.

Regular maintenance isn't just about keeping your warranty valid (though it is required). It's about protecting your investment and avoiding those middle-of-the-night emergency calls when your cooler decides to take an unscheduled vacation.

Door gasket checks should happen monthly. Those rubber seals around your doors are working 24/7 to keep the cold air in and warm air out. Look for cracks, tears, or spots where the gasket isn't sealing properly.

Coil cleaning is another monthly must-do. Your condenser coils are like the radiator in your car - they need to breathe to work efficiently. Dust and debris make your compressor work harder, use more energy, and wear out faster.

Keep your airflow between 75-90% capacity. This might sound counterintuitive, but an empty cooler actually works harder than a properly loaded one.

Routine Care Checklist

Monthly coil cleaning should be as routine as paying your electric bill. Use a soft brush or shop vacuum to remove dust from condenser coils and fan blades. This simple 15-minute task can add years to your compressor's life and keep your energy bills reasonable.

Door seal testing is easier than you might think. Try the dollar bill test - close the door on a dollar bill and try to pull it out. If it slides out easily, your gasket needs attention.

Humidity control between 50-60% keeps everything running smoothly. Temperature logs aren't just bureaucratic busy work - they're your early warning system.

When & How to Upgrade Components

Sometimes you need to upgrade or replace components, and quality American-cooler manufacturers make this straightforward. Strip curtains are one of the best upgrades for high-traffic coolers. These plastic barriers reduce cold air loss every time someone opens the door.

LED retrofits offer immediate benefits - better lighting, lower energy costs, and less heat load on your refrigeration system.

Getting Help When You Need It

When you buy from a reputable American manufacturer, you're not just buying equipment - you're buying relationships. Phone consultations with experienced technicians can often solve problems without expensive service calls.

Nationwide technician networks mean you're covered whether you're in downtown Nashville or rural Montana. American companies understand American business hours, American building codes, and American customer service expectations.

The bottom line? A good American-cooler manufacturer treats warranty and support as part of the product, not an afterthought.

Frequently Asked Questions about American Cooler Options

How does buying direct from a manufacturer save money?

When you buy an American-cooler directly from the manufacturer, you're cutting out the middleman - and that middleman's markup. Dealers typically add 20-40% to cover their showrooms, inventory costs, and sales staff. That's money that comes straight out of your pocket without adding any real value to your purchase.

Direct relationships also mean you get faster answers when you need modifications or have service questions. Instead of playing telephone through a dealer who might not understand the technical details, you're talking to engineers and technicians who know every bolt and wire in your system.

What customization options are available for commercial walk-ins?

This is where American-cooler manufacturers really shine compared to mass-produced alternatives. Pretty much everything can be customized to fit your exact needs.

Panel thickness can be upgraded from the standard 4" to 6" or even thicker if you're dealing with extreme temperature requirements. Door configurations are completely flexible - different sizes, swing directions, or specialized features like viewing windows.

Interior layouts get designed around how you actually work. Need custom shelving for specific products? No problem. Want specialized lighting that won't interfere with your workflow? They can handle that.

Control systems range from simple thermostats all the way up to sophisticated monitoring systems that can send alerts to your phone if something goes wrong.

Are American-cooler units energy-efficient and code-compliant?

Absolutely, and this is actually one area where buying American-made equipment gives you a significant advantage. Modern American-cooler units don't just meet DOE energy efficiency requirements - they exceed them by substantial margins.

The R-29 cooler panels and R-32 freezer panels used in quality American units provide thermal performance that can cut your energy bills by 30-40% compared to cheaper alternatives. Better insulation means your compressor doesn't have to work as hard, which saves money every month and extends equipment life.

Code compliance goes way beyond just energy efficiency though. Quality manufacturers maintain current certifications for safety standards, building codes, and industry-specific regulations.

Conclusion

Choosing an American-cooler system isn't just about buying equipment - it's about investing in a partnership that will support your business for decades to come. After working with hundreds of businesses across different industries, I've seen how the right cooling system becomes the foundation that everything else builds on.

The durability of American-made coolers really shines through in the long run. While cheaper alternatives might look similar on paper, they simply can't match the day-in, day-out reliability of properly constructed domestic units. That 20-year panel warranty from manufacturers like ACT isn't just marketing - it's a reflection of construction quality that's built to last.

Customization remains the biggest advantage of working with American manufacturers. Every business has unique challenges, whether it's fitting a cooler into an oddly shaped space or meeting specialized temperature requirements. Mass-produced imports force you to adapt your operation to their limitations, while American-cooler manufacturers adapt their products to your needs.

The compliance aspect gives me peace of mind when recommending these systems to clients. Knowing that your cooler meets all current codes and certifications protects you from future headaches. Plus, when regulations change, American manufacturers are right here to help you steer any necessary updates.

For funeral homes and related facilities, the stakes are simply too high to compromise on cooling reliability. That's why we focus exclusively on American Mortuary Coolers - because when families trust you with their loved ones, your equipment needs to be absolutely dependable.

Ready to explore your options? Check out The Ultimate Guide to Mortuary Refrigerator Options and Features for detailed insights into specialized cooling requirements. When you're ready to discuss your specific needs, we're here to help you find the perfect solution - learn more and request your custom quote today!