Why American Mortuary Coolers Are Essential for Modern Funeral Operations

American-mortuary-coolers- are specialized refrigeration units designed to preserve human remains at precise temperatures between 34-40°F, serving as critical infrastructure for funeral homes, hospitals, morgues, and medical facilities across the United States.

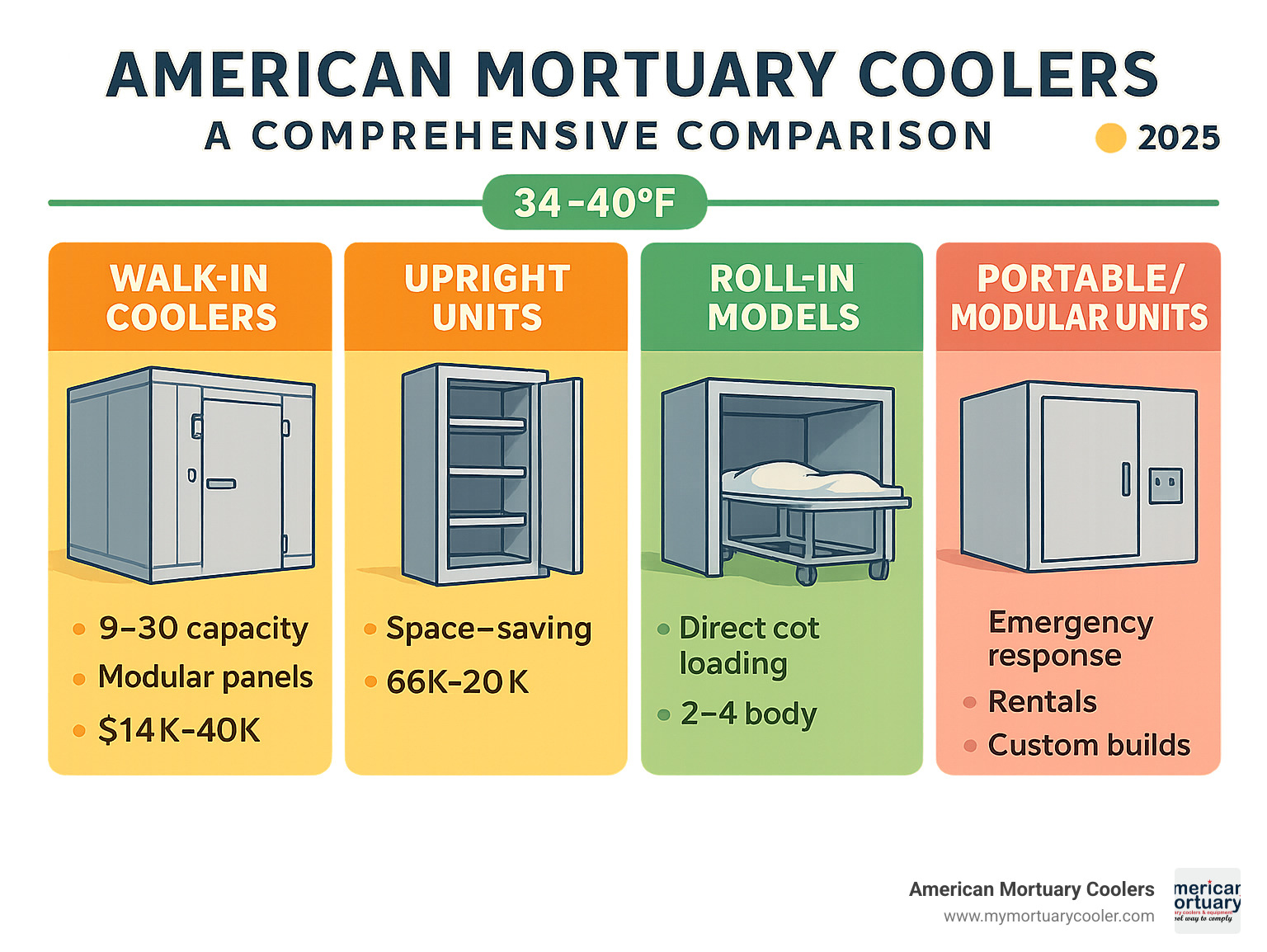

Quick Overview of American Mortuary Cooler Options:

- Walk-in Coolers: Store 9-30 bodies, modular panels, $14,000-$40,000

- Upright Units: Hold 1-6 bodies, space-saving design, $6,000-$20,000

- Roll-in Models: Accept mortuary cots directly, 2-4 body capacity

- Portable/Modular: Emergency response, rental options, custom builds

The mortuary refrigeration industry has experienced significant growth driven by an aging population, pandemic preparedness needs, and stricter health regulations. Recent events like COVID-19 have highlighted the critical importance of adequate cold storage capacity, with many facilities requiring surge solutions to handle overflow situations.

Modern american-mortuary-coolers- must comply with multiple federal standards including the Energy Independence & Security Act of 2007 (EISA), NSF sanitation requirements, and UL safety provisions. Walk-in models can store a minimum of nine bodies with larger configurations accommodating up to 30 bodies, while compact upright units serve smaller facilities with limited space.

As Mortuary Cooler, I've worked extensively as a national level mortuary cooler supplier helping funeral homes and medical facilities select the right american-mortuary-coolers- for their specific needs. My experience spans everything from small 2-body units to large walk-in installations across the continental United States.

Simple guide to american-mortuary-coolers- terms:

Understanding american-mortuary-coolers- Technology & Purpose

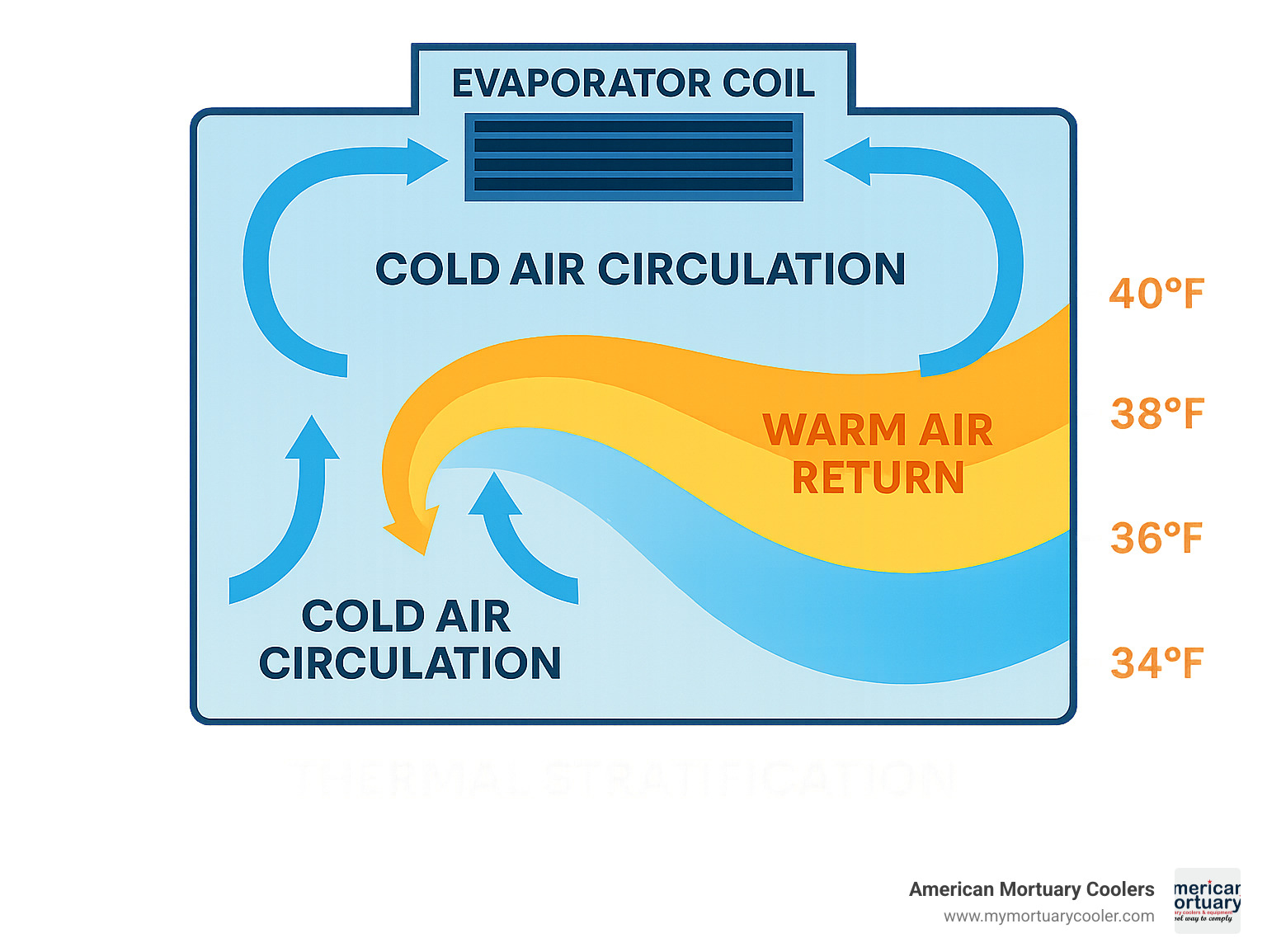

The heart of every american-mortuary-coolers- system lies in maintaining that perfect temperature sweet spot between 34-40°F. Think of it like Goldilocks - not too hot, not too cold, but just right for preserving human remains with dignity and respect.

When temperatures climb above 40°F, bacterial growth kicks into high gear, accelerating decomposition. Drop below 34°F, and you risk tissue damage that can complicate funeral preparations. It's a delicate balance that modern refrigeration science has mastered through decades of research and refinement.

Thermal load calculations might sound complicated, but they're really just smart planning. Every time someone opens a cooler door, warm air rushes in. The ambient temperature of your facility matters too - a cooler in Arizona works harder than one in Minnesota. Even the thermal mass of the remains themselves affects how hard the system needs to work.

The Energy Independence & Security Act of 2007 (EISA) changed everything for commercial refrigeration. Suddenly, manufacturers had to meet much stricter energy efficiency standards. The result? Today's american-mortuary-coolers- use significantly less electricity while maintaining better temperature control than older models.

Safety and sanitation aren't just good ideas - they're the law. OSHA and CDC guidelines became even more stringent after the pandemic, and for good reason. NSF sanitation standards require antimicrobial interior finishes and seamless construction that prevents bacterial growth while making cleaning straightforward and thorough.

The pandemic taught us all some hard lessons about surge capacity. Facilities that never imagined needing extra storage suddenly found themselves scrambling for solutions. Some increased their capacity by 300% during peak periods, driving rapid innovation in portable and modular designs that could be deployed quickly.

Here's some encouraging news: latest research on refrigeration efficiency shows that modern american-mortuary-coolers- achieve 40% better energy efficiency compared to units manufactured before 2010. Improved compressor technology and better insulation systems mean lower operating costs and more reliable performance - a win-win for any facility's bottom line.

Comparing Types & Configurations

Choosing the right american-mortuary-coolers- can feel overwhelming at first, but understanding the basic types makes the decision much clearer. Think of it like buying a car - you need to match the size and features to how you'll actually use it.

The biggest choice you'll face is between permanent installations and flexible solutions. Permanent units give you the best bang for your buck if you have consistent volume, while flexible options let you adapt as your needs change. Neither choice is wrong - it's all about what fits your situation.

Here's something many people don't consider upfront: floor versus floorless configurations. Floorless units save money initially, but you'll need proper site prep and drainage. Floored units cost more but give you complete flexibility on where to install them. I've seen too many facilities regret skipping the floor option to save a few dollars.

Walk-In american-mortuary-coolers-

Walk-in coolers are the workhorses of the mortuary world. If you're handling 9-30 bodies regularly, these units deliver the best value per body stored. The beauty of modular panel construction means you can start smaller and expand later - we've helped plenty of facilities double their capacity just by adding panel sections.

The real advantage shows up in your electric bill. Walk-in units provide the lowest per-body storage cost when you're dealing with volume. Plus, remote condenser options let you put the noisy compressor equipment somewhere else, keeping your prep areas peaceful.

These units use 4-inch high-density insulation with impressive R-values over 25. Combined with professional door sealing, they maintain rock-solid temperatures even when staff are in and out frequently. That consistency matters more than most people realize.

| Feature | Walk-In Coolers | Upright Units |

|---|---|---|

| Capacity | 9-30+ bodies | 1-6 bodies |

| Initial Cost | $14,000-$40,000 | $6,000-$20,000 |

| Energy Efficiency | Excellent | Good |

| Space Required | Large dedicated room | Minimal floor space |

| Expandability | Highly expandable | Fixed capacity |

| Installation Complexity | Professional required | Plug-and-play |

Upright & Roll-In american-mortuary-coolers-

For smaller facilities or tight spaces, upright and roll-in models are absolute game-changers. These space-saving designs deliver professional-grade refrigeration without taking over your entire facility.

The pricing makes sense for most funeral homes. Single-body units start around $5,799, while 6-body configurations reach about $19,799. That sweet spot seems to be the 2-body models at $6,095-$8,199 - enough capacity without breaking the budget.

Roll-in designs are brilliant because they accept mortuary cots directly. No more transferring remains back and forth, which means less handling and smoother workflow. The caster ramps and low-profile thresholds work seamlessly with standard mortuary equipment.

Smart features like telescoping slide rails extend trays outside the unit for easy access. Side-loading configurations let you place units against walls while maintaining full functionality - perfect when every square foot counts.

Portable, Modular & Surge Units

The pandemic taught us all a hard lesson about surge capacity. Portable and modular units aren't just nice-to-have anymore - they're essential for emergency preparedness and handling unexpected volume spikes.

Container-based rental units can be on-site within hours, providing immediate relief during mass casualty events or equipment failures. These maintain the same temperature precision as permanent installations while offering complete mobility.

The MERC liquid-cooling system represents a real breakthrough in portable technology. This patented system provides direct contact cooling with full portability and scalability - pretty impressive engineering.

For budget-conscious facilities, the CoolBot system offers an interesting alternative. Pair a standard air conditioner with the CoolBot controller, and you can build walk-in coolers for around $5,000. One 8×12 foot CoolBot installation handles 25 bodies while maintaining steady 37-38°F temperatures. It's not fancy, but it works.

Key Features, Specs & Compliance Checklist

When you're investing in american-mortuary-coolers-, understanding the key features and specifications isn't just about getting the best value—it's about ensuring your facility operates safely and meets all regulatory requirements for years to come.

The heart of any quality mortuary cooler lies in its high-density insulated panels. These aren't your typical refrigerator walls. Most professional units feature 4-inch thick panels with foamed-in-place insulation that achieves impressive R-values of 25 or higher. This superior insulation keeps temperatures stable even when doors open frequently throughout the day.

The outer cladding makes a real difference in daily operations. You'll typically find 24-gauge steel, stainless steel, or aluminum options. Stainless steel costs more upfront but pays dividends in easy cleaning and long-term durability—especially important when dealing with antimicrobial requirements.

Modern UL and NSF approved lighting systems have come a long way from the old fluorescent fixtures that used to flicker and fail at the worst moments. Today's vapor-proof LED fixtures with exterior switches and pilot lights not only meet safety codes but also slash energy costs while providing better illumination.

Temperature control has become remarkably sophisticated. Digital PID controllers maintain precision within just ±1°F, which is crucial for proper preservation. These systems include high and low temperature alarms, automatic defrost cycles, and data logging capabilities that keep you compliant with health department requirements.

Door gaskets might seem like a small detail, but they're critical for maintaining temperature and preventing moisture infiltration. Quality units feature heavy-duty magnetic gaskets that seal completely and resist wear from constant use.

For facilities in challenging climates, low-ambient packages ensure reliable operation even when exterior temperatures drop below freezing. This feature has saved countless facilities from equipment failures during winter months.

Standard Specs Across american-mortuary-coolers-

The beauty of working with established american-mortuary-coolers- is the consistency you can expect across quality manufacturers. This standardization means you're getting proven technology that works reliably in real-world conditions.

Those 4-inch foamed-in-place panels aren't just thick for show—they eliminate thermal bridges that could compromise efficiency and create temperature variations. The continuous foam core maintains structural integrity while providing consistent insulation throughout the unit's life.

Vapor-proof LED lighting systems have become the industry standard, and for good reason. These systems typically use 50% less power than older fluorescent fixtures while providing superior illumination and lasting years longer. No more dealing with burnt-out bulbs during critical times.

Most units operate on standard 110V power, which is a huge advantage for installation flexibility. You won't need special electrical work or three-phase power in most cases—just plug it in and you're ready to go.

The warranty coverage reflects manufacturers' confidence in their products. Panel warranties typically extend 10 years, while mechanical components carry 1-5 year coverage depending on the specific part and manufacturer. This protection gives you peace of mind for your significant investment.

Customization Options & Innovations

The mortuary cooler industry has acceptd customization in ways that would have been impossible just a few years ago. Today's american-mortuary-coolers- can be custom to fit virtually any facility requirement or workflow need.

Telescoping slide rails represent one of the most practical innovations we've seen. These allow storage trays to extend completely outside the unit, making loading and access much easier—especially valuable when you're working in tight preparation rooms where space around the cooler is limited.

Side-loading door configurations solve a common installation challenge. Instead of requiring clearance in front of the unit, these designs allow placement against walls while maintaining full access to all storage positions. It's amazing how this simple change can transform a cramped space into an efficient workspace.

Aesthetic customization has improved dramatically. Many manufacturers now offer PMS color matching at no additional charge, allowing units to blend seamlessly with existing facility décor. This attention to appearance helps maintain the dignified atmosphere families expect.

WiFi-enabled temperature monitoring systems bring mortuary coolers into the digital age. These systems provide remote alerts and historical data logging, sending notifications to multiple devices to ensure prompt response to any temperature issues. You can monitor your units from home and have complete documentation for regulatory inspections.

The newest frontier involves AI-based predictive maintenance systems that analyze operational data to predict component failures before they occur. While still emerging, these systems promise to significantly reduce unexpected downtime and maintenance costs.

Additional innovations include antimicrobial interior finishes that actively resist bacterial growth, telescoping rails for easier tray access, and stainless or aluminum skin options for improved durability and appearance.

Budgeting, Pricing & Ownership Models

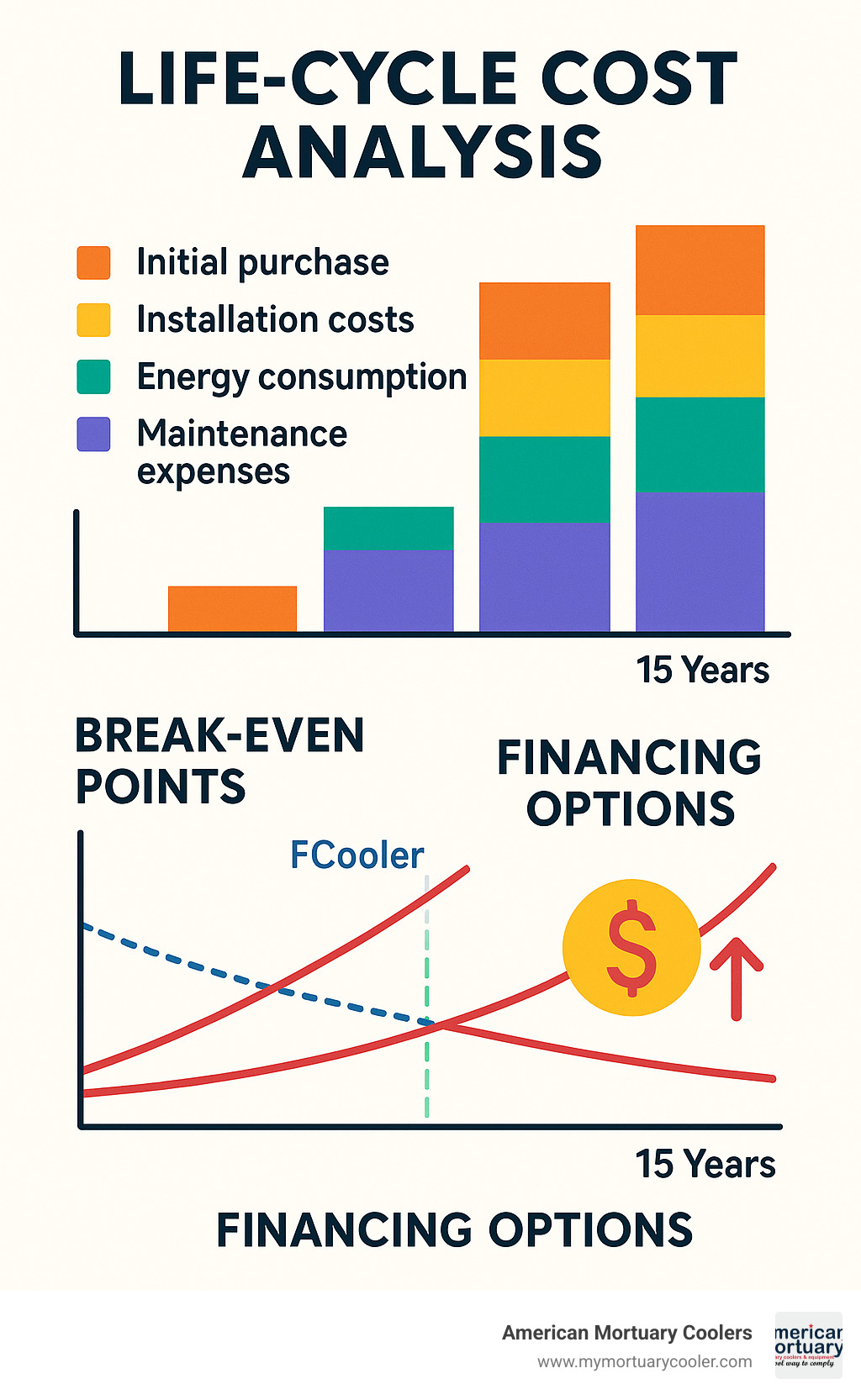

When planning your american-mortuary-coolers- investment, it's important to look beyond the sticker price. The real story lies in understanding total ownership costs over the equipment's 15-20 year lifespan.

Entry-level pricing starts with 2-body coolers ranging from $6,095 to $8,199. These compact units work perfectly for smaller funeral homes or facilities just getting started. The sweet spot for many operations is the 3-body models at $7,611 to $10,425 - they offer better value per body while still fitting tight budgets.

Walk-in coolers require a bigger commitment, typically $14,000 to $40,000 depending on size and features. But here's where the math gets interesting: larger units dramatically reduce your per-body storage cost. A 20-body walk-in might cost twice as much as a 10-body unit, but it stores twice the capacity for much less than double the price.

For the truly budget-conscious, the CoolBot DIY system runs around $5,000 for a complete walk-in setup. You'll need to roll up your sleeves a bit more with maintenance, but one 8×12 foot installation can handle 25 bodies - that's hard to beat for value.

Energy costs shouldn't be overlooked in your calculations. Modern EISA-compliant units consume 30-40% less energy than older models, typically running $50-150 per month in electricity costs. That efficiency improvement can save thousands over the equipment's lifetime.

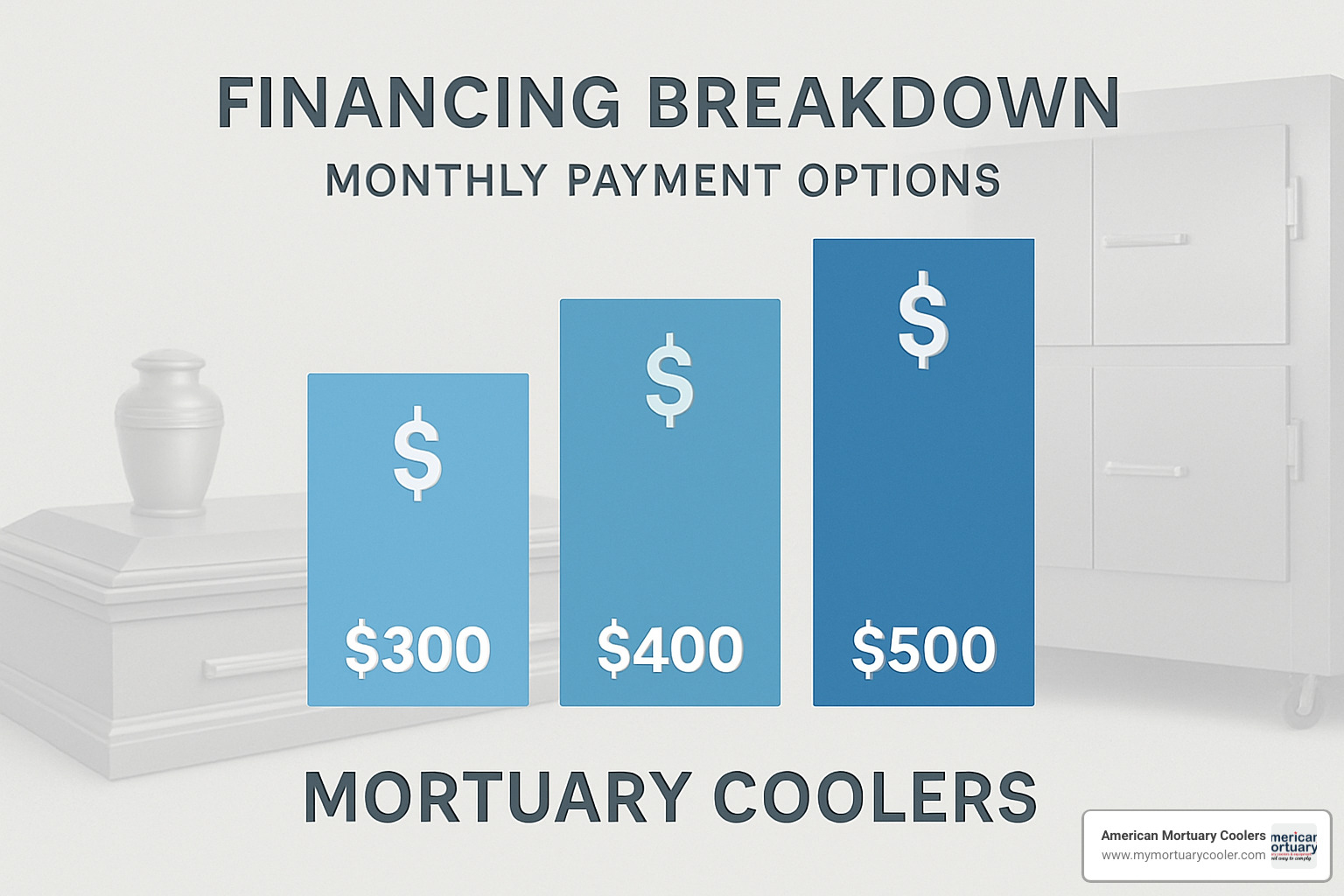

Financing has never been more accessible. Many suppliers now offer 0% down payment plans and 90-day payment deferrals. These programs open doors for facilities that need quality equipment but can't tie up large amounts of capital upfront.

The leasing versus buying decision comes down to your facility's financial strategy. Leasing preserves cash flow and often includes maintenance coverage, but you'll pay more over time. Purchasing costs more upfront but builds equity and typically saves money long-term.

ROI calculations should factor in operational benefits beyond just the purchase price. Modern american-mortuary-coolers- reduce maintenance headaches, improve energy efficiency, and provide better reliability. These improvements often justify spending a bit more for premium equipment through reduced operational expenses and fewer service calls.

The key is matching your investment to your actual needs. A small rural funeral home doesn't need a 30-body walk-in, just like a busy urban facility can't get by with a single 2-body unit. Getting this balance right ensures you're investing wisely in equipment that serves your community effectively for decades to come.

More info about affordable choice

Selecting & Maintaining Your Cooler: Decision Framework

Choosing the right american-mortuary-coolers- requires systematic evaluation of current needs, future growth, and operational constraints. We've developed a comprehensive framework that ensures optimal equipment selection.

Capacity planning starts with analyzing historical volume data and projecting future needs. Consider not just average daily requirements but also peak periods and potential surge events. The pandemic taught us that excess capacity isn't wasteful - it's essential for operational resilience.

Site surveys identify physical constraints that affect equipment selection. Ceiling height, door widths, electrical capacity, and ventilation requirements all influence the final configuration. We've seen installations fail because these factors weren't properly evaluated upfront.

Electrical load calculations ensure adequate power supply for reliable operation. While most units operate on standard 110V power, larger walk-in systems may require 220V or three-phase power. Consulting with qualified electricians during planning prevents costly surprises during installation.

Step-by-Step Selection Guide

Our proven selection process ensures you choose equipment that meets both current needs and future requirements while staying within budget constraints.

Step 1: Needs Analysis Document current and projected storage requirements, including peak capacity needs. Consider seasonal variations and potential surge events. Factor in growth projections for the next 5-10 years.

Step 2: Choose Type Select between walk-in, upright, roll-in, or portable configurations based on capacity needs, space constraints, and operational preferences. Consider workflow efficiency and staff training requirements.

Step 3: Customize Features Specify insulation thickness, door configurations, interior finishes, and optional features like telescoping rails or WiFi monitoring. Balance desired features against budget constraints.

Step 4: Compliance Check Verify that selected equipment meets all applicable regulations including EISA energy requirements, NSF sanitation standards, and local health department specifications.

Step 5: Submit Quote Forms Complete detailed quotation forms with accurate specifications. Include site drawings and electrical information to ensure accurate pricing and proper equipment sizing.

Step 6: Training and Support Arrange for staff training on proper operation, cleaning procedures, and basic maintenance. Establish service contracts for ongoing support and preventive maintenance.

More info about complete guide

Delivery, Installation & After-Sales Support

Proper installation is critical for optimal performance and longevity of american-mortuary-coolers-. Understanding delivery and installation options helps ensure smooth project completion.

Crated delivery reduces shipping costs but requires on-site assembly by qualified technicians. Pre-assembled delivery costs more but reduces installation time and potential assembly errors.

Plug-and-play startup procedures vary by manufacturer and model complexity. Simple upright units may require only electrical connection and initial temperature setting. Walk-in systems need comprehensive commissioning including refrigerant charging and control calibration.

Preventive maintenance programs extend equipment life and prevent costly breakdowns. Most manufacturers recommend quarterly inspections, annual deep cleaning, and bi-annual refrigeration system service.

Extended warranty options provide peace of mind and budget predictability. These programs typically cover both parts and labor for mechanical components beyond the standard warranty period.

Remote monitoring systems enable proactive maintenance by tracking performance parameters and predicting potential failures. These systems can reduce service calls by 40-60% while improving overall reliability.

Frequently Asked Questions about american-mortuary-coolers-

Let me address the three most common questions we hear from funeral directors and facility managers when they're considering american-mortuary-coolers-.

What temperature range do american-mortuary-coolers- keep?

American-mortuary-coolers- are engineered to maintain precise temperatures between 34-40°F, with most facilities setting their units to operate at 37-38°F. This temperature range hits the sweet spot for preservation - cold enough to significantly slow decomposition and bacterial growth, but warm enough to prevent tissue damage from freezing.

The digital PID controllers in modern units maintain this temperature within just ±1°F, ensuring consistent conditions even when doors are opened frequently. This precision is crucial for regulatory compliance and optimal preservation quality.

During my years helping facilities nationwide, I've seen how proper temperature control makes all the difference in maintaining dignity and meeting family expectations during difficult times.

How many bodies fit in a 3-tier roll-in unit?

A standard 3-tier roll-in mortuary cooler is designed to accommodate 3 bodies total - one per tier. Each tier accepts a standard mortuary cot or body tray, making transfers smooth and respectful.

The typical dimensions are 57½" wide x 8 feet deep x 8 feet high, providing adequate clearance for safe loading and removal. The beauty of roll-in units is their efficiency - you can wheel the mortuary cot directly into position without any lifting or transferring of remains.

This design reduces handling and makes the process more dignified while protecting staff from potential injury. The tiered system maximizes storage capacity while maintaining easy access to each level.

Can a modular cooler be expanded after installation?

Absolutely! This is one of the biggest advantages of choosing modular american-mortuary-coolers-. The panel construction system is specifically engineered for future expansion without major reconstruction or downtime.

I've personally helped facilities double their storage capacity by adding panel sections to existing walk-in coolers. The process typically takes just a day or two, and the new sections integrate seamlessly with the existing refrigeration system.

This expandability makes modular systems perfect for growing funeral homes or facilities that want to start smaller and expand as their needs increase. It's much more cost-effective than replacing an entire unit when you outgrow your initial capacity.

The modular approach also allows for creative configurations - you can add length, width, or even create separate temperature zones within the same system.

Conclusion

Choosing the right american-mortuary-coolers- comes down to understanding your specific needs and finding equipment that delivers reliable performance for years to come. The decision impacts daily operations, regulatory compliance, and your facility's ability to serve families during their most difficult times.

Today's mortuary refrigeration technology has come a long way from the basic units of decades past. Whether you're considering a compact 2-body upright unit for a small funeral home or planning a large walk-in system for a busy medical facility, modern equipment delivers precise temperature control with remarkable efficiency.

Durability and compliance aren't just nice-to-have features – they're essential for protecting your investment and meeting strict health regulations. Quality american-mortuary-coolers- maintain that critical 34-40°F range consistently, even during power fluctuations or frequent door openings that would challenge lesser equipment.

The long-term value equation extends beyond the initial purchase price. Energy-efficient operation, minimal maintenance requirements, and extended warranty coverage all contribute to lower total ownership costs. We've seen facilities save thousands annually just by upgrading from older, inefficient units to modern EISA-compliant systems.

Working with the right supplier makes all the difference in your experience. From initial consultation through installation and ongoing support, having knowledgeable partners ensures your equipment performs as expected when you need it most.

American Mortuary Coolers has earned trust across the funeral industry by delivering exactly what we promise – durable, custom solutions custom to each facility's unique requirements. Our Tennessee-based manufacturing gives us complete control over quality, while our nationwide delivery network reaches every corner of the contiguous 48 states.

Whether you're replacing aging equipment, expanding capacity, or opening a new facility, we have the expertise to guide you through the selection process. Our custom approach means you get exactly the features you need without paying for unnecessary extras.

Trust American Mortuary Coolers as your single U.S. source for reliable, compliant mortuary refrigeration solutions. We're here to help you make the right choice for your facility and the families you serve.