Strength Meets Safety: Understanding Stainless Diamond Plate

Stainless diamond plate is a specialized metal sheet featuring a raised diamond pattern that provides superior slip resistance, exceptional corrosion resistance, and outstanding durability for industrial and commercial applications.

For those seeking quick information about stainless diamond plate:

| Feature | Description |

|---|---|

| Material | 304 or 316 stainless steel with raised diamond pattern |

| Thickness Range | 0.125" (1/8") to 0.500" (1/2") |

| Common Sizes | 48" and 60" widths, lengths up to 144" |

| Tensile Strength | 73,200 psi (304 grade) |

| Weight | ~6.15 lbs per square foot (1/8" thick) |

| Finish | HRAP (hot rolled, annealed, pickled) |

| Primary Benefits | Slip resistance, corrosion resistance, durability |

| Common Applications | Flooring, walkways, trench covers, mortuary equipment |

This specialized metal combines the best corrosion resistance of stainless steel with a practical, raised pattern that dramatically improves traction. Unlike standard flat plate, the diamond pattern's liftd surfaces create friction points that reduce slip hazards in wet or oily conditions.

The pattern isn't just functional—it's become an iconic industrial aesthetic that signals durability and safety. Whether you're outfitting a mortuary cooler floor, building safe walkways, or creating heavy-duty work surfaces, stainless diamond plate delivers performance that outlasts alternatives.

Why choose stainless over other metals? While aluminum and carbon steel diamond plates are available, stainless offers superior resistance to rust, chemicals, and environmental wear. This makes it ideal for sanitary environments, coastal locations, and applications where long-term performance justifies the higher initial investment.

I'm Mortuary Cooler, a national-level supplier specializing in mortuary coolers with extensive experience incorporating stainless diamond plate into our high-performance mortuary equipment designs. Over the years, I've witnessed how stainless diamond plate transforms ordinary cooler floors into durable, sanitary surfaces that withstand decades of daily use.

Simple guide to stainless diamond plate:

Stainless Diamond Plate 101

Stainless diamond plate isn't just another pretty metal surface. This specialized stainless steel sheet with its distinctive raised diamond pattern has become the gold standard for industrial flooring where safety and durability can't be compromised.

In the industry, you might hear it called tread plate or checker plate - same material, different nicknames. It's carefully regulated under ASTM A793, which is essentially the rulebook for how stainless steel floor plate should perform.

What makes stainless diamond plate special is really a perfect marriage of material and design. The stainless steel base provides that famous corrosion resistance through its self-healing chromium-oxide layer (pretty amazing when you think about it), while those raised diamonds aren't just for looks - they give you practical traction when you need it most.

"The raised diamond pattern isn't just for show," our lead fabricator at American Mortuary Coolers often tells customers. "Each diamond creates multiple points of contact with shoes, equipment, or anything else placed on the surface, dramatically improving friction even in wet conditions common in mortuary environments."

Most stainless diamond plate comes with what we call an HRAP finish - that's Hot Rolled, Annealed and Pickled. Unlike the super-shiny finish you see on aluminum alternatives, this finish creates a more subdued, non-glare surface. That's particularly helpful in industrial settings where nobody wants blinding reflections while they're working.

If you're the type who appreciates good numbers, 304 grade stainless diamond plate is quite the performer:

- It handles up to 73,200 psi before breaking (tensile strength)

- Starts to permanently deform at 31,200 psi (yield strength)

- Weighs about 0.289 pounds per cubic inch

- Can take heat up to around 2,550°F before melting

- Offers good hardness at Rockwell B70 or Brinell 123

What Makes Stainless Diamond Plate Unique?

The magic of stainless diamond plate really comes down to its remarkable corrosion resistance. Unlike its carbon steel cousin that needs painting or galvanizing to ward off rust, stainless has built-in protection thanks to the chromium in the alloy.

This chromium forms a thin, invisible oxide shield that continuously protects the surface. Even better, if this layer gets scratched, it simply repairs itself! This self-healing quality makes stainless diamond plate perfect for demanding environments like:

Food processing kitchens where you're constantly battling moisture and sanitizing chemicals. Coastal installations where salt spray would eat through lesser materials in months. Chemical processing areas where corrosive substances are an everyday hazard. And of course, medical and mortuary settings where regular, thorough sanitization is absolutely non-negotiable.

Yes, you'll pay more upfront compared to aluminum or carbon steel options. But as we like to tell our customers at American Mortuary Coolers, you're buying something that will still look good and perform perfectly years after the cheaper alternatives have been replaced - often making it the more economical choice in the long run.

How Stainless Diamond Plate is Manufactured

Creating stainless diamond plate is a fascinating blend of old-school metalworking and precise modern manufacturing. The journey from raw material to finished product follows a carefully orchestrated process:

First comes preparation of the base sheet. Mills produce high-quality stainless steel sheet to exact thickness specifications - precision matters here.

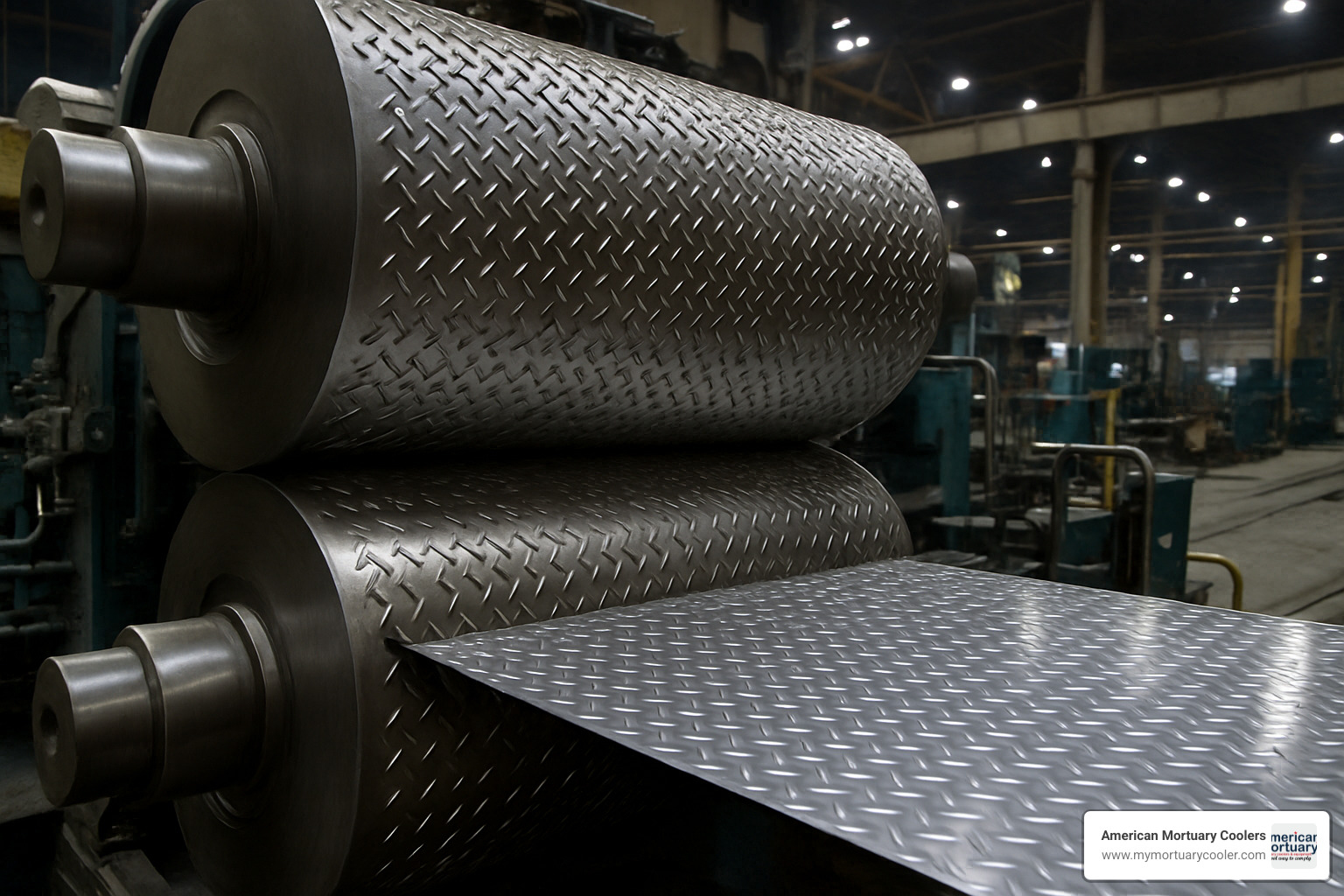

Then comes the hot rolling process, where the sheet is heated above 1,400°F until it reaches its recrystallization temperature. At this point, the steel becomes more malleable but still maintains its structural integrity.

While still hot, the sheet travels through specialized embossing rollers featuring the inverse of the diamond pattern. Under tremendous pressure, these rollers press the pattern into the surface of the steel - think of it as industrial-scale cookie cutters making their mark.

After embossing, the sheet undergoes annealing - a controlled cooling process that relieves internal stresses and ensures dimensional stability. This prevents warping or distortion as the plate cools completely.

Finally, the plate goes through pickling, where a chemical bath removes surface oxides and scale. This step is crucial for achieving that clean stainless appearance and maximizing corrosion resistance.

"The hot-rolling embossing process is highly economical compared to other patterning methods," notes a steel industry expert. "This enables relatively affordable pricing despite the premium material."

This process differs from aluminum diamond plate production, which can use cold stamping since aluminum is naturally more malleable. The hot rolling method used for stainless creates a more durable pattern that stands up to heavy traffic year after year - exactly what you need in demanding environments like mortuary coolers and other industrial applications.

Grades, Sizes, Patterns & Finishes

When you're looking into stainless diamond plate for your project, you'll want to understand all your options. I've helped hundreds of customers choose the right material, and it always comes down to matching the right grade and pattern to your specific needs.

The two most common stainless grades we work with are 304/304L and 316/316L. Think of 304 as your reliable everyday performer, while 316 is like its tougher, slightly more expensive sibling that excels in harsher environments.

Grade Comparison

| Property | 304/304L | 316/316L |

|---|---|---|

| Chromium Content | 18-20% | 16-18% |

| Nickel Content | 8-10.5% | 10-14% |

| Molybdenum | None | 2-3% |

| Corrosion Resistance | Excellent for most environments | Superior, especially in chloride environments |

| Cost | Standard pricing | 20-30% premium over 304 |

| Common Applications | General industrial, food service | Marine, chemical, pharmaceutical |

At American Mortuary Coolers, we use both grades regularly. For our coastal clients in the Southeast and along the Pacific, we typically recommend 316 grade for its improved corrosion resistance. The salt air can be pretty rough on metals, and that extra molybdenum in 316 makes a world of difference over time.

As for sizing, stainless diamond plate comes in several standard dimensions:

- Thickness range: Typically from 1/8" (0.125") up to 1/2" (0.500")

- Common widths: 48" and 60" sheets are standard

- Standard lengths: Usually up to 12 feet (144")

Most of our mortuary cooler floors use 1/8" or 3/16" thickness – strong enough to handle heavy gurneys but not so thick that it becomes difficult to work with.

Standard Dimensions & Weight Chart

One thing people often underestimate is just how heavy these sheets can be. Trust me, you don't want to find you need three more people to help move a sheet after it's delivered!

Here's what you can expect weight-wise with 304 stainless diamond plate:

| Thickness | Weight per Square Foot | 48" × 120" Sheet Weight |

|---|---|---|

| 1/8" (0.125") | 6.15 lbs | 246 lbs |

| 3/16" (0.188") | 8.70 lbs | 348 lbs |

| 1/4" (0.250") | 11.60 lbs | 464 lbs |

| 3/8" (0.375") | 17.40 lbs | 696 lbs |

| 1/2" (0.500") | 23.20 lbs | 928 lbs |

A word of caution about gauges: stainless steel uses different gauge measurements than aluminum or carbon steel. For example, 18-gauge in stainless equals 0.050", while 18-gauge aluminum is only 0.040" thick. Always confirm the actual decimal thickness when ordering to avoid surprises.

Pattern Options for Stainless Diamond Plate

The pattern on your stainless diamond plate isn't just about looks – it affects traction, cleaning ease, and even light reflection. Here are the main styles we see:

Fine-Line Diamonds come in various sizes, measured point-to-point across the diamond. The D4 pattern (4" diamonds) is what we use most often in our mortuary coolers. It provides excellent traction without creating cleaning challenges, and its proportions align perfectly on full sheets, minimizing waste during installation.

Other diamond sizes include D3 (3"), D6 (6"), and D12 (12"), plus rectangular patterns like DT63 (3" × 6") and DT84 (4" × 8"). Each has its place depending on your specific application.

Beveled Edge Patterns feature softer, rounded edges on the raised diamonds. These give a more refined appearance while still maintaining good slip resistance. They're particularly popular in spaces where aesthetics matter alongside function.

For more decorative applications, Two-Tone Patterns create visual interest by combining different finishes within the same sheet – imagine polished diamonds rising from a brushed background. Similarly, Quilted Designs offer more elaborate patterns with interconnected diamonds in various configurations.

As for finishes, you'll typically choose from:

- #8 Mirror: Highly reflective and polished – beautiful but shows fingerprints

- BA (Bright Annealed): A bright, smooth finish with good corrosion resistance

- Mill Finish: The standard HRAP (hot rolled, annealed, pickled) finish – practical and less reflective

When we're designing mortuary coolers, we consider both the practical needs of the space and the aesthetics. After all, even functional spaces deserve to look good while performing their essential duties.

Performance, Safety & Real-World Applications

The true value of stainless diamond plate really shines in demanding environments where ordinary materials just don't cut it. Those raised diamond patterns aren't just for looks – they significantly improve traction and reduce slip hazards, especially important in places where floors might get wet or oily.

One of the things our customers love most about stainless diamond plate is its impressive impact resistance. The embossed pattern adds structural rigidity to the sheet, helping it withstand the bumps and bangs of heavy equipment without denting or deforming. We've seen this in our mortuary coolers, where heavy carts and equipment move across the floor daily without causing damage.

"Even after a decade of daily use, the stainless diamond plate floors in our coolers look almost new," one of our long-term customers recently told us. "That's the kind of durability that justifies the investment."

In settings where cleanliness is non-negotiable, the non-porous surface of stainless steel truly earns its keep. Unlike other materials that can harbor bacteria in tiny scratches or pores, properly maintained stainless diamond plate provides a sanitary surface that meets even the strictest health code requirements. A quick wipe-down with the right cleaner, and you're good to go.

Another practical benefit that often goes unnoticed is the HRAP (hot rolled, annealed, pickled) finish. Unlike highly polished surfaces that can create uncomfortable glare under bright lighting, this finish reduces light reflection, making work environments more comfortable and reducing eye strain for staff.

We've helped install stainless diamond plate in hundreds of applications across the country, including:

- Mortuary coolers and freezers (our specialty!)

- Food processing facilities

- Catwalks and industrial platforms

- Trench covers in heavy-duty environments

- Trailer flooring and loading ramps

- Architectural accents in commercial spaces

- Stair treads and elevator floors in high-traffic buildings

"We installed a stainless diamond plate floor in a busy Tennessee mortuary fifteen years ago," shares our installation manager with a smile. "When I visited last month, it looked almost as good as the day we put it in. That's the kind of longevity our customers have come to expect."

Stainless Diamond Plate vs Aluminum & Carbon Steel

While all diamond plate materials share that distinctive raised pattern, they're definitely not created equal. Here's how stainless diamond plate stacks up against its competitors:

When it comes to corrosion resistance, stainless diamond plate is the undisputed champion. While aluminum puts up a good fight, especially in indoor settings, it can't match stainless in harsh environments. Carbon steel, meanwhile, requires regular painting or coating to prevent rust – an ongoing maintenance headache nobody needs.

Strength-wise, both stainless and carbon steel diamond plates offer excellent durability, while aluminum, being about a third of the weight, sacrifices some strength for its lightweight advantage. This makes aluminum great for decorative applications or situations where weight is a primary concern, but less ideal for heavy-duty industrial use.

The initial investment for stainless diamond plate is higher than both alternatives – no way around it. But as one of our customers wisely put it: "I only want to install this floor once in my lifetime." When you factor in the minimal maintenance and decades-long service life, stainless often provides the best long-term value.

"For mortuary applications, we almost always recommend stainless diamond plate," explains our product development team. "The combination of corrosion resistance, strength, and cleanability makes it ideal for environments where bodily fluids may be present and thorough cleaning is absolutely essential."

Industry Spotlights Using Stainless Diamond Plate

Food Processing Industry Walk into any major food processing facility, and you'll likely find stainless diamond plate on floors, platforms, and equipment surfaces. Food manufacturers appreciate how the non-porous surface prevents bacterial growth, while the slip-resistant pattern helps prevent workplace accidents. When cleanliness standards are measured in parts per million, only the best materials will do.

Pharmaceutical Clean Rooms In pharmaceutical manufacturing, even microscopic contaminants can compromise product quality. Stainless diamond plate provides surfaces that can be thoroughly sanitized while standing up to harsh disinfectants. The pattern also offers ergonomic benefits for workers standing for long periods on clean room floors.

Transportation Industry From ambulance floors to fire truck steps, stainless diamond plate delivers durability and slip resistance for emergency vehicles. We've even supplied material for custom medical transport vehicles where regular disinfection is required. The material handles frequent cleaning while maintaining its appearance year after year.

Architectural Applications Beyond purely functional uses, architects have acceptd the industrial chic aesthetic of stainless diamond plate for decorative applications. We've seen it used creatively in restaurants, retail spaces, and even high-end residential projects. It adds visual interest while providing practical durability that other decorative materials can't match.

"We're seeing more funeral homes requesting visible stainless diamond plate accents in their preparation rooms," notes our design director. "They appreciate both the practicality and the professional, industrial appearance it provides. It communicates quality and attention to detail – exactly the message they want to convey."

Fabrication, Installation, Maintenance & Buying Tips

Working with stainless diamond plate reminds me of cooking with a premium ingredient - it requires the right techniques, but the results are worth it! At American Mortuary Coolers, we've spent years perfecting our approach to this specialized material across all our service regions.

Fabrication Methods

When it comes to cutting and shaping stainless diamond plate, you've got several great options:

Shearing gives you clean, straight cuts for simple shapes with about a ±0.062" tolerance - perfect for straightforward projects. For more intricate work, laser cutting offers impressive ±0.015" precision. We often use waterjet cutting when we need intricate designs without creating heat-affected zones that might compromise the steel's properties. For thicker plates, plasma cutting works efficiently, though you'll likely need to finish the edges afterward.

When joining pieces of stainless diamond plate, proper stainless steel welding techniques are essential. Pay special attention to preventing warping and maintaining those corrosion-resistant properties at the weld joints.

"The first time I drilled through diamond plate, I learned a valuable lesson about countersinking," shares our head fabricator. "Creating those flush mounting surfaces makes all the difference in the final installation." We always deburr all cut edges and drilled holes to prevent any sharp edges that could cause injury during handling.

Cutting & Forming Stainless Diamond Plate

Stainless diamond plate has its own personality when it comes to fabrication. Those raised patterns that make it so functional also create unique challenges:

Use carbide-tipped blades specifically designed for stainless steel - your regular blades will dull faster than ice cream melts in August! Good lubrication during cutting reduces heat build-up and extends your tool life significantly. We've learned to avoid "pattern crush" by using proper clamping techniques that respect those raised diamonds.

"When cutting stainless diamond plate, think 'low and slow' - like good barbecue," advises our fabrication specialist. "Slower cutting speeds than you'd use for aluminum reduces heat build-up and prevents work hardening that makes further fabrication a headache."

For bending operations, the raised pattern affects the bend radius and can create stress points. Using tooling that accommodates the diamond pattern helps prevent material damage - something we learned the hard way so you don't have to!

Care & Cleaning Best Practices

Keeping your stainless diamond plate looking great isn't complicated, but it does require some specific care:

Regular cleaning with mild detergent and warm water takes care of most dirt and spills. Avoid chloride-containing cleaners - they're like kryptonite to the protective oxide layer that keeps stainless steel corrosion-resistant. For stubborn stains, stick with cleaners specifically formulated for stainless steel.

"In our mortuary coolers, we recommend daily cleaning with stainless-friendly sanitizers," notes our maintenance team. "This maintains both the strict hygiene standards needed in that environment and keeps the material looking professional."

It's worth periodically inspecting your stainless diamond plate surfaces for any damage or contamination, removing foreign matter promptly to prevent potential corrosion sites. For installations in particularly harsh environments, consider passivation to improve that protective oxide layer.

For new installations, we often apply protective films to prevent fingerprints and installation damage. These peel off after all construction work is complete, revealing pristine surfaces underneath.

FAQs About Stainless Diamond Plate

How do I cut stainless diamond plate without blunting tools?

"The first time I cut stainless with regular blades, I thought someone had replaced my tools with butter knives by the end of the job," jokes our fabrication manager. "Now we only use carbide-tipped blades designed specifically for stainless."

Beyond blade selection, use cutting oil or appropriate lubricant to reduce friction and heat. Set your cutting speeds about 30-40% slower than you would for mild steel, and always start with sharp tools. If precision matters or you have complex requirements, consider professional cutting services - sometimes it's worth letting the experts handle it.

Which grade should I choose for coastal or marine use?

"I remember installing a 304 grade system near Virginia Beach years ago, only to be called back for replacement much sooner than expected," recalls our coastal region manager. "Now we always recommend 316/316L stainless for installations within 5 miles of saltwater."

The molybdenum content in 316 grade provides superior resistance to chloride attack from salt spray. While 304 grade might handle brief exposure, any long-term installation near saltwater benefits tremendously from 316 grade. Yes, there's a 20-30% price premium, but the extended service life makes it a wise investment.

Can I order custom sizes and still get quantity discounts?

Custom sizing and quantity discounts can absolutely go hand-in-hand!

"At American Mortuary Coolers, we offer custom leveling of diamond plate coil to exact lengths," explains our sales team. "This actually reduces scrap and handling costs, which often allows us to extend quantity discounts even for custom dimensions."

We offer same-day shipping for in-stock stainless diamond plate and provide custom cutting services with quantity discounts for larger orders. The key is specifying your exact requirements when requesting quotes - this helps us provide the most accurate and competitive pricing possible.

Conclusion

Stainless diamond plate truly represents the gold standard of industrial flooring and surfaces. Throughout this guide, we've explored how this remarkable material combines stainless steel's superior corrosion resistance with the practical safety benefits of that iconic raised diamond pattern.

When you're considering stainless diamond plate for your next project, keep these key factors in mind:

First, think about your environment. If you're dealing with particularly harsh or corrosive conditions (like coastal areas or chemical exposure), the 316 grade offers that extra protection you'll appreciate years down the road. For standard applications, 304 grade provides excellent performance at a more accessible price point.

Next, consider your load requirements. Those heavy mortuary carts or industrial equipment need adequate support, so match your plate thickness to the weight and traffic you anticipate. Thicker isn't always better—it's about finding the right balance for your specific needs.

Pattern preference matters too! While the standard diamond pattern works wonderfully for most applications, you might prefer fine-line diamonds for a more refined look or beveled edges for certain architectural applications. Don't be afraid to ask for samples before making your final decision.

"The right finish can make all the difference," shares our installation team leader. "While many of our customers prefer the practical HRAP mill finish for mortuary cooler floors, others select the mirror #8 finish for more visible areas where appearance matters."

At American Mortuary Coolers, we've incorporated stainless diamond plate into hundreds of custom mortuary coolers across our service regions. From our Tennessee manufacturing facility to installation sites from Maine to California, we've seen how this premium material improves safety, durability, and professional appearance in demanding environments.

The truth is, investing in stainless diamond plate flooring pays real dividends over the lifetime of a mortuary cooler. Yes, the initial cost exceeds alternative materials, but when you factor in the extended service life, minimal maintenance requirements, and improved safety for your staff, the long-term value becomes crystal clear.

Whether you're outfitting a new mortuary facility, upgrading an existing one, or designing food processing equipment, stainless diamond plate delivers uncompromising performance that truly stands the test of time. Its perfect combination of functionality and industrial aesthetic has made it the go-to choice for professionals who understand that safety, sanitation, and durability simply cannot be compromised.

For more information about how we incorporate stainless diamond plate into our premium mortuary equipment, or to discuss your specific project requirements, our team is just a phone call away. With service regions covering the entire continental United States, we're ready to craft customized solutions that fit your exact specifications and budget.

Learn more about our mortuary coolers and find why funeral professionals nationwide trust American Mortuary Coolers for equipment that performs flawlessly year after year.