A Comprehensive Guide to Comparing Embalming Tables

Why Choosing the Right Embalming Table Is Critical for Your Funeral Home

Embalming-tables are specialized stainless steel platforms designed for body preparation, featuring drainage systems, adjustable heights, and ventilation connections to ensure safe, hygienic handling of human remains during the embalming process.

Quick Reference for Embalming Table Buyers:

- Standard Dimensions: 32-35" wide x 80-85" long with 30-38" adjustable height range

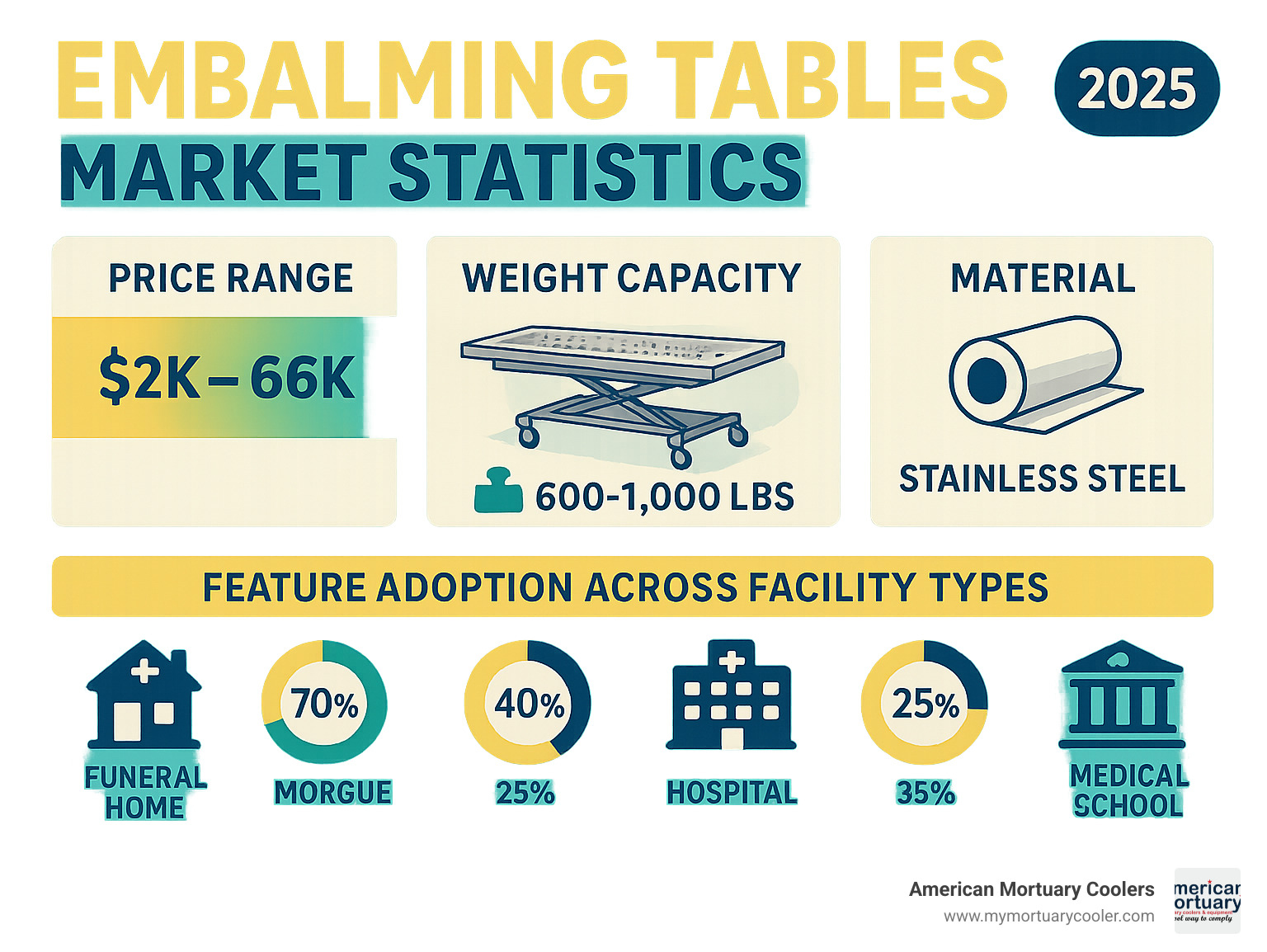

- Weight Capacity: 600-1,000 lbs (standard), up to 1,500 lbs (bariatric models)

- Material: 304 stainless steel construction for durability and sanitation

- Key Types: Hydraulic ($2,885-$5,665), Folding ($1,095+), Multi-height, Stationary

- Essential Features: Downdraft ventilation, 3" drainage slope, locking casters

- Price Range: $1,095 (basic folding) to $20,000+ (premium hydraulic with ventilation)

The right embalming table directly impacts your staff's safety, workflow efficiency, and compliance with OSHA standards. Poor drainage can create slip hazards, inadequate height adjustment leads to back injuries, and missing ventilation connections expose your team to dangerous chemical fumes.

Modern embalming tables address three critical objectives: reducing chemical exposure through integrated downdraft systems, minimizing biological risks with proper drainage slopes, and preventing musculoskeletal disorders through ergonomic height adjustment.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral homes select durable, budget-friendly equipment including embalming-tables that meet specific space and workflow requirements.

Embalming-tables helpful reading:

Understanding Embalming-Tables: Purpose, Parts & Prep-Room Impact

Embalming-tables are specialized platforms that combine drainage systems, ventilation connections, and ergonomic features to protect your staff while ensuring proper disinfection and hygiene standards.

Think of your embalming table as mission control for your prep room. Every component works together to provide a sterile, controlled environment for body preparation while minimizing exposure to chemical and biological hazards. The integrated drainage slopes channel fluids away from work areas, while ventilation ports connect to downdraft systems that capture harmful fumes.

Safety and hygiene requirements drive every design decision in modern embalming tables. OSHA universal precautions mandate seamless surfaces that prevent bacterial accumulation and quick-disconnect assemblies that enable rapid sanitization between cases.

What Is an Embalming Table?

An embalming table is a specialized platform designed specifically for cadaver handling and body preparation. Unlike hospital tables, these units feature permanent drainage slopes, perforated surfaces, and integrated rinse systems uniquely suited for mortuary work.

The convex surface channels fluids toward central drainage troughs, preventing pooling and reducing slip hazards. The perforated deck allows thorough drainage while supporting body weight, and quick-connect fittings let you hook up water and electrical systems in seconds.

Standard dimensions typically run 32-35 inches wide by 80-85 inches long, accommodating most cases while fitting through doorways. The 304 stainless steel construction resists daily chemical exposure without corroding, while seamless welds eliminate crevices where bacteria could hide.

More info about what is an embalming table provides additional technical details.

Why the Right Table Matters for Workflow & Safety

Choosing the wrong embalming-tables creates serious problems. Poor drainage leads to slip hazards, inadequate ventilation exposes staff to dangerous fumes, and fixed-height tables force operators into positions that cause injuries.

Chemical exposure represents one of the biggest risks. Tables with integrated downdraft ventilation connections capture fumes at their source, dramatically reducing ambient chemical levels in your prep room.

Musculoskeletal disorders affect many embalmers who work at improperly adjusted tables. Height-adjustable tables that move from 30-38 inches let each operator find their optimal working position, reducing fatigue and improving precision.

Major Types of Embalming-Tables Compared

Choosing the right embalming-tables becomes easier when you understand the main categories, each designed for specific situations you'll recognize from your own facility.

The key is matching your daily reality to the right table type. Do you handle steady case volume or occasional surges? Working with limited space or plenty of room? These considerations guide you toward the right category.

Hydraulic vs. Manual Multi-Height Models

Hydraulic tables use powered actuators to glide from 30-38 inches with just a foot pedal press. Premium models like the Ferno 101-H support up to 1,000 pounds while staying rock-solid throughout the height range.

Manual multi-height tables use hand-crank mechanisms for independent adjustment at both ends. This creates possibilities like angling the table for better drainage or easier access to specific areas.

| Feature | Hydraulic Tables | Manual Multi-Height |

|---|---|---|

| Height Range | 30-38 inches | 32.5-38.5 inches |

| Weight Capacity | 650-1,000 lbs | 600-650 lbs |

| Adjustment Method | Foot pedal/electric | Hand crank |

| Price Range | $2,885-$5,665 | $1,674-$2,500 |

| Best For | High volume facilities | Budget-conscious buyers |

Folding & Portable Designs for Small Spaces

Folding embalming tables solve the problem of "where do we put this when not using it?" These designs fold compactly for storage - some models stand on end to barely take up floor space.

The Ferno Model 102 Folding Embalming Table represents the gold standard. Despite folding neatly, it maintains quality stainless steel construction, proper drainage slopes, and solid 600-pound weight capacity.

Stationary, Bariatric & Religious-Compliant Tables

Bariatric embalming tables typically support 1,500 pounds while providing wider surfaces - often up to 42 inches - for better access and positioning.

Faith-specific tables serve communities with particular requirements. Muslim ghusl tables incorporate specific drainage patterns, while Orthodox Jewish tahara tables meet kashrut requirements with specialized materials.

Stationary pedestal tables are workhorses of high-volume facilities. By eliminating moving parts, these fixed-base designs offer maximum stability and longevity.

Key Materials, Features & Specifications to Evaluate

When shopping for embalming-tables, focus on features that matter for daily work: materials that won't corrode when exposed to chemicals, drainage systems that work, and ergonomic features that keep staff comfortable.

304 Stainless Steel: The Industry Standard

304 stainless steel contains 18% chromium and 8% nickel, giving it resistance to acids, bases, and oxidizing agents used daily. Its non-porous surface means bacteria can't hide, and it handles formaldehyde exposure without breaking down.

14-gauge tubing with 1.5-inch diameter represents the sweet spot for professional tables. Quality manufacturers use 0.12-inch wall thickness because thinner materials don't hold up under real-world conditions.

Drainage, Ventilation & Hygiene Improvements

A 3-inch permanent slope ensures fluids flow properly instead of creating puddles. The convex tabletop shape ensures consistent flow regardless of body positioning.

Perforated surfaces let fluids drain quickly instead of sitting on work surfaces. Central drainage troughs collect everything efficiently, typically with 6-inch drain stems connecting directly to your facility's waste system.

Downdraft ventilation connections capture fumes at the source, preventing them from floating around your prep room. This source-capture approach works better than general room ventilation alone.

Ergonomics & Load Capacity Essentials

Height adjustability from 30-38 inches accommodates all staff members. Most facilities do fine with 600-1,000 pound capacity, but bariatric models extending to 1,500 pounds ensure you're prepared for any situation.

Eight-inch diameter casters with locking mechanisms provide smooth movement while ensuring the table stays put during procedures. Quality casters feature sealed bearings that resist contamination from cleaning chemicals.

Price Ranges & Budget Planning for Embalming-Tables

Understanding embalming-tables pricing helps you make smart decisions for both current budget and future needs. There's something for every funeral home, from basic folding units to premium hydraulic systems.

Folding Tables Around the $1K Mark

Budget-friendly folding tables starting around $1,095 deliver core functionality - reliable 600-pound capacity, proper drainage, and space-saving storage.

In the $1,095 to $1,700 range, you'll find solid performers with 304 stainless steel construction, manual height adjustment, and essential drainage slopes. The swivel casters with brakes make positioning easy, while folding capability saves space.

These tables work beautifully for smaller funeral homes, mobile services, or as backup units in busier facilities.

Multi-Height & Combination Units ($2K–$4K)

The $2,000 to $4,000 range offers significant upgrades while staying within reach. Multi-height tables with independent end adjustment transform ergonomics without hydraulic complexity.

You get dual-end height adjustment, 650-pound weight capacity, and improved drainage systems. The Multi-Height Folding Embalming Table at $1,674 perfectly illustrates this category's value with independent adjustment from 32.5 to 38.5 inches.

Premium Hydraulic & Ventilated Systems ($5K+)

Premium embalming tables starting around $5,000 represent serious investments in safety and efficiency. Hydraulic lift systems eliminate manual adjustment strain, while integrated ventilation protects staff from chemical exposure.

Features include powered hydraulic adjustment, integrated downdraft ventilation, and bariatric weight capacity exceeding 1,000 pounds. Ventilated systems commanding $10,000+ integrate sophisticated fume capture technology.

Return on investment calculations should factor in reduced injury risks, better staff retention, regulatory compliance benefits, and improved efficiency. Premium tables often carry 15-year structural warranties.

Selecting & Maintaining the Best Embalming Table for Your Facility

Finding the perfect embalming-tables isn't about picking the cheapest or fanciest model. It's about understanding your specific needs and making a choice that'll serve your staff and families well for years.

Workflow, Room Layout & Storage Considerations

Measuring your space requires accounting for details. That 35-inch wide table needs to fit through your 36-inch doorway when you factor in the door frame.

Most standard embalming tables measuring 32-35 inches wide need elbow room. Your staff needs to move around comfortably, with space for equipment carts and other essentials.

Door width limitations often become the deciding factor. If you're working with standard 36-inch doorways, that 32-inch wide table makes more sense than the roomier 35-inch model.

Refrigeration proximity matters for facilities where staff constantly moves bodies between cooling units and prep tables. Mobile tables with quality casters pay dividends in reduced strain and improved efficiency.

More info about choosing tables walks through infrastructure considerations.

Regulatory, Safety & Cultural Requirements

OSHA formaldehyde standards aren't suggestions - they're requirements with hefty fines if ignored. Current limits of 0.75 ppm for 8-hour exposure make downdraft ventilation increasingly important.

Universal precautions require surfaces that can be thoroughly cleaned between cases. Seamless stainless steel construction prevents bacterial accumulation in cracks and crevices.

Religious requirements vary dramatically. Muslim families may need specialized drainage for ghusl procedures, while Orthodox Jewish families might require tables meeting kashrut requirements.

Cleaning, Disinfection & Routine Maintenance

Daily cleaning with neutral pH cleaners protects stainless steel while removing biological contaminants. Avoid chlorine-based products that pit and discolor expensive tables.

Monthly inspections should cover drainage function, caster operation, height adjustment mechanisms, surface condition, and ventilation connections. Most checks take just minutes but prevent major problems.

Innovations & Trends Shaping Future Embalming-Tables

The funeral industry is experiencing improvements in embalming-tables technology, driven by stricter safety regulations and focus on protecting funeral service professionals.

Integrated downdraft systems have moved from luxury features to near-essentials. Unlike clunky add-on ventilation units, today's systems are built into table structure for better fume capture and cleaner air.

IoT sensors solve genuine problems by tracking usage patterns and predicting when components need replacement. Imagine getting alerts when drainage systems start backing up or automated maintenance reminders.

Powered lateral tilt mechanisms reduce physical strain on embalmers. Instead of manually repositioning bodies - leading to back injuries - these systems allow precise positioning at the touch of a button.

Antimicrobial coatings go beyond standard stainless steel protection, creating surfaces that actively fight bacterial growth while proper cleaning remains essential.

The trend toward modular accessories reflects how funeral homes demand more flexibility. Rather than buying separate specialized tables, modern systems adapt single high-quality tables for various needs through removable inserts and positioning aids.

Scientific research on ergonomic advances continues pushing toward designs that prioritize operator comfort and procedural efficiency.

Frequently Asked Questions about Embalming-Tables

What is the standard weight capacity I should look for?

When shopping for embalming-tables, you'll find most professional models support between 600-1,000 pounds - which handles the vast majority of cases you'll encounter. If you're running a typical funeral home, a table rated at 600-650 pounds will serve you well for everyday operations.

However, I'd recommend considering the 1,000-pound capacity models if your budget allows. The extra safety margin gives you peace of mind, and you'll be prepared for bariatric cases without scrambling for alternative solutions. The price difference is usually pretty reasonable compared to the operational flexibility you gain.

Think about your community demographics too. If you serve a diverse population or frequently handle larger individuals, that higher capacity becomes essential rather than just nice-to-have.

How often should I deep-clean my embalming table?

This is where consistency really pays off for both safety and equipment longevity. Daily cleaning after each use should be your non-negotiable baseline - use neutral pH cleaners and give special attention to those drainage areas where residues love to hide.

Weekly deep cleaning takes things up a notch. Pull apart any removable components, thoroughly decontaminate every surface, and check that your drainage systems are flowing properly. This prevents biofilm buildup and catches potential problems before they become expensive repairs.

Monthly maintenance cleaning is your chance to really examine everything. Lubricate those casters, inspect all mechanical components, and look for any signs of wear or damage. This schedule keeps your table performing optimally while extending its service life significantly.

A well-maintained embalming table isn't just about cleanliness - it's about protecting your investment and ensuring reliable operation when you need it most.

Can one table serve embalming, dressing, and transfer functions?

Absolutely! Multi-purpose tables can be incredibly practical, especially for smaller funeral homes where space and budget matter. The key is choosing a table that's properly designed for multiple functions rather than trying to force a single-purpose table into roles it wasn't meant for.

Combination embalming/dressing tables work beautifully when they feature appropriate drainage for embalming procedures while providing smooth, clean surfaces suitable for dressing and cosmetology work. You get the functionality you need without duplicating equipment costs.

Transfer capability really comes down to caster quality and overall mobility. Tables equipped with high-quality swivel casters and reliable brake systems can safely transport remains between prep room stations when needed. Just make sure those brakes actually hold under load!

Workflow considerations might push you toward dedicated tables if you're running a high-volume operation where multiple procedures happen simultaneously. But for smaller operations where procedures occur one after another, a single versatile table can be a smart, cost-effective solution that doesn't compromise on quality or safety.

Conclusion

Choosing the perfect embalming table for your funeral home isn't about finding the cheapest option - it's about making a smart investment that protects your staff, improves operations, and serves families with dignity.

Quality construction matters. That 304 stainless steel stands between your table and years of chemical damage. Proper drainage slopes prevent slip hazards. Seamless welds keep bacteria from hiding. When manufacturers offer 15-year warranties, they're telling you how long these tables should last.

Your staff's safety should never be negotiable. Tables with downdraft ventilation connections aren't expensive upgrades - they're essential protection systems. The same goes for height adjustability. Your embalmers shouldn't choose between quality work and protecting their backs.

The right table makes your job easier. Smooth-rolling casters mean less strain. Proper drainage means faster cleanup. Good ergonomics mean staff can work longer without fatigue. These aren't luxury features - they're the difference between struggling and running efficiently.

At American Mortuary Coolers, we've helped funeral homes across Tennessee, Atlanta, Chicago, and throughout all regions select equipment that improves operations. We've seen how the right embalming table transforms prep rooms from sources of frustration into spaces where professionals do their best work.

Whether you're dealing with a table that's seen better days or planning a new facility, this equipment forms the foundation of everything you do. Your families trust you to care for their loved ones with dignity. Your staff trusts you to provide safe working conditions. The right table helps honor both responsibilities.

More info about mortuary tables

Ready to find the table that's right for your facility? We'd love to help you sort through options and find equipment that fits your space, budget, and needs. The best embalming table is the one that helps you serve families better while keeping your team safe and comfortable.