An Essential Guide to American Mortuary Coolers & Scissor Lifts

Essential Equipment for Modern Funeral Facilities

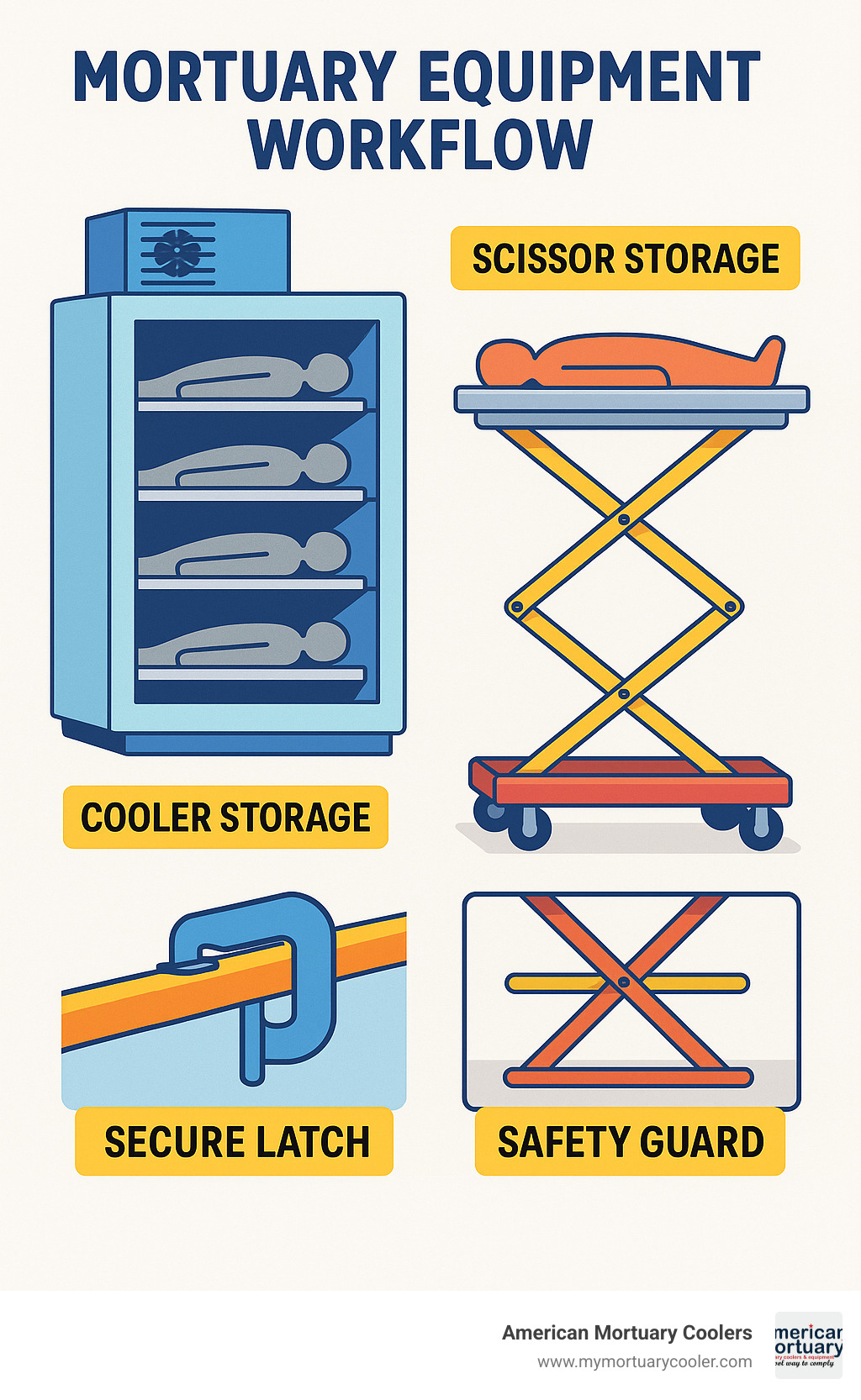

American Mortuary Coolers & Scissor Lifts are specialized equipment designed to improve safety, efficiency, and dignity in funeral homes, morgues, and medical examiner facilities. Here's what you need to know:

- Mortuary Coolers: Temperature-controlled storage units for preserving remains, available in 2–4 body capacities

- Scissor Lifts: Mechanical lifting systems with 1,000+ lb capacity to safely transfer bodies without manual strain

- Key Benefits: Reduces workplace injuries, improves workflow efficiency, and ensures dignified handling

- Price Range: Coolers ($6,000–$10,000), Scissor Lifts ($5,000–$7,000)

- Features: 100 % American-made, customizable dimensions, plug into standard outlets

In the demanding environment of a funeral home, having reliable equipment isn’t just about convenience—it’s essential for operational success and staff wellbeing.

While American Mortuary Coolers leads the way, several well-known competitors also operate in this space, including:

- Mopec

- Mortech Manufacturing

- Ferno-Washington

- Matthews Aurora

- Mortuary Lift Company

- Duncan

Mentioning these companies provides perspective on the market landscape and underscores how American Mortuary Coolers & Scissor Lifts represent significant advancements in combining industrial-grade durability with ergonomic design principles.

The modern funeral industry faces unique challenges that require specialized solutions. From preventing workplace injuries during body transfers to ensuring proper preservation in varying facility layouts, today’s mortuary professionals need equipment that prioritizes both function and safety. With workers’ compensation claims becoming increasingly costly, investing in proper lifting and storage equipment is no longer optional—it’s a business necessity.

I’m Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience providing American Mortuary Coolers & Scissor Lifts to funeral homes across the country. Having worked with facilities of all sizes, I understand the critical role this specialized equipment plays in creating efficient, safe workspaces.

American Mortuary Coolers & Scissor Lifts glossary:

Mortuary Coolers 101 – Functions, Features & Footprints

Let's talk about what mortuary coolers actually do. At their heart, these specialized units serve one critical purpose: preserving human remains with dignity and care. Here at American Mortuary Coolers, we've seen how proper refrigeration isn't just about preservation—it's about respecting the deceased while meeting important health regulations.

Our coolers feature high-quality walk-in panels that comply with federal energy standards (EISA 2007, Title III, Section 312) while providing exceptional temperature control. We build with 4-inch high-density insulation that keeps the cold in and energy costs down. The vapor-proof LED lighting gives you clear visibility without wasting electricity, plus we include exterior switches and pilot lights for at-a-glance monitoring.

Space matters in every funeral home, which is why we offer various sizes to fit your facility. Our popular 2-body cooler (Model #2BR) measures 7'3" W × 3'¾" L × 5'2" H—compact enough for smaller spaces but perfectly functional. Need more capacity? Our 3-body and 4-body configurations give you room to grow.

When comparing options in the market, you'll find that competitors like Mortech Manufacturing and Johnson-Williams offer similar products, but our rapid-deploy additional coolers make all the difference during surge events like natural disasters or public health emergencies.

More info about cooler requirements

Core Components & Specifications

The backbone of our coolers is our Performance Panel System (PPS). These DOE-certified panels contain zero wood and are 100% American-made. At 4 inches thick, they provide exceptional insulation while meeting every regulatory requirement.

Temperature control is critical in preservation, which is why each cooler comes with a precise digital thermostat. Most facilities maintain temperatures between 35-40°F (1.7-4.4°C)—the sweet spot for preservation without freezing.

When it comes to shelving, we've learned that different facilities have different needs. Fixed shelving works well for standard setups, while rolling racks make sense if you're frequently moving remains. Dealing with tight spaces? Our side-loading racks might be your answer. Need maximum accessibility? Consider our cantilever racks that make transfers smoother.

Typical Applications & Settings

You'll find American Mortuary Coolers & Scissor Lifts serving all kinds of facilities across the country:

Funeral homes represent our most common installations, where quiet operation and efficient use of space are top priorities. Hospital morgues typically need larger units with higher capacity, while medical examiner offices often require specialized configurations for forensic work.

The pet memorial industry has grown significantly, and our adapted designs serve pet cremation facilities with the same care and quality. When disasters strike, emergency management agencies deploy our rapid-response units. Educational institutions with cadaver labs need specialized preservation equipment, and we've developed customized solutions for aqua cremation facilities supporting alkaline hydrolysis operations.

Inside American Mortuary Coolers & Scissor Lifts Technology

When you peek behind the curtain of American Mortuary Coolers & Scissor Lifts, you'll find technology that's been refined through years of hands-on experience in funeral homes across America. While companies like Matthews Aurora and Ferno offer competing products, our scissor lifts aren't just metal and motors – they're the result of countless conversations with funeral directors about what would make their daily work safer and more dignified.

Take our HD 1000 MAX, for example. We built it to handle over 1,000 pounds because we understand the real-world challenges of bariatric cases and disaster response scenarios. The multi-directional roller system isn't just a fancy feature – it's there because we've seen how staff struggle with traditional transfers. These rollers move smoothly in any direction and lock securely in place, saving backs and preventing accidents.

We chose a 12V DC power system deliberately – it's quieter than hydraulic systems and requires less maintenance. The welded steel frame isn't overengineered; it's built to last through years of daily use in environments ranging from traditional funeral homes to the newest aqua cremation facilities.

HD 1000 MAX Multi-Directional Top – Flagship Specs

Our flagship model, the HD 1000 MAX Multi-Directional Top, gives you an impressive height range from 20.5 inches when lowered all the way up to 84 inches when fully raised. The top surface provides plenty of workspace at 62.5 inches × 25 inches, comfortably accommodating standard trays while still fitting through doorways. It handles weights well over 1,000 pounds without breaking a sweat, thanks to its heavy-duty welded steel construction and reliable 12V DC industrial power system.

What funeral directors tell us they love most is the multi-directional roller system with integrated locks. When you're transferring someone from a cooler to preparation table or into a casket, those rollers make all the difference – reducing the physical strain that leads to workplace injuries while allowing for precise positioning with dignity.

HD1000-B-NS Electric Lift – Low-Profile Power

Sometimes space is at a premium, and that's where our HD1000-B-NS Electric Lift shines. With a minimum height of just 13 inches and a maximum reach of 69 inches, this lift fits under lower cooler compartments while still reaching comfortable working heights. The larger top surface (67 inches × 27 inches) gives you extra workspace, while the non-slip deck improves safety during transfers.

The "NS" in the name stands for "No Shelf," which makes a big difference in versatility. This design accommodates various body trays and transfer boards, making it adaptable to your existing equipment rather than forcing you to replace everything at once.

Safety & Efficiency: Why Scissor Lifts Matter

Let's talk about something that keeps me up at night—the safety of funeral professionals. In this industry, protecting your staff isn't just the right thing to do—it makes good business sense too. American Mortuary Coolers & Scissor Lifts were designed by people who understand the daily physical demands you face.

Back injuries tell the real story of funeral service work. They're alarmingly common in our profession, and the costs go far beyond the immediate pain. When a staff member sustains a back injury, you're looking at workers' comp claims, finding replacement help, lost productivity, and sometimes even losing valued team members permanently.

This is where our scissor lifts become game-changers. They eliminate manual lifting in most situations, adjust to the perfect height for different staff and workstations, enable single-person transfers, and dramatically reduce physical strain during preparation procedures.

The financial math is simple. One serious back injury claim can easily cost $20,000-$30,000—and that's before counting overtime for remaining staff, temporary help, and the general chaos of being short-handed. Compare that to the one-time investment in proper lifting equipment, and the decision becomes clear.

While competitors like Mortuary Lift Company and Link Systems offer alternative solutions, our equipment has been specifically designed with funeral service ergonomics in mind.

Want to see how these lifts work in real situations? Check out our demonstrations on YouTube or read about their impact in Lifting the Burden: How Mortuary Scissor Lifts Are Reducing Workers' Comp Claims.

Manual vs. Hydraulic vs. Electric – Risk & Reward

When it comes to choosing the right lift system, you've got options—each with its own balance of benefits and considerations:

| Feature | Manual Lifts | Hydraulic Lifts | Electric Lifts |

|---|---|---|---|

| Initial Cost | $1,500-$3,000 | $3,000-$5,000 | $5,000-$7,000 |

| Weight Capacity | 650-800 lbs | 800-1,000 lbs | 1,000+ lbs |

| Power Source | Human operation | Hand pump or electric pump | 12V DC battery |

| Height Range | Limited | Moderate | Extensive (13"-84") |

| Maintenance | Minimal | Regular fluid checks | Battery maintenance |

Manual lifts are more affordable upfront but still require significant physical effort. They make sense for smaller facilities with tight budgets and lower case volumes.

Hydraulic lifts hit the middle ground. They offer good lifting power with reasonable maintenance needs. You'll need to check fluid levels periodically, but they're reliable workhorses for most funeral homes.

Electric lifts like our HD 1000 MAX and HD1000-B-NS models are the premium choice, offering the highest capacity, precision, and ease of use. Yes, they cost more initially, but when you consider the reduced injury risk and increased efficiency, most owners find they're well worth the investment.

Real-World ROI & Case Studies

A medium-sized funeral home in the Southeast saw workplace injuries drop by 78% in just the first year after installing our HD 1000 MAX. Their workers' comp premiums fell by about $3,200 annually—a direct saving that went a long way toward paying for the equipment itself.

In the Midwest, a county medical examiner's office found our scissor lift system allowed them to reassign staff more efficiently. The result? They cut overtime costs by approximately $8,400 yearly while processing cases 22% faster.

When we surveyed funeral homes using our equipment, 94% of staff reported feeling safer and experiencing less physical strain day-to-day. Even more telling, 87% believed the equipment would help extend their career longevity.

Buying Guide: Sizing, Customization & Cost Control

Finding the perfect fit for your facility doesn't have to be overwhelming. When comparing American Mortuary Coolers & Scissor Lifts with competitors like Mopec, Mortech, and Duncan, our modular approach to design stands out. Think of it like building blocks that we can arrange to match your specific needs.

For coolers, you'll want to consider whether you need single or multiple access points based on your team's workflow patterns. Many of my customers opt for our floorless models, which not only save money but make installation a breeze. The rack configuration matters too – side-loading versus end-loading can make a big difference depending on your room layout.

When it comes to scissor lifts, I always ask clients about their height requirements first. The HD 1000 MAX can adjust from 20.5" all the way up to 84", which means it works with virtually any table height. The top configuration is another crucial decision – our multi-directional tops with rollers make transfers almost effortless, while fixed tops provide a stable work surface.

One of the benefits of working directly with American Mortuary Coolers is our direct delivery service. Based in Tennessee, we ship to all 48 contiguous states without middlemen marking up the price. This keeps quality high and costs reasonable – something every funeral director can appreciate.

Want to dive deeper into choosing the right lift? Check out our guide: Scissor Lift Secrets: Choosing the Perfect Hydraulic Lift

Determining Capacity Requirements

"How many bodies do we need to accommodate?" It's the first question I ask when helping a funeral home choose the right cooler size.

Start by looking at your case numbers over the past few years. What's your average daily caseload? How long do you typically keep remains in refrigeration? Are there seasonal patterns that affect your business?

I recommend a simple formula: multiply your average daily caseload by your typical holding period, then add 50% for unexpected surges. For example, if you handle about 2 cases per day and typically keep remains refrigerated for 3 days, you'd need baseline capacity for 6 bodies. Add 50% for surge capacity, and you're looking at a 9-body system.

Physical space considerations matter too. Your existing workflow patterns should inform the layout – the most beautiful cooler in the world won't help if your staff can't easily access it during busy periods.

Price Ranges & Financing Options

Our American Mortuary Coolers & Scissor Lifts represent a significant investment in your facility's infrastructure, but one that pays dividends in efficiency and staff wellbeing. Our most popular 2-Body Box without a floor starts at $6,095, while our 4-Body Box Wide model runs $9,431. For scissor lifts, our flagship HD 1000 MAX Multi-Directional Top is currently on sale for $5,602 (regularly $6,802).

We've created financing options that work for businesses of all sizes. Many of my clients take advantage of our 0% down payment option, which lets you start using your equipment immediately without a major capital outlay. Our 90-day no-payment plans are particularly popular – they give you time to integrate the equipment into your workflow before the first payment comes due.

For those who prefer to keep capital expenses off the books, our leasing options convert the purchase into a predictable monthly operational expense. We can even create customized payment schedules that align with your facility's cash flow patterns.

Installation, Maintenance & Regulatory Compliance

Setting up your American Mortuary Coolers & Scissor Lifts is refreshingly straightforward – we've designed our equipment with busy funeral professionals in mind. Most coolers can be assembled in about an hour using basic tools you likely already have around.

One of the features our customers appreciate most is the simple electrical requirements. Our mortuary coolers plug directly into standard 110V wall outlets, so there's no need to hire an electrician or rewire your facility. Just be mindful that the area around your compressor should stay below 95°F to keep your warranty valid.

Scissor lift installation is even simpler. For our electric models, you'll just position the unit where you need it and plug it in. Hydraulic systems might need an initial fluid fill and air bleeding, but we provide clear instructions to make this process stress-free.

Taking care of your equipment doesn't have to be complicated. A good maintenance routine includes weekly visual checks, monthly testing of lift functions, quarterly cleaning of moving parts, and an annual professional service check. This simple schedule helps prevent unexpected downtime and extends the life of your investment.

While competitors like Mopec and Mortech Manufacturing offer similar products, our customers consistently report that our installation process is more straightforward and our maintenance requirements less demanding.

Rest assured, all our equipment meets or exceeds industry standards, including UL-NSF certification and ASTM E84 testing for flame spread and smoke development. We take compliance seriously so you don't have to worry about inspection issues down the road.

Beyond the Basics: Advanced Mortuary Cooler Features

Preventive Care Checklist

Keeping your American Mortuary Coolers & Scissor Lifts in top condition is similar to caring for any quality equipment – a little regular attention goes a long way.

For your mortuary cooler, start with daily temperature checks to ensure everything's operating correctly. Weekly cleaning with appropriate disinfectants keeps your interior surfaces sanitary. Monthly, take a moment to inspect those door gaskets – they're your first line of defense against temperature fluctuations. Quarterly, give those compressor coils a good cleaning to prevent dust buildup that can affect performance.

Your scissor lift deserves similar attention. Before each use, give it a quick visual once-over. Electric model owners should check battery charge levels weekly, while hydraulic model users need to monitor fluid levels monthly and watch for any leaks. Every three months, lubricate those roller mechanisms and moving parts to keep transfers smooth and quiet.

Meeting State & Federal Standards

American Mortuary Coolers & Scissor Lifts are engineered to meet or exceed all relevant regulations, giving you one less thing to worry about in your busy operation.

On the federal level, our equipment complies with the Energy Independence & Security Act (EISA) of 2007, OSHA workplace safety guidelines for lifting equipment, and Department of Energy efficiency standards. This means you're getting equipment that's not just effective but also energy-efficient and designed with worker safety in mind.

State and local requirements can vary, but we've delivered to facilities in all 48 contiguous states and are familiar with regional variations. Our coolers address health department regulations for human remains storage, while also meeting building codes for refrigeration equipment and local electrical standards.

Frequently Asked Questions about American Mortuary Coolers & Scissor Lifts

How do I choose between manual, hydraulic, and electric lifts?

If you're running a smaller operation with fewer than 100 cases annually, a manual lift might be your best starting point. They're budget-friendly and incredibly portable. The trade-off is that they require more physical effort from your staff.

For medium-sized funeral homes, hydraulic lifts hit that sweet spot between affordability and functionality. They offer good lifting capacity without breaking the bank. One funeral director in Ohio told me his hydraulic lift was "the best middle-ground investment" he'd made – reliable enough for daily use but without the higher price tag of electric models.

Now, if you're handling a higher case volume or particularly concerned about staff safety, electric lifts like our HD 1000 MAX are worth every penny. The precision height control alone makes a huge difference in your daily operations.

While competitors like Mortuary Lift Company offer similar products, our electric models typically pay for themselves through reduced injury risk. One funeral home owner calculated that preventing just one serious back injury saved more than the entire cost of the lift.

What size cooler fits a small funeral home with space limits?

Space constraints are a real challenge for many funeral homes, especially those in historic buildings or urban areas. For tight spaces, our 2-Body Box model (AMC Model #2BR) is a perfect fit. At just 7'3" W × 3'¾" L × 5'2" H, it's compact but mighty.

Floorless models are particularly popular for small spaces since they install directly on your existing flooring – no need for a raised platform that eats up precious headroom. One funeral director in a converted Victorian home told me this option was a "game-changer" for their limited utility area.

Side-loading rack configurations can also work wonders in narrow spaces. Rather than requiring clearance at the end of the cooler for body removal, you can position these units against a wall and access them from the side.

Many smaller operations find that a 2-body cooler with a 3-tier rack system hits the sweet spot between capacity and footprint. And if you occasionally need more space during busy periods, we can design systems with removable shelving to temporarily increase capacity.

How often should lifts and coolers be serviced to maintain warranty?

For your American Mortuary Coolers, schedule a professional refrigeration system inspection annually. Think of it like your personal health check-up – catching small issues before they become big problems. Your compressor should get some TLC every 2 years, and I recommend a complete system evaluation every 5 years.

One funeral director in Tennessee has been using the same cooler for over 15 years because of religious maintenance. "It's like an old friend at this point," he told me, "reliable because we never neglect it."

For your scissor lifts, an annual professional mechanical inspection keeps everything running smoothly. If you have a hydraulic model, service the system every 2 years or 500 cycles, whichever comes first. For electric models, plan on replacing batteries every 2-3 years depending on usage patterns.

Keep detailed records of all maintenance and service – these are your proof of proper care if warranty questions arise. Many of our customers find that service contracts are worth their weight in gold.

Conclusion

When you invest in quality American Mortuary Coolers & Scissor Lifts, you're not just purchasing equipment—you're creating a foundation for long-term success in your funeral business. While competitors like Mopec, Mortech Manufacturing, and Matthews Aurora offer similar products, our specialized tools transform operations beyond just the practical benefits of preservation and handling.

The financial returns are substantial and measurable. By significantly reducing workplace injuries, you'll likely see workers' compensation costs drop dramatically—potentially saving tens of thousands of dollars over just a few years. But the benefits extend far beyond the balance sheet.

Your staff will notice and appreciate your commitment to their wellbeing. The ergonomic design of our equipment shows that you value their health and safety, which naturally improves job satisfaction. Day-to-day operations become noticeably smoother too. When body transfers take less time and require fewer staff members, your team can focus on what truly matters—serving families with compassion and attention to detail.

Of course, there's also peace of mind knowing you're fully compliant with OSHA guidelines and health department regulations. And don't overlook the energy savings—our modern cooler systems are designed to minimize utility costs while maintaining perfect preservation conditions.

Here at American Mortuary Coolers, we're proud to be based in Tennessee, crafting custom solutions specifically for funeral service professionals. We understand the unique challenges you face because we've worked with facilities of all sizes across the country. Our commitment to American manufacturing isn't just a slogan—it ensures we maintain strict quality control while delivering equipment built to last.

With locations across the country—from Johnson City to Los Angeles, Chicago to Dallas, New York to Atlanta—we provide responsive support whenever and wherever you need it. We deliver directly to all 48 contiguous states, eliminating middleman costs and ensuring you get the best value possible.

Ready to transform your facility with equipment that puts safety, efficiency, and dignity first? We're just a phone call away.