An Essential Guide to Choosing Personal Protective Gear

Protecting Your Team: The Essentials of Personal Protective Gear

Personal protective gear is equipment worn to minimize exposure to workplace hazards that can cause injuries and illnesses. When properly selected and used, PPE creates a crucial barrier between workers and potentially harmful substances or environments.

| Personal Protective Gear - Quick Guide |

|---|

| 1. Purpose: Minimizes exposure to workplace hazards |

| 2. When Required: After engineering and administrative controls are insufficient |

| 3. Common Types: Head, eye, face, hearing, respiratory, hand, foot, and body protection |

| 4. Employer Responsibilities: Provide appropriate PPE at no cost to employees, ensure proper fit, and provide training |

| 5. Employee Responsibilities: Use PPE correctly, attend training, report damaged equipment |

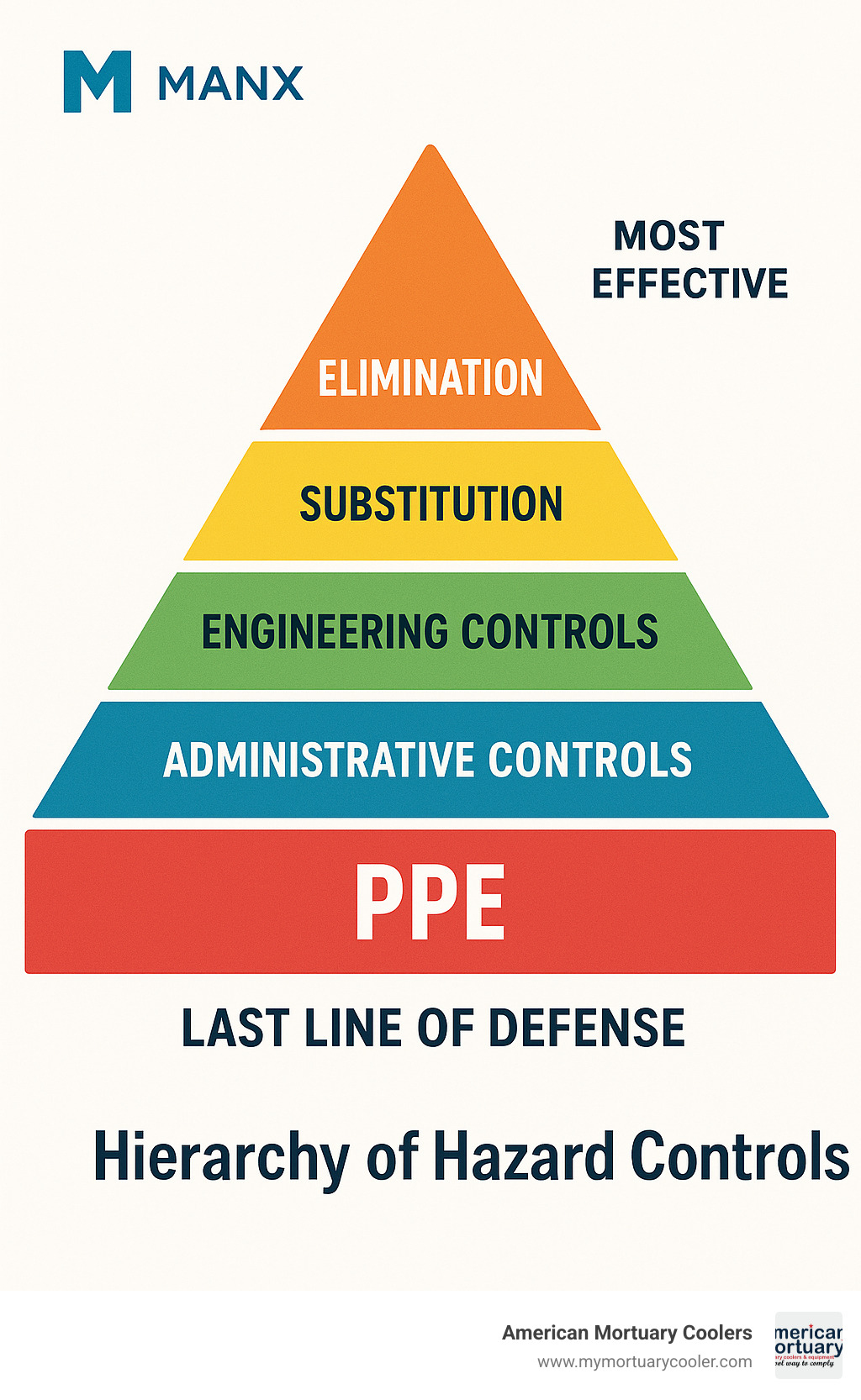

According to OSHA, proper use of personal protective gear could prevent approximately 37,000 injuries and illnesses and 1,000 deaths annually in the United States alone. This lifesaving equipment serves as the final line of defense when other control measures (elimination, substitution, engineering controls, administrative controls) aren't feasible or don't provide sufficient protection.

The importance of personal protective gear became dramatically apparent during the COVID-19 pandemic, when the World Health Organization reported global demand increased by up to 100 times, with prices rising up to 20 times. This unprecedented surge highlighted both the critical role of PPE and the challenges in ensuring adequate supply during crisis situations.

For funeral home directors and mortuary staff, proper personal protective gear is especially critical when handling remains that may pose biological or chemical hazards. From fluid-resistant gowns and nitrile gloves to face shields and respirators, the right equipment ensures both staff safety and dignified care for the deceased.

I'm Mortuary Cooler, a national-level supplier of mortuary equipment with extensive experience providing personal protective gear solutions for funeral professionals across the country. My team specializes in helping funeral directors identify and procure the appropriate personal protective gear for every aspect of mortuary operations.

What Is Personal Protective Gear and Why It Matters

Personal protective gear isn't just equipment—it's your invisible shield against workplace dangers. PPE includes all the specialized clothing and equipment designed to keep workers safe from hazards they might encounter on the job, whether chemical splashes, falling objects, or biological risks. When other safety measures like engineering controls or administrative policies can't fully protect workers, PPE becomes your critical last line of defense.

The numbers tell a sobering story: workplace injuries cost U.S. businesses over $171 billion in 2019 alone, according to the National Safety Council. Many of these incidents could have been prevented with proper PPE use. For those of us in the mortuary profession, the stakes are particularly high—daily exposure to bloodborne pathogens, chemical preservatives, and biohazards requires specialized protection.

As Dr. Sarah Thompson, an occupational health specialist, puts it: "Everything a mortuary professional does relates to safety. Therefore, it only makes sense that mortuary staff deserve the highest-quality personal protective equipment."

The responsibility for safety is shared. Under OSHA regulations, employers must provide appropriate personal protective gear at no cost when needed to protect against workplace hazards. This includes conducting thorough hazard assessments, selecting the right equipment, communicating clearly about why certain PPE was chosen, and providing comprehensive training.

Employees play their part too—using PPE correctly, attending training sessions, maintaining their equipment, and promptly reporting any damage. This partnership creates the foundation for an effective safety program that protects everyone.

Core Components of Personal Protective Gear

When we talk about personal protective gear, we're referring to a comprehensive system that protects your entire body:

For your head, protective coverings prevent contamination and shield your hair from harsh chemicals commonly used in preparation rooms. Your eyes and face need shields, goggles, or glasses to guard against chemical splashes and biological fluids—absolutely essential during embalming procedures.

Your hearing deserves protection too, especially in crematory operations or when using noisy preparation equipment. Your respiratory system requires specialized masks or respirators, from simple N95s to powered air-purifying respirators, depending on the hazards present.

Your hands—perhaps your most valuable tools in mortuary work—need appropriate gloves made of nitrile, latex, or neoprene to protect against chemicals, cuts, and biological hazards. Your feet benefit from safety shoes with puncture-resistant soles and toe protection, while your body stays protected with coveralls, aprons, and fluid-resistant gowns.

For mortuary professionals specifically, the daily PPE essentials typically include fluid-resistant gowns, chemical-resistant gloves, reliable eye protection, and appropriate respiratory gear—all working together to keep you safe while you perform your important work.

Limitations of Personal Protective Gear

While personal protective gear is vital, it's important we acknowledge its limitations with clear eyes.

First, PPE doesn't eliminate hazards—it simply creates a barrier. If that barrier fails for any reason, you're exposed to the full danger. As one study participant bluntly noted, "If it doesn't fit right, it's not protecting you—period." Proper fit is non-negotiable for effective protection.

Comfort challenges can't be ignored either. When PPE causes heat stress, restricts movement, or makes communication difficult, people become less likely to wear it consistently. And as we all learned during the COVID-19 pandemic, supply chain problems can create critical shortages exactly when protection is most needed. The WHO estimated monthly requirements of 89 million medical masks, 76 million examination gloves, and 1.6 million goggles just for the pandemic response.

There's also an environmental cost to consider. Single-use PPE generates significant waste, requiring proper disposal protocols to minimize environmental impact, particularly for contaminated items.

Dr. Michael Chen, an infection control specialist, puts it well: "PPE is crucial but imperfect. The best approach combines multiple control strategies with properly fitted, high-quality protective equipment."

At American Mortuary Coolers, we understand the unique protection needs of funeral professionals. While we specialize in mortuary refrigeration, we recognize that comprehensive safety in your facility includes properly selecting and using personal protective gear every day.

Hazard Assessment: Matching Risks to the Right Gear

Finding the perfect match between workplace hazards and personal protective gear is a bit like dating – the right pairing can be lifesaving, while the wrong one could spell disaster. A thorough hazard assessment forms the foundation of any effective PPE program, helping identify exactly what protection your team needs before anyone steps into a potentially dangerous situation.

OSHA doesn't just suggest these assessments – they require them. And for good reason! Different environments present vastly different risks, especially in mortuary settings where staff face unique combinations of biological and chemical hazards daily.

Let's break down the main hazard types you might encounter and what protection they demand:

| Hazard Type | Examples | Recommended PPE |

|---|---|---|

| Impact | Falling objects, flying particles | Hard hats, safety glasses, face shields, steel-toed boots |

| Chemical | Splashes, vapors, fumes | Chemical-resistant gloves, goggles, face shields, aprons, coveralls, respirators |

| Biological | Blood, tissue, bodily fluids | Fluid-resistant gowns, nitrile gloves, face shields, respirators, booties |

| Radiological | X-rays, radioactive materials | Lead aprons, thyroid shields, dosimeters, gloves |

| Electrical | Live circuits, static electricity | Insulating gloves, non-conductive footwear, face shields |

| Heat/Cold | Extreme temperatures, fire, cryogenic materials | Heat-resistant gloves, cooling vests, insulated clothing |

| Noise | Equipment operation, machinery | Earplugs, earmuffs, acoustic barriers |

For mortuary professionals, certain hazards take center stage. During embalming, formaldehyde exposure requires specific chemical-resistant gloves, proper respiratory protection, eye shields, and fluid-resistant clothing. When handling remains, biological hazards call for comprehensive barrier protection against bloodborne pathogens.

As James Wilson, a mortuary safety consultant I recently spoke with, puts it: "The key is to match the protection to the specific risk. Not all gloves protect against all chemicals, and not all respirators filter all contaminants. Specificity matters."

Conducting a Workplace PPE Survey

Walking through your facility with "hazard vision" might not sound like the most exciting afternoon, but it's one of the smartest investments you can make in your team's wellbeing. A good workplace survey helps identify exactly what personal protective gear you need and where.

Start with a methodical walkthrough of each area in your facility. In a mortuary setting, pay special attention to preparation rooms, crematory areas, refrigeration units, and chemical storage spaces. Look at each task performed and consider what could potentially go wrong.

Don't ignore history – those injury logs gathering dust might contain valuable patterns revealing your most problematic areas. Has anyone experienced chemical burns in the prep room? Are there repeated minor cuts happening during certain procedures? This information is gold for your assessment.

When evaluating hazards, don't reinvent the wheel. Consult established OSHA guidelines and ANSI standards like Z87.1 for eye and face protection selection. These references provide excellent frameworks for your assessment.

Document everything you find. Your written certification should include which workplace areas you evaluated, who conducted the assessment, when it happened, what hazards you identified, and which personal protective gear you selected for each risk. This documentation isn't just good practice – it's required by law.

At American Mortuary Coolers, we've found that annual comprehensive assessments work best for most funeral homes, with additional mini-assessments whenever you introduce new equipment or processes. Our team is always available to help develop custom assessment protocols custom specifically to mortuary operations.

When PPE Is Legally Required

Navigating the legal requirements for personal protective gear can feel like trying to read the fine print on a contract while wearing someone else's glasses. Let me clarify the essentials you need to know.

In the United States, OSHA lays out general PPE requirements in 29 CFR 1910.132, with specialized standards for different body parts. There's 1910.133 for eye and face protection, 1910.134 covering respiratory protection, 1910.135 for head protection, 1910.136 addressing foot protection, 1910.137 for electrical protective equipment, and 1910.138 focusing on hand protection. It's quite the regulatory family tree!

Our European colleagues follow Directive 89/686/EEC, which takes a different approach by categorizing equipment based on risk levels. Category I covers simple designs for minimal risks, Category II addresses intermediate risks, and Category III tackles the serious stuff – equipment designed to protect against mortal dangers or severe health risks.

Here's something critical that many funeral homes miss: OSHA's "PPE Payment Rule," effective since February 2008, requires employers to provide and pay for personal protective equipment when needed for OSHA compliance. Your staff shouldn't be reaching into their own pockets for safety gear. There are some exceptions like ordinary safety-toed footwear, regular prescription safety eyewear, logging boots, and ordinary clothing – but these rarely apply in mortuary settings.

For our industry specifically, the Bloodborne Pathogens Standard (29 CFR 1910.1030) is non-negotiable. It requires appropriate gloves, face shields or masks with eye protection, and protective clothing whenever exposure to blood or other potentially infectious materials might occur – which, let's face it, is a daily reality in mortuary work.

At American Mortuary Coolers, we understand these regulations can be overwhelming. That's why we're committed to helping our clients not just understand what's required, but implement practical, comfortable solutions that keep your team safe and your facility compliant.

Main Categories of Personal Protective Gear

Personal protective gear comes in many shapes and sizes, each designed to shield specific parts of your body from workplace hazards. Think of PPE as your body's security team, with different specialists protecting different zones.

Head Protection

When it comes to protecting what's above your shoulders, hard hats and helmets lead the way. Following ANSI standards, Type I hard hats shield the top of your head, while Type II versions protect both top and sides.

The electrical protection varies too: Class E hats withstand an impressive 20,000 volts, Class G handles 2,200 volts, and Class C offers no electrical protection at all.

In funeral homes and preparation rooms, you'll rarely need impact protection. Instead, lightweight bouffant caps or hoods help prevent contamination and keep hair safely tucked away during procedures.

Eye & Face Protection

Your eyes and face deserve special attention, especially in mortuary settings where chemical splashes are a real concern. Safety glasses provide basic impact protection, but for embalming procedures, you'll want safety goggles that create a complete seal around your eyes.

When working with formaldehyde and other preservatives, a face shield offers that extra layer of protection against splashes. For maximum protection, some mortuary professionals opt for full-face respirators that shield both your breathing passages and eyes in one integrated unit.

Hearing Protection

Though often overlooked, hearing protection is crucial in certain mortuary operations, particularly around crematory equipment. Earplugs insert directly into the ear canal, while earmuffs cover the entire outer ear for more substantial protection. Canal caps offer a middle ground, sealing the ear canal at its opening.

The key to selection is the Noise Reduction Rating (NRR) – the higher the number, the greater the protection. Once hearing damage occurs, it's permanent, so this is one area where prevention truly matters.

Respiratory Protection

Breathing protection comes in several forms, from simple masks to complex air-supply systems. Filtering facepiece respirators like N95s filter airborne particles, while half-face respirators use replaceable cartridges to target specific contaminants.

For mortuary professionals, respirators with formaldehyde-specific cartridges are essential during embalming. When higher protection levels are needed, full-face respirators or powered air-purifying respirators (PAPRs) provide superior protection with greater comfort during extended wear.

Hand & Arm Protection

Your hands face perhaps the greatest exposure risk in mortuary operations. Chemical-resistant gloves made from nitrile are the workhorses of the preparation room, providing barrier protection against bodily fluids and commonly used chemicals.

For heavy-duty embalming work, sturdier gloves made from neoprene, butyl rubber, or PVC offer improved chemical resistance. Some tasks might require cut-resistant or puncture-resistant gloves, especially when handling instruments or working with cases involving trauma.

Foot & Leg Protection

While we focus on protecting our hands and face, foot protection sometimes gets forgotten. In mortuary settings, fluid-resistant shoe covers or dedicated work shoes prevent contamination from traveling home with you.

For areas with heavy equipment, safety shoes with protective toe caps guard against crush injuries. When working with chemicals, chemical-resistant footwear and sometimes leggings provide additional splash protection for the lower body.

Body Protection

Your torso and limbs need comprehensive coverage during preparation procedures. Fluid-resistant gowns or coveralls serve as the foundation of body protection in mortuary settings, creating a barrier against splashes and contamination.

For added protection during heavy fluid exposure, aprons provide an extra layer over your primary garments. Many funeral professionals keep lab coats handy for lighter-duty tasks where full coverage isn't necessary but some protection is still wise.

High-Visibility Clothing

Though less common inside funeral homes, high-visibility clothing becomes important during outdoor cemetery operations or transport activities. These garments follow ANSI/ISEA 107 standards with specific categories: Type O for off-road use, Type R for roadway environments, and Type P for public safety activities.

The reflective materials help ensure worker visibility in low-light conditions or around moving vehicles – an important consideration when working at gravesites or directing funeral processions.

Fall Arrest Systems

While not daily equipment for most mortuary staff, fall protection becomes crucial during facility maintenance or when accessing storage areas at height. Full-body harnesses distribute fall forces across the body's strongest parts, while lanyards and self-retracting lifelines connect you securely to anchor points.

These systems require proper training and regular inspection to ensure they'll perform when needed – something we at American Mortuary Coolers emphasize when discussing facility safety with our clients.

Selecting Personal Protective Gear for Each Body Zone

Choosing the right personal protective gear means matching the protection to both the hazard and the body part at risk. For head protection, follow ANSI Z89.1 standards and ensure proper fit – a hard hat should sit about 1-1¼ inches above your head for optimal protection.

Eye protection selection should align with ANSI Z87.1 guidelines. Look for impact resistance (marked with a "+" symbol) when projectiles are possible, and chemical splash protection (sealed or indirectly vented goggles) when working with liquids.

Hand protection, governed by OSHA 1910.138, should be selected based on both task requirements and duration of use. Chemical resistance varies dramatically between materials – what protects against formaldehyde might fail completely against another chemical.

For high-visibility needs, EN ISO 20471 and ANSI/ISEA 107 standards provide guidance, with class 3 garments offering maximum visibility through greater amounts of reflective material.

"Finding the right balance between protection and comfort is essential," shares one of our mortuary clients. "When PPE fits well and feels good, staff actually wear it consistently rather than finding excuses to remove it."

Innovations & Smart PPE

The world of personal protective gear is evolving rapidly, with technology creating exciting new possibilities. Sensor-equipped PPE can now monitor environmental conditions and even worker vital signs. Imagine a respirator that alerts you when formaldehyde levels rise too high or when your filter needs replacement.

Advanced cooling materials address one of the biggest complaints about protective gear – heat buildup. Cooling vests and garments using phase-change materials can make wearing multiple layers of protection much more comfortable during long preparation procedures.

Connected wearables are bringing PPE into the digital age, allowing communication between workers and supervisors. Some smart systems can track usage patterns and exposure levels, creating documentation that helps prove regulatory compliance.

Predictive maintenance technologies take the guesswork out of equipment replacement. Rather than changing respirator filters on a fixed schedule, sensors can monitor actual breathing resistance and alert you when replacement is truly needed – saving money while ensuring safety.

Ergonomically improved designs make today's PPE more comfortable than ever before. Lighter materials, better weight distribution, and increased flexibility all contribute to gear that protects without feeling like a burden.

At American Mortuary Coolers, we keep a close eye on these innovations, recommending only proven technologies that improve both safety and comfort for mortuary professionals. After all, the best protective gear is the kind you'll actually wear.

Standards, Fit, and Quality Assurance

When it comes to personal protective gear, three things make all the difference between safety and risk: following established standards, ensuring proper fit, and maintaining rigorous quality control. Let's face it - even the most expensive PPE won't protect you if it doesn't meet standards, doesn't fit right, or is poorly made.

Several organizations work tirelessly to keep workers safe through comprehensive standards:

ANSI (American National Standards Institute) develops the voluntary consensus standards we rely on in the U.S. Think of them as the friendly neighborhood safety experts who bring together manufacturers, users, and safety professionals to agree on what makes PPE effective.

ASTM International creates the test methods and performance specifications that determine whether your protective equipment can actually do its job. They're the ones asking, "Will these safety glasses really stop that flying debris?"

ISO takes a global view, establishing worldwide standards so that personal protective gear in Tokyo meets the same basic requirements as equipment in Toledo.

NIOSH focuses specifically on respiratory protection, testing and certifying equipment to ensure it actually filters what it claims to filter. Their approval is what separates real protection from false security.

The CE Marking serves as Europe's stamp of approval, indicating conformity with health, safety, and environmental protection standards throughout the European Economic Area.

These organizations don't just make up standards for fun - they develop specific guidelines for each type of protection. ANSI Z87.1 covers eye and face protection, ANSI Z89.1 addresses industrial head protection, ANSI S3.19 tackles hearing protection, and NIOSH 42 CFR Part 84 governs respiratory protection.

During recent shortages, counterfeit products flooded the market, putting workers at serious risk. As NIOSH researcher Dr. Jonathan Miller observed, "During the pandemic, we saw an alarming increase in counterfeit N95 respirators. These products looked legitimate but failed basic filtration tests, putting wearers at risk."

Fit-Testing and Sizing Best Practices

A respirator that doesn't seal properly is like an umbrella with holes - it creates a false sense of security while letting danger in. Proper fit is absolutely crucial for personal protective gear to do its job.

Respirator fit testing comes in two main flavors:

Qualitative fit testing relies on your senses - if you can taste the sweet saccharin or bitter Bitrex solution while wearing your respirator, you've got leaks. It's simple but effective for many applications.

Quantitative fit testing takes a more high-tech approach, using specialized instruments to measure the actual amount of leakage around your face seal. This gives precise numbers rather than just a pass/fail result.

OSHA doesn't mess around with fit testing requirements. They mandate testing before first use, whenever you switch to a different respirator model, and at least once a year after that. And if your face changes due to weight fluctuation, dental work, or facial surgery, you'll need retesting.

For hearing protection, the personal attenuation rating (PAR) measures how much noise reduction you personally achieve with your earplugs or earmuffs. This individual approach recognizes that the manufacturer's Noise Reduction Rating might not reflect your real-world protection.

When it comes to gloves, size really does matter. Properly sized gloves should feel like a natural extension of your hands - not so tight they restrict blood flow or so loose they bunch up and catch on equipment. Following standardized sizing charts based on hand circumference and length helps get this right.

Eye protection needs to sit securely on your face without uncomfortable gaps, pinching, or obstructing your vision. Many models offer adjustable features like flexible temple length and angle adjustments to better fit different face shapes.

At American Mortuary Coolers, we've seen how proper sizing makes all the difference for mortuary professionals handling delicate preparation procedures. That's why we recommend maintaining detailed sizing charts and fit test records for all employees, with regular reassessment as part of a comprehensive PPE program.

Ensuring PPE Quality in Procurement

Buying personal protective gear is a bit like dating - it pays to be selective and check credentials before committing. Here's how to make sure you're getting the real deal:

Start with supplier qualification by evaluating potential vendors' quality management systems, regulatory compliance history, and product certifications. A supplier with a spotty history might not be the best partner for life-protecting equipment.

Always verify certifications by checking NIOSH approval numbers for respirators, looking for ANSI compliance markings, confirming CE markings with accompanying documentation, and ensuring FDA clearance for medical PPE. These aren't just fancy logos - they represent rigorous testing and compliance.

Before making large purchases, request samples for evaluation. This hands-on approach lets you verify material quality, construction, and comfort. Your team will thank you for testing comfort before committing to hundreds of units.

Don't skip the paperwork! Examining technical data sheets, user instructions, and certification documentation might not be exciting, but it's essential for confirming you're getting legitimate protection.

Establish lot traceability so products can be traced to specific manufacturing batches. This becomes crucial if quality issues arise or recalls become necessary. It's the difference between replacing a few dozen items and your entire inventory.

Implement receiving inspection procedures to check for obvious defects, proper labeling, and complete packaging when supplies arrive. A quick visual inspection can catch problems before equipment reaches your staff.

For mortuary operations specifically, we recommend building relationships with reliable suppliers who truly understand funeral professionals' unique needs. This includes finding vendors who can provide documentation of chemical resistance for gloves and gowns used with embalming fluids and other preparations.

At American Mortuary Coolers, we've built our reputation on quality and reliability for mortuary equipment, and we apply those same standards when helping our clients source appropriate personal protective gear for their specific needs. After all, your safety equipment should be as dependable as our coolers!

For more specific information about prep room supplies, including appropriate PPE, check out our comprehensive buying guide for prep room supplies.

Proper Use, Maintenance, and Disposal

Even the best personal protective gear in the world won't keep you safe if you're not using it correctly. Think of PPE as your personal shield—it needs proper handling to work effectively.

When putting on (or "donning") your protective equipment, there's a method to the madness. Start with inner layers and work outward. Always inspect everything first—a tiny tear can make your protection worthless. Put on your gown or coveralls, then your mask or respirator (with a seal check!), followed by eye protection, and finally your gloves, making sure they overlap your sleeves to leave no skin exposed.

Taking off (or "doffing") your gear safely is even more crucial. As infection control specialist Maria Santos puts it: "Most contamination exposures happen during PPE removal when proper technique isn't followed." The golden rule? Remove the most contaminated items first—typically your gloves—then work your way inward, finishing with hand hygiene.

Keeping your personal protective gear clean isn't just about looking professional; it's about staying safe. Different equipment needs different care:

Your reusable respirator needs regular disassembly, cleaning with mild soap, proper disinfection, thorough rinsing, and complete air-drying before reassembly. Eye protection usually needs a simple soap-and-water cleaning followed by disinfection according to the manufacturer's instructions. And don't forget those reusable gowns—they need proper laundering following protocols for contaminated textiles.

Storage might seem like an afterthought, but it's crucial for extending the life of your gear. Keep respirators in clean, breathable containers away from sunlight and moisture. Never stack hard hats—hang them by their brims instead. And keep rubber gloves away from motors and electrical equipment, as the ozone these produce can degrade the material.

Regular inspection keeps you safe. Before each use, visually check for tears, punctures, or degradation. After use, perform a more thorough cleaning and integrity check. And periodically, evaluate everything against the manufacturer's specifications.

Knowing when to retire your gear is just as important as knowing how to use it. It's time for replacement when you see visible damage, when fit tests fail, when you've exceeded the manufacturer's service life, or after exposure to chemicals that might have compromised the material integrity.

In mortuary settings, this last point deserves special attention. The chemicals used in embalming can degrade many materials, so inspect your gear extra carefully after preparation procedures.

Training & Compliance Programs

A great personal protective gear program needs more than just equipment—it needs well-trained people who know exactly how to use it. OSHA requires employers to train each PPE user on when and what PPE is necessary, proper donning and doffing, limitations of the equipment, and proper care and maintenance.

We've found that toolbox talks work wonders in keeping safety top-of-mind. These quick, 10-15 minute discussions can address seasonal concerns like heat stress during summer months, update team members on procedure changes, or simply refresh everyone on proper techniques.

Don't just tell people how to use PPE—make sure they can show you. Competency sign-offs document that employees have demonstrated proper use, not just heard about it. This hands-on verification ensures everyone can correctly select, inspect, and use their equipment when it matters most.

Technology can make compliance easier. Digital checklists streamline documentation and create records you can easily reference later. Mobile apps can guide your team through proper inspection procedures and even alert you when equipment needs replacement.

Training isn't one-and-done. Refresher training should happen at least annually, whenever you introduce new hazards or equipment, when you notice improper use, after workplace incidents, or when regulations change.

At American Mortuary Coolers, we strongly recommend that mortuary facilities keep detailed training records including dates, content covered, instructor qualifications, and competency assessments. Trust us—these records are worth their weight in gold during regulatory inspections.

Overcoming Common Barriers to PPE Use

We all know personal protective gear is important, but let's be honest—sometimes it's a pain to wear. Understanding these barriers is the first step to overcoming them.

Heat stress is probably the number one complaint we hear, especially with impermeable protective clothing in warm environments. Combat this by scheduling regular cooling breaks, implementing strict hydration protocols, ensuring your preparation rooms have proper climate control, and considering cooling vests under PPE when appropriate.

When masks and hearing protection make normal conversation difficult, communication barriers arise. Consider investing in PPE with built-in communication systems, establishing clear hand signals for common instructions, posting written procedure cards in work areas, or implementing a buddy system to verify understanding.

Sometimes the biggest barrier is attitude. Creating a positive safety culture requires leadership that visibly models proper PPE use, peer safety champions who reinforce good practices, recognition programs for consistent compliance, and non-punitive reporting systems for PPE issues.

Physical discomfort from ergonomic issues like restricted movement or added weight can also reduce compliance. The solution? Involve workers in PPE selection, provide multiple options when standards allow, consider modifying tasks to reduce PPE burden, and schedule more frequent breaks when heavy PPE is required.

As occupational health researcher Dr. Elaine Park notes: "The most effective PPE programs recognize and address these barriers proactively. When workers' concerns are acknowledged and accommodated, compliance improves dramatically."

At American Mortuary Coolers, we understand the unique challenges funeral professionals face with protective equipment. We're committed to helping you find solutions that keep your team safe without sacrificing comfort or efficiency. After all, the best personal protective gear is the kind your team will actually wear.

Personal Protective Gear in Healthcare vs Other Industries

When it comes to personal protective gear, not all industries face the same hazards. The specific risks workers encounter shape the type of protection they need—and few settings have more unique requirements than healthcare and mortuary services.

In healthcare environments, personal protective gear primarily guards against invisible threats. Doctors, nurses, and technicians need protection from bloodborne pathogens like HIV and Hepatitis, airborne risks such as tuberculosis and COVID-19, and contact pathogens like MRSA. They also face chemical hazards from cleaning agents, chemotherapy drugs, and sterilization materials.

Mortuary professionals share many of these concerns while facing additional challenges. "Working with the deceased requires protection not just from pathogens, but also from the chemicals used in preservation," explains Diana Martinez, funeral director and safety trainer. Personal protective gear in mortuary settings must address formaldehyde and glutaraldehyde exposure, potential sharps injuries during postmortem procedures, and the natural decomposition process that can release harmful gases and fluids.

Construction workers, by contrast, need personal protective gear focused on very different risks. Hard hats protect against falling objects, steel-toed boots guard against crushing injuries, and harnesses prevent deadly falls. Their respiratory protection targets construction dust and fumes rather than biological hazards.

The forestry industry has its own specialized equipment needs. Workers wear chainsaw-resistant chaps with cut-resistant fibers that can jam a saw before it cuts through to the skin. Mesh face shields protect against flying debris, and in some regions, snake gaiters prevent potentially deadly bites.

For road construction crews working alongside traffic, high-visibility clothing becomes the most critical personal protective gear. These bright garments, which must meet specific ANSI/ISEA standards, ensure workers can be seen by drivers from a safe distance, especially in low-light conditions.

Even respiratory protection varies significantly across industries. An N95 respirator—which filters at least 95% of airborne particles but isn't resistant to oil—works well in healthcare settings. However, workers exposed to oil-based particulates need P100 respirators, which filter 99.97% of particles and resist oil degradation.

"Understanding these distinctions isn't just about compliance—it's about providing meaningful protection," notes industrial hygienist Robert Johnson. "The right personal protective gear for a hospital isn't necessarily right for a sawmill or a preparation room."

Lessons from COVID-19 and Ebola

Recent public health emergencies have transformed how we think about personal protective gear—revealing both vulnerabilities and inspiring innovation.

The COVID-19 pandemic created a perfect storm for PPE supply chains. When the World Health Organization estimated frontline healthcare workers needed 89 million masks, 76 million gloves, and 1.6 million goggles monthly, global systems simply couldn't keep pace. This unprecedented demand taught us several valuable lessons.

Many organizations now maintain 3-6 month supplies of critical personal protective gear rather than relying on just-in-time ordering. "We'll never again assume we can get what we need when we need it," says James Wilson, operations director at a multi-location funeral home. "Maintaining adequate reserves has become standard practice."

Supply chain diversification has also become essential. Organizations that depended on single-source suppliers—especially those concentrated in one geographic region—faced the greatest challenges during border closures and export restrictions.

Perhaps most remarkably, the pandemic forced innovation in extending the life of personal protective gear. Emergency protocols emerged for decontaminating N95 respirators using hydrogen peroxide vapor, UV-C light, or moist heat. Healthcare workers learned to safely extend respirator use across multiple patient encounters, often using face shields as an outer barrier to reduce contamination.

Creativity flourished as new designs emerged, including 3D-printed face shields, reusable elastomeric respirators with replaceable filters, and improvised isolation gowns made from water-resistant materials.

The earlier Ebola outbreak (2014-2016) provided different but equally important lessons about personal protective gear. The deadly nature of the virus highlighted the importance of full-body protection with absolutely no exposed skin. Supervised doffing—having a trained observer watch as workers removed contaminated gear—proved critical in preventing self-contamination.

Workers in hot climates wearing impermeable protective clothing faced dangerous heat stress, leading to the development of cooling strategies and work rotation schedules. The complex donning and doffing procedures required intensive, repeated training—far beyond watching a single demonstration video.

For mortuary operations, these experiences highlighted several critical needs. Maintaining inventories of essential personal protective gear became non-negotiable. Staff cross-training ensured more people could properly use various types of protection. Documented contingency plans provided clarity during supply disruptions, and alternative supplier relationships offered backup options when primary vendors couldn't deliver.

"At American Mortuary Coolers, we've seen how these lessons have changed the funeral industry," notes our safety specialist. "We now help funeral homes develop comprehensive PPE contingency plans that include minimum stock levels, rotation procedures to prevent expiration, and alternative sourcing strategies—because being prepared isn't just good business, it's essential for protecting the dedicated professionals who care for the deceased."

Frequently Asked Questions about Personal Protective Gear

What responsibilities do employers and employees share?

When it comes to personal protective gear, safety truly becomes a team effort. Both employers and employees play crucial roles in making sure everyone goes home safely at the end of the day.

Employers shoulder the primary responsibility for creating a safe workplace. They must conduct thorough hazard assessments to identify what dangers exist, then select appropriate protection that actually fits each worker properly. This equipment can't come out of employees' pockets either—with few exceptions, employers must provide all necessary PPE free of charge.

"I always tell the funeral homes we work with that training isn't optional—it's essential," says Mark Williamson, safety coordinator at American Mortuary Coolers. "Workers need to understand not just how to wear their gear, but also its limitations and proper care."

Employers must also replace worn or damaged equipment, maintain comprehensive documentation of their PPE program, and ensure consistent enforcement of safety policies. As OSHA wisely points out, "It is definitely a good idea to select PPE that will provide a level of protection greater than the minimum required to protect employees from hazards."

On the employee side, responsibilities focus on proper implementation. Workers need to use their personal protective gear exactly as they've been trained, attend all required training sessions, and take reasonable care of their equipment. This includes proper cleaning, storage when not in use, and promptly reporting any damage or wear that might compromise protection.

"The partnership between employers and employees is essential," explains safety consultant Jennifer Adams. "Employers provide the equipment and knowledge, while employees apply that knowledge daily through proper PPE use."

How do I know if my PPE meets current standards?

Determining whether your personal protective gear meets current standards doesn't require a chemistry degree, but it does take some attention to detail.

First, examine the equipment itself for telltale markings. Compliant eye protection should display "Z87" or "Z87+" to indicate it meets ANSI Z87.1 standards. Hard hats will show both type and class markings according to ANSI Z89.1. For respirators, look for NIOSH TC-approval numbers (formatted as TC-84A-XXXX), while European-compliant equipment bears the CE marking.

Don't hesitate to request documentation from your suppliers. Legitimate manufacturers provide certificates of compliance that reference specific standards and test results. Many reputable suppliers can even help you understand what these certifications mean in practical terms.

"Standards are living documents that change as technology and knowledge advance," notes regulatory compliance expert Thomas Williams. "Regular verification ensures your PPE meets current requirements, not just those in place when it was purchased."

For respirators specifically, the NIOSH Certified Equipment List provides a searchable database where you can verify approval numbers. This became especially important during the pandemic when counterfeit respirators flooded the market.

Standards evolve over time. The current ANSI Z89.1-2014 for head protection, for instance, replaced the 2009 version with updated testing procedures. Staying current means regularly checking whether your equipment meets the latest requirements, not just those from when it was purchased.

Can single-use PPE be safely reused or decontaminated?

The question of reusing single-use personal protective gear became particularly relevant during recent supply shortages. While generally discouraged, certain emergency situations may necessitate careful reuse protocols.

For N95 respirators, the CDC developed crisis capacity strategies that include limited reuse—using the same respirator for multiple patient encounters but removing it between exposures. Research has identified several viable decontamination methods, including hydrogen peroxide vapor (effective for up to 20 cycles), UV-C light (up to 10 cycles), and moist heat (up to 5 cycles). However, common disinfectants like alcohol and bleach actually damage the filtering material, making respirators less effective.

"I remember when funeral homes couldn't get enough masks during COVID," shares Emma Thompson from American Mortuary Coolers. "Those who had decontamination protocols in place managed much better than those scrambling at the last minute."

Disposable gloves present a different challenge. Their reuse is strongly discouraged because removal and reapplication significantly increases both tear risk and contaminant transfer. In high-risk settings like preparation rooms, double-gloving might be appropriate, but reusing single gloves rarely is.

For disposable gowns, the evidence supporting decontamination is limited. Reprocessing may compromise the fluid resistance that makes these gowns effective in the first place. In some situations, extended use (wearing the same gown for multiple encounters with the same pathogen) may be preferable to taking it off and putting it back on.

"Any reuse of single-use PPE should be considered a last resort during critical shortages," cautions infection preventionist Dr. Rebecca Chen. "When implemented, strict protocols must govern the process to minimize risks."

At American Mortuary Coolers, we recommend that mortuary facilities maintain sufficient PPE supplies to avoid reuse scenarios whenever possible. The unique combination of chemical and biological hazards present in preparation rooms makes fresh, properly rated protection particularly important for funeral professionals.

Conclusion

Navigating the complex world of personal protective gear can feel overwhelming, but it's a journey worth taking. As we've seen throughout this guide, PPE serves as that crucial final line of defense between mortuary professionals and the daily hazards you face – from bloodborne pathogens that could cause serious illness to chemical exposures that might affect your long-term health.

When I talk with funeral directors about safety, I'm often reminded that personal protective gear isn't just about checking regulatory boxes. It's about making sure you return home safely to your loved ones each day, with your health intact after providing compassionate care to families during their most difficult moments.

A truly effective PPE program brings together several key elements working in harmony. It starts with really understanding the specific risks in your preparation room through thorough hazard assessments. From there, you'll want to carefully select equipment that not only meets applicable standards but actually fits and works for your unique team members. Even the highest-quality gear won't protect someone if it doesn't fit properly!

Training shouldn't be a one-and-done affair either. Your team needs comprehensive instruction on proper use, maintenance limitations, and when to replace worn equipment. And perhaps most importantly, you'll want to nurture a workplace culture where safety isn't just tolerated but genuinely valued.

Here at American Mortuary Coolers, we see ourselves as more than just equipment providers. Having worked with funeral professionals across the country, we understand the unique challenges you face. Our commitment extends beyond delivering high-quality mortuary coolers to ensuring you have the knowledge and resources to operate safely day in and day out.

Of course, we should acknowledge that personal protective gear represents just one piece of a comprehensive safety approach. Whenever possible, you should first look to engineering controls like properly designed preparation rooms with excellent ventilation. Administrative controls like smart chemical handling procedures and substituting less hazardous materials when available should always come before relying solely on PPE.

Recent public health emergencies have taught us all valuable lessons about preparedness. The importance of resilient supply chains and adaptability in PPE programs can't be overstated. By incorporating these lessons into your facility's safety planning, you can ensure your team remains protected even during challenging circumstances.

I encourage all mortuary professionals to regularly review and update your PPE programs. Keep those communication channels open with your staff about safety concerns, and stay informed about evolving standards and best practices. Your wellbeing and that of your team isn't just important for regulatory compliance – it's fundamental to providing the dignified care families expect during their time of need.

For additional guidance on mortuary safety equipment and protocols, our team at American Mortuary Coolers is always available to help with needs assessment, product selection, and implementation strategies custom to your specific facility. After all, the safest preparation room is one designed with your unique needs in mind.