Everything You Need to Know About Comparing Roller Storage Racks

Maximizing Space and Efficiency with Roller Storage Racks

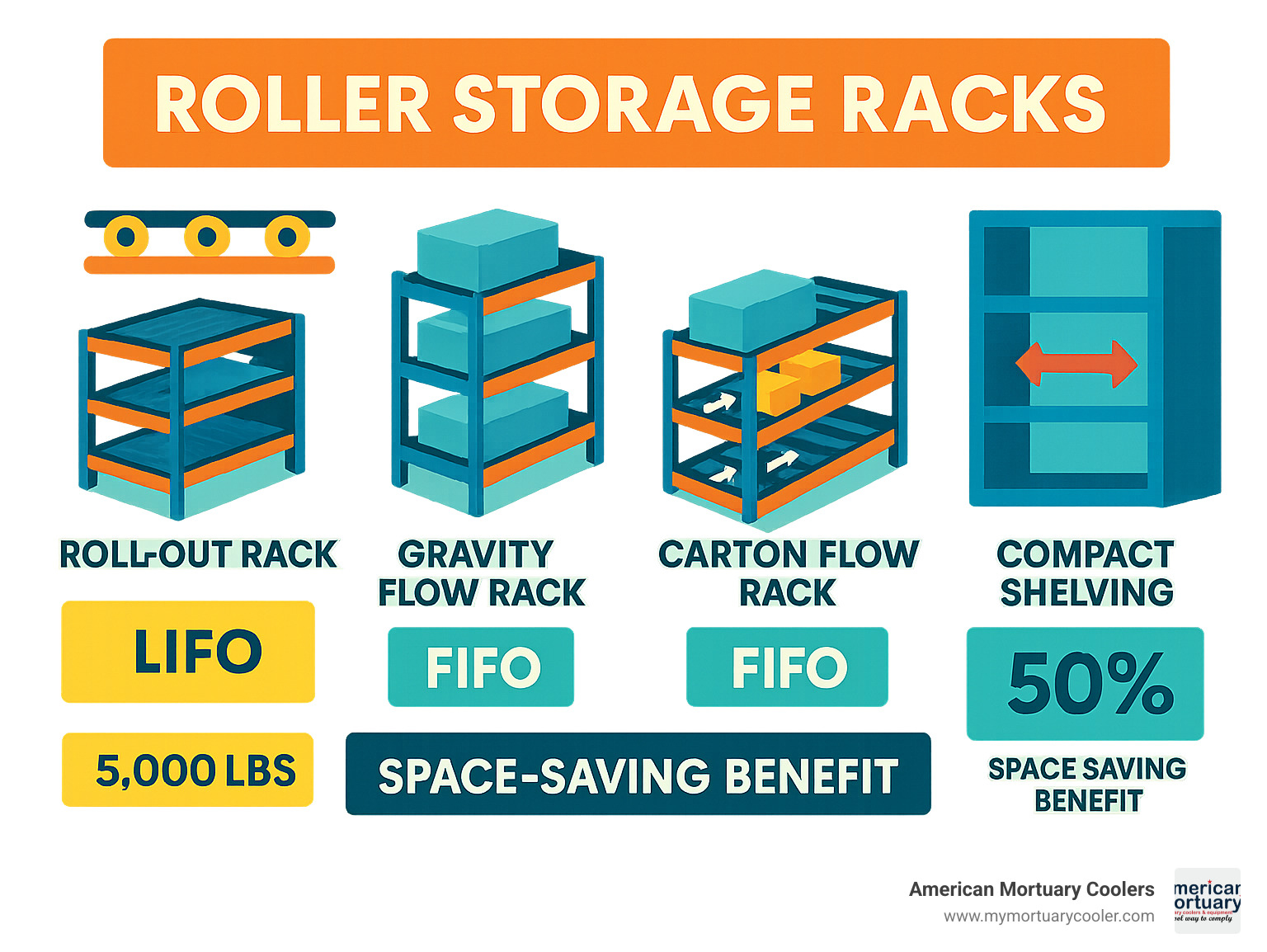

Roller storage racks are specialized shelving systems that use rollers or wheels to facilitate movement, access, and organization of stored items. They come in various types to suit different needs:

| Type of Roller Storage Rack | Key Benefit | Best Application |

|---|---|---|

| Roll-Out Racks | Easy access without unloading | Heavy parts & sheet metal (up to 5,000 lbs) |

| Gravity Flow Racks | Automatic FIFO rotation | Order picking & inventory management |

| Carton Flow Racks | Increases throughput by 150% | Warehouse picking operations |

| Compact Shelving | Reduces storage footprint by 50% | Archives & high-density storage |

| Vertical Lift Modules | 80% floor space savings | Small parts & components |

Roller storage racks transform traditional static shelving into dynamic systems that dramatically improve accessibility, organization, and space utilization. By eliminating fixed aisles and incorporating sliding mechanisms, these innovative storage solutions can reduce picker travel time by up to 80% while maximizing vertical space usage.

Whether you're managing a warehouse operation, organizing inventory in a retail setting, or looking to optimize storage in a specialized facility, roller storage systems offer significant advantages over conventional shelving.

The true power of roller storage racks lies in their ability to combine high-density storage with ergonomic access – no more reaching, straining, or removing front items to reach what's behind them.

I'm Mortuary Cooler, a national-level supplier specializing in mortuary equipment including customized roller storage racks designed for funeral homes and medical facilities. Having worked with hundreds of funeral directors to implement space-efficient roller storage racks, I understand the unique challenges of balancing accessibility, space constraints, and careful handling requirements in mortuary settings.

Roller storage racks terms to learn:

What Are Roller Storage Racks?

Roller storage racks are a game-changer in the storage world. Unlike traditional shelving where everything sits still, these systems put your items in motion with rollers, wheels, or tracks. Think of them as shelving that works with you, not against you!

These clever systems can handle everything from lightweight boxes (a few hundred pounds) all the way up to massive industrial materials weighing 5,000 pounds. The beauty of roller storage racks is how they transform your space - giving you better access while packing more into every square foot.

As one funeral director from our Dallas location told us: "The roller storage system we installed last year has been a game-changer. We can now store 40% more in the same floor space while actually improving access to each decedent. It's made our operations much more dignified and efficient."

How Roller Storage Racks Work

The magic behind roller storage racks comes down to some straightforward but brilliant engineering:

First, there are the rollers and bearings - the workhorses of the system. Good quality racks use precision bearings that ensure smooth movement even when fully loaded. Depending on what you're storing, you might have simple cylinder rollers, full-width rollers that span the entire shelf, or specialized wheel beds designed for specific containers.

Then there's the flow dynamics at work. In gravity systems, we carefully pitch the racks (usually between 1/4" to 3/4" per foot) to create just the right movement. Too steep and your items will race forward like they're in the Kentucky Derby; too shallow and they'll stubbornly refuse to budge.

Roller storage racks are designed around two main inventory principles:

- FIFO (First In, First Out): Perfect for inventory that needs rotation. Load items from the back, and gravity helpfully presents them at the front for picking.

- LIFO (Last In, First Out): Both loading and retrieval happen from the same side - ideal when space is tight and access is limited.

Finally, the movement mechanisms vary widely. Some systems have manual pull-out shelves on ball-bearing slides, while others use gravity, motors, or mechanical-assist handles to move entire shelving sections with minimal effort.

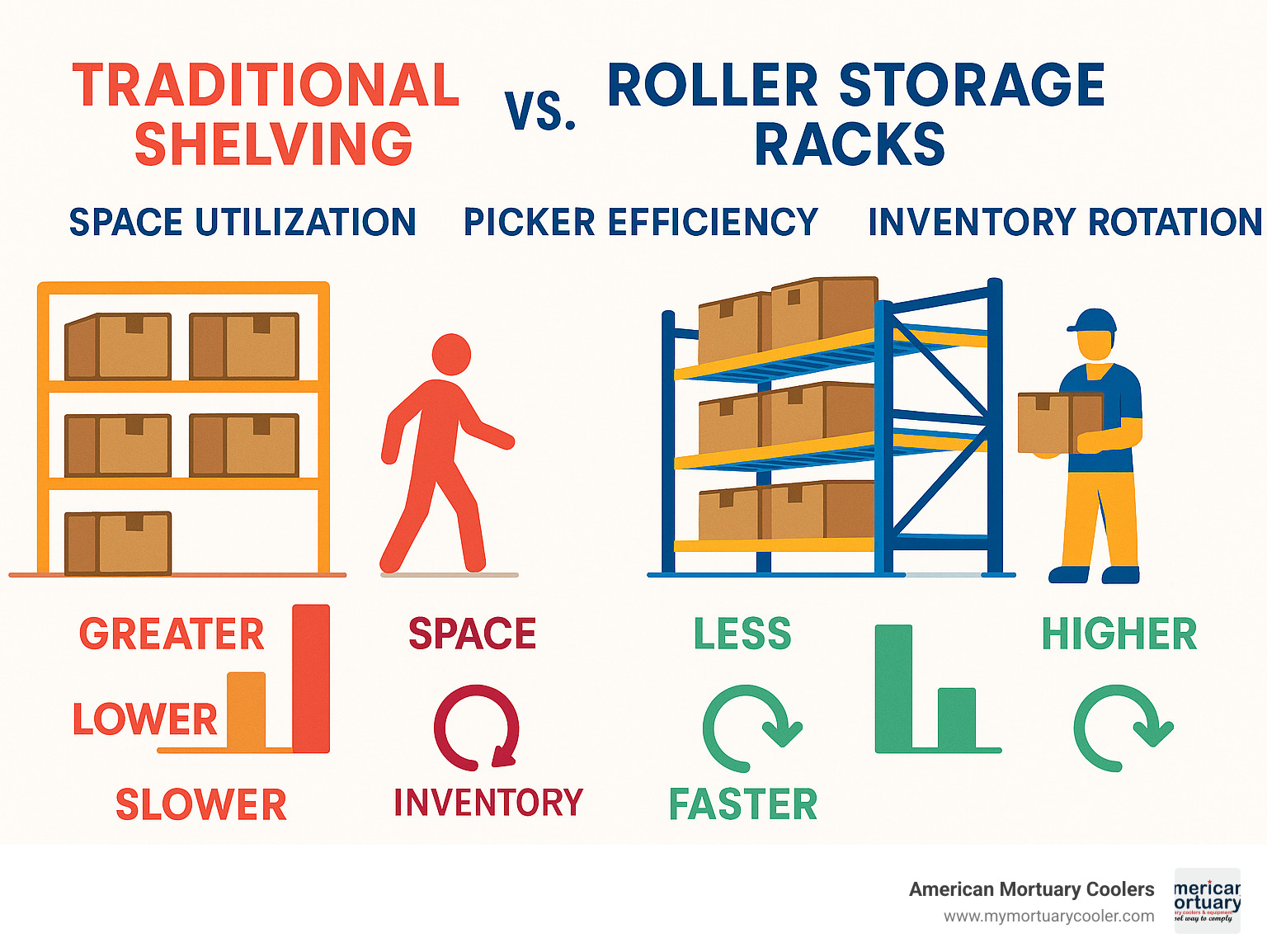

Static Shelving vs Roller Storage Racks

When comparing traditional shelving to roller storage racks, the differences quickly add up:

| Feature | Static Shelving | Roller Storage Racks |

|---|---|---|

| Access Method | Fixed position, reach-in | Dynamic movement, slide-out or flow-through |

| Storage Density | Requires fixed aisles between each row | Can eliminate fixed aisles, up to 50% more storage |

| Inventory Rotation | Manual (move items to rotate) | Automatic in gravity flow systems (FIFO) |

| Ergonomics | Requires reaching, bending, lifting | Brings items to the picker, reduces strain |

| Space Utilization | 30-40% of floor space for aisles | Up to 80% of floor space for actual storage |

| Initial Cost | Lower upfront investment | Higher initial cost but better ROI |

| Weight Capacity | Typically 500-800 lbs per shelf | Up to 1,500 lbs for roll-out shelves, 5,000 lbs for specialized systems |

One of our Atlanta funeral directors initially hesitated at the price difference: "We initially balked at the price difference between static shelving and the roller system. But after a year, the labor savings and reduced strain on our staff has more than made up for it. Plus, we've been able to take on more clients without expanding our facility."

The bottom line? Roller storage racks might cost more upfront, but the space savings, improved efficiency, and reduced physical strain quickly turn that investment into a smart business decision.

Main Types of Roller Storage Racks

When it comes to roller storage racks, there's a whole family of solutions designed to tackle different storage challenges. Let's explore the main types you'll encounter and how each one shines in its own way.

Roll-Out Racks

Imagine never having to unload the front items to reach what's in the back. That's the beauty of roll-out racks with their slide-out shelves that extend outward for complete access to everything stored inside.

These workhorses can handle up to 1,500 pounds per shelf even when fully extended – perfect for those heavy items that would be awkward to access in traditional shelving. For industries dealing with die storage, tool organization, or heavy parts, these racks are absolute game-changers.

In our mortuary work, roll-out racks have become essential for respectful body tray storage. One customer from Chicago told us, "Our 4-Tier MOBI Multi-Directional Loading Mortuary Roller Rack has been a workhorse in our facility. The ability to roll out each shelf makes transfers so much safer for our staff and more respectful for the deceased."

For those handling especially heavy equipment, many facilities pair these systems with tug devices to make movement even easier and safer.

Gravity & Carton Flow Racks

There's something almost magical about watching products gently glide from the loading side to the picking side all on their own. Gravity flow rack systems use slightly inclined roller tracks to move products naturally – no power needed!

These systems are perfect for high-volume picking operations. With automatic FIFO (First In, First Out) inventory rotation, you'll never worry about products expiring in the back of the shelf again. Our customers regularly report picking throughput increases of up to 150% compared to static shelving, with picker travel time cut by as much as 80%.

A warehouse manager in Pittsburgh shared with us, "We implemented gravity flow racks in our distribution center last year and saw picking rates improve by over 40% in the first month alone." That's the kind of immediate impact that makes a real difference to the bottom line.

For more specialized configurations, Roller Rack gravity flow racks offer options like knuckled fronts that present items at ergonomic angles, lane dividers to keep different products separated, and even speed controllers for heavier items.

Compact Shelving on Tracks

Why have five aisles when you could have just one? Compact shelving places traditional shelving units on floor-mounted tracks, allowing entire rows to slide sideways. This clever design eliminates the need for fixed aisles between each row, cutting your storage footprint by up to 50%.

A funeral home director in New York told us, "When we renovated our records room, the compact shelving system allowed us to double our storage capacity without expanding the footprint. Every square foot counts in Manhattan, so this was a substantial win for us."

These systems come with either mechanical-assist handles for manual operation or powered movement options for larger installations. They're ideal for archival storage, medical records, and any situation where space is at a premium but access is still important.

Specialty & Home Solutions

Roller storage racks aren't just for warehouses and industrial settings – they've found their way into our homes and specialty spaces too.

Garage enthusiasts use bin racks with roller tracks to organize tools and supplies with easy pull-out access. Fitness studios have acceptd solutions like the Synergee Yoga Mat Storage Roller Rack for keeping exercise equipment tidy and accessible.

One of my favorite stories comes from a model train enthusiast who got creative with a ten-drawer rolling organizer: "I lined each drawer with small-bubble wrap, bubbles up, and can now store and transport 120 model train cars around my layout. It's been a game-changer for my hobby."

From mortuary coolers to craft rooms, roller storage racks prove that good organization isn't just about storing more – it's about smarter access to what you already have.

Benefits, Applications, and ROI of Roller Storage Racks

The right roller storage racks can truly transform how you use your space, move inventory, and protect your team. These systems bring practical, day-to-day improvements to workplaces and homes—and they pay for themselves faster than you might expect.

First, let's talk about the changes you'll see right away. With roller storage racks, picker travel time can drop by as much as 80%. That’s a lot less walking (and a lot fewer sore feet at the end of the day). By reducing the need for fixed aisles, you can reclaim 40–50% of your floor space for actual storage, rather than wasted empty space.

Order picking is much faster—some companies see a 150% boost in throughput, just by switching to gravity or carton flow racks. And since these racks bring items out to meet you, not the other way around, reaching, bending, and heavy lifting are reduced. This means fewer workplace injuries, better ergonomics, and a happier team. Inventory stays organized and visible, with automatic FIFO rotation so nothing gets stuck at the back or forgotten until it’s too late.

All of these benefits add up to a clear return on investment. Yes, roller storage racks cost more up front than standard shelving, but most facilities make their money back in 12 to 24 months thanks to saved labor, smarter use of space, and fewer on-the-job injuries.

Industrial & Warehouse Advantages

In industrial and warehouse settings, roller storage racks solve challenges that old-fashioned shelving just can’t touch. For manufacturing, gravity flow racks are perfect for lean production—they act as simple kanban systems for just-in-time parts delivery. Roll-out racks make it easy and safe to store heavy items like sheet metal, with some shelves supporting up to 5,000 pounds.

These racks shine in tool and die storage as well. Instead of crawling and digging, staff can simply slide out a shelf and see everything at a glance—no forklifts required. In order fulfillment, carton flow racks speed up picking, while pallet flow systems keep inventory rotating efficiently and safely. Add in multi-level pick modules, and you can combine roller racks with conveyors for massive productivity boosts.

One logistics manager in Los Angeles told us, “With a three-level pick module, we tripled our picking capacity and cut labor costs by a quarter. Our new system paid for itself in just over a year.” That’s the power of smart storage.

Commercial & Retail Uses

Roller storage racks aren’t just for warehouses. Commercial businesses and retail stores rely on them too. In e-commerce, carton flow racks make split-case picking a breeze, cutting down on mistakes and wasted steps. They’re also perfect for organizing returned inventory and batch picking.

Grocery stores and pharmacies put gravity flow racks to work for FIFO rotation, so fresh items always go out first. Compact shelving makes the most of tight spaces in retail back rooms, pharmacies, and offices. No more stacking boxes to the ceiling and hoping the aspirin isn’t expired! In places like libraries and records rooms, mobile shelving systems can double your storage without expanding your footprint—a huge win in cities where every square foot is precious.

A pharmacy manager in the Southeast told us, “With our new compact shelving, we store 40% more inventory in the same space, and FIFO racks have helped reduce waste from expired meds by 60%.”

Residential & Hobby Applications

Let’s not forget the home and hobby crowd. Roll-out racks in the garage mean no more digging through heaps of tools or car supplies. Pantry storage becomes simple and accessible, bringing every can and box to the front. In craft rooms, slide-out drawers keep everything organized and easy to reach—no more forgotten supplies hiding in the back.

Closet systems with roll-out shelves make picking clothes and shoes quick and painless, and model train enthusiasts use specialty carts to keep their collections neat and mobile. One homeowner told us, “Installing roll-out pantry shelves has been a game-changer. Nothing gets lost in the back anymore, and my wife doesn’t have to crawl around to find what she needs.”

No matter the setting—from a busy warehouse to a cozy craft room—roller storage racks help you work smarter, not harder. They improve safety, boost productivity, and make the most of every inch. That’s peace of mind and value you can see every single day.

For more custom solutions, American Mortuary Coolers is here to help with custom designs and direct delivery across the contiguous 48 states.

Selecting & Customizing the Right Roller Storage Rack System

Finding your perfect roller storage rack isn't just about picking something off a shelf—it's about finding a solution that fits your unique needs like a glove. Think of it as choosing a custom suit rather than something off the rack.

When our funeral director clients come to us at American Mortuary Coolers, we start by asking some fundamental questions that help narrow down the options:

How heavy are the items you'll be storing? A mortuary body tray has very different weight requirements than office supplies, and your rack needs to handle the load safely. For some industrial applications, you might need racks supporting up to 5,000 pounds, while lighter applications might only need a few hundred pounds of capacity.

The dimensions of your items matter tremendously too. There's nothing more frustrating than installing a beautiful new rack system only to find your items are an inch too tall or wide to fit properly. We take careful measurements of not just the items themselves, but also the clearances needed for proper handling.

Flow dynamics might sound technical, but it's simply about how your items move through your space. Do you need FIFO (First In, First Out) for proper inventory rotation, or is LIFO (Last In, First Out) more suitable for your operation? A funeral home managing decedents has very different flow needs than a warehouse managing dated inventory.

"We were constantly struggling with inventory rotation before installing gravity flow racks," shared one of our Memphis customers. "Now the system naturally ensures we're using oldest stock first, which has reduced our waste by nearly 30%."

How often you access items makes a big difference too. Frequently accessed items benefit from different solutions than rarely accessed archives. And don't forget to consider your environment—a refrigerated mortuary cooler has different requirements than a dry storage area.

Assessing Storage Density Goals

When it comes to maximizing your storage space, thinking three-dimensionally is key. Most facilities only use about 40% of their available cubic space—leaving money on the table (or rather, in the air above your shelves).

Vertical cube utilization is about making the most of your ceiling height. Many of our funeral home clients are surprised to find they can double their storage capacity by using taller systems or adding mezzanine levels. One simple tip: adjust your shelf spacing to fit your actual items, not some arbitrary standard height. You'd be amazed how much space you can reclaim.

Smart aisle width planning can dramatically increase your storage density. Traditional storage requires fixed aisles between every row, but compact shelving on tracks can eliminate most of these aisles, creating one movable aisle instead. As one of our Nashville clients put it, "We increased our storage capacity by 40% without adding a single square foot to our building."

For busy operations, analyzing your SKU velocity (how frequently items move in and out) helps balance accessibility with density. Fast-moving items deserve prime positions with easy access, while slower-moving inventory can be placed in higher-density areas.

"We analyzed our case patterns over a year and realized we could optimize our workflow by putting our most frequently accessed decedents in roll-out racks near the preparation room," explained a funeral director from our South Carolina service area. "It's saved our staff countless steps and made transfers much more dignified."

Custom Options & Add-Ons for Roller Storage Racks

The beauty of modern roller storage racks is how customizable they are to your specific needs. It's like building a system with LEGO bricks rather than being stuck with a one-size-fits-all solution.

For facilities handling heavier items, impact plates protect your investment by absorbing the shock when loading heavy items onto rollers. Brake rollers are another smart addition that control the descent speed of heavier products in gravity systems—preventing that heart-stopping moment when a valuable item comes crashing down too quickly.

Mobile units benefit from lockable wheels that secure them in place when needed, while color-coded components can significantly improve picking accuracy in busy environments. One of our pharmacy clients reduced picking errors by 22% simply by color-coding different medication categories.

"The custom dividers American Mortuary Coolers installed in our system have been a game-changer," shared a funeral director from Louisville. "Each decedent has their own clearly defined space, which has eliminated any confusion and added an extra level of dignity to our care."

The aesthetic side matters too, especially in customer-facing environments. Powder coat finishes come in virtually any color to match your facility's decor, while end panels give visible units a polished, professional appearance. One of our more design-conscious clients in Miami even matched their roller racks to their brand colors, creating a cohesive look throughout their facility.

The best system is one designed specifically for your needs. At American Mortuary Coolers, we pride ourselves on creating custom solutions that fit not just your space constraints but also your workflow, budget, and future growth plans.

"When we first called about roller racks, I was worried we'd get pushed toward some standard solution," a funeral director from Dallas told us. "Instead, they asked questions I hadn't even thought to consider, and designed a system that works perfectly for our unique situation."

Installation, Safety & Maintenance

Installing roller storage racks properly isn't just about functionality—it's about creating a safe, efficient workspace that stands the test of time. At American Mortuary Coolers, we've seen how the right installation approach makes all the difference in how these systems perform day after day.

Most facilities choose between several installation methods based on their specific needs. Bolt-in systems provide maximum stability by anchoring directly to the floor—ideal for high-traffic areas or facilities in seismic zones. For more flexibility, drop-in components let you integrate roller elements into existing shelving. Many smaller operations prefer free-standing units that require no floor anchoring, while space-conscious facilities often opt for track-mounted systems that move laterally on floor rails.

"When we installed our new mortuary storage system, I was impressed by how carefully the team considered our specific workflow," shares a funeral director from Memphis. "They didn't just set up racks—they created a system that makes our daily operations smoother and safer."

OSHA compliance isn't optional with these systems, especially when handling heavy loads like mortuary trays. Proper anchoring prevents dangerous tipping incidents, while adequate aisle width ensures emergency egress routes remain clear. We always include appropriate load capacity signage so staff know exactly what each shelf can safely hold.

Our safety coordinator puts it best: "Safety is paramount in any storage system. We ensure all our installations meet or exceed OSHA guidelines, particularly for heavy-duty applications like mortuary storage where worker safety and dignified handling go hand in hand."

Safe Operation Features in Roller Storage Racks

Today's roller storage racks come equipped with thoughtful safety features that protect both your team and stored items.

Speed controllers are particularly important in gravity systems, preventing items from racing down inclines too quickly. For heavy-duty applications, roller brakes provide essential control, while anti-tip devices secure extended shelves to prevent dangerous tipping accidents. Clear load capacity indicators eliminate guesswork about weight limitations, and progressive extension limiters prevent multiple drawers from opening simultaneously—a common cause of tipping incidents.

The ergonomic benefits of these systems can't be overstated. By positioning items at optimal picking height, roller storage racks dramatically reduce back strain. Presentation angles minimize reaching, while quality bearings reduce the force needed to move even heavy loads.

A funeral director from our Dallas service area shared this insight: "The roller brake system on our mortuary rack has been a game-changer for staff safety. The controlled movement means no more struggling with heavy body trays or risking injury during transfers. I wish we'd made the switch years ago."

Easy Maintenance & Reconfiguration

One of the most appealing aspects of roller storage racks is their longevity when properly maintained. A simple routine can keep your system running smoothly for years.

Regular maintenance doesn't need to be complicated. Inspect rollers periodically for signs of wear or damage. Clean tracks to remove dust and debris that could impede smooth movement. Check and tighten fasteners that may loosen over time with regular use. Lubricate moving parts according to manufacturer recommendations, and always verify brake and speed control functionality before trusting these systems with heavy loads.

What truly sets these systems apart is their adaptability as your needs change. You can adjust shelf heights seasonally or as inventory changes, modify lane widths to accommodate different product sizes, and add or remove sections as your business grows. Some facilities even relocate entire systems during renovations without needing complete replacement.

To help our clients maintain their investment, we offer a comprehensive Warehouse Inspection Checklist covering all critical maintenance points. This free resource has helped countless facilities extend the life of their storage systems.

"The modularity of our roller rack system has been invaluable," a Northeast Region funeral director told us recently. "As our business has grown, we've been able to expand our storage capacity incrementally without disrupting operations or requiring a complete system replacement. It's grown right alongside our business."

Real-World Case Studies & Cost Comparison

Let me share some real success stories that show just how transformative roller storage racks can be in actual businesses. These aren't just theoretical benefits – they're real results from companies just like yours.

Automotive Manufacturing: A parts supplier in our Midwest Region was struggling with their sheet metal storage. After implementing roll-out racks that could handle a whopping 5,000-pound loads, they saw remarkable changes. Their floor space needs dropped by 35%, and workers spent 60% less time handling materials. The best part? The entire system paid for itself in just 16 months through labor savings and needing fewer forklifts.

Pharmaceutical Distribution: One of our medical supplier clients in the Rocky Mountain Region had inventory rotation challenges with dated products. Their solution was a three-level carton flow system with perfect FIFO rotation. The results were impressive – picking rates jumped by 120% while errors dropped by 30%. Despite spending more upfront compared to basic shelving, they reached their ROI in only 14 months thanks to much more efficient operations.

E-Commerce Fulfillment: An online retailer in our Pacific Region took a smart hybrid approach. They installed compact shelving for slow-moving inventory and gravity flow racks for their fast-moving products. This thoughtful combination optimized both their space and picking efficiency. Orders processed per hour increased by 40%, and they achieved ROI in just 18 months.

When comparing costs, it's important to look beyond just the initial price tag. Yes, roller storage racks typically cost 30-50% more upfront than static shelving, but the total ownership picture tells a different story:

| System Type | Initial Cost (Relative) | Space Utilization | Labor Efficiency | Typical ROI Timeframe |

|---|---|---|---|---|

| Static Shelving | 100% (baseline) | Baseline | Baseline | N/A |

| Roll-Out Racks | 140-160% | 30-40% improvement | 20-30% improvement | 18-24 months |

| Gravity Flow | 150-180% | 40-50% improvement | 40-150% improvement | 12-18 months |

| Compact Shelving | 180-220% | 40-50% improvement | 10-20% improvement | 24-36 months |

| Vertical Lift Modules | 300-400% | 70-80% improvement | 200-600% improvement | 24-48 months |

Roller Storage Racks in Funeral & Mortuary Operations

At American Mortuary Coolers, we've developed some truly special roller storage rack solutions that address the unique needs of funeral homes and mortuaries.

Multi-Directional Loading Racks: Our mortuary roller racks aren't just off-the-shelf products – they're purpose-built with multi-directional loading capabilities. This means body trays can be accessed from multiple sides, giving you maximum flexibility even in tight spaces. As one funeral director told me, "The ability to load and unload from different sides has been a game-changer in our limited preparation room."

Body Tray Handling Systems: We understand the importance of dignified handling in your profession. That's why our roller systems are specifically engineered to support stainless steel body trays while providing smooth, controlled movement. The gentle glide of our rollers ensures respectful handling of decedents while protecting your staff from strain and injury.

One of our funeral directors recently shared: "The 5-tier stainless steel roller rack we purchased has transformed our preparation room workflow. The smooth operation and space efficiency have allowed us to handle a 30% increase in case volume without expanding our facility."

I've seen how these systems can transform a cramped, inefficient space into a model of organization and dignity. The right storage solution doesn't just store – it improves your ability to provide compassionate care.

For more specialized information on mortuary storage solutions, I recommend our guide on Top Mortuary Body Racks for Your Needs. It dives deeper into the specific options that might be right for your facility.

Frequently Asked Questions about Roller Storage Racks

What load capacity can a typical roller storage rack handle?

When folks ask me about load capacities for roller storage racks, I always tell them it's like buying a truck – you need to match the equipment to the job at hand.

For light-duty needs around 200-500 pounds per shelf, a standard roll-out system works perfectly. Think office supplies or lightweight inventory. Medium-duty shelves handle 500-1,000 pounds and are great for most warehouse applications.

When you're dealing with serious weight, our heavy-duty roll-out shelves support 1,000-1,500 pounds each – perfect for those bulky mortuary trays. And for our customers in manufacturing, our sheet metal roll-out racks are absolute beasts, supporting up to 5,000 pounds!

Carton flow systems are designed differently, typically handling 50-100 pounds per lane, while our pallet flow systems can manage 2,000-4,000 pounds per position.

One funeral director in Nashville called me after accidentally overloading a shelf and said, "I learned the hard way that those capacity ratings aren't just suggestions!" Always distribute weight evenly and never exceed manufacturer specifications – your equipment and your back will thank you.

Do roller storage racks support both FIFO and LIFO?

Absolutely! Roller storage racks are versatile enough to handle both inventory management approaches, and we customize systems for each client's specific needs.

For FIFO (First In, First Out) operations, gravity flow racks are the gold standard. Items loaded from the back naturally flow forward for picking at the front. This setup is perfect for date-sensitive items like perishables or medical supplies. One of our pharmacy clients reduced their expired inventory waste by 65% after switching to a FIFO system.

LIFO (Last In, First Out) works differently, with push-back racks or roll-out shelving where items are both loaded and retrieved from the same side. This approach maximizes space efficiency in tight quarters – something many of our funeral home customers appreciate in their limited preparation rooms.

Many of our clients actually use both approaches. A funeral director in Memphis told me, "We use FIFO flow racks for our prep supplies to ensure nothing expires, but LIFO for body storage since we typically need access to our most recent cases first."

How difficult is it to relocate or expand a system later?

Good news – most roller storage racks are designed with change in mind! After all, your business isn't static, so why should your storage be?

For relocation, the process depends on your system type. Bolt-in systems require proper uninstallation and reinstallation, but the process is straightforward. Our track-mounted systems need some floor preparation at the new location, while free-standing units can often be moved with minimal fuss.

When it comes to expansion, most systems grow quite happily. You can typically add sections to existing installations, explore vertical expansion if your ceiling height allows, or reconfigure modular components as your needs evolve.

I remember working with a funeral home in Chattanooga that started with a modest 2-tier system. Over five years, they gradually expanded to a 5-tier configuration and added two additional sections – all without replacing their original investment.

"I was worried we'd outgrow our storage system and have to start from scratch," the director told me. "But the modular design meant we could add capacity piece by piece as our business grew. It was like playing with really expensive LEGO blocks!"

At American Mortuary Coolers, we design with your future in mind, creating systems that adapt to your changing needs across our entire 48-state service area.

Conclusion

Let's be honest - storage might not be the most exciting topic in the world, but the right roller storage rack system can absolutely transform your operation. I've seen it across countless funeral homes we've worked with.

When we install a custom roller system, the difference is immediate and dramatic. Suddenly, staff members aren't straining their backs to access items. The space that once held 10 body trays now accommodates 15. Inventory rotates properly, and the workflow just... flows.

At American Mortuary Coolers, we've built our reputation on understanding the unique challenges funeral directors face. Our engineered roller storage racks aren't just generic industrial shelving – they're thoughtfully designed for the dignified handling that mortuary work demands.

The math makes sense too. Yes, quality roller storage racks require a higher initial investment than basic static shelving. But when you calculate the space savings, reduced staff strain, improved inventory management, and overall operational efficiency, most of our customers see complete ROI within 12-24 months.

Whether you're managing a busy funeral home in downtown Chicago, a warehouse in Los Angeles, or a medical facility in New York, the fundamental benefits remain the same: more storage in less space, better ergonomics, and improved workflow.

I invite you to explore our equipment options to see what might work for your specific needs. We deliver nationwide across the contiguous 48 states, with service centers strategically located in Johnson City TN, Atlanta GA, Chicago IL, Columbia SC, Dallas TX, Los Angeles, New York NY, and Pittsburgh PA.

In today's competitive business environment, every square foot matters, every staff injury hurts your bottom line, and every efficiency gained gives you an edge. The right roller storage rack system doesn't just store your items – it becomes a silent but powerful contributor to your success.