The Ultimate Guide to Custom Walk-In Coolers

Custom walk in coolers are specialized refrigerated storage units designed to meet specific size, layout, and temperature requirements for businesses. If you're looking for information about custom walk-in coolers, here's what you need to know:

| Quick Facts About Custom Walk-In Coolers |

|---|

| Temperature Range: 33°F to 38°F (optimal for perishable storage) |

| Customization Options: Size, panel thickness, door type, shelving, finishes, security features |

| Common Applications: Restaurants, floral shops, breweries, mortuaries, laboratories, warehouses |

| Key Benefits: Space optimization, energy efficiency, precise temperature control |

| Installation: Can be pre-assembled or modular, indoor or outdoor options |

| Warranty: Typically 12-25 years for structural components, 5 years for refrigeration |

A custom walk in cooler provides significant advantages over standard, pre-fabricated units. Instead of forcing your business to adapt to a one-size-fits-all solution, custom units are built specifically for your space constraints, workflow needs, and product requirements. This custom approach not only maximizes your available square footage but also improves energy efficiency by eliminating wasted cooling volume.

Custom units offer flexibility in design, from panel thickness and insulation type to door placement and shelving configuration. Whether you need a small 6'×6' unit or a massive 16'×65' cold storage facility, custom solutions ensure you get exactly what your operation requires.

The modular construction of custom walk in coolers means they can be designed for virtually any application – indoor installation in tight spaces, outdoor placement to free up interior room, or even specialized environments like mortuaries and laboratories with precise temperature and humidity requirements.

I'm Mortuary Cooler, a national-level supplier of mortuary coolers and custom walk in coolers with extensive experience designing refrigeration solutions for funeral homes and other specialized applications. My expertise ensures that your custom cooling project will meet both technical specifications and practical needs.

Simple guide to custom walk in coolers:

What Sets Custom Walk-In Coolers Apart?

When you're looking at refrigeration options, custom walk in coolers stand out from standard models in ways that truly matter for your business. Instead of forcing your operation to adapt to pre-made sizes, our custom units are built around your needs using modular panel systems that fit your exact dimensions—not just the "close enough" sizes you'd get off the shelf.

Think of these modular panels as building blocks that create the perfect cold space for your specific industry. Whether you're a florist needing display doors to showcase beautiful arrangements, a brewery requiring specialized racking for kegs, or a funeral home needing precise temperature control, custom walk in coolers deliver exactly what your business demands.

Here at American Mortuary Coolers, we've seen how different businesses have unique refrigeration requirements. That's why we design units for both indoor spaces and outdoor installations, with proper weatherproofing for units exposed to the elements. Our high R-value insulation exceeds Department of Energy standards, keeping your cooling costs down while maintaining perfect temperatures.

One feature our customers particularly value is our seamless construction approach. Unlike some prefabricated units where panel joins can create weak points, our seamless fiberglass construction eliminates potential "hot spots" and moisture entry points. This means more consistent cooling and a significantly longer lifespan for your investment.

Need refrigeration quickly? We understand that sometimes waiting isn't an option. Our quick-ship custom walk in coolers can be delivered in as little as 14 days while still meeting your specific requirements. And every unit we build meets or exceeds NSF and UL compliance standards, so you can be confident in both safety and regulatory compliance.

Standard vs. Custom Units

Picture this: you measure your available space at 7'6"×9'4", but standard walk-in coolers only come in nominal sizes like 8'×10' or 8'×20'. What happens? Either you're reconfiguring your entire layout or watching valuable square footage go to waste.

Custom walk in coolers solve this common problem by fitting exactly where you need them. Have an unusual corner that would be perfect for cold storage? We can design a unit that fits precisely in that space. This isn't just about maximizing square footage—it's about improving your workflow by placing refrigeration exactly where it makes the most sense for your operation.

I remember a restaurant owner who wanted a prep cooler near their deli counter but found standard units were too large for the space. With our custom solution, we built a cooler that fit the exact dimensions available, preserving their efficient workflow while providing the necessary refrigeration.

The customization goes beyond just measurements. While standard units typically come with fixed door placements and limited shelving options, our custom walk in coolers let you specify exactly where doors should go, what type and size they should be, and how the interior should be configured to best serve your storage needs.

Performance Benefits of Custom Walk-In Coolers

The performance advantages of going custom are substantial and directly impact your bottom line. First, there's the insulation quality. Our custom units use high-performance polyurethane or expanded polystyrene (EPS) insulation with impressive R-values—up to R-29 for coolers and R-32 for freezers—exceeding federal energy standards.

This superior insulation translates to real energy savings. Better-insulated panels reduce heat transfer, so your refrigeration system doesn't have to work as hard to maintain the perfect temperature. Over time, these energy savings often offset the initial investment premium of choosing a custom unit.

Humidity control is another area where custom walk in coolers shine. For certain applications—like floral storage, wine cellars, or laboratory environments—controlling humidity is just as crucial as maintaining temperature. Our custom units can include specialized humidity control systems that maintain the perfect conditions for your specific products.

Perhaps most importantly, custom units help extend product longevity. By maintaining more consistent temperatures and humidity levels, they help preserve perishable goods longer, reducing waste and improving profitability. For specialized applications like mortuary coolers, this consistent, reliable performance isn't just preferred—it's absolutely essential.

Planning Your Custom Walk In Coolers Project

Let's face it - planning a custom walk in cooler isn't something most people do every day. But don't worry! We'll walk through this together, step by step, just like we've done for hundreds of other businesses across the country.

First, you'll need to consider your layout footprint - basically, the exact dimensions where your cooler will live. Unlike off-the-shelf units, your custom cooler can be designed to fit perfectly in your available space. Got an awkward L-shaped area or a narrow corridor? No problem! We can design around those challenges to maximize every square inch.

Think about where your cooler will be installed. Indoor installations bring considerations like ceiling height restrictions and doorway access (nothing worse than designing the perfect cooler only to find it won't fit through your building's entrance!). For outdoor installations, we'll incorporate proper weatherproofing, durable roofing, and additional security features to protect your investment from the elements.

One big decision: floor or floorless? If you're installing on a ground-level concrete slab, a floorless model often makes sense. But for above-grade installations or situations requiring extra insulation, we'll include a heavy-duty insulated floor that can support up to 1,200 pounds of distributed weight. That's enough for practically anything you might store!

Calculating your refrigeration load is crucial for selecting the right cooling system. This depends on:

- Your cooler's overall volume

- The typical temperature where it will be installed

- How often doors will be opened throughout the day

- What types of products you'll be storing

- Your target temperature range

Most of our custom walk in coolers use refrigeration systems between 1½-3 horsepower, requiring 15-30 amps and 208-230 volts, typically with 3-phase power. Don't worry if that sounds technical - our team will help determine exactly what your specific situation needs.

Want to dig deeper into the design process? Check out our guide on custom cooler design for more detailed information custom to your establishment.

Key Design Considerations for Custom Walk In Coolers

When designing your custom walk in cooler, several key elements will dramatically impact both performance and daily usability.

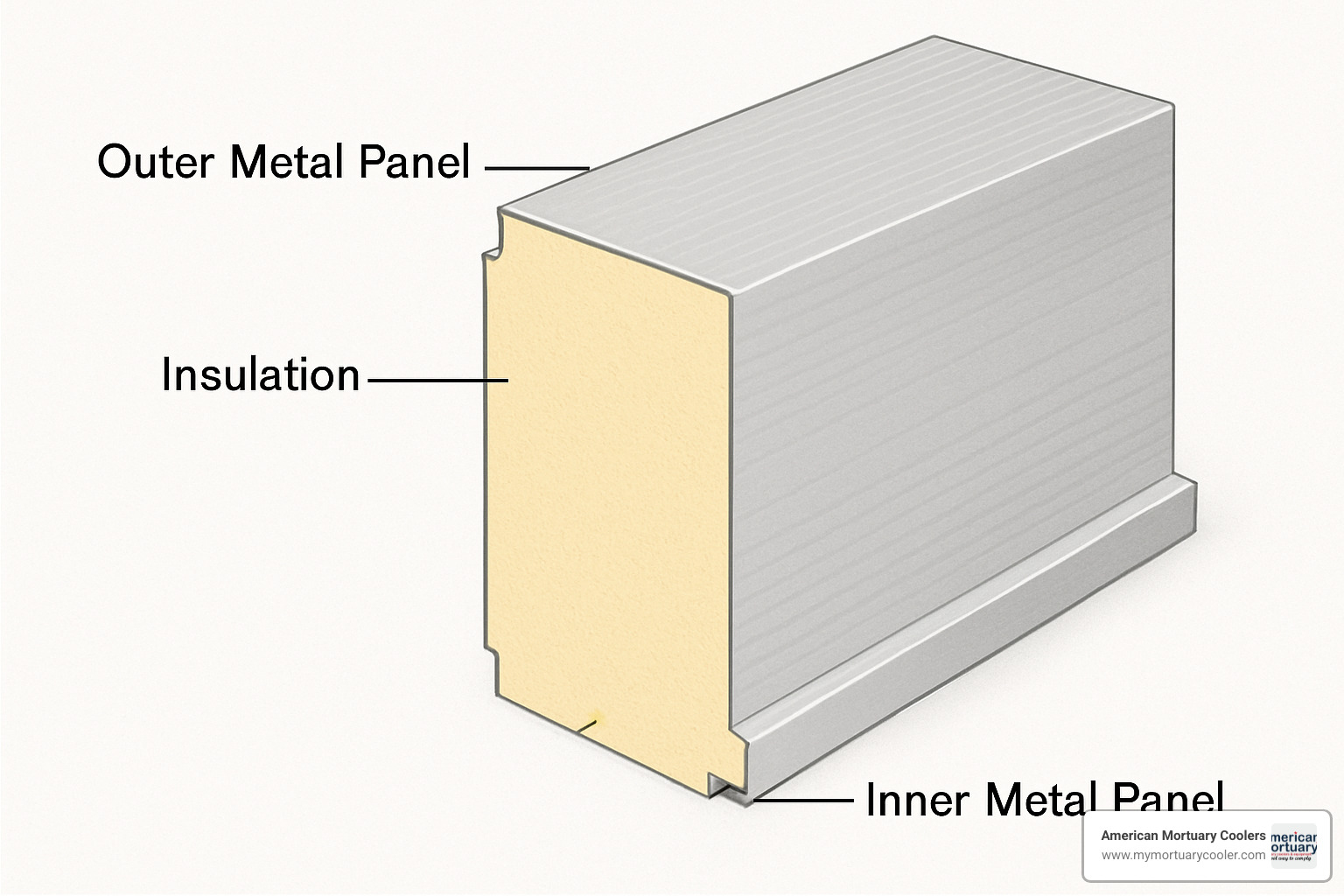

Panel thickness matters more than you might think. We typically offer 3½", 4", or 5" thick panels. Thicker panels provide higher R-values and better insulation, potentially saving you money on energy costs over time. We'll help you select the right thickness based on your temperature requirements and local climate conditions.

Doors are another critical decision point. A standard swing door works great for many applications, but have limited space? Sliding doors might be your best bet. Running a retail operation where customers need to see products? Glass display doors could boost your sales. High-traffic environment? Consider traffic doors that can withstand constant use. For frequent access areas, strip curtains (which we include free with every order!) help maintain temperatures while allowing easy passage.

Accessibility is important too. If your cooler includes a floor, you might need a ramp for rolling carts or equipment in and out. These can be installed externally or internally depending on your space constraints and workflow patterns.

The right shelving transforms a good cooler into a great one. We can design interior storage solutions specifically for your products - whether that's basic wire shelving for general storage, meat hanging rails for a butcher shop, or specialized racks for kegs in a brewery. The goal is maximizing storage while maintaining efficient access to everything inside.

Security features should match your needs. Simple padlock hasps work for some, while others might require deadbolts or even electronic access systems. We'll recommend options based on your location and the value of what you're storing.

Finally, don't forget about aesthetics! Your cooler's finish can be customized to complement your facility. Beyond standard white galvanized steel, we offer custom colors, stainless steel finishes, or even custom graphics to match your branding.

Materials & Insulation Choices

The materials in your custom walk in cooler aren't just about looks - they directly impact performance, durability, and your monthly energy bills.

At the heart of every great cooler is the insulation. We primarily use two types: polyurethane foam and expanded polystyrene (EPS). Polyurethane is foamed-in-place between the inner and outer panel skins, creating a seamless thermal barrier. It's CFC-free (good for the environment!) and provides excellent insulation without excessive thickness - perfect when space is tight.

EPS core panels offer an excellent balance of cost and performance. They're often Energy Star qualified and meet or exceed current energy codes. Many of our customers appreciate their stable long-term insulation values.

For exterior surfaces, you've got options. Galvanized steel with an embossed finish is our standard, economical choice. Need something that can stand up to harsh cleaning chemicals or moisture? Stainless steel offers maximum durability and sanitation benefits. Aluminum works well for lightweight applications, while fiberglass provides seamless construction and superior moisture resistance.

We're particularly fond of seamless fiberglass construction at American Mortuary Coolers. It resists corrosion beautifully and eliminates seams where moisture could sneak in. This means your cooler lasts longer and maintains energy efficiency year after year.

Don't underestimate the importance of vapor barriers! These prevent moisture from penetrating the insulation, which would reduce its effectiveness over time. Our panels incorporate continuous polyethylene vapor barriers to ensure long-term performance.

When we talk about R-value, we're referring to insulation's resistance to heat flow - higher numbers mean better insulation. For walk-in coolers, we typically achieve R-29, while freezers reach R-32, both exceeding federal EISA requirements. Translation? Your unit will keep temperatures stable while minimizing energy costs.

Custom Features & Accessories

This is where your custom walk in cooler truly becomes yours - with specialized features that match exactly how you'll use it.

Glass display doors are perfect for retail applications - they let customers see products without letting all that precious cold air escape. Our self-closing models feature magnetic gaskets that create a tight seal while still allowing easy access.

Want to monitor your cooler from anywhere? Our smart control systems let you check temperatures remotely, receive automated alerts, and maintain data logs. Imagine getting a text if temperatures drift out of range or if someone leaves a door open - potentially saving thousands in product loss!

Data loggers provide documented temperature records, which are especially important if you're subject to regulatory oversight. Whether you're in food service, pharmaceutical storage, or mortuary services, these systems help you demonstrate compliance.

Some products need precise humidity control, not just temperature regulation. Our humidity systems can be calibrated to maintain specific moisture levels for sensitive items like flowers, produce, or laboratory specimens.

We include energy-efficient LED lighting with every cooler at no extra charge. These fixtures provide excellent visibility while generating minimal heat and using less electricity than traditional lighting. They come pre-wired to exterior switches for easy operation.

For additional peace of mind, we can integrate alarm systems that alert you to temperature problems, power failures, or unauthorized access. It's like having a 24/7 guardian for your valuable inventory.

At American Mortuary Coolers, we believe in providing value at every turn. That's why we include those free PVC entrance strip curtains and free LED lighting with every order. It's just one more way we make sure your custom walk in cooler exceeds expectations from day one.

Installation, Compliance & Maintenance

Getting your custom walk in cooler installed right is just as important as choosing the perfect design. We've streamlined this process to make it as hassle-free as possible for you.

Before your cooler arrives, we'll help you prepare your site properly. This means ensuring you have a level surface (crucial for proper door operation), appropriate clearances for airflow, and all necessary utilities ready to go. A little preparation goes a long way toward a smooth installation.

Whenever possible, we factory pre-assemble your cooler components. This approach significantly cuts down on-site installation time and reduces the chance of errors. Many of our custom walk in coolers actually arrive fully assembled – just needing final placement and an electrical hookup from your licensed electrician.

One thing our customers truly appreciate is our white-glove delivery service. Available across all 48 contiguous states, this service ensures your cooler arrives in perfect condition and is properly positioned exactly where you need it. Need crane or forklift placement? We've got you covered, minimizing disruption to your day-to-day operations.

When it comes to regulations, we never cut corners. Your custom walk in cooler will meet NSF Standard #7 for food safety, incorporate UL-listed panels and doors, and comply with all local building codes. We provide all the documentation and certifications you'll need for your specific location – one less thing for you to worry about.

To keep your cooler running efficiently for years to come, regular maintenance is key. We recommend scheduling quarterly checks of:

- Door gaskets (these are the unsung heroes of energy efficiency)

- Condenser coils (clean coils mean lower energy bills)

- Refrigerant levels and system operation

- Hinges, handles, and other hardware

- Temperature control accuracy

For the latest information on refrigeration safety standards, you can review the latest guidelines.

Regulatory Certifications for Custom Walk In Coolers

Navigating regulatory compliance can feel overwhelming, but we've got you covered. Your custom walk in cooler needs to meet various standards, and we ensure it will.

Our panels exceed the Energy Independence and Security Act (EISA) requirements with impressive R-values – R-29 for coolers and R-32 for freezers. This isn't just about checking a regulatory box; it means your cooler will operate more efficiently, saving you money month after month.

Department of Energy (DOE) standards are non-negotiable for commercial refrigeration equipment. Rest assured, all our systems meet or exceed current requirements. We stay on top of changing regulations so you don't have to.

Living in an earthquake zone or coastal region? We understand the special engineering needs for these areas. Our team can provide the necessary seismic certification or hurricane engineering stamps required for your location. These aren't just paperwork – they're peace of mind that your investment is properly protected.

For food service applications, NSF certification ensures all materials and construction methods meet strict sanitation requirements. At American Mortuary Coolers, we maintain current certifications for all applicable standards and provide complete documentation to support your permit applications and inspections.

Maintenance & Durability Best Practices

We build our custom walk in coolers to last, but a little care goes a long way toward maximizing their lifespan.

Smart design features can prevent common damage before it happens. Kick plates are a perfect example – these diamond-tread aluminum or stainless steel guards protect the lower portions of doors and walls from impacts by carts, pallets, or other equipment. It's a small addition that can prevent costly repairs down the road.

For outdoor installations, consider adding bollards around the perimeter. These protective posts prevent vehicle impacts that could otherwise cause significant damage. Think of them as an insurance policy that actually prevents the accident rather than just paying for it afterward.

Even the best-built coolers benefit from regular attention. We recommend quarterly inspections to check for door alignment issues, gasket integrity, condensation buildup, unusual noises from the refrigeration system, proper lighting operation, and any signs of panel damage.

We stand behind our work with comprehensive warranty coverage: 20 years on panels, 5 years on entrance doors, and 5 years on compressors. For complete peace of mind, we also offer optional extended labor warranties.

Want to learn more about keeping your cooling solution in top shape? Visit our comprehensive guide to custom cooling solutions for additional maintenance tips and best practices.

Cost, Warranty & ROI

Let's talk dollars and sense when it comes to custom walk in coolers. I know this is a significant investment for your business, and understanding the costs, warranties, and return on investment will help you make the best decision.

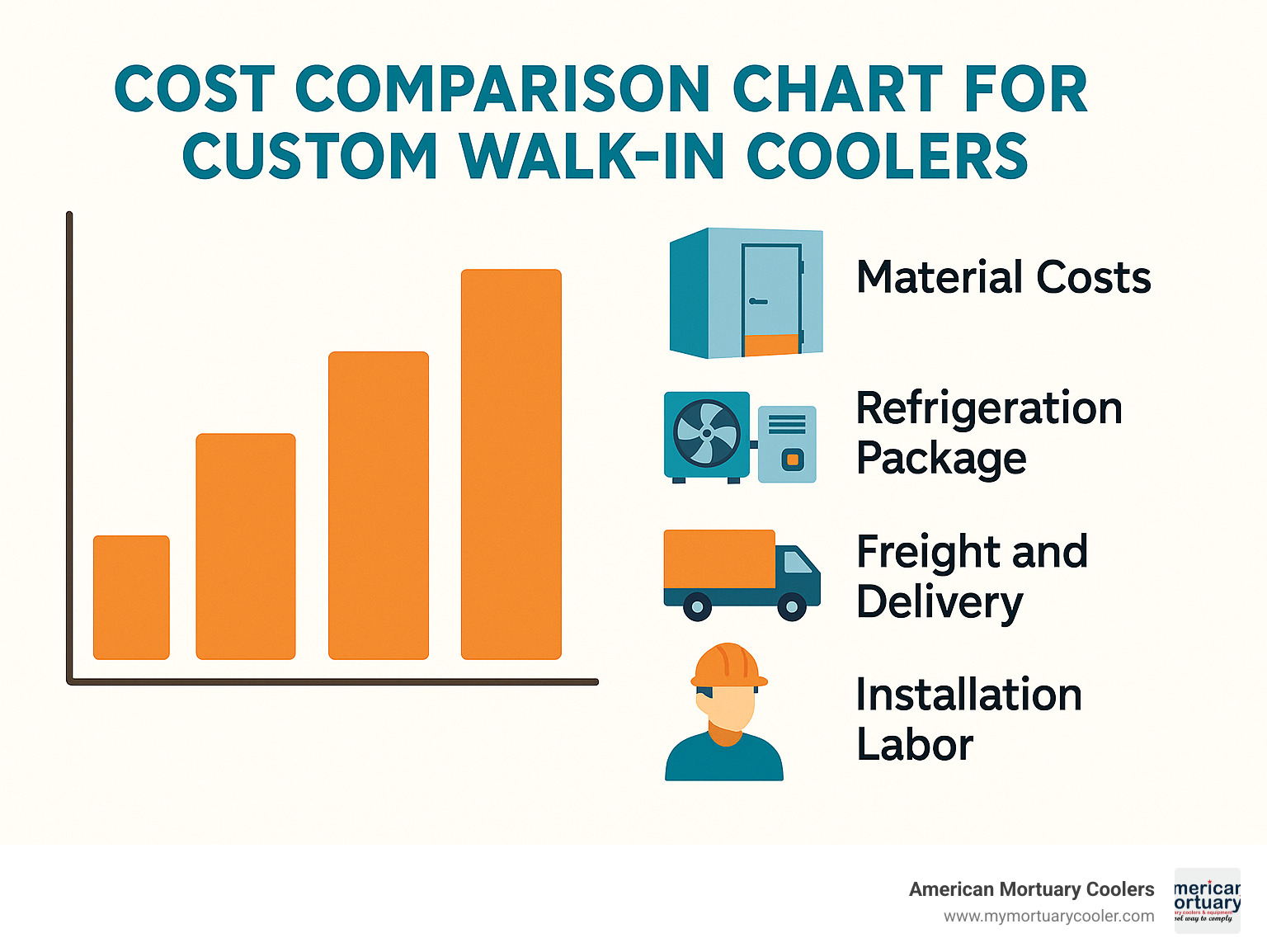

When pricing out your cooler, several factors come into play. The material costs for panels, doors, and hardware form your base price. Then there's the refrigeration package (all those important components like the evaporator, condensing unit, and controls). Don't forget about freight and delivery charges – after all, these aren't exactly small packages! Installation labor is another consideration, along with any optional accessories that make your cooler perfect for your specific needs.

Yes, a custom unit typically costs more upfront than a standard off-the-shelf model. But here's the good news – you might qualify for energy rebates from your local utility company if you choose a high-efficiency unit. These rebates can take a nice chunk out of your initial investment.

Worried about the upfront cost? We've got you covered. At American Mortuary Coolers, we offer 100% financing solutions to qualified buyers. This means you can start using your cooler right away while spreading the payments over time – kind of like buying a car, but much cooler (pun intended!).

Our warranty coverage is something we're particularly proud of. Your custom walk in cooler comes protected with a 20-year panel warranty, a 5-year entrance door warranty, a 5-year compressor warranty, and a 1-year parts warranty. For extra peace of mind, we also offer optional extended labor warranties.

When calculating your return on investment, think beyond just the purchase price. A well-designed custom cooler delivers significant energy savings over its lifetime. It also reduces product loss through more consistent temperatures. The improved workflow efficiency can save labor costs, and the longer equipment lifespan means you won't be replacing it anytime soon.

| Cost Component | Standard Unit | Custom Unit | Long-term Advantage |

|---|---|---|---|

| Initial Purchase | Lower | Higher | Custom units last longer |

| Installation | Variable | Often included | Professional installation reduces issues |

| Energy Costs | Higher | Lower | Better insulation means less energy use |

| Maintenance | Similar | Similar | Both require regular maintenance |

| Product Loss | Higher | Lower | More consistent temperatures reduce spoilage |

| Space Utilization | Less efficient | Maximized | Custom units use available space optimally |

| Resale Value | Lower | Higher | Custom units retain value better |

Budgeting a Custom Walk-In Cooler

Size matters when budgeting for your custom walk in cooler, but not always in the way you might think. While larger units cost more overall, the cost per cubic foot actually decreases as size increases. It's like buying in bulk – more economical per unit of storage space.

For a ballpark figure, smaller units (around 6'×6') start at approximately $4,625. Mid-sized units around 8'×10' typically range from $7,000 to $9,000. If you need something larger or more specialized, prices can exceed $15,000.

Those fancy add-ons will impact your bottom line, but they often deliver tremendous value. Glass display doors might add $800-1,500 per door compared to standard doors, but they could dramatically boost sales if you're in retail. Heavy-duty shelving adds about $100-300 per section but can significantly increase your storage capacity. Advanced control systems ($500-2,000) and specialized humidity control ($1,000-3,000) might seem pricey, but they can pay for themselves by protecting valuable inventory.

Need your cooler in a hurry? Quick-ship options typically add a 10-15% premium to the base price. It's like paying for express shipping – sometimes worth every penny when time is of the essence.

We believe in transparency at American Mortuary Coolers. Our quotes itemize all costs associated with your project, so you'll know exactly what you're paying for and can make informed decisions about which features make the most sense for your specific situation.

Understanding Warranty & After-Sales Support

The warranty on your custom walk in cooler isn't just fine print – it's your investment protection plan. Our comprehensive coverage includes structural protection with our 20-year panel warranty that guards against defects in materials and workmanship. Your cooler's heart – the compressor – is covered by a 5-year compressor warranty, while other mechanical elements get a 1-year parts warranty. Those hardworking doors? They're protected by a 5-year entrance door warranty.

But a warranty is only as good as the company behind it. That's why our after-sales support extends across the contiguous 48 states with qualified technicians ready when you need them. We maintain a comprehensive inventory of parts for both current and legacy models, minimizing any downtime if repairs are needed.

For our mortuary customers, we understand that continuous operation isn't just convenient – it's absolutely essential. That's why we offer priority service response to address issues promptly. Our friendly technical support team is just a phone call away, ready to provide troubleshooting assistance and maintenance guidance throughout your cooler's lifetime.

We're your neighbors, with locations across the country – Johnson City TN, Atlanta GA, Chicago IL, Columbia SC, Dallas TX, Los Angeles, New York NY, Pittsburgh PA, and regional offices serving the Midwest, Northeast, Rocky Mountain, Southeast, Southwest, and Pacific regions. Wherever you are, we're never too far away to provide the support you need.

Frequently Asked Questions about Custom Walk-In Coolers

How long does design and delivery take?

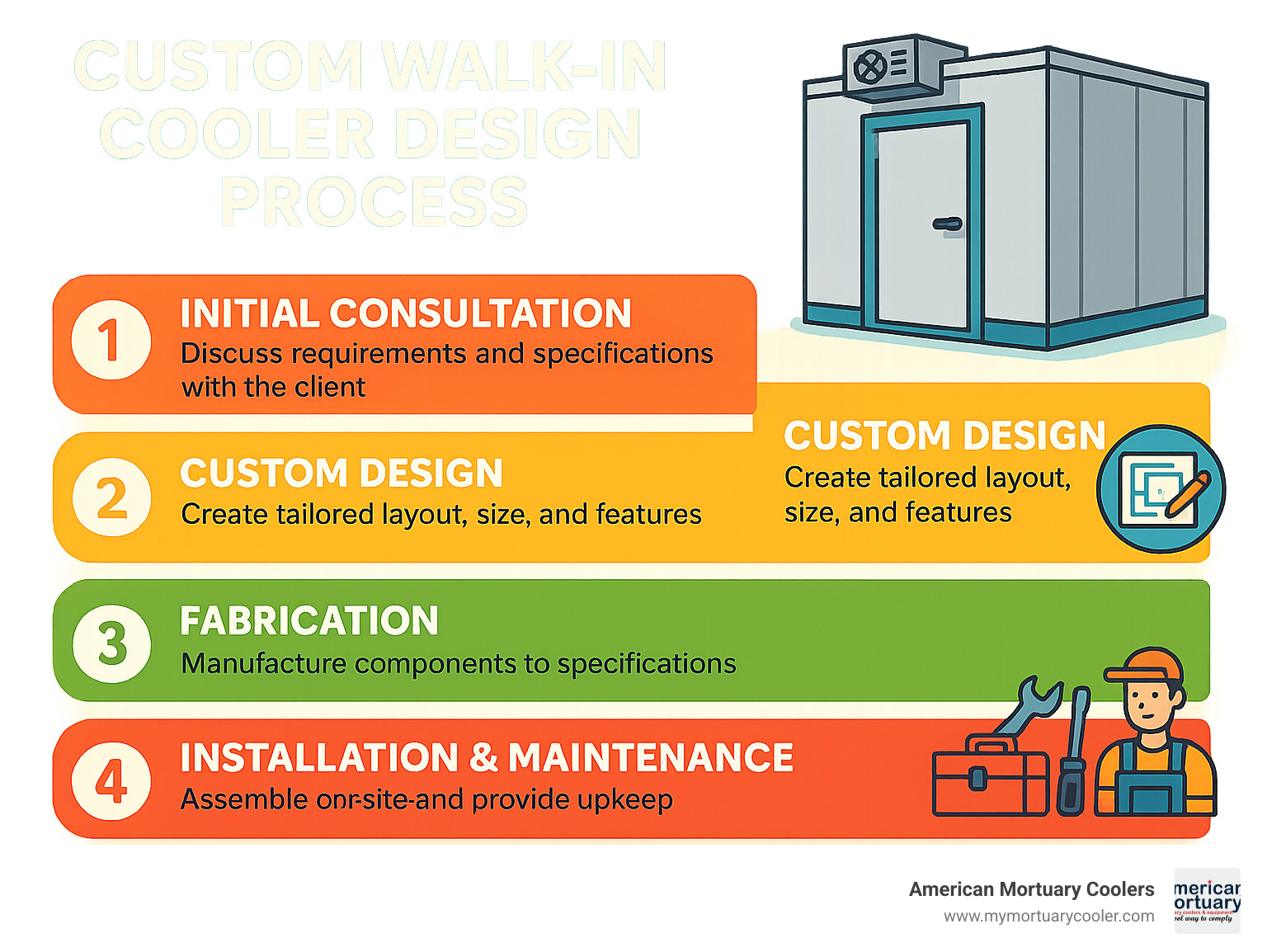

When customers ask me about timelines for their custom walk in coolers, I like to walk them through our typical project flow. Most projects follow a natural rhythm that starts with a friendly chat about your needs (usually just a day or two), followed by our design team creating your custom solution within 3-5 business days.

After you've had a chance to review and approve the design (which typically takes 1-3 days, depending on how quickly you can make decisions), we move into manufacturing. This is where your cooler actually comes to life over the next 10-20 business days, with the timeline varying based on just how specialized your unit needs to be.

Shipping usually takes 3-7 days depending on where you're located, and then installation is surprisingly quick – just 1-2 days for most units. We've streamlined this process over many years!

If you're in a time crunch, you'll be happy to know our quick-ship program can deliver standard-sized custom walk in coolers within 14 days or less after approval. The best advice I can give? Reach out early in your planning process. Our team loves working with customers to create realistic timelines, and we're pretty good at finding ways to speed things up when necessary.

What electrical requirements should I plan for?

Let's talk power! Most custom walk in coolers need 208-230 volts to operate efficiently. Depending on the size of your unit, you'll either use single-phase power (for smaller units) or three-phase power (which works better for larger coolers and is more energy efficient).

Your cooler will typically draw between 15-30 amps, with the exact requirement depending on the size and features of your specific unit. One important note: always plan for a dedicated circuit with the appropriate breaker – your cooler shouldn't share power with other equipment.

The refrigeration system is the main power consumer here. Most applications use a 1½-3 horsepower system, with larger units or those keeping things extra cold needing more powerful systems.

I always recommend having a licensed electrician look at your facility's electrical capacity early in the planning process. This small step can save huge headaches later by identifying any necessary upgrades before installation day. Our technical team is happy to provide detailed electrical specifications for your specific unit to help your electrician prepare.

Rest assured, all electrical components in our custom walk in coolers are UL-listed and pre-wired as much as possible, making those final connections at your site straightforward for your electrician.

Can my cooler be expanded later?

Yes! This is actually one of my favorite benefits of our modular custom walk in coolers – they can grow along with your business. Our panel systems are specifically designed with future flexibility in mind, allowing for expansion or reconfiguration as your needs evolve.

When it comes to expansion options, you have several choices. You might add length, width, or even height (though there are some structural considerations here). You can reconfigure door locations or types, upgrade your refrigeration capacity, or even add compartments. Some customers have even converted portions of their cooler to freezer space as their needs changed.

The feasibility of any expansion depends on a few key factors: how your unit was originally installed, the available space around it, your current refrigeration system's capacity, and structural considerations (especially important for outdoor units).

Here's a pro tip I share with all my clients: even if budget or space constraints mean starting smaller, discuss your long-term vision with us during the initial design. We can incorporate features that make future expansion much easier and more cost-effective – things like removable end panels or slightly oversized refrigeration systems that can handle additional cooling load down the road.

Think of it as planning for success – your business may grow, and your cooling needs along with it. We're here to make sure your custom walk in cooler can keep up with that growth without starting from scratch.

Conclusion

Taking the plunge into a custom walk in cooler is a big move for any business – but it's one that pays dividends through perfect-fit design, maximized space usage, and long-term energy savings. When you partner with professionals who truly understand your industry's unique challenges, you create a refrigeration solution that feels tailor-made because, well, it is!

Your journey begins with a thorough consultation where we dig into your specific needs, space limitations, and goals. From there, our design team crafts a detailed quote covering everything from panel specifications to refrigeration components and all those special features that make your cooler uniquely yours.

What makes the process smooth? You'll work with a dedicated point person from day one through final installation. This one-contact approach eliminates the frustration of explaining your project repeatedly to different team members and keeps everything moving forward efficiently.

Here at American Mortuary Coolers, we've built our reputation on specialized expertise in mortuary applications, but we bring that same attention to detail to every industry we serve. With our nationwide presence – from Johnson City TN to Los Angeles, New York NY to Dallas TX, and regional offices spanning the Midwest, Northeast, Rocky Mountains, Southeast, Southwest, and Pacific regions – you'll receive consistent, high-quality service no matter where you're located.

Custom walk in coolers aren't just boxes that keep things cold – they're strategic investments in your operation's efficiency, product quality, and bottom line. Whether you need a compact unit for your restaurant's prep area, a specialized mortuary cooler with precise temperature control, or an expansive cold storage facility for your distribution center, we have the know-how, manufacturing capability, and service network to exceed your expectations.

Ready to start the conversation about your refrigeration needs? We're here to help transform your cooling challenges into perfect-fit solutions that work as hard as you do.

For those specifically interested in our mortuary cooling solutions, we invite you to explore our mortuary coolers information page for specialized insights into how our coolers benefit funeral homes and mortuary operations.