Everything You Need to Know About Overhead Track Systems

Understanding Overhead Track Systems: A Complete Guide

An overhead track system is a rail-based mechanism mounted to ceilings or walls that enables smooth movement of items above floor level. These systems use trolleys that glide along tracks to transport loads in various settings.

What is an overhead track system?

- Definition: A ceiling or wall-mounted rail system with trolleys that move loads overhead

- Common uses: Material handling, patient transfers, curtain movement, industrial conveyors

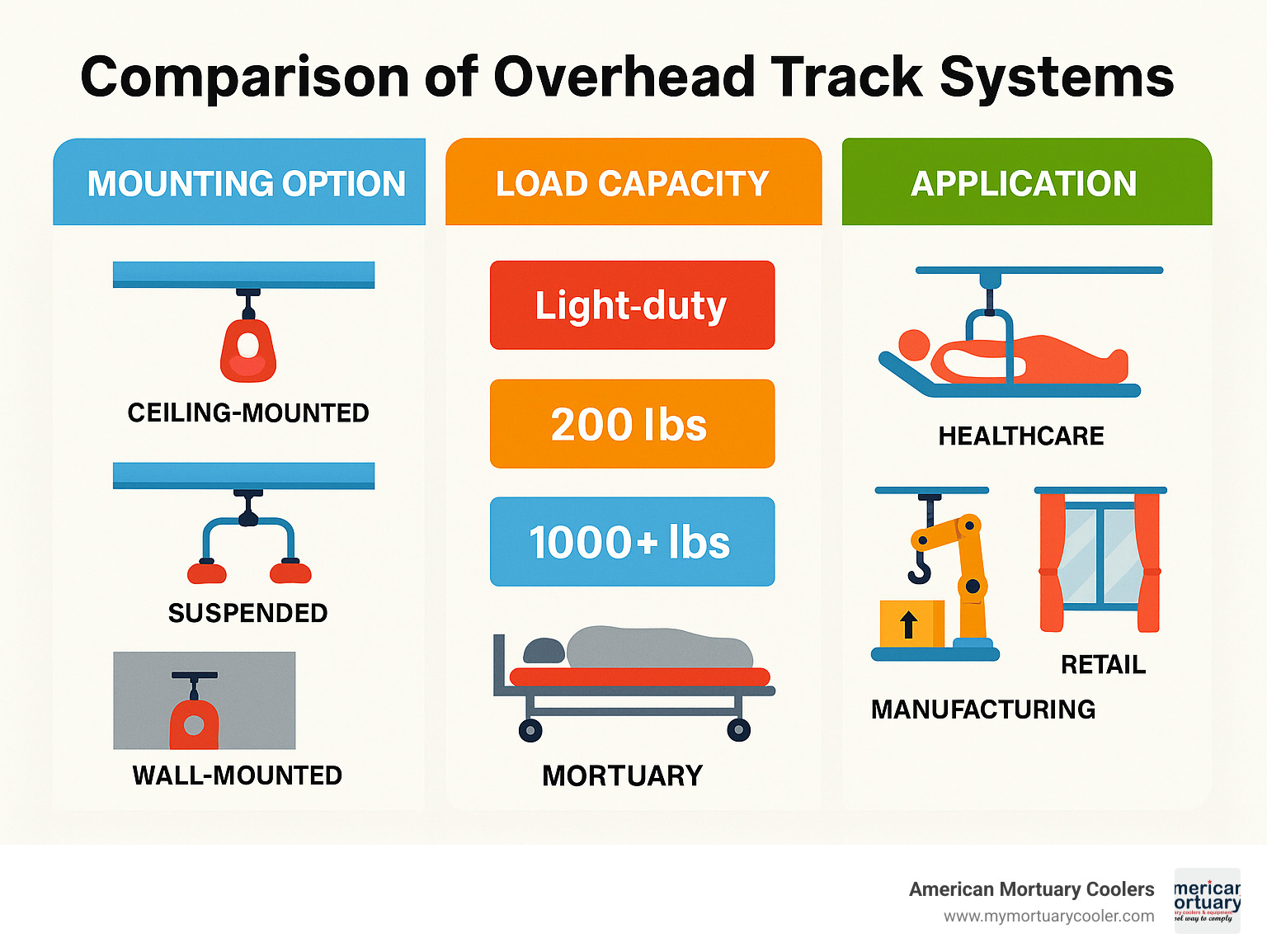

- Load capacity: Ranges from 40 lbs (light-duty) to 1000+ lbs (heavy-duty)

- Key benefits: Saves floor space, improves workflow efficiency, reduces injury risk

- Industries: Healthcare, mortuary, manufacturing, retail, residential, agricultural

Overhead track systems revolutionize workflow by utilizing ceiling space that would otherwise go unused. These versatile systems can be found in numerous environments, from hospitals where they assist with patient transfers to funeral homes where they facilitate the movement of remains. Industrial facilities use them to transport materials through production lines, while homeowners install them for curtain systems or storage solutions.

The primary advantage of an overhead track system is the elimination of floor obstacles, creating safer and more efficient workspaces. By moving loads above rather than across the floor, these systems minimize trip hazards while maximizing available space. This approach proves particularly valuable in environments where floor space is limited or where maintaining clear pathways is essential.

I'm Mortuary Cooler, a national-level supplier of mortuary equipment with extensive experience designing and implementing overhead track systems for funeral homes and medical facilities across the United States. My expertise includes customizing overhead track systems to meet the unique spatial constraints and workflow requirements of mortuary operations.

Why This Guide Matters

Whether you're managing a funeral home, running a hospital, operating a manufacturing facility, or simply looking to optimize your home space, understanding overhead track systems is crucial for making informed decisions. This comprehensive guide will help you:

- Solve common workspace problems like limited floor space and inefficient workflows

- Determine which track system best suits your specific needs

- Avoid costly installation mistakes and safety hazards

- Understand maintenance requirements to extend system lifespan

- Maximize your return on investment

At American Mortuary Coolers, we've seen how the right overhead track solution can transform operations, particularly in the funeral industry where dignity, efficiency, and safety must coexist. Our experts have compiled this guide based on decades of experience designing and installing custom solutions across the contiguous 48 states.

Overhead Track System Basics: How It Works

There's something almost magical about watching an overhead track system in action – items gliding smoothly above your head while the floor remains completely clear. But behind this seemingly simple concept lies clever engineering that makes it all possible.

At its heart, an overhead track system works on a beautifully straightforward principle. Imagine railroad tracks, but flipped upside down and mounted to your ceiling. Steel or aluminum rails form the pathway, while wheeled trolleys roll along these tracks carrying whatever needs to be moved.

The tracks themselves come in various profiles – some are open like a channel, others fully enclosed to protect the mechanism from dust or debris. Most systems in funeral homes use either galvanized steel for durability or aluminum when weight is a concern. For specialized environments like prep rooms, stainless steel offers superior corrosion resistance.

The trolleys are the workhorses of the system, featuring wheels that roll smoothly along the track. For lighter applications like curtain systems, nylon wheels provide quiet operation. When handling heavier loads like remains transport in a mortuary setting, steel wheels offer the necessary strength and longevity.

Support brackets connect everything securely to your ceiling structure, with proper spacing being absolutely critical. We've found through years of installation experience that supports should never be placed more than 6 feet apart, and for maximum capacity, 3-foot spacing is ideal. This careful distribution ensures the system can safely handle its rated load without putting undue stress on your building.

Most systems rely on either gravity or manual movement – simply push the trolley and it glides along the track. For more sophisticated applications, motorized drives can automate the process entirely, moving loads on a predetermined path without human intervention.

What makes these systems truly shine is their modularity. Tracks can be straight, curved, or even form complete loops. They can include switches to direct trolleys down different paths or incorporate lifting mechanisms to add vertical movement. This flexibility allows us to design custom solutions that perfectly match each funeral home's unique layout and workflow needs.

What Makes an Overhead Track System Different?

The genius of an overhead track system lies in its use of space that would otherwise go unused. While traditional material handling happens at floor level, overhead systems operate in that empty zone between your head and the ceiling.

This approach creates a floor-free workflow that's transformative for busy environments. In funeral homes we've equipped across Tennessee and beyond, directors immediately notice how much more spacious their preparation rooms feel when equipment and transport systems move overhead rather than cluttering the floor.

Safety improves dramatically too. With fewer obstacles at ground level, the risk of trips and falls decreases significantly – particularly important in environments where staff may be focused on delicate tasks rather than watching where they step.

The three-dimensional movement capability adds another layer of efficiency. Unlike floor-based transport systems that can only move horizontally, overhead tracks can incorporate lifting mechanisms to raise and lower items as needed. This vertical dimension allows for more complex and efficient movement patterns within a single space.

For funeral homes where dignity and space efficiency must coexist, these systems prove invaluable. We've seen how they transform cramped preparation rooms into spacious, organized environments where professionals can work with respect and care.

Core Physics Behind an Overhead Track System

Understanding a few basic principles of physics helps explain why overhead track systems work so reliably – and why proper installation matters so much.

First, center of gravity plays a crucial role. Any load suspended from an overhead track naturally wants to hang directly below its connection point. This self-centering effect creates stability, but only if the system is properly designed. If a load's center of gravity extends too far to one side, it creates torque that can stress components beyond their limits.

Load distribution is equally important. When we install a system, we're essentially creating a network that spreads weight across multiple connection points. Each bracket transfers force to the building structure, which is why understanding your ceiling's construction is so important. A track mounted to solid joists can handle far more weight than one attached to lightweight drop ceiling components.

The interplay between momentum and friction determines how your system feels in daily use. Heavier loads build more momentum and require more force to stop. The rolling resistance of trolley wheels – higher with steel, lower with nylon – affects how easily loads move and come to rest. Finding the right balance ensures smooth operation without unwanted drift.

Through our experience installing systems in funeral homes across the country, we've learned that these physical principles aren't just theoretical – they directly impact daily operations. When we recommend specific support spacing or trolley types, it's based on these fundamental properties that determine whether a system will operate safely for years to come.

At American Mortuary Coolers, we consider all these factors when designing custom overhead solutions for our clients, ensuring systems that not only work today but continue performing reliably through years of service.

Types & Applications Across Industries

Overhead track systems have evolved to serve diverse needs across multiple industries. Their versatility has led to specialized designs optimized for specific applications:

Walk into any modern manufacturing plant, hospital, or even some homes, and you might notice something interesting overhead. Those tracks aren't just architectural features—they're working hard to make life easier below.

In industrial settings, overhead conveyors like Bridgeveyor's C-250™ have been quietly revolutionizing production lines since 1970. These robust systems move parts through assembly, painting, and packaging with their 1.5 lbs-per-foot chain capacity. They're the unsung heroes keeping manufacturing floors clear and workflows efficient. For readers unfamiliar with how these conveyors generally work, the overview on overhead conveyors provides helpful background. For more specialized industrial applications, Nikotrack Overhead Conveyors and Tracks offer solutions custom to specific manufacturing needs.

The healthcare world has adopted overhead track systems in a particularly meaningful way. Hospitals and nursing homes use ceiling-mounted tracks with patient lifts that can safely move individuals weighing up to 440 lbs. The Handicare Pressure Fit systems are especially popular because they reduce injury risk for caregivers while preserving dignity for patients during transfers.

We've seen how these systems transform funeral homes and mortuaries. Our clients appreciate the custom steel monorail tracks that can support up to 1000 lbs and span 23 continuous feet (with splice joints available for longer runs). These specialized systems allow for respectful handling of remains between preparation areas, coolers, and viewing rooms—a crucial aspect of providing dignified service.

Even in residential spaces, overhead tracks have found their place. From IKEA's ceiling curtain tracks that create flexible room dividers to creative homeowners installing model train displays that don't consume precious floor space, these systems bring functionality and sometimes even whimsy to everyday living.

Physical therapists have finded the confidence-building power of overhead rehabilitation tracks. Solo-Step's aluminum systems can support 1000 lbs per 7.5-foot section, allowing patients to practice walking without fear of falling. The psychological security this provides often accelerates recovery times significantly.

Down on the farm, particularly in dairy operations, overhead monorails like Latrak's systems (manufactured since 1996) move milking equipment and supplies efficiently above the busy work areas. This keeps pathways clear—particularly important when working with large animals.

Even retail environments benefit from these systems. Stores use overhead tracks for displaying merchandise, hanging signage, and creating flexible spaces that can be reconfigured as needed. The tracks blend discreetly into ceiling designs while providing tremendous versatility below.

Light-Duty to Heavy-Duty Lines

The weight-bearing capacity of an overhead track system determines which applications it can serve. Chainveyor's light-duty systems handle loads up to 120 pounds—perfect for retail displays or lightweight manufacturing components. Their medium-duty options step up to 400 pounds for more substantial needs.

AKON's versatile trolley systems support up to 125 lbs per trolley when properly installed with supports every 3 feet. For truly demanding applications, both Mortuary Lift Company and Solo-Step offer heavy-duty systems rated for 1000 lbs, though they achieve this capacity through different design approaches.

At American Mortuary Coolers, we carefully match funeral homes with the appropriate system based on their specific handling requirements. A small family-owned funeral home in rural Tennessee has very different needs than a high-volume operation in Chicago, and we tailor our recommendations accordingly.

Specialized Tracks for Funeral & Morgue Use

The funeral industry presents unique challenges that standard overhead track systems simply can't address. That's why specialized designs have emerged to meet these specific needs.

Body lift systems with 1000-lb capacity ensure dignified and safe transfers between preparation tables, coolers, and caskets. These systems reduce the physical strain on funeral directors and their staff—something I've personally heard many thanks for during installations.

The layout of preparation rooms varies widely across facilities, so customized track configurations are essential. Some funeral homes benefit from simple straight runs, while others need L-shaped or complete room circuits to accommodate their workflow. We've even designed U-shaped systems for particularly challenging spaces.

Hygienic considerations are paramount in mortuary settings. Many of our systems feature white fiberglass encasing that not only looks professional but also allows for easy cleaning and sanitation—a critical feature in preparation rooms.

Advanced mortuary systems incorporate freedom pivots that enable multidirectional movement along the track. This feature proves invaluable when transferring remains in tight spaces, allowing for more graceful, dignified handling even in smaller preparation rooms.

From our Tennessee headquarters to funeral homes in Dallas, Los Angeles, and everywhere in between, we've seen how properly designed mortuary lifts and cadaver lifts transform operations. The right overhead track system doesn't just make work easier—it lifts the level of care and respect funeral homes can provide during their most important services.

Key Components, Materials & Load Capacities

When you're looking at an overhead track system, understanding what goes into it helps you make smart choices. Think of it like buying a car – you want to know about the engine, tires, and safety features before making a decision.

Essential Components

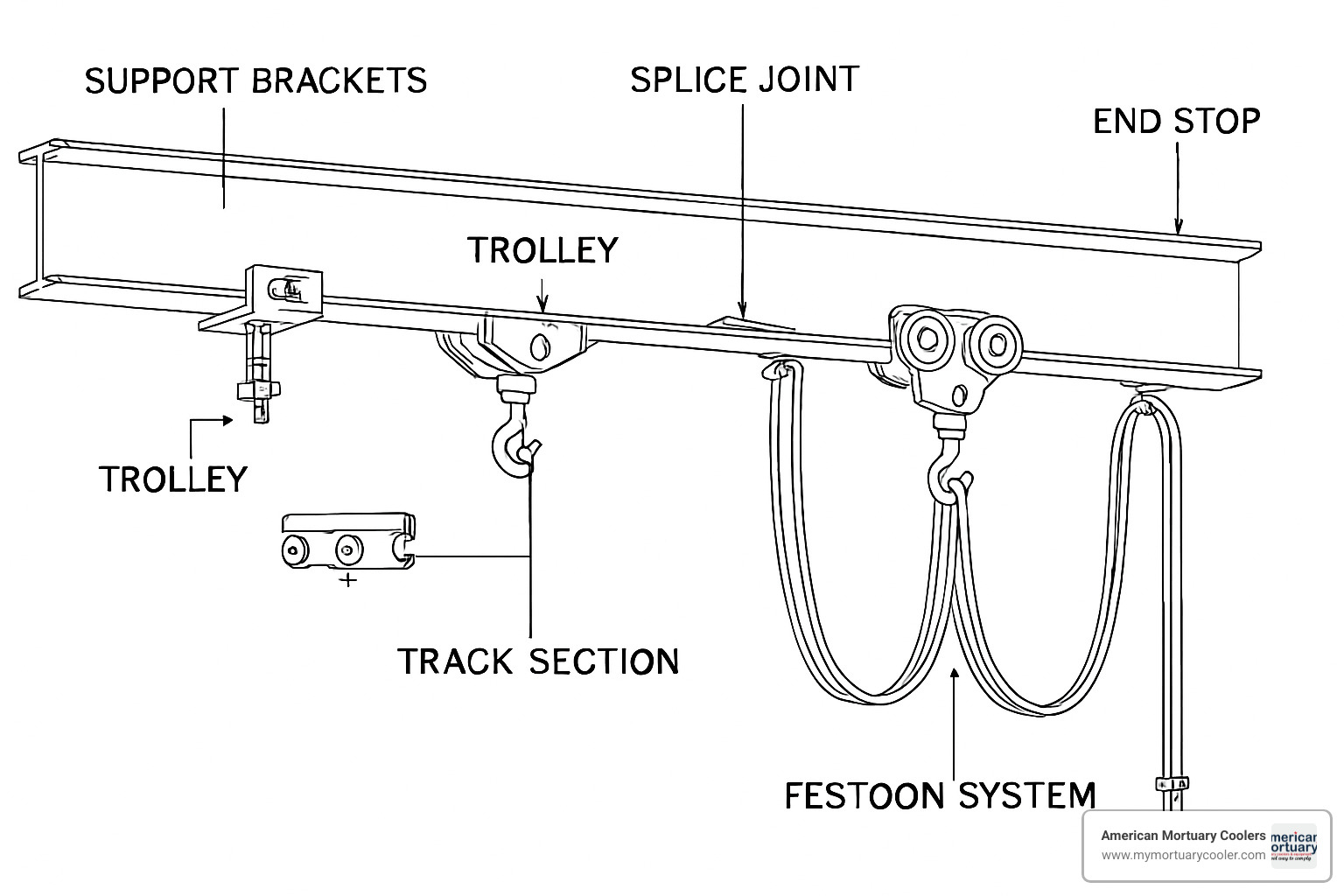

The heart of any overhead track system is the track itself – those rails that guide everything along. These come in straight sections for hallways, curved pieces for corners, and even specialized switches that let you direct trolleys to different areas of your facility.

Rolling along these tracks are the trolleys – the workhorses that actually carry your loads. Some trolleys include hoists for lifting, while others are designed just for horizontal movement. If you need automation, powered trolleys with motors can do the heavy lifting for you.

Of course, these systems don't float in mid-air! They need proper support hardware – brackets and hangers that secure everything to your ceiling or wall. Whether you have a standard flat ceiling, exposed beams, or even a sloped roof, there's a mounting solution available. For longer runs, splice joints connect track sections together, while end stops act as safety bumpers to prevent trolleys from rolling off the track.

One component people often overlook is the festoon system – those clever arrangements that manage cables, hoses, or other utilities that need to move alongside your trolleys. Think of them as the track system's nervous system, keeping everything connected as it moves.

Material Choices & Environmental Factors

Choosing the right material for your overhead track system is like picking the right clothing for the weather – it needs to match your environment.

Galvanized steel is the workhorse of industrial applications, offering good strength and decent corrosion resistance without breaking the bank. AKON's heavy-duty ceiling tracks use 16 gauge galvanized steel that stands up to daily use.

For environments where cleanliness is critical – like funeral preparation rooms – stainless steel is worth the investment. It resists corrosion beautifully and can be thoroughly sanitized. Bridgeveyor's stainless steel systems are even certified for food and medical handling.

Aluminum shines when weight is a concern. It's strong but lightweight, making it perfect when your ceiling structure might not support heavier systems. Solo-Step uses aircraft-grade extruded aluminum for their rehabilitation tracks, giving patients confidence during therapy.

Many mortuary lifts feature fiberglass enclosures around motors and controls. These smooth white casings aren't just for looks – they make cleaning and sanitizing much easier in environments where that matters.

The environment where you'll use your system matters tremendously. In high-humidity settings like morgues or wash-down areas, you'll need corrosion-resistant materials. Systems exposed to chemicals (common in preparation rooms) need special protection. And if you're installing outdoors or near heat sources, you'll need materials designed to withstand those specific challenges.

At American Mortuary Coolers, we've seen how the Southeast Region's humidity affects equipment differently than the varied conditions of our Pacific Region customers, and we select materials accordingly.

Load Capacities and Performance Factors

Understanding load capacity is about more than just a single number – it's about how several factors work together:

Trolley design makes a huge difference. Nylon wheels work well for lighter loads (up to 40 lbs each in AKON systems), while steel wheels handle the heavy lifting (up to 125 lbs per trolley).

The track material and gauge (thickness) affects strength significantly. Heavier gauge materials provide greater strength but may require more substantial support structures.

Support spacing is critical – our research shows brackets should be placed every 3 feet for maximum load capacity, with 6 feet being the absolute maximum recommended spacing. Space them too far apart, and even the strongest track will sag.

Don't forget about your ceiling structure – it needs to support both the track system and whatever you're moving. Sometimes structural reinforcement might be necessary before installation.

Also consider dynamic vs. static loads. A static 200-pound load sitting still puts less stress on a system than that same 200 pounds in motion, starting and stopping.

| System Type | Typical Load Range | Key Advantages | Common Applications |

|---|---|---|---|

| Overhead Track | 40-1000+ lbs | Space-saving, reduced trip hazards, flexible routing | Mortuary lifts, patient transfers, industrial conveyors |

| Floor-Based | 500-10,000+ lbs | Higher capacity, easier installation, lower ceiling requirements | Heavy manufacturing, warehouse logistics |

| Wall-Mounted | 40-500 lbs | No floor or ceiling impact, good for temporary installations | Curtain systems, light retail display, home storage |

How to Size an Overhead Track System

Sizing your overhead track system correctly is crucial for safety and performance. Start with a thorough structural ceiling assessment – can your ceiling actually support what you're planning to hang from it? Sometimes you'll need reinforcement before proceeding.

Calculate your support spacing carefully. For heavy loads, place supports every 3 feet. Even with lighter loads, never exceed 6 feet between supports – that's a recipe for sagging tracks and potential failure.

When selecting trolley capacity, always build in a safety margin. If you typically move 100-pound loads, choosing AKON's 125-pound capacity trolleys gives you a 25% buffer for peace of mind.

Plan your track configuration thoughtfully. Standard tracks can run continuously up to 23 feet before needing a splice joint. Try to minimize these joints while still creating a layout that supports your workflow.

Dynamic loads create more stress than static ones. When an object starts moving, stops, or changes direction, it creates additional forces your system must handle.

At American Mortuary Coolers, we perform detailed assessments of funeral home facilities before recommending any overhead track solution. In preparation rooms, where precise movement and absolute reliability are non-negotiable, proper sizing isn't just about convenience – it's essential for dignity and safety.

Selecting, Installing & Customizing Your Overhead Track System

Picking the perfect overhead track system doesn't have to be overwhelming. Think of it as finding the right tool for a specific job—it's all about matching your unique needs with the right solution. Let me walk you through how to choose, install, and customize a system that works beautifully for your space.

Assessment Checklist

Before you start comparing different systems, take a moment to evaluate what you really need. What will you be moving with this system? A 300-pound body in a funeral home requires very different equipment than lightweight retail displays.

Start by clearly defining your purpose and the weight you'll be handling regularly. Next, grab a tape measure and map out your space, noting ceiling heights and any obstacles that might get in the way. Consider how often you'll use the system—daily use demands more durable components than occasional operation.

Your budget matters too, but think beyond just the initial purchase price. A quality system from a reputable provider like American Mortuary Coolers might cost more upfront but save you thousands in the long run through reduced maintenance and longer lifespan. And don't forget to consider your future needs—will your requirements change in a year or two?

Configuration Options

Overhead track systems are wonderfully adaptable to different spaces. The simplest option is a straight run—perfect for moving items directly from point A to point B. Need to steer around corners? An L-shaped configuration might be your answer, incorporating a 90° turn to follow your room's perimeter.

For more complex spaces, U-shaped designs with two 90° corners create an efficient three-sided workflow that's perfect for preparation rooms. If you need continuous movement, oval or loop configurations allow trolleys to circulate without stopping or reversing direction.

Some facilities benefit from traverse designs with switching mechanisms that direct trolleys down different paths—imagine a railway switching track, but overhead. And if ceiling mounting isn't possible, free-standing gantry systems like the Mackworth Easy Fit 440 Gantry offer 440 pounds of lifting capacity without requiring any permanent installation.

Installation Considerations

When it comes to installation, safety should be your top priority. Most systems offer three main mounting options: direct ceiling mounts attached to joists, wall-to-wall supports that don't rely on ceiling strength, or free-standing gantry styles that require no attachment to building elements at all.

Before installation begins, make sure your ceiling structure can handle the load. I've seen too many cases where tracks were mounted to decorative ceiling elements rather than structural supports—a dangerous mistake. Your ceiling needs to support both the weight of the system itself and whatever you'll be moving with it.

While some residential systems are DIY-friendly, I strongly recommend professional installation for any system used in healthcare or funeral settings. At American Mortuary Coolers, our installation teams work across all 48 contiguous states, bringing specialized expertise to every funeral home we serve.

Don't forget to check local building codes before installation begins. Commercial installations typically require permits and inspections, and healthcare and funeral facilities often face additional regulatory requirements. A professional installer will help steer these requirements, saving you headaches down the road.

Choosing the Right Overhead Track System for Home Care

Home care presents unique challenges—systems need to be effective while also looking appropriate in a residential setting. For bedroom applications, ceiling-mounted tracks above beds make transfers between bed and wheelchair smooth and dignified. These typically support between 300-440 pounds, plenty for most home care situations.

Bathroom solutions require special consideration since they'll be exposed to moisture. Water-resistant materials are essential, and tracks should be positioned to facilitate safe transfers to toilets, showers, and baths.

For those who can't make permanent modifications (like renters), pressure-fit options such as the Handicare Pressure Fit Patient Lift Systems create stable structures without drilling into ceilings or floors. These systems use tension between floor and ceiling, making them perfect for temporary installations.

Aesthetics matter in home environments too. Many manufacturers now offer systems in neutral colors like "warm white" that blend seamlessly with residential décor rather than looking institutional.

Installation Mistakes to Avoid

Even the best overhead track system can fail if installed improperly. One common mistake is misaligning track joints, which creates friction points that impede smooth movement and accelerate wear on components. Imagine trying to roll a suitcase over a bumpy sidewalk—that's what a misaligned track does to your trolleys.

Another critical error is insufficient support. Mounting brackets spaced too far apart or attached to non-structural elements can lead to catastrophic failure under load. Always follow manufacturer guidelines for support spacing—typically every 3-6 feet.

Sloped ceilings require special attention. A track mounted to a sloped ceiling without proper accommodation will create an incline that can cause trolleys to roll uncontrolled. Specialized sloped ceiling mounted hanger assemblies solve this problem by keeping the track level even when the ceiling isn't.

Using underrated hardware is like wearing a belt that's too small—it might hold for a while, but will eventually fail at the worst possible moment. Always use fasteners and brackets rated for your intended load.

Finally, ensure proper clearance around your track. I've seen beautifully installed systems rendered useless because they were mounted too close to light fixtures or doorways. Your system needs adequate headroom and clearance from obstacles to function properly.

At American Mortuary Coolers, our installation teams have seen it all—from Tennessee to Texas, New York to Nevada. This experience helps us anticipate and prevent these common installation mistakes, ensuring your overhead track system performs safely and effectively for years to come.

Maintenance, Safety & Compliance

Keeping your overhead track system in top shape isn't just about preventing breakdowns—it's about ensuring safety, extending its lifespan, and protecting your investment. At American Mortuary Coolers, we've seen how proper maintenance transforms a good system into a great one that serves funeral homes reliably for years.

Maintenance Schedule

Think of your overhead track system as you would your car—regular check-ups prevent major problems down the road.

Start with quick daily visual inspections—these take just moments but can catch developing issues before they become dangerous. Look for anything unusual: damaged components, loose hardware, or obstacles in the track's path.

Monthly, take a few minutes to test your system's operation. Listen for any unusual sounds as trolleys move along the track—those squeaks and grinding noises are your system's way of asking for attention. This is especially important in busy funeral homes where systems get daily use.

Quarterly, schedule a more thorough inspection. This is when you'll want to examine all components carefully, including those brackets and fasteners that keep everything secure overhead. In the funeral industry, where dignity and reliability are paramount, these regular checks are non-negotiable.

Once a year, bring in the professionals. At American Mortuary Coolers, we recommend an annual assessment by qualified technicians who understand the unique needs of mortuary equipment. They'll perform load testing if appropriate and identify potential issues before they become problems.

Between these scheduled checks, lubricate moving parts according to your manufacturer's guidelines. Proper lubrication is like giving your system a drink of water on a hot day—essential, but too much can create its own problems by attracting dust and debris.

Safety Considerations

Safety isn't just a buzzword when it comes to overhead track systems—it's the foundation everything else rests upon.

Always respect your system's load ratings. These aren't suggestions; they're carefully calculated limits that ensure safe operation. Whether you're moving a 300-pound load in a hospital or handling remains in a funeral home, exceeding these limits puts everyone at risk.

Clear signage is your first line of defense against misuse. Post the system's capacity where operators can't miss it. In busy environments like funeral homes, where multiple staff members might use the equipment, these visual reminders are invaluable.

Training matters tremendously. Even the best-designed system can become dangerous in untrained hands. Make sure everyone who uses your overhead track system understands proper loading procedures and what to do if something goes wrong.

Appropriate personal protective equipment should be standard practice for operators. In mortuary settings, this includes not just safety gear but also proper protective clothing for handling remains with dignity and safety.

Establish emergency procedures before you need them. What happens if power fails with a load suspended? Having clear protocols in place ensures everyone knows exactly what to do when seconds count.

Preventive Care for an Overhead Track System

Preventive maintenance is where the real savings happen—both in system longevity and in avoiding costly emergency repairs.

Regular cleaning deserves more attention than it often gets. Dust and debris can accelerate wear on trolley wheels and create friction in tracks. In mortuary settings, proper sanitization isn't just about maintenance—it's about maintaining the highest standards of dignity and hygiene.

Bolt torque checks might seem minor, but vibration gradually loosens even the most secure connections. A quarterly check with a torque wrench takes minutes but can prevent a catastrophic failure.

Trolley wheels typically show wear before other components. Replace them at the first signs of deterioration—flattened spots, cracks, or excessive noise during operation. These relatively inexpensive parts protect your more substantial investment in the overall system.

Lubrication management requires balance. Follow manufacturer guidelines precisely—too little lubricant causes wear, while too much attracts contaminants. In the controlled environments of funeral homes, proper lubrication also helps ensure quiet, dignified operation.

Detailed records of maintenance aren't just good practice—they're often required for compliance and warranty purposes. Document every inspection, maintenance task, and repair, creating a history that helps identify patterns and predict future needs.

At American Mortuary Coolers, we understand that funeral homes across different regions face unique challenges—from the humidity of our Southeast Region that can accelerate corrosion to the temperature fluctuations in our Midwest Region that affect system performance. Our maintenance recommendations account for these regional differences.

Regulations & Industry Standards

Navigating the regulatory landscape for overhead track systems can feel overwhelming, but compliance isn't optional—it's essential for safety, insurance, and liability protection.

The American National Standards Institute provides guidance through ANSI B30.16, which covers overhead hoists. If your system includes lifting components, these standards apply to your installation.

For patient lifting applications, CSA Z10535 offers comprehensive guidelines. While primarily Canadian, these standards are often referenced for best practices in American healthcare and long-term care facilities.

Healthcare facilities must also consider NFPA 99 requirements from the National Fire Protection Association, which address various safety aspects including overhead systems.

Food processing and medical environments face additional scrutiny under FDA regulations, which may affect material choices and sanitation procedures for your system.

Local building codes vary significantly by location but typically address how your system attaches to the building structure, electrical safety requirements, and load rating documentation. Before installation, always check with local authorities about permit requirements.

In workplace settings, OSHA requirements apply to overhead systems, particularly regarding fall protection during installation and maintenance, and safe load handling procedures during operation.

At American Mortuary Coolers, we design our systems to meet or exceed all relevant standards for funeral industry applications nationwide. From our Tennessee headquarters to our customers in all 48 contiguous states, we ensure that every installation complies with both national standards and local requirements.

Compliance isn't just about avoiding fines—it's about protecting your staff, your business, and the families you serve. A properly maintained, compliant overhead track system provides years of safe, reliable service when you need it most.

Costs, ROI & Real-World Case Studies

Let's talk dollars and cents. I know that for many funeral directors and facility managers, the bottom line matters just as much as functionality. While overhead track systems represent a significant upfront investment, they often pay for themselves through improved operations and safety.

Cost Factors

When budgeting for an overhead track system, several elements contribute to the total price tag. The basic equipment costs—tracks, trolleys, and brackets—vary widely depending on the capacity and materials you choose. A simple aluminum system for light loads costs considerably less than a heavy-duty stainless steel setup for a busy preparation room.

Installation labor adds another layer to your investment. While some residential systems might be DIY-friendly, commercial installations in funeral homes typically require professional expertise. Our installation teams have seen how proper installation prevents costly problems down the road.

Don't forget to account for possible structural modifications. Some older buildings need ceiling reinforcement to safely support these systems. You'll also want to budget for staff training and ongoing maintenance to protect your investment.

For a typical mortuary installation, you're looking at anywhere from $6,000 for a basic system to $35,000 for a comprehensive solution with multiple tracks and specialized features. The wide range reflects the customized nature of these installations—no two funeral homes have identical needs or spaces.

Return on Investment Considerations

The beauty of an overhead track system is how quickly it can pay for itself. Most of our funeral home clients see returns in several key areas:

First, these systems dramatically improve labor efficiency. Tasks that once required two or three staff members can often be handled by one person with the right track system in place. This efficiency translates directly to your bottom line.

Perhaps even more valuable is injury prevention. Back injuries from lifting and moving remains can sideline your staff and lead to significant workers' compensation claims. One prevented injury can potentially offset the entire system cost. According to the Occupational Safety and Health Administration, reducing manual lifting is one of the most effective ways to lower musculoskeletal disorders in the workplace.

Better space utilization means you can optimize your existing facility rather than expanding. Equipment lasts longer when it's not being bumped or damaged during manual transfers. And perhaps most importantly for funeral directors, the ability to handle remains with greater dignity and precision improves your reputation and service quality.

One funeral director in Michigan told me, "The system paid for itself the first time we avoided a workplace injury. Everything since then has been pure savings."

Comparing Quotes & Hidden Expenses

When evaluating proposals, be on the lookout for costs that might not appear in the initial quote. Freight charges for shipping heavy track components across the country can add up, especially for nationwide delivery to places far from our Tennessee headquarters.

Permitting fees vary by locality, and some jurisdictions require formal building permits for installation. You might need a structural engineer to assess your ceiling's capacity, particularly in older buildings. Powered systems require appropriate electrical work, and there's always some business disruption during installation to consider.

At American Mortuary Coolers, we believe in transparency. Our quotes include all anticipated costs for custom mortuary track systems. We've delivered and installed systems from New York to California, and we understand the regional variations in both regulations and building styles.

Illustrative Case Studies of Overhead Track System Success

Real-world examples speak volumes about the practical benefits of these systems:

A rehabilitation center installed a Solo-Step overhead track system and saw remarkable results. Patients gained confidence knowing they couldn't fall, which allowed them to attempt more challenging exercises. One particular patient doubled their walking distance from 30 to 60 feet after just three therapy sessions. Meanwhile, therapists reported less physical strain and better ability to focus on technique rather than constantly preventing falls.

Closer to home, a mid-sized funeral home in our Midwest service region implemented a custom overhead track system in their preparation room with impressive outcomes. Staff reported an 80% reduction in back strain incidents—a game-changer for their small team. Preparation time decreased by approximately 25% due to more efficient transfers. Perhaps most interestingly, the funeral director began mentioning their "dignified handling system" during facility tours, and families responded positively to this attention to detail.

Even in completely different industries, the ROI story remains consistent. A dairy farm installed an overhead track for moving milking equipment and saw labor efficiency improve by 35%. Equipment damage plummeted, and the entire system paid for itself within 18 months through labor savings alone.

Some overhead conveyor manufacturers have documented significant efficiency improvements and cost savings for their clients across various manufacturing sectors.

Most overhead track systems deliver complete return on investment within 1-3 years, depending on how frequently they're used. For busy funeral homes handling multiple cases daily, the payback period often falls on the shorter end of that spectrum.

As one of our long-time customers put it: "It's not about whether you can afford to install an overhead track system—it's whether you can afford not to."

For funeral homes looking to improve their handling systems, our Efficient Mortuary Cadaver Lift with Multi-Directional Ball Top offers a perfect example of how innovative overhead systems can transform operations.

Frequently Asked Questions about Overhead Track Systems

What ceiling structure is needed for an overhead track system?

When considering an overhead track system for your facility, the ceiling structure is a critical factor. Your ceiling needs to support both the weight of the system itself and whatever you'll be moving with it.

Most tracks need to be attached directly to solid structural elements like joists, trusses, or beams. Think of it as hanging a really heavy picture – you wouldn't trust just drywall to hold it, right?

For homes, standard wood joists are usually strong enough for lighter systems like curtain tracks or small storage solutions. But for funeral homes and other commercial settings, you might need steel beams or concrete structures to handle heavier loads.

The spacing of your ceiling joists matters too. Ideally, you want to attach supports directly to structural elements every 3-6 feet, following what the manufacturer recommends. And naturally, larger, stronger joists provide better support – steel joists typically offer more capacity than wood ones.

Drop ceilings present a special challenge. You can't just attach to the suspended grid – the track must connect to the actual structural ceiling above. If ceiling mounting simply isn't possible in your space, don't worry! Wall-to-wall installations or free-standing gantries can work wonderfully as alternatives.

Here at American Mortuary Coolers, we never guess about structural capacity. Before installing any overhead track system in funeral homes across the country, we conduct thorough structural assessments to ensure safety and compliance with your local building codes.

How do load capacities vary among systems?

Load capacity is where overhead track systems really show their differences – they're designed for everything from lightweight curtains to heavy mortuary transfers.

For residential needs, light-duty systems like curtain tracks typically support 40-75 pounds per trolley. AKON's nylon wheel trolleys, for example, can handle up to 40 pounds each – perfect for home use.

Moving up to medium-duty applications like patient lift systems, you'll find capacities generally ranging from 120-440 pounds. The Handicare Pressure Fit Patient Lift Systems accommodate up to 440 pounds, making them suitable for most patient transfer needs.

For industrial and mortuary applications, heavy-duty systems can support 1000 pounds or more. The Mortuary Lift Company's custom steel monorail track systems have a robust 1000-pound capacity – essential for dignified and safe handling in funeral home settings.

Several factors affect how much weight a system can handle. The trolley design matters tremendously – wheel material, bearing quality, and frame construction all impact capacity. The track material and profile make a difference too, with stronger materials and more robust profiles increasing capacity.

Support spacing is particularly critical. Our research shows that support brackets should be placed every 3 feet for maximum heavy load capacity. And don't overlook connection methods – the strength of splice joints, support brackets, and other connections can limit overall system capacity.

Always build in a safety margin by selecting a system rated well above your anticipated maximum load. It's better to have capacity to spare than to push the limits of your system.

Can I retrofit an overhead track system into an existing room without major construction?

Good news – in many cases, you absolutely can add an overhead track system to your existing space without turning it into a major construction zone. We've helped funeral homes across the country do exactly this.

The feasibility depends on a few key factors. First, what's your ceiling like? Exposed joists or beams make installation much simpler, while finished ceilings might require more work to access the structural elements hiding above. But don't worry – even with finished ceilings, experienced installers can often work with minimal disruption.

Next, we need to evaluate your ceiling's structural capacity. Can it support the intended load? Some buildings may need reinforcement, but many are perfectly capable of supporting a well-designed system without modifications.

If traditional ceiling mounting isn't practical in your space, you have several alternatives. Wall-to-wall mounting uses opposing walls for support instead of the ceiling. Pressure-fit systems don't require permanent attachment at all – perfect for rental spaces. And free-standing gantries can be assembled in place without attaching to the building structure.

Modern track systems are increasingly designed with retrofits in mind. Many feature modular components that can steer around existing obstacles like lighting fixtures or HVAC ducts, making installation in established facilities much more straightforward.

At American Mortuary Coolers, retrofitting overhead track systems into existing funeral homes is one of our specialties. From Chicago to Dallas and across our service regions, we've completed countless installations with minimal disruption to daily operations. We understand that your business can't stop for construction – and with our approach, it doesn't have to.

Conclusion

Let's be honest - overhead track systems might not be the first thing that comes to mind when thinking about game-changing equipment. But as we've explored throughout this guide, these ceiling-mounted marvels truly transform how businesses operate across countless industries.

From helping factory workers move heavy parts through assembly lines to allowing nurses to transfer patients with dignity, these systems make the seemingly impossible feel effortless. And in our world of funeral service, they've revolutionized how we care for the deceased with respect and efficiency.

Here's what I hope you'll take away from our journey through overhead tracks:

First, these systems are incredibly versatile. Whether you need a light-duty rail for home curtains or a robust industrial conveyor handling 1000+ pounds, there's a solution designed for your specific needs.

Second, the space efficiency is remarkable. By moving activities upward, you reclaim valuable floor space - something particularly precious in compact environments like funeral preparation rooms.

Third, the safety benefits simply cannot be overstated. When staff members don't need to manually lift and transport heavy items, their risk of injury drops dramatically. I've seen this in funeral homes where back injuries were once considered an unavoidable occupational hazard.

Fourth, the customization possibilities are nearly endless. Tracks can weave around existing fixtures, accommodate unusual room shapes, and integrate perfectly with your specific workflow patterns.

Finally, while these systems represent a meaningful investment upfront, the return on investment is substantial through improved efficiency, fewer workplace injuries, and maximized space utilization. Most of our funeral home clients report that their systems paid for themselves within 12-36 months.

At American Mortuary Coolers, we've spent years perfecting overhead track systems specifically for funeral service applications. Based in Tennessee, we're proud to serve funeral professionals across all 48 contiguous states with solutions that truly understand the unique demands of your profession.

Our systems feature durable construction that withstands the rigors of daily use in mortuary environments. We provide custom design services that work harmoniously with your existing space and processes. Our nationwide delivery ensures that whether you're in Boston, Miami, Seattle or San Diego, we've got you covered. Our technicians provide expert installation, and we stand behind everything with ongoing support you can count on.

Whether you're building a new facility from the ground up or looking to improve operations in your existing space, the right overhead track system can transform how you work - making your team more efficient while enhancing both safety and dignity in the sensitive work of funeral service.

For more information about our mortuary equipment solutions, including overhead track systems designed specifically for funeral home applications, contact American Mortuary Coolers today. Our team is ready to help you find the perfect configuration for your unique facility.