Everything You Need to Know About Syringe Hub Types

The Critical Component: Understanding Syringe Hubs

A syringe hub is the connector portion of a syringe that secures the needle to the barrel, ensuring proper medication delivery and minimizing fluid waste. If you're looking for quick information about syringe hubs, here's what you need to know:

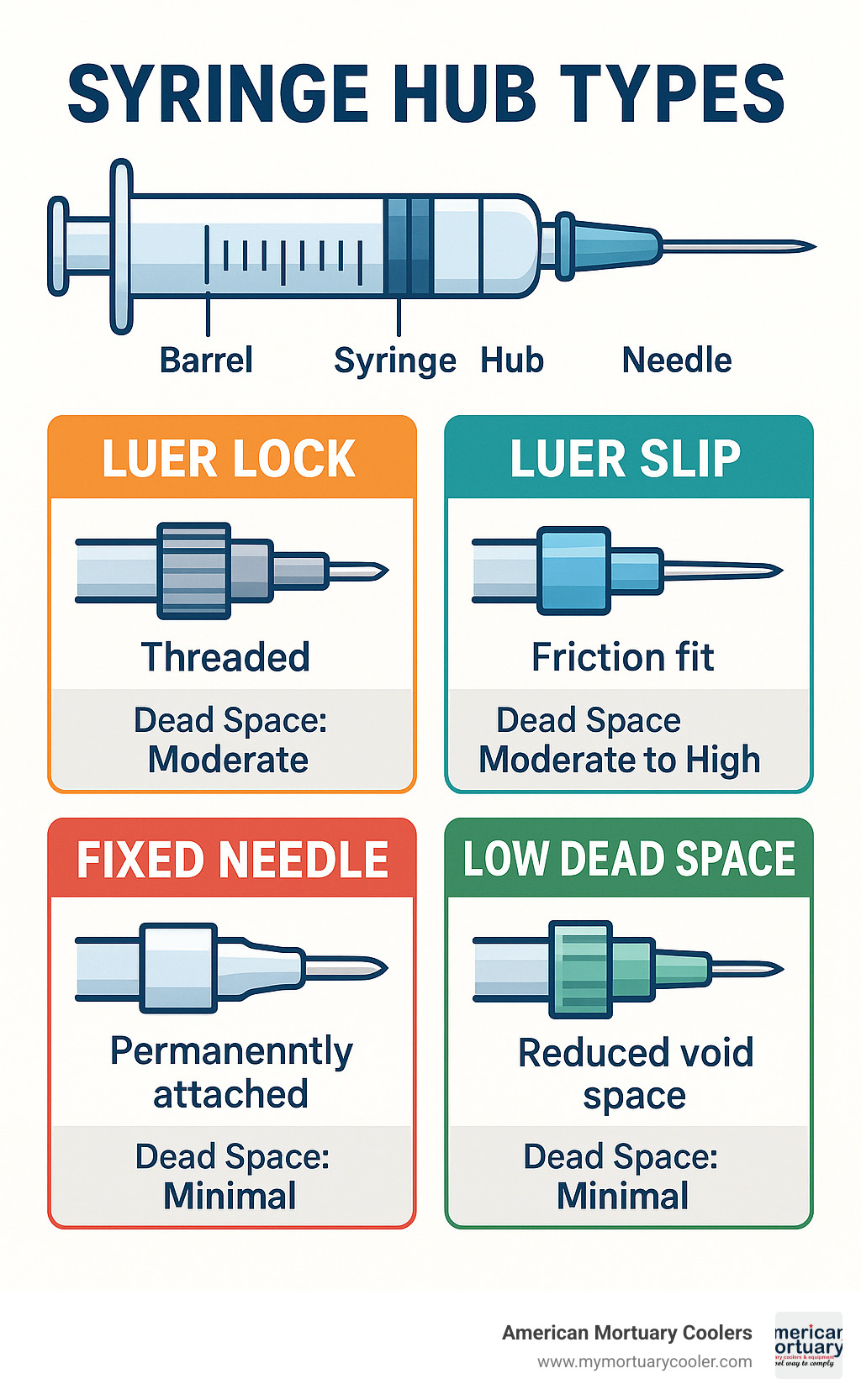

| Syringe Hub Type | Key Characteristics | Best For | Dead Space |

|---|---|---|---|

| Luer Lock | Threaded for secure connection | High-pressure injections | Moderate |

| Luer Slip | Simple friction fit | Quick procedures | Moderate to High |

| Fixed Needle | Permanently attached | Precise dosing (insulin) | Minimal |

| Low Dead Space | Reduced void space | Minimizing waste | Minimal |

| Threaded | Specialized fittings | Industrial applications | Varies |

The syringe hub might seem like a small component, but it plays a crucial role in medication delivery accuracy, safety, and waste reduction. This often-overlooked part determines how securely needles attach, how much medication is wasted, and even impacts the risk of needlestick injuries.

When healthcare providers or embalmers select syringes, the hub design significantly affects both function and safety. Hub styles vary from simple friction fits to threaded connections, each with advantages for specific applications.

I'm Mortuary Cooler, and I've spent over a decade working with medical and mortuary equipment including specialized syringe hubs used in embalming and preservation procedures. My experience with syringe hub technologies spans both clinical and mortuary applications, ensuring proper fluid delivery in critical processes.

Easy syringe hub word list:

Understanding the Syringe Hub

The syringe hub might be small, but it's the unsung hero of every injection. Think of it as the critical bridge connecting the syringe barrel to the needle - ensuring medications flow properly while maintaining a secure, leak-proof seal. Without this little connector, the whole system falls apart!

When you're handling syringes daily (as many in the funeral preparation industry do), understanding this component becomes essential. A well-designed syringe hub needs to balance several important factors: it must attach securely, minimize wasted medication, fit standard equipment, and be made of materials appropriate for its purpose.

Today's syringe hubs follow the ISO 80369-7 standards (which replaced the older ISO 594). These standards aren't just bureaucratic red tape - they ensure that when you pick up a syringe from any manufacturer, it will connect properly with your needles. This standardization has prevented countless medication errors and incompatibility headaches over the years.

What Is a Syringe Hub?

Simply put, a syringe hub is the connecting piece that joins the needle to the barrel. If you've ever changed a needle on a syringe, you've handled the hub - it's the base of the needle that attaches to the syringe tip. Some syringes come with fixed needles where the hub is permanently attached during manufacturing.

The name "hub" makes perfect sense when you think about it - just like the hub of a wheel serves as the central connection point, the syringe hub is where everything comes together. Most hubs feature either a simple tapered design (called a Luer taper) or a more secure threaded connection (known as a Luer lock).

As detailed in this breakdown of Syringe Parts Name & Function, the hub is completely different from the barrel (which holds the fluid) and the plunger (which pushes the fluid). While the barrel determines how much medication a syringe can hold, the hub design affects how securely the needle attaches and - importantly for precision work - how much medication gets left behind after injection.

Interestingly, syringe hubs can be crafted from either metal or plastic, accommodating needle diameters from tiny .008" up to much larger .220" sizes. This versatility is what allows manufacturers to create hubs that work with everything from the finest insulin needles to larger bore needles used in embalming procedures.

How the Syringe Hub Connects Needle and Barrel

The genius of the syringe hub connection lies in its simplicity. Most modern syringes use the Luer taper system - a 6% conical connection standardized worldwide. Named after German instrument maker Hermann Wülfing Luer (who probably never imagined his design would become so universal), this system creates a secure seal through precisely matched surfaces.

When you attach a needle to a syringe, you're connecting two perfectly matched conical surfaces - the male Luer taper on the syringe tip slides into the female Luer taper in the needle hub. This creates a seal that prevents leaking while allowing fluid to flow through the central channel. The beauty of the tapered design is that the more pressure applied, the tighter the seal becomes - simple physics working in your favor!

For applications requiring extra security, Luer lock systems add threads that let you twist the connection tight without excessive force. This is particularly valuable when working with thick fluids or high-pressure applications where a simple friction fit might fail - situations familiar to those performing embalming procedures.

The internal flow path through the hub significantly impacts both dosing accuracy and waste. Ideally, the channel should maintain a consistent diameter without abrupt transitions that could trap fluid. Modern hub designs increasingly focus on minimizing "dead space" - those tiny voids where valuable medications (or embalming fluids) can get trapped, never reaching their intended destination.

Syringe Hub Types Compared

Shopping for syringes can feel overwhelming with all the different hub types available. Let me break it down for you in simple terms. Each syringe hub design has its own personality and purpose – some are built for security, others for speed, and some are specially designed to waste as little medication as possible.

| Hub Type | Security Level | Dead Space | Best Applications | Limitations |

|---|---|---|---|---|

| Luer Lock | High | Moderate | High-pressure injections, viscous fluids | Requires more time to attach/detach |

| Luer Slip | Moderate | Moderate-High | Quick procedures, low-pressure applications | Can disconnect under pressure |

| Fixed Needle | Very High | Minimal | Insulin delivery, precise dosing | Not interchangeable |

| Low Dead Space | High | Minimal | Resource-sensitive settings, hazardous materials | May have limited needle options |

| Threaded (Industrial) | Very High | Varies | Automated dispensing, industrial applications | Not typically for medical use |

If you've ever noticed the colorful bases on needle hubs, those aren't just for show. The color coding system helps professionals quickly identify needle gauge – orange typically means a 25G needle, while green indicates a chunkier 21G. This international color standard saves time and reduces errors in environments.

Most syringe hubs are designed to work with standard Luer Lock Adapters, allowing them to connect to various delivery systems from IV lines to specialized equipment.

Luer Lock Syringe Hub

The Luer lock syringe hub is like the belt-and-suspenders approach to needle security – it doesn't just rely on friction but adds a twist-lock mechanism for extra safety. If you've ever seen a syringe with what looks like little "ears" that twist onto the needle, that's a Luer lock.

"The Luer lock system has been around since the days of glass syringes with metal fittings," a colleague once told me. It's reassuring to know these connections are manufactured to strict international standards (ANSI/ISO 594-1 and ISO 80369-7), ensuring your needle won't pop off mid-procedure.

The beauty of Luer locks comes into play when you're dealing with thick, viscous fluids or need to apply significant pressure during injection. In 2015, many suppliers switched to Luer lock as their standard fitting, recognizing the added security was worth the extra second it takes to twist on and off. In settings like embalming, where consistent pressure is critical, this security isn't just convenient – it's essential.

Luer Slip Syringe Hub

The Luer slip syringe hub takes a simpler approach – it's the quick-change artist of the syringe world. With no threading to fuss with, these hubs rely solely on that precisely engineered 6% Luer taper to create a friction seal.

I've found that many people underestimate how secure a properly seated Luer slip connection can be. When pressed together correctly, the tapered design creates a wedge effect that actually increases sealing pressure. It's simple but clever engineering.

Luer slip syringe hubs shine in situations where you need to switch needles quickly or when you're working with thin fluids under low pressure. They're typically less expensive too, which matters in high-volume settings. The downside? They can disconnect if significant pressure builds up – not ideal when working with thick embalming fluids or other viscous materials.

Fixed-Needle Syringe Hub

Fixed-needle syringe hubs take the "inseparable duo" approach – the needle and syringe are permanently married during manufacturing. This design eliminates the connection point entirely, which brings two major benefits: virtually no dead space and zero risk of disconnection.

The classic example is the insulin syringe. When you're measuring life-sustaining medication by the unit, you can't afford to waste a single drop in the hub. The integrated design ensures what you measure is exactly what gets delivered.

Another bonus of fixed-needle designs is improved sterility – there's no risk of contamination during needle attachment because there is no attachment step. The trade-off is flexibility – you're stuck with whatever needle gauge and length came with the syringe.

Threaded & Specialty Hubs

Beyond the medical world, specialized syringe hubs serve industrial and laboratory needs with alternative threading patterns and connection systems.

Industrial settings often use different thread patterns like 1/4-28 NPT (National Pipe Thread), 10-32 UNF (Unified Fine Thread), or metric patterns like M6 or M10. These specialized fittings are designed for specific applications – from precision dispensing in electronics manufacturing to lubricating industrial equipment.

Specialty hubs for oiling machinery feature unique designs optimized for delivering lubricants precisely where needed. Pneumatic adapters represent another category, designed to connect syringes to air-powered dispensing systems for automated manufacturing processes. As one manufacturer explained to me, "Pneumatic syringe adapters deliver air supply to the piston for precise dispense control."

Low Dead Space Syringe Hub Innovations

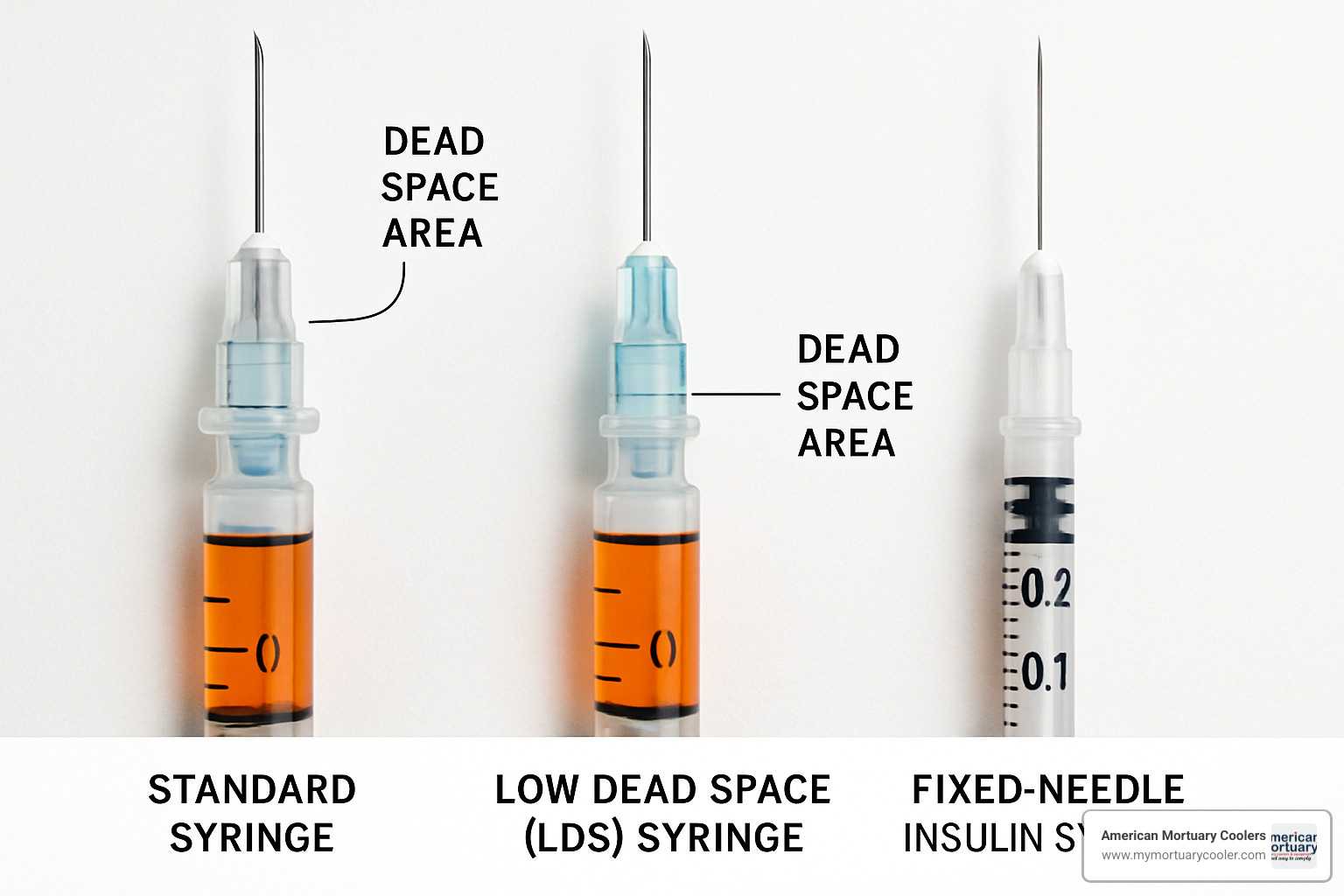

In recent years, syringe hub design has increasingly focused on reducing "dead space" – that pesky volume within the hub that traps fluid after injection. It's not just about waste (though that's important too); it's also about safety and accuracy.

Low dead space (LDS) syringe hubs represent one of the most important innovations in this field. By minimizing or eliminating voids within the hub, these designs reduce residual volume and improve dosing accuracy. Research has shown these designs can "significantly reduce blood-borne virus transmission" by minimizing the amount of blood retained in the hub after injection.

The QD Syringe with its "GlyFlo Technology" showcases this innovation with a single molded tip that "eliminates the need for separate draw needles" while minimizing dead space. Beyond being safer, these designs are more environmentally friendly due to reduced waste.

The benefits extend beyond waste reduction. By minimizing residual medication, these innovative hubs improve dosing accuracy, reduce costs (especially important with expensive medications), and decrease infection risks. For professionals in mortuary services, these advancements mean more precise fluid delivery and less waste of specialized embalming fluids.

Engineering Factors & Selection Guide for Syringe Hubs

Choosing the right syringe hub is a bit like finding the perfect pair of shoes – it needs to fit well, work reliably, and be right for the job at hand. Whether you're in healthcare or the funeral industry, understanding the engineering behind these small but mighty components can make a huge difference in your daily work.

When I talk with funeral directors about equipment selection, I often explain that the syringe hub is just one piece of the puzzle – but an important one! The Syringe Adapter | Pneumatic Adapter Assembly guide mentions that these assemblies typically use "clear PE tubing with a head that holds the syringe and a tab that locks into dispensers." This shows how hubs need to play nice with other equipment while still doing their main job properly.

For those working in funeral homes, you might also want to check out our More info about embalming supplies guide for a broader look at related equipment.

Material Choices and Performance

The materials used in syringe hubs make a big difference in how they perform. Think of it like choosing between a plastic or metal water bottle – each has its place:

Polypropylene (PP) is the everyday workhorse of hub materials. It's what you'll find in most standard medical syringes – affordable, reasonably resistant to chemicals, and gets the job done for routine use. If you're handling standard embalming procedures, these will typically serve you well.

Polycarbonate (PC) is the premium plastic option – clearer and stronger than polypropylene. I like these when I need to see exactly what's happening with fluid flow. The QD Syringe smartly combines "a polypropylene body and polycarbonate tip" to get the best of both worlds.

Brass hubs shine in industrial settings where durability matters. They're like the heavy-duty work boots of the syringe world. One manufacturer notes they've developed "proprietary plating technology" that makes brass adapters more economical to produce than traditional methods.

Stainless Steel is the premium choice when strength and chemical resistance are must-haves. Just be aware that, as one source points out, "stainless steel syringes generally are not available in sizes smaller than 5 mL" because they're trickier to manufacture in smaller sizes.

The material you choose affects everything from how much pressure the hub can handle to whether it will stand up to the chemicals you're using. For instance, if you're working with organic solvents in embalming, plastic hubs might break down, while metal hubs won't let you see what's flowing through them.

Dead Space, Accuracy & Waste

Ever noticed how there's always a bit of liquid left in the syringe after you've pushed the plunger all the way? That's "dead space," and in the syringe hub, it matters more than you might think.

Here's the reality: "Glass syringes typically have about a 1% volumetric error, while plastic syringes can have up to 5%." That might not sound like much, but when you're working with precise medications or expensive embalming fluids, it adds up fast.

Another challenge is that "plastic syringe plungers and barrels can flex under pressure, leading to volume inaccuracies as high as 5%." This is especially important to remember when you're applying significant pressure during embalming procedures.

Modern designs like the QD Syringe address this by creating "a low residual volume syringe, significantly reducing medication waste compared to traditional high dead space syringes." For funeral homes watching their bottom line, this means less wasted embalming fluid over time.

For best results, experts suggest that "the smallest dispensing volume should be ≥10% of total syringe capacity." In plain English: don't use a huge syringe for tiny amounts. A 1ml error might not matter in a 20ml syringe, but it could be disastrous in a 2ml application.

Safety, Sterility & Ergonomics

Let's talk about keeping everyone safe – including yourself. The design of a syringe hub directly affects safety, sterility, and how comfortable it is to use, especially during long embalming sessions.

Needle-stick injuries are no joke in any setting, including funeral homes. Modern hub designs are increasingly including safety features to reduce this risk. Some clever designs even eliminate the need for separate draw needles, which means fewer needle changes and lower chance of accidental sticks.

The way a syringe hub feels in your hand matters too. Products like SyringePro feature "an angled design [that] supports a natural grasp for better control" during injections. When you're doing multiple injections during an embalming procedure, ergonomics like this can prevent hand fatigue and improve precision.

Keeping things sterile is crucial, especially in funeral preparation where preventing cross-contamination is important. Luer lock hubs have an edge here – their secure connection reduces contamination risk during handling. Those individually packaged sterile needles with protective caps aren't just for show – they help maintain hub sterility until you're ready to use them.

Selecting the Right Syringe Hub for Your Application

Choosing the perfect syringe hub is about matching the tool to the task. Here's what to consider:

First, think about fluid viscosity. Embalming fluids tend to be thicker than many medical solutions, so Luer lock hubs are usually your best bet to prevent disconnection when you're applying pressure.

Need precise dosing? Low dead space hubs will minimize waste and improve consistency – particularly important when working with specialty chemicals or cosmetic embalming techniques.

Consider your safety needs based on your experience level and working environment. If you're training new staff, hubs with needle-stick prevention features might be worth the investment.

Don't forget about pressure requirements. High-pressure applications, like arterial injection, demand hubs with appropriate pressure ratings and secure connections to prevent leaks or separation.

Finally, check compatibility with your existing equipment. There's nothing more frustrating than finding your new syringes don't work with the rest of your setup!

For most embalming procedures, I recommend Luer lock hubs due to the viscosity of embalming fluids and the pressure often needed. For facial feature work and other detailed applications, fixed-needle syringes might be your best option for precision.

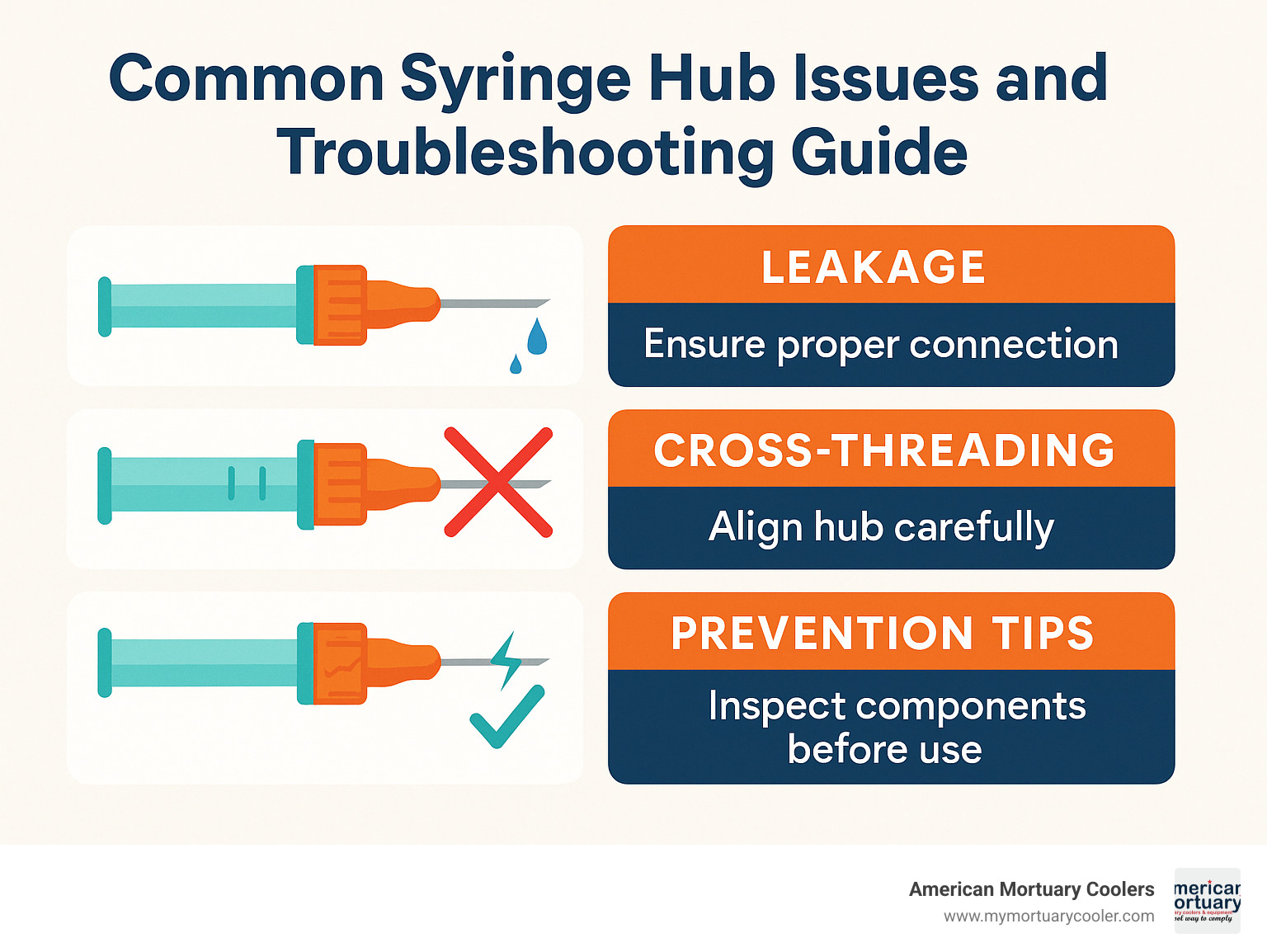

Common Issues and Troubleshooting

Even the best syringe hubs can sometimes give you trouble. Here's how to handle the most common issues:

Leakage is the number one complaint with hubs. This typically happens because of:

- Not tightening Luer locks enough

- Not fully inserting Luer slip connections

- Damaged connection surfaces

- Trying to mix and match incompatible parts

The fix? Make sure connections are properly secured, inspect parts before use, and replace damaged components rather than trying to force them to work.

Cross-threading happens when Luer lock hubs aren't lined up correctly before twisting. It's like trying to screw on a jar lid at an angle – it just doesn't work. Always align the hub carefully before applying rotational force, and if it doesn't feel right, don't force it.

Hub cracks can appear in plastic hubs if you overtighten them or use them with chemicals they're not designed to handle. Apply appropriate torque (firm but not Hulk-level!) during attachment and double-check chemical compatibility before use.

To prevent problems before they start:

- Take a quick look at all components before using them

- Follow the manufacturer's attachment instructions

- Store your supplies properly

- Replace anything that looks damaged or worn

Frequently Asked Questions about Syringe Hubs

How do I properly attach and detach a needle from a syringe hub?

Let's face it - properly connecting and disconnecting needles isn't just about getting the job done; it's about keeping yourself safe and ensuring everything works as it should. The technique differs slightly depending on what type of syringe hub you're working with.

If you're using a Luer Lock hub, think of it like screwing the lid on a jar. First, keep everything sterile by only handling the hub and syringe tip - avoid touching the needle or inner surfaces (your future self will thank you!). Line up the hub with the syringe tip so the threads match nicely, then twist clockwise until it's secure. Just be careful not to channel your inner Hercules here - overtightening can crack plastic components. When it's time to remove it, simply twist counterclockwise while maintaining your sterile technique, and immediately dispose of the needle in a sharps container.

For Luer Slip hubs, it's more of a push-and-twist motion. Keep everything sterile as before, align the hub directly with the syringe tip, then push with firm, even pressure while giving a slight twist until it's fully seated. Removing is the reverse - pull straight out with a gentle twisting motion, then straight into the sharps container it goes!

You might notice most detachable needles have two small tabs on the outside that fit into the Luer lock thread. These aren't just decorative - they provide extra security and help guide proper alignment during attachment.

What standards govern syringe hub compatibility?

Ever wonder why syringes and needles from different manufacturers work together? It's not magic - it's standards! The syringe hub world has several international standards ensuring everything plays nicely together:

ISO 80369-7 (which replaced the older ISO 594-1 and 594-2) serves as the primary international standard that specifies exact dimensions and performance requirements for Luer connectors. This is essentially the rulebook that ensures your components will connect properly.

In America, we also have ANSI/HIMA MD70.1, which aligns with the ISO requirements to maintain consistency across borders.

For the overall syringe performance, ISO 7886 specifies requirements for sterile hypodermic syringes for single use, including how the hub should perform.

These standards aren't just arbitrary rules - they specify critical details like the 6% taper angle, minimum engagement length, thread pitch for Luer locks, and material performance requirements. When manufacturers follow these standards, it ensures that hubs from different companies will connect properly, maintaining both security and proper fluid flow. It's like having a universal language for medical connections!

Which hub type minimizes medication waste the most?

If you're concerned about getting every last drop of medication (and who isn't these days with rising costs?), the Low Dead Space (LDS) syringe hubs are your best friends. These clever designs minimize waste by reducing or eliminating those pesky void spaces where fluid likes to hide after injection.

The absolute champions of waste reduction are fixed-needle insulin syringes. By eliminating the connection point between needle and syringe entirely, they deliver more accurate dosing with virtually no waste. It's like the difference between pouring water from one cup directly into another versus using a funnel that always keeps a few drops.

For situations where you need detachable needles, purpose-designed low dead space hubs like the QD Syringe hub significantly outperform standard options. These smart designs optimize the internal flow path to minimize trapped medication.

How much difference does it make? We're talking about 20-80 microliters per injection depending on the specific designs. That might sound tiny for a single use, but multiply that by dozens or hundreds of injections, and suddenly you're talking about significant amounts of medication being saved.

For our funeral home friends, while embalming fluids aren't as expensive as specialized medications, standard Luer lock hubs usually provide a good balance of security and waste minimization. However, if you're working with precise amounts of specialty chemicals or additives in your preparation room, those low dead space options might be worth considering. At American Mortuary Coolers, we've found that many of our customers appreciate having the right tools for specialized procedures, which is why we offer custom equipment solutions designed specifically for mortuary applications.

Conclusion

The humble syringe hub plays a far more significant role than most people realize. It's easy to overlook this small component, but as we've seen, it dramatically impacts medication delivery, safety, and waste reduction in both medical and mortuary settings.

Throughout this guide, we've explored how different hub designs serve unique purposes. The secure threaded connection of Luer locks provides peace of mind during high-pressure applications, while the minimal dead space of fixed-needle designs ensures maximum accuracy and minimal waste. Each design represents thoughtful engineering to solve specific challenges.

When selecting the right syringe hub for your needs, remember to consider several key factors. Think about the security requirements of your application – will you be dealing with viscous fluids or high pressures that demand a Luer lock's security? Consider how important it is to minimize waste and maximize accuracy in your specific procedures. Don't forget to evaluate the safety features needed for your particular setting and confirm compatibility with your existing equipment.

Material selection matters too – different chemicals and pressure requirements may necessitate specific materials for optimal performance and longevity. Taking time to match these requirements to the right hub design can significantly improve your procedural outcomes.

For most medical and mortuary applications, Luer lock hubs offer the best balance of security, standardization, and availability. They've become the industry standard for good reason. However, if your work demands minimal waste and maximum accuracy, investing in low dead space designs can deliver significant advantages despite their potentially higher initial cost.

At American Mortuary Coolers, we understand that even seemingly minor components like syringe hubs can make a meaningful difference in the quality and efficiency of mortuary procedures. While our primary focus is providing custom mortuary coolers and refrigeration solutions across the contiguous 48 states, we're committed to helping funeral professionals understand all aspects of their equipment needs.

For more information about our mortuary cooler expertise and custom solutions for the funeral industry, please visit our guide on mortuary cooler expertise.

By making informed choices about components like syringe hubs, funeral professionals can improve both the efficiency and quality of their preservation procedures while enhancing safety for themselves and their staff. The right hub might seem like a small detail, but as with many aspects of our profession, attention to these details ultimately reflects in the quality of care we provide.