The Ultimate Guide to Custom Built Coolers

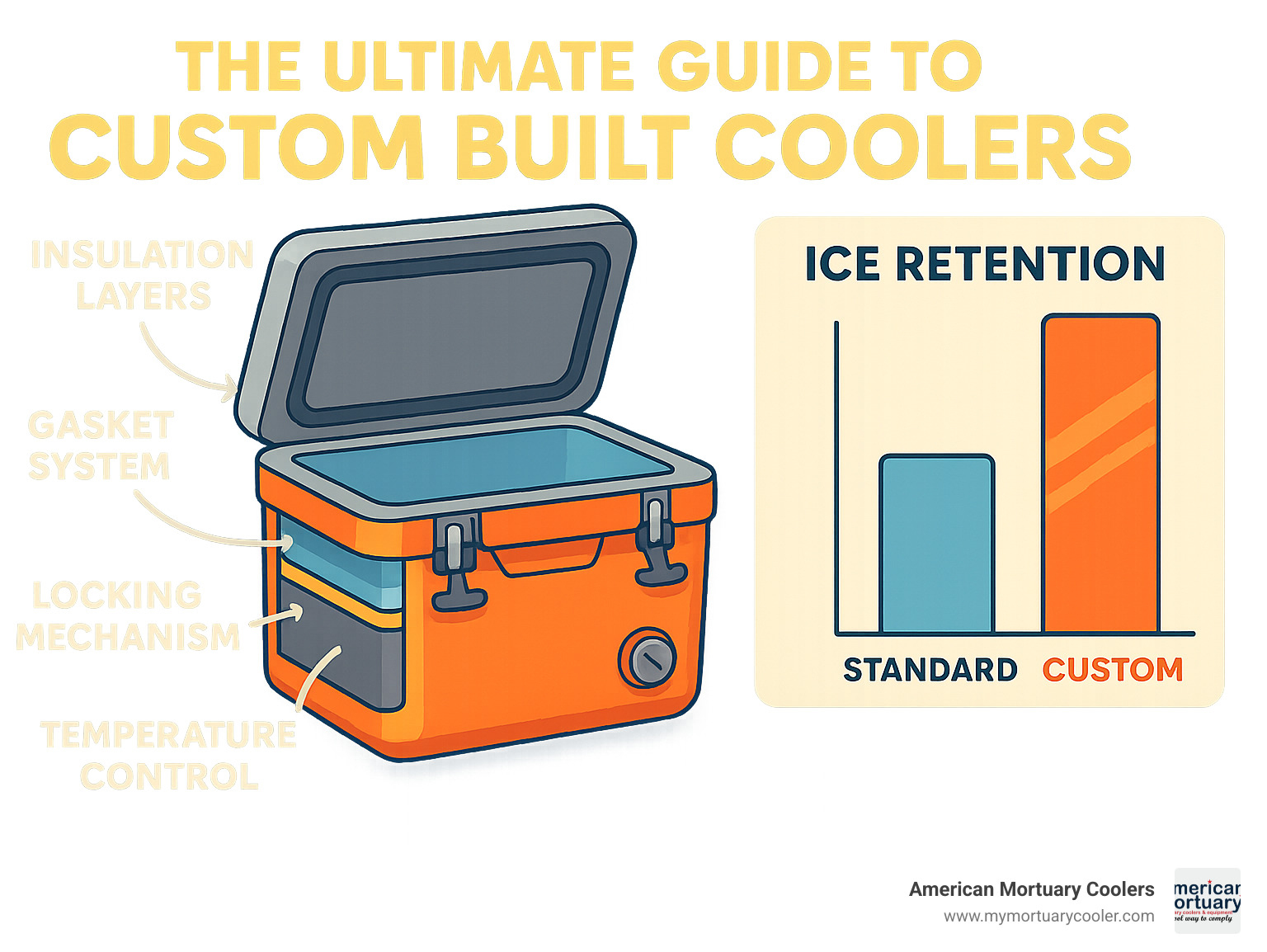

Custom built coolers are specialized cooling units designed to meet specific requirements that standard, off-the-shelf models cannot fulfill. Unlike mass-produced options, these custom solutions offer precise temperature control, customized dimensions, and personalized features to match exact needs.

| Types of Custom Built Coolers | Primary Benefits | Typical Applications |

|---|---|---|

| Hard-shell custom coolers | 5-7 day ice retention, extreme durability | Outdoor trips, hunting, fishing |

| Soft-sided custom coolers | Lightweight, 1-3 day ice retention | Day trips, beach outings, lunch transport |

| Walk-in custom coolers | Large storage capacity, precise temperature control | Restaurants, funeral homes, breweries |

| Motorized custom coolers | Remote-controlled mobility, branding opportunities | Events, tailgating, promotional use |

| Mortuary custom coolers | Specialized temperature regulation, dignified presentation | Funeral homes, medical facilities |

When investing in cooling equipment, customization provides significant advantages over standard models. Custom built coolers offer custom dimensions to maximize available space, specific temperature controls for precise preservation, and branding opportunities that lift your professional presentation.

The decision between standard and custom solutions often comes down to your specific needs. While mass-produced coolers might work for general applications, custom units shine when space constraints, unique temperature requirements, or specialized functions come into play.

"Just like your adventurous spirit separates you from the pack, your custom cooler can, too." – This philosophy from Taiga Coolers represents why many businesses and individuals choose custom solutions – they perfectly match specific needs while reflecting quality and attention to detail.

I'm Mortuary Cooler, a national-level supplier specializing in custom built coolers for funeral homes and mortuaries across the United States. With years of experience designing and manufacturing custom cooling solutions, I've helped countless funeral directors find the perfect custom built coolers to improve their facilities and services.

Simple guide to custom built coolers terms:

Understanding Custom Built Coolers: Types, Benefits & Performance

Ever wondered what makes a custom built cooler special? Imagine having a cooling solution designed exactly for your needs—whether you're planning an extended fishing trip or equipping a funeral home. The world of custom coolers is surprisingly diverse, with options ranging from portable personal units to impressive walk-in installations.

These specialized cooling champions deliver remarkable advantages that mass-produced alternatives simply can't match. Restaurant and convenience store owners love custom walk-in coolers because they slash energy costs compared to running multiple standard refrigerators. Outdoor enthusiasts treasure their personalized hard coolers from companies like Taiga, which keep ice frozen for up to 7 days—ensuring your wilderness trip includes perfectly chilled beverages from start to finish.

Quality sets custom built coolers apart. Most feature NSF certification, giving you peace of mind about public health protection—crucial for food service applications. Many walk-in models incorporate clever tongue-and-groove panels with cam-lock systems, making them easy to disassemble and relocate. This feature proves particularly valuable for growing businesses that might need to reconfigure their space down the road.

What Makes a Cooler "Custom Built"?

A custom built cooler breaks free from the one-size-fits-all approach of standard models. While off-the-shelf coolers come with predetermined dimensions, colors, and features, custom coolers are crafted to your exact specifications.

What truly separates standard coolers from their custom cousins? Dimensional flexibility tops the list—custom coolers can perfectly maximize your available space rather than forcing you to adapt to pre-set sizes. You'll also enjoy material selection freedom, choosing specific components based on your durability needs or weight requirements. Need specialized feature integration like custom racks or unique access points? No problem with a custom build.

Many businesses appreciate the branding opportunities custom coolers provide, incorporating company colors, logos, and graphics that strengthen brand identity. Perhaps most importantly, custom coolers offer performance optimization with insulation thickness and cooling systems custom to your specific temperature requirements.

High-end custom coolers often feature sophisticated cam-lock construction, creating secure assembly while maintaining the ability to disassemble and relocate when needed. This proves especially valuable in commercial settings where spatial needs evolve over time.

Main Categories of Custom Built Coolers

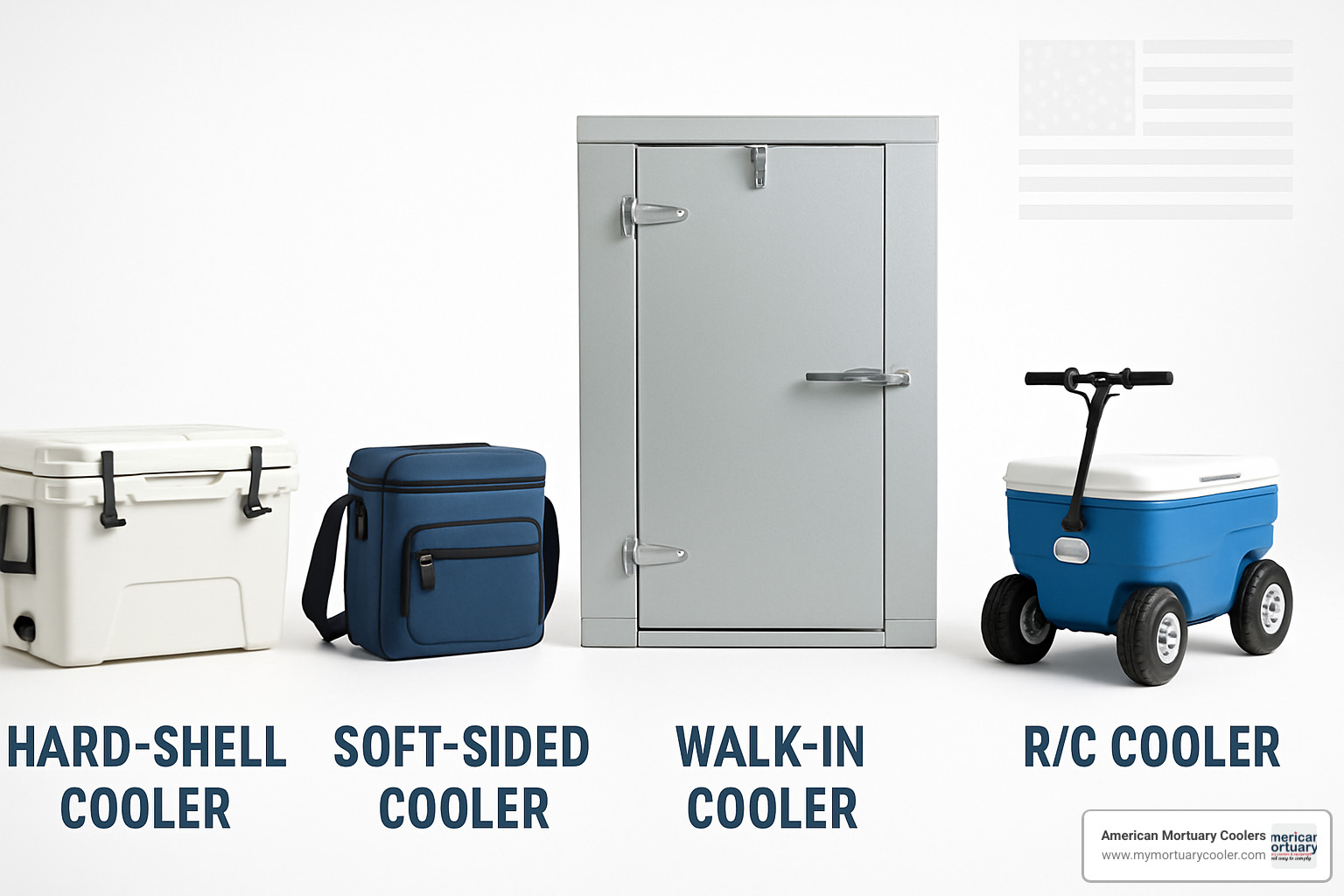

The custom built cooler marketplace includes several distinct categories, each serving unique purposes:

Hard-Shell Custom Coolers stand as the durability champions, featuring rotomolded construction with exceptional insulation properties. Companies like Taiga Coolers craft these rugged performers with thick, virtually indestructible polypropylene walls and R5 rated foam insulation. With ice retention up to 7 days, they're perfect companions for extended outdoor trips where cooling performance cannot be compromised.

Soft-Sided Custom Coolers prioritize portability without sacrificing too much performance. Engel's soft-sided models can maintain ice for an impressive 3+ days, using innovative welded seams instead of traditional stitching to create truly airtight, leakproof construction. Their lightweight design makes them ideal for day trips or situations where every ounce matters.

Walk-In Custom Coolers serve as temperature-controlled rooms essential for restaurants, floral shops, breweries, and funeral homes. American Cooler Technologies offers these professional-grade units with robust 3.5" and 5" thick panel construction and standard 8-foot heights, available in numerous sizes. They provide extensive storage with precise climate control capabilities.

Motorized Remote-Control Coolers occupy a fun, specialized niche. These innovative units can be driven via remote control, making them perfect conversation starters at events, tailgating parties, and promotional activities. Companies like C3 offer models with sports team licensing, corporate branding, or fully custom graphics options.

Mortuary Coolers address the specialized needs of funeral homes and medical facilities. At American Mortuary Coolers, we craft these units with meticulous attention to dignity, temperature precision, and whisper-quiet operation—essential qualities for this sensitive application.

| Cooler Type | Typical Capacity | Insulation Thickness | Average Ice Retention |

|---|---|---|---|

| Hard-Shell | 27-88 quarts | 2-3 inches | 5-7 days |

| Soft-Sided | 12-48 quarts | 0.5-1.5 inches | 1-3 days |

| Walk-In | 6x6x8 to custom | 3.5-5.38 inches | Continuous refrigeration |

| Motorized | 16-30 quarts | 1-2 inches | 1-2 days |

| Mortuary | 1-6 body capacity | 3.5-5 inches | Continuous refrigeration |

Key Performance Metrics That Matter

When shopping for custom built coolers, several performance factors should guide your decision-making process:

Durability stands as a fundamental consideration. The finest custom coolers use high-density materials like polypropylene with gusseted walls for maximum structural integrity. This robust construction ensures they withstand rough handling, extreme conditions, and years of demanding use.

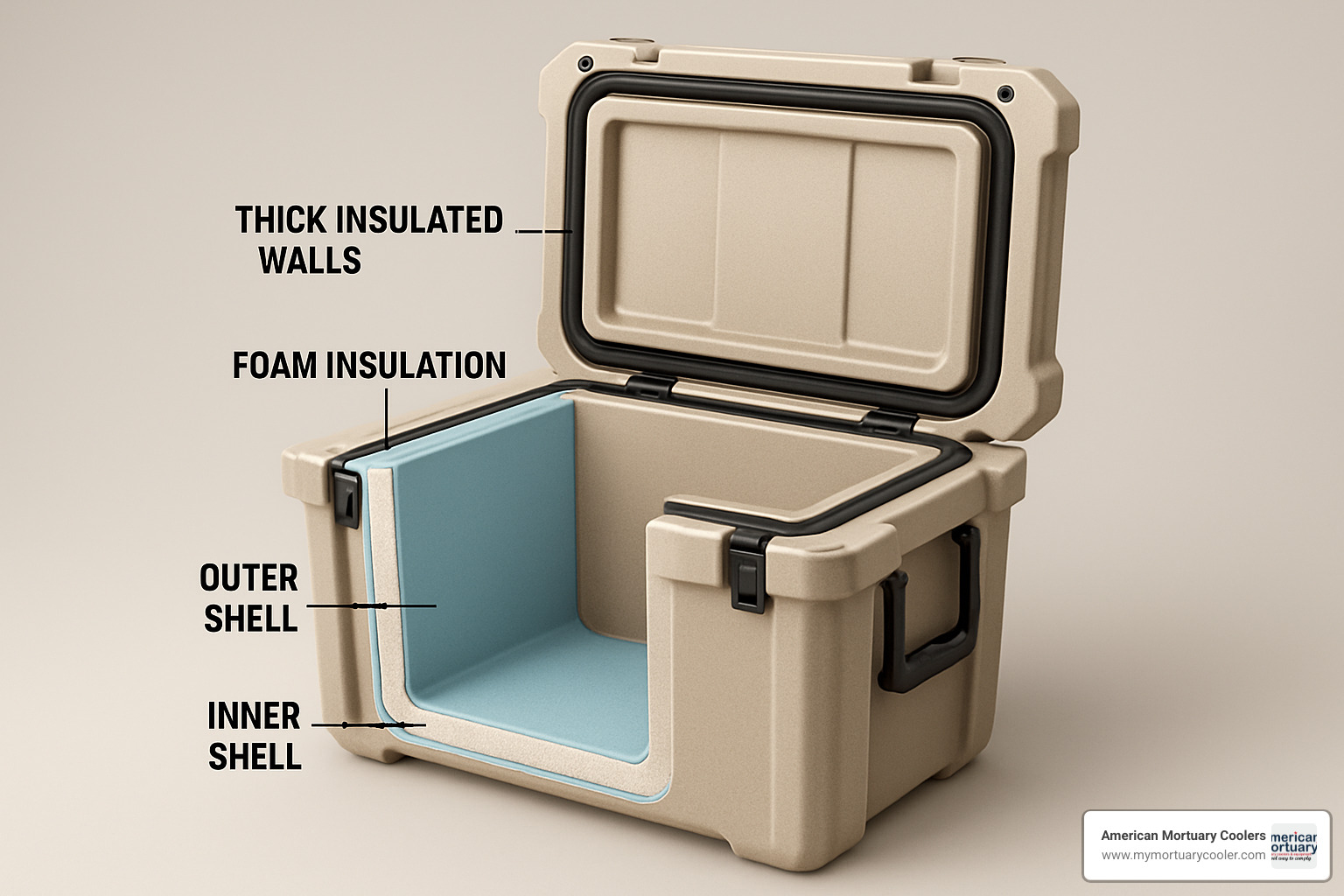

Insulation quality directly impacts performance, measured through R-value—higher numbers indicate superior insulation. Premium custom coolers feature R5 rated foam insulation or better. Closed-cell foam provides dramatically better insulation compared to open-cell alternatives, trapping cold air more effectively.

Ice retention offers a practical, real-world performance measure. Top-tier models like Taiga Coolers and Engel's UL60 hard-shell cooler preserve ice for up to a week, while quality soft-sided models typically maintain ice for three days or more—perfect for weekend getaways.

Seam construction makes a surprising difference, especially in soft coolers. Welded seams create airtight seals that prevent water leaks and retain cold air better than traditional sewn seams. This technology significantly improves cooling performance and longevity.

Weight-to-performance ratio matters tremendously for portable coolers. Innovative designs like Engel's injection-molded UL60 cooler use ultra-light, closed-cell foam insulation to maximize cooling efficiency while keeping weight manageable for real-world use.

For the DIY-inclined, resources like How to Make your own Cooler provide interesting guidance. However, professionally manufactured custom built coolers typically deliver substantially better performance thanks to specialized materials and precision construction techniques that are difficult to replicate at home.

Design, Materials & Build Process

The magic behind custom built coolers isn't just in keeping things cold—it's in the thoughtful engineering that goes into every component. When you pick up a premium custom cooler, you're holding something that's been designed from the ground up to perform in ways that mass-produced options simply can't match.

Walk-in coolers use polyurethane panels with impressive R-values that maintain steady temperatures no matter what's happening outside. For personal coolers, those beautiful rotomolded shells aren't just pretty—they create seamless, thick-walled exteriors that can take a beating while keeping the heat at bay. Companies like Taiga Coolers pack up to 3 inches of R5 rated foam insulation into their walls and lids, which is why your ice stays ice for days, not hours.

But let's be honest—looks matter too! Taiga's color options let you express yourself with single colors, two-color swirls, or even three-color camouflage patterns that make your cooler unmistakably yours. Add a custom logo plate, and suddenly your cooler becomes a conversation piece. Engel's soft-sided coolers feature a clever vacuum valve technology that creates a tighter seal—practical innovation that improves performance while looking good doing it.

Popular Customization Options for Custom Built Coolers

When it comes to making a cooler truly yours, the possibilities are nearly endless. The color palette available these days goes way beyond basic white or blue—manufacturers like Taiga can match almost any color you can imagine, and some offer those eye-catching two-color swirls or three-color camo patterns that turn heads at the campsite.

Size matters too! Whether you need a walk-in cooler from American Cooler Technologies precisely sized to fit that awkward corner in your shop, or you're choosing between Taiga's 27, 55, or 88 quart personal coolers, getting the right dimensions makes all the difference in usability.

For businesses, custom built coolers offer fantastic branding opportunities. A beautifully embossed logo or high-quality printed graphic transforms a practical item into a powerful marketing tool. Unlike those cheap stickers that peel off after one summer, proper in-house printing ensures your brand stays visible for years.

The customization doesn't stop at appearances. Practical add-ons like bait trays for fishing enthusiasts, cargo nets for extra storage, or vertical dividers to keep drinks separate from sandwiches all improve functionality. Tie-down kits, specialized handles, and rugged latches can be selected based on how you'll actually use your cooler in the real world.

At American Mortuary Coolers, we believe that even equipment for solemn purposes deserves thoughtful design that balances dignity with practicality. Our mortuary coolers may serve a specialized purpose, but they're crafted with the same attention to detail as any premium cooling solution.

From Concept to Production: Step-By-Step

Creating your perfect custom built cooler follows a journey that turns your vision into reality:

The process begins with a conversation about what you actually need—how much capacity, what temperature range, exact dimensions, where you'll use it, and any special features that would make your life easier.

Once we understand your requirements, companies like Taiga Coolers provide free renderings and quotes so you can see what you're getting before committing. This visualization step helps refine the design until it's exactly right.

After you give the thumbs-up, our engineering teams finalize all the technical specs, ensuring your cooler will perform as promised in real-world conditions.

For hard coolers, we might create custom molds, while walk-in coolers require precise panel cutting based on your approved dimensions. The manufacturing process varies by cooler type—hard coolers undergo rotational or injection molding before insulation installation, soft coolers require cutting, welding, and assembly of specialized materials, and walk-in coolers start with panel fabrication followed by door and refrigeration system installation.

Then comes the fun part—adding your custom colors, logos, or graphics. Taiga uses a patented mold process that makes their custom designs incredibly durable, while Engel applies post-mold graphics with a proprietary heating system that ensures logos don't fade or peel.

Before shipping, every cooler undergoes rigorous testing for insulation performance, structural integrity, and proper operation. When everything passes inspection, we carefully package and deliver your cooler. At American Mortuary Coolers, we handle direct delivery across all 48 contiguous states, ensuring your custom solution arrives in perfect condition.

High-Performance Materials & Construction Methods

What separates good custom built coolers from great ones comes down to materials and construction techniques that you might never see, but will definitely appreciate.

The shells of hard coolers use thick no-break polypropylene walls with internal gusseting that can take years of abuse without failing. Quality soft coolers feature 840 denier shells with TPU-filmed surfaces that resist water and stand up to rough handling. Walk-in coolers typically use aluminum or stainless steel skins over their insulation panels for durability and easy cleaning.

Insulation makes all the difference in performance. Closed-cell foam in premium hard coolers provides that coveted R5 rating that keeps ice frozen for days. High-end soft coolers might incorporate vacuum insulation technology, while walk-in coolers rely on polyurethane for its excellent R-value and structural properties.

The sealing systems are where engineering really shines. NSF-approved wrap-around vinyl gaskets create airtight seals in walk-in coolers, while magnetic closures on many mortuary cooler doors provide reliable, consistent sealing. In soft coolers, welded seams (rather than stitched ones) prevent air and water leaks that would compromise performance.

The way components connect matters too. Cam-lock systems allow walk-in panels to join securely while remaining easy to disassemble if needed. Cam-lift hinges machine-bolted to steel backing plates prevent door sagging in walk-ins, and tongue-and-groove construction creates those seamless joints between panels that maintain the cold chain.

Some of the most impressive techniques include foamed-in-place panels that eliminate thermal bridges, one-piece corners that add structural integrity to walk-ins, and vacuum valve technology that improves cooling performance in soft-sided models.

These materials and methods aren't just technical details—they're the reason your custom built cooler will outperform standard models year after year, whether you're preserving food, keeping beverages cold, or fulfilling the solemn duties of a funeral professional.

More info about designing your ideal mortuary cooler

Cost, Lead Time & Compliance Considerations

Let's talk dollars and sense when it comes to custom built coolers. I won't sugarcoat it—custom solutions typically cost more than grabbing something off the shelf. But there's real value in getting equipment that fits your exact needs like a glove and performs better too.

The price tag on your custom cooler trip will vary quite a bit depending on what you're looking for:

- Personal hard coolers from quality makers like Taiga start around $249 for a 27-quart personalized model

- Soft-sided custom options usually run between $100-300, depending on size and bells and whistles

- Walk-in coolers represent a bigger investment, typically $5,000-30,000+ based on how large and feature-rich you need it

- Those fun motorized custom coolers from C3? They'll set you back between $299-399

Good news if you're ordering in bulk—many manufacturers offer volume discounts that make custom coolers more budget-friendly for corporate gifts or promotional items. And if financing is a concern, companies like American Walk In Coolers offer 100% financing options to help spread out the investment.

As for timing, patience is sometimes required. Quick-ship walk-in coolers might arrive in as little as 14 days, while fully customized units often take 4-8 weeks. For personal coolers, a simple color customization might add just a week to production, but complex custom graphics will stretch that timeline further.

Budget Breakdown: What Influences Price?

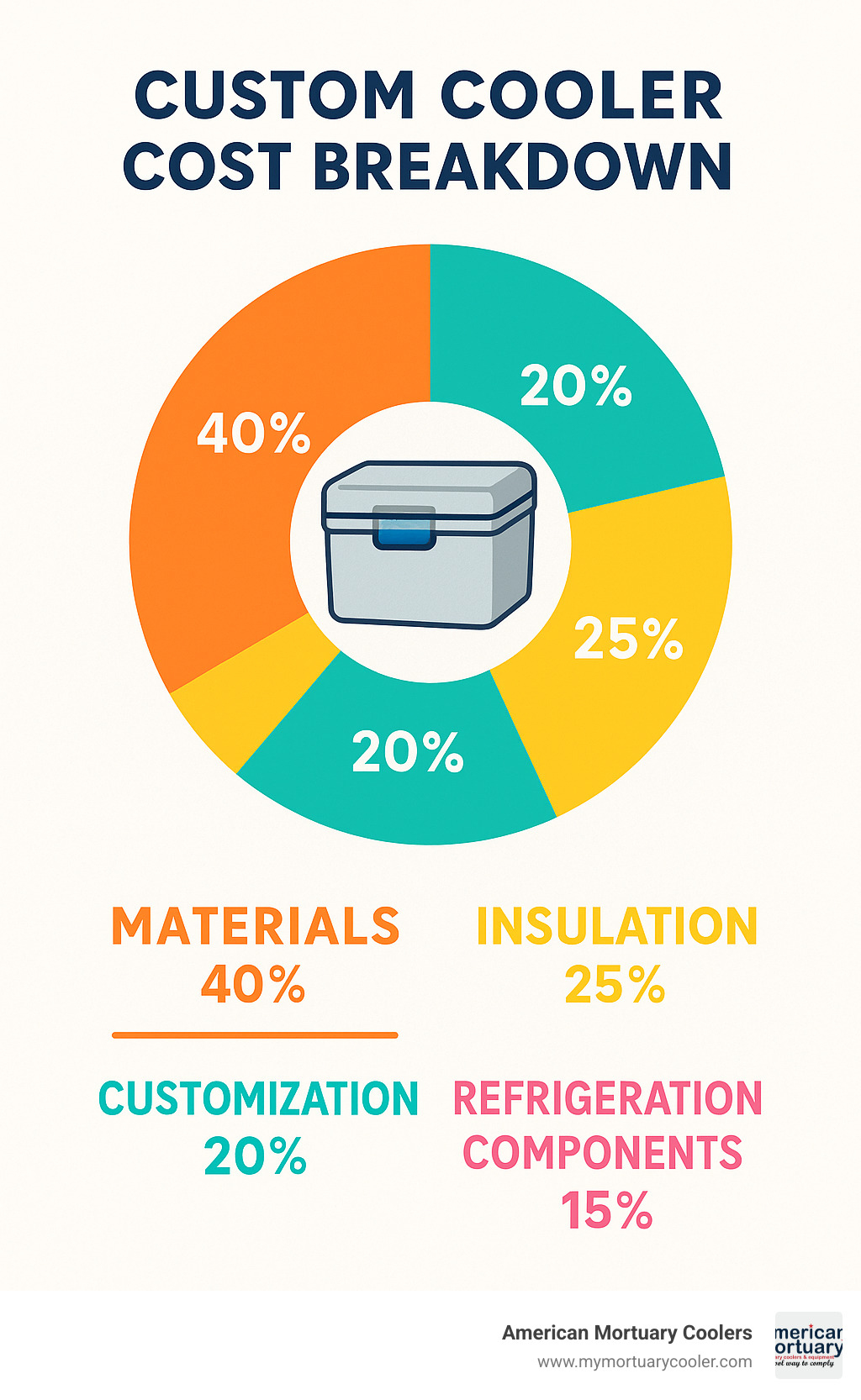

When you see the price tag on a custom built cooler, several factors are working behind the scenes to determine that number.

Size matters in the cooler world. Larger units need more materials and often involve more complex construction. You can see this clearly with Taiga's lineup—their 88-quart cooler runs about $479, nearly double the cost of their 27-quart model at $249.

Insulation quality plays a huge role too. Better insulation with higher R-values costs more but pays you back with better performance and energy efficiency. Walk-in coolers with thicker 5-3/8" panels cost more upfront than those with 4" panels, but they'll keep your energy bills lower over time.

The materials themselves influence price significantly. Premium materials like high-density polyethylene, stainless steel, or specialized composites might hit your wallet harder initially, but they'll outlast cheaper alternatives by years.

Customization complexity directly affects cost. A simple color choice won't break the bank, but multi-color swirls or custom graphic wraps require more time and expertise. Each additional feature—logo plates, custom handles, or specialized accessories—adds incrementally to the bottom line.

For powered coolers, the refrigeration system quality makes a big difference. Higher-end components like EcoNet® Enabled Unit Coolers with intelligent electronic operation cost more initially but often save money through improved energy efficiency.

Even where your cooler is made affects the price. Domestically manufactured coolers typically cost more than imported options, but often deliver higher quality and better support. Taiga Coolers proudly positions itself as "the only truly custom cooler made in the USA," with manufacturing in Texas and veteran ownership.

Here at American Mortuary Coolers, we focus on value engineering—finding ways to streamline costs without cutting corners on quality—to deliver the best possible value to funeral homes across our service regions.

Ordering Logistics & Lead Times

The journey from "I want a custom cooler" to "it's here!" involves several steps worth understanding.

Many manufacturers require minimum order quantities for custom graphics or colors, but some companies, like us at American Mortuary Coolers, happily provide single-unit custom options. Taiga Coolers also offers low minimums for custom branding, making personalization accessible for smaller orders.

The ordering process typically flows through these stages: initial consultation to nail down your specifications, creation of custom drawings or renderings, quote approval and deposit, production scheduling, manufacturing with quality control, and finally, delivery and installation if needed.

Several factors can affect your lead time. The complexity of your customization is a big one—simple changes move faster than elaborate designs. Current production queues, seasonal demand spikes, material availability, and shipping distance all play their parts too.

Shipping considerations vary by cooler type. Personal coolers ship via standard carriers, while walk-in coolers require freight shipping with special handling. Installation services may be available for larger units. We're proud to provide direct delivery across all 48 contiguous states.

Need your cooler in a hurry? Some manufacturers offer expedited options. American Walk In Coolers provides quick-ship lead times of 14 days or less for certain models. Standard sizes or limited customization options typically qualify for these faster delivery options.

If you're working with a tight deadline, it's always best to communicate those timeline requirements early in the process. This allows manufacturers like us to advise on what's feasible and explore potential expediting opportunities.

Legal & Safety Essentials

When it comes to custom built coolers, there's more to consider than just looks and performance—especially for commercial, food service, or mortuary applications.

Food safety standards are non-negotiable for coolers used in food storage. These units must maintain temperatures below 41°F/5°C and use food-safe materials. NSF Standard #7 sets the bar for refrigerated equipment compliance, ensuring public health protection.

Refrigerant regulations come into play for powered units. The EPA requires certification for anyone working with refrigerants in the U.S., with fines for improper handling potentially reaching thousands of dollars. This is particularly important for walk-in coolers and powered refrigeration units.

Energy efficiency requirements are mandated by law. The Federal Energy Independence and Security Act (EISA) specifies minimum R-values for commercial refrigeration—R-29 for coolers and R-32 for freezers. All panels and doors must meet these standards.

Several certification standards may apply to your custom cooler, including UL 471 certification for commercial refrigerators, NSF approval for food-contact surfaces, and ASTM E84 (UL 723) for fire characteristics and flame spread ratings.

Warranty coverage varies significantly between manufacturers. For walk-in coolers, 20-year panel warranties, 5-year door and compressor warranties, and 1-year parts warranties are common. Personal coolers typically offer 1-5 year warranties depending on the brand.

At American Mortuary Coolers, we ensure all our products meet or exceed relevant regulations for the funeral industry. We believe peace of mind should come standard with every cooler we build.

For more detailed information about custom cooling solutions and compliance considerations, you might find our comprehensive guide to custom cooling solutions helpful.

Choosing, Maintaining & Innovating in Custom Built Coolers

Finding the perfect partner for your custom built cooler needs isn't just about comparing prices—it's about finding a manufacturer who understands your unique requirements and can deliver quality that lasts. When I talk with funeral directors about selecting a supplier, I always emphasize the importance of checking for established reputations and relevant certifications.

Quality manufacturers proudly display their credentials. For instance, Arctic Industries has their panels certified by Intertek to meet NSF 7, UL 471, and ASTM E84 standards—not just fancy acronyms, but real assurances that their products meet rigorous safety and performance benchmarks.

Many of our clients appreciate our factory-direct approach at American Mortuary Coolers. As our friends at American Walk In Coolers put it, "because we manufacture walk-in coolers ourselves and sell them directly, there's no need for a middleman." This direct relationship often means better value and more responsive service when you need support.

Even the best custom built cooler needs some TLC to deliver years of reliable service. A little preventative care—checking gaskets regularly, cleaning condenser coils, and monitoring temperature controls—can prevent small issues from becoming big problems. Think of it like dental checkups—a little maintenance now prevents painful experiences later!

How to Select the Right Supplier

When investing in a custom built cooler, your choice of manufacturer makes all the difference. Start by evaluating their manufacturing capabilities—companies with in-house production generally maintain better quality control than those who outsource. At American Mortuary Coolers, we oversee every step of the process, ensuring each unit meets our exacting standards.

Experience matters tremendously in specialized cooling. Our deep understanding of funeral industry needs informs every design decision we make. Similarly, you'll want to ensure your supplier thoroughly understands your specific application, whether it's for a brewery, restaurant, or medical facility.

Certifications aren't just wall decorations—they're proof that a manufacturer meets industry standards. For food-related applications, NSF certification is essential. If electrical components are involved, look for UL listing. And with increasing environmental concerns, EPA compliance for refrigerant handling demonstrates responsible business practices.

The relationship with your supplier doesn't end when your cooler is delivered. Quality after-sale support can make or break your experience, especially for complex installations like walk-in coolers. American Cooler Technologies highlights their "best customer service" as a key differentiator, and we at American Mortuary Coolers pride ourselves on being there for our clients long after installation.

For long-term peace of mind, verify that replacement parts will be readily available when needed. As American Walk In Coolers notes, "we stock a complete line of replacement doors, hardware, and refrigeration components," ensuring that maintenance won't become a treasure hunt for obscure parts.

We serve funeral professionals across multiple regions including the Southeast, Southwest, Midwest, Northeast, Rocky Mountain, and Pacific regions, with locations in Johnson City TN, Atlanta GA, Chicago IL, Columbia SC, Dallas TX, Los Angeles, New York NY, and Pittsburgh PA.

Caring for Your Custom Cooler

Your custom built cooler is an investment worth protecting. A thoughtful maintenance routine extends its lifespan and ensures optimal performance when you need it most.

Start with regular inspections of critical components. Check those gaskets every few months—they're the frontline defense against temperature loss. A worn gasket is like leaving your refrigerator door slightly ajar; it forces your system to work harder and wastes energy. While you're at it, take a moment to inspect hinges and latches for smooth operation and look for any drain plug issues.

Keeping your cooler clean isn't just about appearances—it's essential for proper function and hygiene. Use mild soap and water for interior surfaces, avoiding harsh chemicals that might damage finishes or create unsafe conditions. For walk-in units, those condenser coils need quarterly cleaning to maintain efficiency—dust-covered coils make your system work much harder than necessary.

A little preventative care goes a long way. Annual lubrication of hinges and moving parts prevents wear and ensures smooth operation. If your unit includes refrigeration, regular system pressure checks help catch issues before they lead to failures. Temperature control accuracy is particularly crucial for mortuary applications, where precision maintains dignity and compliance.

Different seasons bring different challenges. Outdoor units benefit from shade during extreme heat, while humid environments require vigilance against condensation issues. In colder climates, ensure heater wires in freezer door frames are functioning properly to prevent frost buildup and door sticking.

When something seems off, address it promptly. Temperature fluctuations might indicate gasket problems or refrigeration issues. Excessive condensation could signal insulation failure. Door alignment problems affect sealing and energy efficiency. Following your manufacturer's specific guidelines ensures your custom cooler remains in optimal condition for years to come.

Cool Examples of Custom Built Coolers in Action

The world of custom built coolers is full of innovative solutions that blend function with personality. Some of my favorite examples showcase just how versatile custom cooling can be.

Have you seen those motorized remote-control coolers at tailgating events? C3's sports-licensed versions, like their Green Bay Packers model priced at $399.99, let fans transport beverages hands-free while showing team spirit. They're conversation starters that serve a practical purpose—keeping drinks cold while eliminating the need to lug a heavy cooler across crowded parking lots.

For outdoor enthusiasts who want something truly distinctive, Taiga's three-color camouflage pattern coolers demonstrate remarkable customization capabilities. These aren't just eye-catching; they deliver serious performance with up to 7-day ice retention for extended hunting or fishing trips.

The DIY community has acceptd custom cooling challenges with impressive results. Tech enthusiasts have created passive stack-effect CPU coolers using ingenious designs. One notable example featured on a Korean forum uses 36 copper tubes arranged in a radial pattern to passively cool a 125W computer processor—a beautiful marriage of form and function.

Craft breweries face unique cooling challenges, requiring specialized environments for fermentation and storage. Custom walk-in solutions with reinforced flooring support heavy tanks, while specialized racking systems and precise temperature controls create the perfect conditions for creating exceptional beer.

Advanced DIY builders have pushed boundaries with phase-change cooling systems, repurposing compressors and fabricating custom components. One builder documented achieving cooling from 95°F to 41°F in just 15 minutes under substantial heat load—an impressive feat of engineering.

At American Mortuary Coolers, we've developed specialized transport cooling solutions that maintain dignity during transfers between facilities. These units feature whisper-quiet operation, precise temperature control, and discreet exterior design—because we understand that respectful care continues even during transport.

These examples show how specialized needs drive creative cooling solutions across various industries. Whether it's keeping beverages cold at a football game or providing dignified care in the funeral industry, custom built coolers continue to evolve to meet unique challenges. For more information about custom walk-in fridges, check out our detailed guide at More info about custom walk-in fridges.

Frequently Asked Questions about Custom Built Coolers

I've spent years talking with customers about their cooling needs, and certain questions come up time and again. Let me share some straight answers to the questions we hear most often about custom built coolers.

Are custom built coolers more durable than off-the-shelf models?

In my experience, the answer is a resounding yes. When you invest in a custom built cooler, you're getting something designed to last significantly longer than mass-produced alternatives.

Think about it - when a cooler is custom-made, it uses higher-quality materials from the start. At our facility, we select premium high-density polyethylene and thicker insulation that simply outlasts what you'll find in standard retail coolers.

The construction methods make a huge difference too. Techniques like rotational molding create one-piece shells without seams that might crack under pressure. For our soft coolers, welded seams stand up to wear and tear far better than stitched alternatives that can separate over time.

I've seen countless examples where custom built coolers include reinforced hinges, handles, and corners - all those high-stress points that tend to fail first in standard models. It's like the difference between a suit off the rack versus one custom specifically for your body - both might look similar at first glance, but the custom version fits your specific needs perfectly.

How many units do I have to order for a custom design?

This is where good news comes in for many of our customers. While some manufacturers require large minimum orders (sometimes 50-100 units), the industry has evolved to accommodate smaller needs too.

For personal hard coolers, companies like Taiga have made custom branding accessible even for modest orders. If you're looking at walk-in coolers, these are typically built one at a time to your specifications, so minimum orders don't apply at all.

Here at American Mortuary Coolers, we understand that funeral homes have unique requirements, and forcing minimum orders doesn't make sense. That's why we offer single-unit customization for our mortuary coolers. Every funeral home deserves equipment that perfectly meets their specific needs, whether they're ordering one unit or twenty.

The truth is, minimum order requirements really depend on what you're customizing. Simple color choices often have lower minimums than complex custom graphics or structural modifications. It's always worth asking - you might be surprised at what's possible even for a single unit.

What is the typical lead time for a custom built cooler?

Lead times vary widely depending on what you're ordering and how customized it is. Let me break it down in real-world terms:

For personal hard coolers, you're typically looking at 2-6 weeks from order to delivery. The more complex your customization (think multi-color designs or unusual features), the longer it takes. Simple color changes might add just a week to production time.

Walk-in coolers generally take 3-8 weeks for fully custom builds, though many manufacturers offer "quick-ship" options that can arrive in as little as 14 days if you can work within certain size parameters.

Timing also depends on when you're ordering. Just like trying to book a wedding venue in June, ordering coolers during peak seasons (spring and summer for personal coolers, construction season for walk-ins) may extend your wait time.

At American Mortuary Coolers, we understand that funeral directors often face unexpected or time-sensitive situations. That's why we work closely with our customers to meet their timeline requirements whenever possible. We've developed production processes that allow for flexibility while maintaining the quality our customers depend on.

For any custom built cooler project, my best advice is simple: discuss your deadline with the manufacturer early in the process. Most of us can accommodate rush orders when necessary, and being upfront about your timeline helps us plan accordingly.

The wait is worth it, though - a perfectly custom cooling solution delivers value for years beyond what a standard unit could provide.

Conclusion

When it comes to keeping things cool, not all solutions are created equal. Custom built coolers stand in a league of their own, offering tailor-made answers to specific cooling challenges that off-the-shelf options simply can't address.

Think about it - whether you're preserving beverages on a week-long fishing trip, storing valuable inventory in a restaurant, or providing dignified care in a funeral home, the right cooling solution makes all the difference. Custom coolers deliver that difference through precise fits, optimal performance, and features designed specifically for your unique situation.

I've seen how the right custom cooler transforms operations. When you invest in customization, you're not just buying a cooler - you're eliminating the compromises and workarounds that come with standard options. That perfect dimensional fit means maximizing your available space. That specific temperature control ensures everything stays exactly as cold as it needs to be. And those branded elements lift your professional presentation in ways that generic equipment never could.

Here at American Mortuary Coolers, we take pride in crafting durable, custom cooling solutions for funeral homes across the country. Our deep understanding of funeral service allows us to create mortuary coolers that balance technical performance with the dignity your profession demands. From Tennessee to Texas, New York to California, we're committed to serving funeral professionals with equipment that truly meets their needs.

So whether you're outfitting your funeral home, planning your next outdoor trip, or equipping your commercial kitchen, I encourage you to explore the custom route. The possibilities extend far beyond what standard products can offer, resulting in equipment that works better, lasts longer, and aligns perfectly with your specific requirements.

For more information about mortuary coolers and our custom cooling solutions, please visit our resources on mortuary coolers or reach out to our team at any of our nationwide locations. We're here to help you find the perfect cooling solution for your unique needs.