The Ultimate Guide to Choosing an Embalmers Supply Company

The Evolution of Embalming Supply Companies: A Comprehensive Guide

Embalming supply companies information at a glance:

| Top Companies | Founded | Known For | Product Range |

|---|---|---|---|

| ESCO | 1886 | Porti-Boy embalming machine, first US formaldehyde fluids | Chemicals, instruments, equipment |

| Frigid Fluid | 1892 | Silicone-based fluids, casket lowering devices | Cemetery products, embalming supplies |

| H.S. Eckels | 1895 | Educational resources, global distribution | Full-service funeral supplies |

| Arlington Chemical | 1924 | National and international shipping | Chemicals, prep room supplies |

The embalming supply companies industry has evolved significantly since the late 19th century, when pioneers like C.B. Dolge and Max Huncke founded what would become one of the earliest suppliers in 1886. These early innovators transformed funeral service by introducing the first American-made embalming instruments, establishing the first U.S. embalming school, and transitioning the industry from arsenic-based preservatives to formaldehyde fluids.

Today's funeral professionals face different challenges when selecting a supplier – from ensuring product safety and compliance to finding reliable equipment that maximizes efficiency in the preparation room. The right supplier partnership can significantly impact both your operational costs and the quality of service you provide to grieving families.

I'm Mortuary Cooler, with over a decade of experience supplying specialized refrigeration solutions to funeral homes and working closely with various embalming supply companies to ensure compatibility with preservation chemicals and equipment. My work has given me unique insights into how supply choices affect the daily operations of modern funeral facilities.

Simple guide to embalming supply terms:

Tracing the Roots: History of Embalming Supply Companies

The story of modern American embalming isn't just about chemicals and techniques—it's about the visionaries who transformed funeral care. On April 13, 1886, two German immigrants with complementary talents joined forces to create what would become one of the cornerstones of the embalming industry. C.B. Dolge, a creative inventor with chemistry expertise, and Max Huncke, a skilled pharmacist, founded one of the earliest embalming supply companies in America.

Their timing couldn't have been more perfect. The Civil War had introduced Americans to embalming, but the practice remained primitive. Most supplies came from across the Atlantic, and preservation methods varied wildly in effectiveness.

About four years after establishing their company, Dolge and Huncke set up shop in the coastal town of Westport, Connecticut. What made their partnership truly special was how their skills complemented each other—Dolge's inventive mind paired with Huncke's pharmaceutical knowledge created the perfect foundation for scientific breakthroughs in preservation.

In those early days, they manufactured both chemicals and instruments out of pure necessity—there simply wasn't another reliable American source. This problem-solving approach became a hallmark throughout the industry's history: see a gap in funeral service, create a solution to fill it.

By 1893, their company underwent its first major transition when Huncke purchased Dolge's interest in the business. Under Huncke's guidance, the company continued to flourish and eventually incorporated in Connecticut as The Embalmers' Supply Company—one of the pioneering embalming supply companies we still recognize today.

Early Innovation and the First U.S. Embalming School

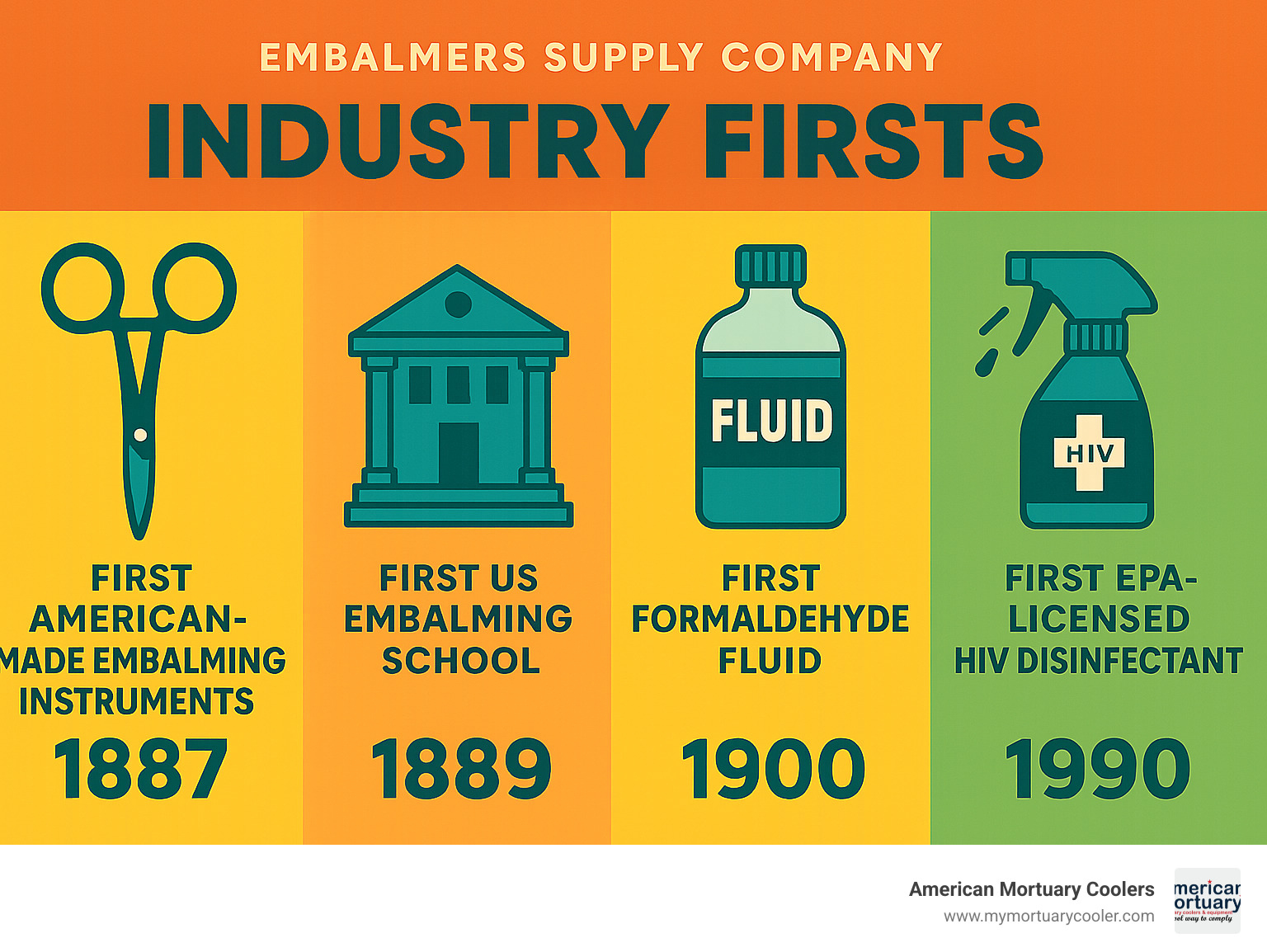

The early suppliers weren't content with just selling products—they wanted to lift the entire profession. In 1887, just a year after opening their doors, one of the first companies introduced American-made embalming instruments. This was a game-changer for funeral directors who previously relied on expensive, hard-to-get European tools.

But their most lasting contribution came in 1889, when the first permanent embalming school in the United States was established. This bold move transformed funeral service from a trade learned through apprenticeship to a legitimate profession with scientific foundations.

The school's curriculum blended chemistry, anatomy, and hands-on techniques—creating professional standards that would shape funeral education for generations to come. By formalizing training, these early companies weren't just creating customers for their products; they were elevating the dignity of funeral service and contributing to public health standards nationwide.

This educational initiative reflected a profound understanding that business success was intertwined with the professionalization of the entire industry. A better-trained embalmer meant better service for families and communities—and yes, a more knowledgeable customer for innovative products.

From Arsenic to Formaldehyde—Chemistry Milestones

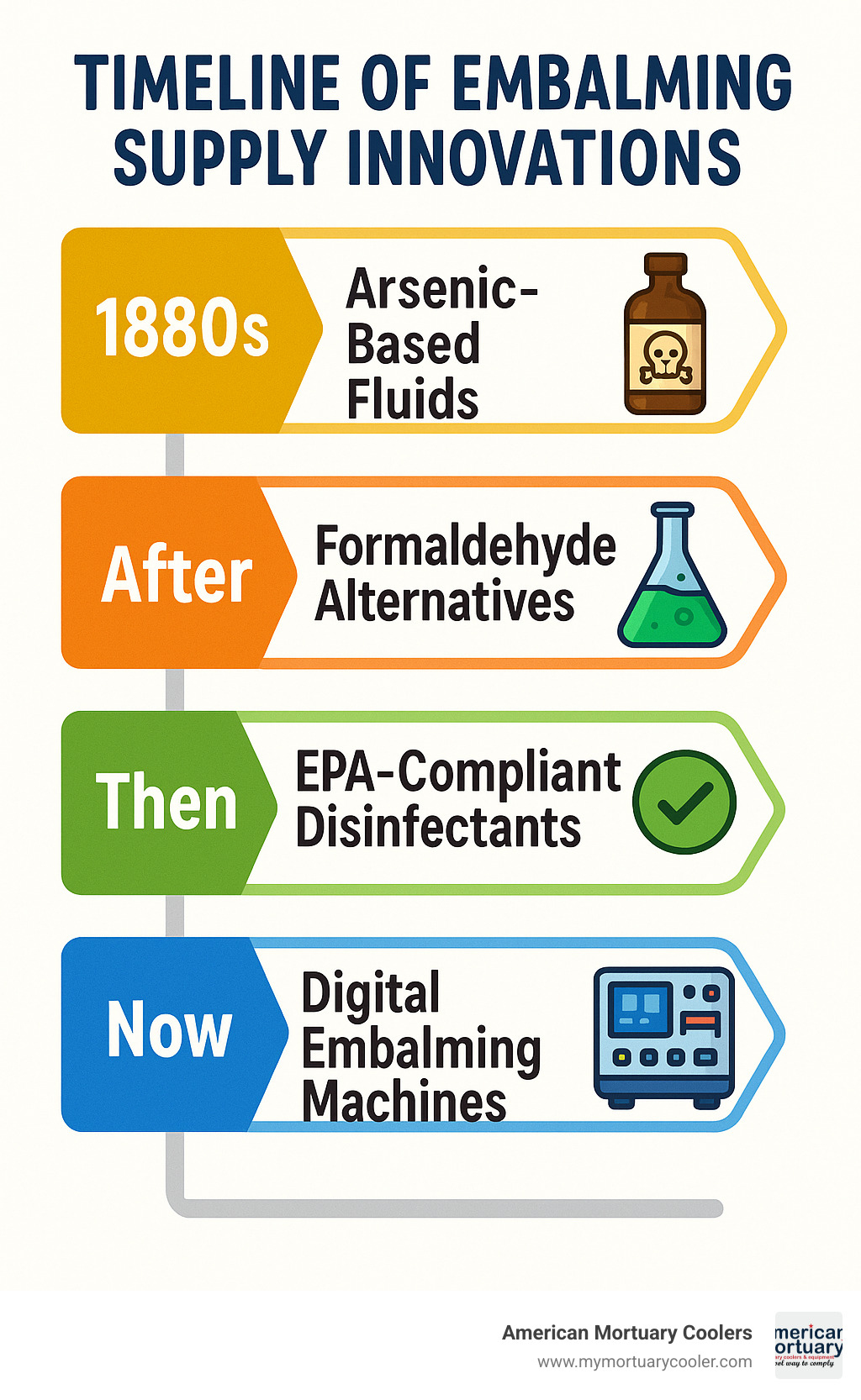

The evolution of embalming chemistry represents one of the most significant contributions from embalming supply companies, with ripple effects that transformed funeral care forever. When the industry began in the 1880s, embalming fluids contained arsenic because formaldehyde wasn't yet commercially available in America.

In 1891, a breakthrough occurred with the creation of the first compound-base embalming fluid in the United States. This innovation marked the beginning of the transition away from dangerous arsenic-based formulations.

The watershed moment arrived in 1898 when commercial formaldehyde was first imported into the United States from Germany. This single action changed American embalming forever. By 1900, the first U.S.-manufactured commercial formaldehyde fluid was being produced, establishing American independence in embalming chemistry.

Over the decades, embalming supply companies continued refining their formulations. A notable leap forward came in 1935 when synthetic wetting agents were incorporated into embalming fluids. These additives dramatically improved how preservation fluids distributed throughout the body, enhancing both preservation quality and the natural appearance of the deceased.

As historical records simply state: "Before formaldehyde was available, embalming fluids contained arsenic." This straightforward statement underscores the change in safety and effectiveness that embalming supply companies helped pioneer—a change that made modern funeral service possible.

Key Innovations that Shaped Modern Embalming

The embalming supply industry has evolved through waves of innovation, with several companies standing at the forefront of many game-changing developments. These advancements have transformed how funeral professionals care for the deceased and serve grieving families.

Back in 1903, the first American-made morgue table was manufactured, creating a standardized preparation environment for embalmers nationwide. This wasn't just another piece of equipment – it revolutionized the workspace, bringing dignity and efficiency to care for the deceased at a time when preparation rooms varied wildly in their setup and capabilities.

Throughout the 20th century, embalming supply companies continued their tradition of practical innovation. A particularly strategic move came in 1975 when the Porti-Boy embalming machine was acquired by one of the industry leaders. This wasn't merely an acquisition; it was recognizing excellence and ensuring its availability to funeral professionals everywhere. The Porti-Boy would go on to become one of the most trusted tools in preparation rooms across the globe.

Perhaps the most timely innovation came in 1990 during the height of the AIDS crisis. When funeral professionals faced serious concerns about exposure risks, the industry responded with the first EPA-licensed disinfectant specifically formulated to kill HIV. This development wasn't just about business; it was about protecting the safety of an entire profession during a time of uncertainty and fear.

The innovative spirit of embalming supply companies didn't stop there. They were the first to package cavity fluid in plastic bottles (1964), making handling safer and more convenient. They pioneered the use of plastic containers for embalming fluid (1968), reducing breakage and exposure risks. They even developed specialized instruments for specific embalming challenges, showing their deep understanding of the practical needs of funeral professionals.

These weren't just random products – they represented the industry's commitment to making embalmers' daily work safer, more efficient, and more dignified.

Spotlight on the Porti-Boy Embalming Machine

Among all the contributions to funeral service, the Porti-Boy embalming machine stands as perhaps one of the industry's crowning achievements. Acquired in 1975, this workhorse has become the gold standard in embalming equipment – the machine against which all others are measured.

The current Mark V Porti-Boy has earned its reputation through sheer reliability. As industry experts note, it's "the most versatile and dependable machine on the market with tens of thousands in service worldwide." This isn't marketing hype – it's a reality recognized across the profession.

What makes the Porti-Boy so beloved is its brilliant combination of simplicity and effectiveness. The Mark V features a magnetic drive pump with just one moving part – fewer parts mean fewer problems. Its pressure range (0-80 lbs) and flow rate (up to 1 gallon per minute) provide precise control. The 3.5-gallon glass jar offers ample capacity, while the automatic shut-off prevents running dry – a small feature that saves big headaches.

| Feature | Porti-Boy Mark V | Modern Digital Machines |

|---|---|---|

| Pressure Range | 0-80 lbs | 0-100 lbs |

| Flow Rate | 0-1 gpm | 0-1.2 gpm |

| Pump Type | Magnetic drive | Variable (often magnetic) |

| Control System | Analog | Digital touchscreen |

| Jar Capacity | 3.5 gallon glass | 3-4 gallon (glass or plastic) |

| Dimensions | 24.5" x 14" x 14" | Various (often larger) |

| Warranty | 2-year full | 1-3 years (varies) |

| Price Range | $3,400-$3,700 | $4,000-$7,000 |

While newer digital machines offer flashy touchscreens and programmable cycles, many funeral directors remain loyal to the Porti-Boy. As one 25-year veteran of the profession put it: "I've used digital machines that cost twice as much, but I always come back to the Porti-Boy. It's like the difference between a complicated smartphone and a reliable landline—when you need something to work every time without fail, the simpler option often wins."

In the funeral profession, where failure isn't an option, the Porti-Boy's enduring popularity speaks volumes about the understanding that embalming supply companies have of what really matters to the professionals they serve – reliability when it counts most.

Product Evolution: What Modern Embalming Supply Companies Offer Funeral Professionals Today

When you open a comprehensive catalog from today's leading embalming supply companies, you're looking at more than a century of refinement in funeral service supplies. From traditional preservation chemicals to state-of-the-art equipment, modern suppliers offer solutions for every aspect of preparation room work.

At the heart of most product lines are chemical formulations, thoughtfully organized into three essential categories that address the complete embalming process. Drainage chemicals like primers and specialized drainage products use chemical action rather than mechanical force to promote effective blood drainage. Premium drainage products stand out by sequestering 50% more calcium than competitors' products—a significant advantage when working with bodies in hard water regions.

The arterial fluids collections, including premium formulations from various manufacturers, often feature a slightly alkaline chemistry that optimizes both germ-killing power and protein cross-linking. I've heard from many funeral directors that these fluids deliver exceptional penetration and create that natural coloration families appreciate during viewings.

Completing the chemical trio are cavity fluids, high-index preservatives specifically designed for thorough treatment of body cavities after arterial embalming is finished.

Beyond chemicals, catalogs offer practical preparation room accessories that reflect a deep understanding of funeral professionals' daily needs. Features like 3-gallon stainless steel pails with smooth interiors make cleaning a breeze—a small detail that makes a big difference at the end of a long day. The industry has thought through the complete preparation process with innovations like chemical-resistant pail liners, visceral bags, trocar sterilization systems, and specialized tissue dryer sets with multiple attachments.

From instruments to tables and beyond, each product in the lineup of quality embalming supply companies is designed by people who truly understand the practical challenges funeral professionals face every day.

More info about Essential Embalming Equipment

Differentiating Embalming Chemicals

What makes certain chemical formulations stand apart from others on the market is their scientific approach to preservation challenges. Professional-grade fluids represent decades of research and refinement, incorporating advanced chemistry to improve performance under diverse conditions.

Many formulations feature a distinctive triple-base composition containing bacterin, destrin, and lanolin. According to technical literature, each base alone would adequately preserve a body, but the combination delivers superior results across varying conditions—a belt-and-suspenders approach to preservation reliability.

Blood liquefying agents have earned their reputation as powerful tools for mineral sequestering in the industry. They're particularly valuable when handling challenging cases with arteriosclerosis or thrombosis where blood drainage becomes problematic.

Specialized primers outperform competing products by sequestrating significantly more calcium, enhancing both blood drainage and subsequent fluid distribution throughout the tissues.

For those difficult cases involving drug-induced discolorations or physiological staining, specialized stain removers offer targeted solutions when used alongside drainage chemicals.

The slight alkalinity of quality arterial fluids improves both their germicidal properties and protein cross-linking capabilities. Many contain specialized cosmetic coloring agents designed to produce natural tissue appearance that families find comforting during viewings.

The industry demonstrated its leadership in safety innovation when the first disinfectant received EPA licensing in 1990 with specific HIV-kill claims—a groundbreaking advancement for funeral professional safety during the AIDS epidemic.

How Embalming Supply Companies Ensure Safety & Compliance in 2024

In today's highly regulated environment, embalming supply companies have adapted with rigorous quality control and comprehensive documentation practices that give funeral professionals peace of mind.

Every chemical product from reputable suppliers comes with detailed Safety Data Sheets (SDS) that meet or exceed OSHA requirements. These documents provide clear information about chemical composition, potential hazards, proper handling procedures, and emergency measures—all regularly updated to reflect the latest regulatory standards and scientific understanding.

Products requiring EPA registration carry appropriate labeling and detailed usage instructions, ensuring funeral homes can maintain full environmental compliance while using these chemicals effectively.

When the COVID-19 pandemic created unprecedented challenges, the industry stepped up by providing updated guidance and appropriate disinfection products. While many businesses struggled with closures, embalming supply companies maintained operations as essential businesses, recognizing that funeral professionals needed reliable access to embalming supplies during the public health crisis.

The approach to safety goes beyond checking regulatory boxes—leading companies accept a philosophy of continuous improvement. As scientific understanding of chemical safety evolves, they refine their formulations to minimize hazards while maintaining or enhancing effectiveness.

Scientific research on formaldehyde safety

At American Mortuary Coolers, we've seen how the commitment to safety from quality embalming supply companies complements our own focus on creating preparation environments that protect funeral professionals. Our custom mortuary coolers are designed with compatibility in mind, ensuring they work seamlessly with the chemicals and equipment supplied by respected companies across the industry. After all, when you're dealing with preservation science, having systems that work together isn't just convenient—it's essential for both safety and results.

Choosing the Right Embalming Supply Company: 7 Criteria to Compare

Finding the perfect embalming supply company isn't just about price—it's about finding a partner who'll support your funeral home through thick and thin. After years of working alongside funeral professionals, we've watched this decision make or break their daily operations. Let's walk through the seven factors that truly matter when you're comparing suppliers:

Customer Service makes all the difference when you're facing a challenging preparation at 7 PM on a Friday. The best companies offer round-the-clock support from people who've actually worked in preparation rooms—not just call center staff reading from scripts. I've heard countless stories from funeral directors who credit a knowledgeable technical specialist with saving a difficult case.

Legacy and Credibility tell you something important about reliability. Companies like ESCO (since 1886), Frigid Fluid (1892), and H.S. Eckels (1895) have weathered world wars, depressions, and pandemics while continuing to serve the profession. That kind of staying power doesn't happen by accident—it comes from consistently meeting the needs of funeral professionals across generations.

Product Breadth considerations depend on your particular operation. Some funeral homes I've worked with prefer the simplicity of one-stop shopping, ordering everything from instruments to fluids from a single trusted source. Others have developed preferences for specific products from different suppliers—perhaps one company's embalming machine, another's cavity fluid, and a third's cosmetics. There's no wrong approach here; it's about what works for your team.

Innovation Track Record became particularly important during the COVID-19 pandemic. Some suppliers responded quickly with updated protocols and specialized products, while others lagged behind. This adaptability matters because our profession faces new challenges constantly—from emerging pathogens to changing family expectations.

Safety Records and Documentation aren't just about compliance—they're about protecting your team. Look for suppliers who provide comprehensive Safety Data Sheets that go beyond the minimum requirements, with clear handling instructions and emergency protocols. EPA registrations for disinfectants should be current and clearly displayed. The best suppliers make this information easily accessible, not buried in fine print.

Logistics and Availability can make or break your preparation schedule. Regional warehousing means faster delivery times, while inventory management systems prevent backorders of critical supplies. Some funeral homes in remote locations tell me they maintain larger inventories because of shipping delays, while others in major metropolitan areas can rely on same-day delivery for emergencies. Your location should influence your supplier choice.

Pricing Transparency goes beyond the number on a catalog page. The true cost includes shipping, handling fees, and potential volume discounts. Some suppliers offer loyalty programs or professional association discounts that can significantly reduce costs over time. Ask about payment terms too—net 30 payment options can help manage cash flow for smaller operations.

At American Mortuary Coolers, we've delivered to funeral homes from small-town Tennessee to downtown Los Angeles, giving us a unique perspective on how supply chain decisions impact daily operations. We've seen how the right supplier relationships create smoother workflows and fewer emergency situations.

Comparing Major North American Embalming Supply Companies

The embalming supply landscape features several major players, each with their own distinctive approach and specialties. Understanding these differences helps you build supplier relationships that truly fit your needs:

ESCO stands as one of the elder statesmen of the industry with over 135 years of continuous operation. Their Porti-Boy embalming machine has achieved almost legendary status for reliability, with many funeral homes still using models that are decades old. Their chemical formulations—particularly the triple-base arterial fluids and specialized drainage products—have loyal users who swear by their consistent performance in challenging cases.

Frigid Fluid has carved out a unique position since 1892 with their silicone-based embalming fluids, which many embalmers find particularly effective for cases requiring superior diffusion. Their cemetery equipment division produces casket lowering devices engineered for smooth, quiet operation. I've attended several of their educational webinars and found the practical tips from experienced embalmers to be genuinely valuable rather than just sales pitches.

H.S. Eckels & Company has developed perhaps the most extensive global distribution network since their founding in 1895. Their international reach makes them a go-to source for funeral homes serving diverse cultural communities. Their password-protected professional portal offers clinical care guidelines that many funeral directors find particularly helpful for unusual cases.

Arlington Chemical Company has built their reputation on reliability since 1924. Their selective distribution model—requiring credential verification to access their online store—creates a more controlled environment. Their international shipping to the Caribbean and West Africa serves funeral homes working with families who want loved ones returned to ancestral homelands.

Champion Chemical Company, though younger than some competitors, has gained market share through responsive regional representatives and competitive pricing. Several funeral directors have told me they appreciate Champion's personalized inventory recommendations based on their specific case volume and types.

Dodge Company differentiates itself through education, with their widely-read Dodge Magazine offering practical preparation techniques rather than just product promotions. Their hands-on seminars attract embalmers looking to refine their techniques for challenging cases. Their chemical formulations often include proprietary components designed for specific preparation challenges like jaundice or tissue gas.

Many of the most successful funeral homes I've worked with maintain relationships with multiple suppliers, selecting specific products from each based on performance for their particular needs and case types.

Tips for Evaluating Catalogs, Samples, and Tech Support

When researching an embalming supply company, looking beyond glossy marketing materials gives you the real story. Here's how to conduct a thorough evaluation before committing to a supplier:

Dig deep into catalogs to find the details that matter. The best suppliers provide specific information about ingredients rather than vague claims about "superior performance." Look for detailed usage instructions that address different scenarios you might encounter. Technical specifications should be clearly stated—for example, pressure ranges and flow rates for embalming machines. Safety information should be prominent, not hidden in fine print or omitted entirely.

Request samples strategically to evaluate real-world performance. Don't just test arterial fluids on routine cases—try them on the challenging situations that cause you headaches. Notice how drainage chemicals perform on difficult cases with compromised vasculature. Even examine the packaging—is it designed for practical use in a busy prep room with easy pouring and clear labeling? The best suppliers send samples promptly with complete documentation, not just product in unlabeled containers.

Test technical support before you need it in an emergency. Call with a specific scenario—perhaps a case with severe edema or unusual discoloration—and evaluate whether you get practical advice or just a recommendation to use more product. Ask about after-hours support availability; preparation challenges don't always happen during business hours. Inquire about training opportunities, both in-person and virtual, to help your team maximize product performance.

Scrutinize warranty and service terms, especially for equipment investments. Compare not just the length of coverage but what's actually included and excluded. Ask pointed questions about replacement part availability—will they still support that embalming machine five years from now? For larger equipment like lifts or preparation tables, check whether service technicians are available in your region without excessive travel charges.

At American Mortuary Coolers, we've noticed that many of our customers value suppliers who provide comprehensive documentation and responsive technical support. This becomes particularly important when integrating new equipment like our custom mortuary coolers with existing preparation room systems.

More info about Comparing Embalming Fluid Prices

Frequently Asked Questions about Embalming Supply Companies

What makes the Porti-Boy machine unique?

If you've spent any time in preparation rooms across America, you've likely encountered a Porti-Boy embalming machine. There's a good reason they're everywhere! The Porti-Boy's magnetic drive high-speed pump is a marvel of simplicity – it has no seals and just one moving part. This means fewer headaches with maintenance and fewer chances for something to break when you least need it to.

The cabinet itself is something special too. The manufacturing techniques borrowed from the aircraft industry for manufacturing and painting it give the Porti-Boy exceptional staying power in the harsh chemical environment of a prep room. I've seen these machines still running perfectly after decades of daily use.

Performance-wise, the Mark V model gives you all the flexibility you need – pressure from 0 to 80 lbs and flow rates up to 1 gallon per minute. One feature funeral directors particularly appreciate is the automatic shut-off that prevents the machine from running dry, saving both the equipment and potentially the embalming process.

What truly sets the Porti-Boy apart, though, is its legendary reliability. With tens of thousands of units humming away in prep rooms worldwide, it's earned its reputation through consistent performance. While newer digital machines certainly have their fancy bells and whistles, many seasoned professionals still reach for the Porti-Boy when they need something they can count on every single time.

Do embalming supply companies ship internationally and what are lead times?

Yes, many major embalming supply companies maintain robust global distribution networks, making their products available to funeral professionals practically everywhere. If you're ordering within the United States, you can typically expect delivery within 1-3 business days for items they have in stock. Your wait time largely depends on how far you are from their distribution centers, which are often strategically located throughout the country.

International shipping is a bit more complex, with delivery times ranging from 7-14 business days for standard orders. This timeline can stretch depending on your location, local customs procedures, and which shipping method you select. For those urgent situations we all face in funeral service, expedited options are available – though at a premium, of course.

It's worth noting that chemical products often require additional documentation for international shipment, which can extend your wait time. If you're ordering specialized equipment like embalming machines (especially 220V export models designed for international markets), expect longer lead times. Your best bet is to contact customer service directly for current estimates – they're quite helpful and can give you the most up-to-date information.

How have embalming supply companies adapted their formulas for COVID-19 and future pathogens?

When COVID-19 hit, funeral professionals faced unprecedented challenges. Leading embalming supply companies stepped up by providing clear, practical guidance for handling coronavirus cases. While they maintained confidence that their existing high-index arterial fluids were effective against the virus, they placed strong emphasis on proper PPE usage and thorough disinfection protocols – something we at American Mortuary Coolers also prioritize.

Industry-standard disinfectants, which earned EPA licensing for HIV kills back in 1990, became essential tools for preparation room sanitation during the pandemic. Many suppliers also offered specific recommendations about which fluids to select and at what concentrations when embalming COVID-19 cases, particularly addressing the unique challenges of compromised lung tissue.

Looking forward, embalming supply companies continue to evolve their formulations based on the latest research. Their R&D teams keep a close eye on scientific developments in preservation chemistry and disinfection, incorporating new findings into product updates as they emerge.

At American Mortuary Coolers, we've noticed that the approach to handling pathogens from quality suppliers complements our own focus on creating preparation environments that minimize cross-contamination risks. Our custom mortuary coolers feature smooth, easily sanitized surfaces that work seamlessly with industry-standard disinfection products, creating a comprehensive solution for today's challenging cases.

Conclusion

The journey through the embalming supply industry gives us a fascinating window into how funeral service has evolved over generations. From the humble beginnings of pioneering companies in the 1880s to today's high-tech chemical formulations and precision equipment, these specialized suppliers have been the quiet partners helping funeral professionals provide dignified care.

Choosing the right embalming supply partner isn't just a business decision—it's about finding a company that understands your unique challenges and supports your commitment to families. Whether you value a company with century-plus experience, innovative silicone-based formulations, global reach, or reliable shipping networks, each supplier brings something special to the table.

I've seen how the right supplier relationships can transform a funeral home's operations. At American Mortuary Coolers, we've designed our products to work harmoniously with chemicals and equipment from all major embalming supply companies. This compatibility gives you the freedom to create your ideal preparation room setup without worrying about integration issues.

When we deliver our custom coolers—whether to a family-owned funeral home in Johnson City, a multi-location firm in Chicago, or a modern facility in Los Angeles—we're always impressed by the thoughtful supplier choices funeral professionals make. Your careful selection of preservation chemicals, instruments, and equipment directly impacts both your operational efficiency and the meaningful experiences you create for grieving families.

The embalming supply world continues to evolve, with new safety protocols, environmentally conscious formulations, and technological advances emerging regularly. By staying informed about each supplier's strengths and innovations, you position your funeral home to provide the most respectful, effective care possible.

The best supplier relationships are partnerships built on trust, reliability, and shared values. When your embalming supply company truly understands your mission, they become an invaluable extension of your team.