Why Alkaline Hydrolysis Equipment is Changing Modern Funeral Services

Alkaline hydrolysis equipment uses water, heat, and alkali to break down human or animal remains into bone fragments and sterile liquid - offering funeral homes a gentler, more eco-friendly alternative to flame cremation.

Key Types of Alkaline Hydrolysis Equipment:

- Human Systems: 100-500 lb capacity, 3-16 hour cycles, installed in funeral homes

- Pet Systems: 1-50 kg capacity, mobile or stationary units for veterinary facilities

- Laboratory Units: Tissue digesters for research facilities and hospitals

- Agricultural Models: Large-capacity BioLiquidator systems for farm mortality management

Operating Specifications:

- Low-temp systems: 93-98°C (200-208°F) at atmospheric pressure

- High-temp systems: 150°C (302°F) with 2+ cycles per day capability

- Water usage: 90% less than traditional 1800s chemical formulations

- Capacity range: 65 to 10,000 lb (30 to 4,500 kg)

The numbers tell the story of growing acceptance. Over 80% of families select aquamation when given the choice, and one funeral director noted: "When I purchased my machine I was hoping 50% of our families would choose Aquamation. Since the beginning, over 90% have chosen Aquamation over flame cremation."

This shift isn't just about consumer preference - it's about practical business advantages. Unlike traditional crematories that require re-bricking every 5-10 years, alkaline hydrolysis systems are built to last well over 25 years with minimal maintenance.

As Mortuary Cooler, I've worked with funeral home directors nationwide who are evaluating alkaline hydrolysis equipment to meet growing demand for sustainable disposition options.

Must-know alkaline hydrolysis equipment terms:

Why This Guide Matters

When we help funeral directors across our regions - from Johnson City, TN to Los Angeles - the most common question we hear is: "How do I choose the right alkaline hydrolysis system?" With alkaline hydrolysis equipment representing a significant investment, informed decision-making is crucial for long-term success.

Understanding Alkaline Hydrolysis Equipment & How It Works

Alkaline hydrolysis equipment creates the perfect environment for tissue dissolution using water, heat, and alkaline chemicals - typically potassium hydroxide (KOH) or sodium hydroxide (NaOH). The process breaks down organic tissue into amino acids, peptides, sugars, and soap, while leaving bone structure intact.

Instead of flame cremation's extreme temperatures over 1800°F, alkaline hydrolysis operates much cooler - essentially mimicking what happens naturally in soil, but accelerating the timeline from years to hours. The end result? A sterile solution packed with beneficial nutrients and clean bone fragments that are about 32% more abundant than traditional cremation produces.

The first alkaline hydrolysis patent was filed in 1888. Universities and hospitals have trusted this technology for donated-body programs since the 1990s. The funeral industry caught on in 2011, and now about 30 practitioners operate in approved states and provinces across North America.

Low-Temperature vs High-Temperature Systems

Low-temperature systems run between 93-98°C (200-208°F) at normal atmospheric pressure. They take longer - sometimes 16 hours for a full cycle - but they're incredibly safe and energy-efficient. There's no pressure vessel complexity, no explosion risk, and they'll run reliably for decades.

High-temperature systems operate at 150°C (302°F) and use pressure to speed things along. These are capable of running 2 or more cycles per day. They're perfect for high-volume operations, but require more energy and come with pressure vessel complexity.

Human, Pet, Laboratory & Agricultural Unit Types

Funeral homes typically install human systems with 100-500 pound capacity. These feature basket-free loading, automatic pH control, and integrated bone recovery systems. Cycle times run 3-16 hours depending on the system design.

Veterinary clinics often choose pet systems handling 1-50 kg per cycle. These come in mobile units that can travel between locations or stationary installations. At just $0.30 per kg processed, they're incredibly cost-effective.

Biocontainment labs use specialized tissue digesters for research waste. These systems completely sterilize biological material, producing DNA-free effluent after 10-20 hour cycles.

Agricultural operations rely on large-capacity BioLiquidator systems for farm mortality management, processing in just one day with zero emissions.

Core Components & Workflow

Every alkaline hydrolysis equipment system shares the same basic components:

The sealed vessel is the heart of everything - typically holding about 100 gallons of solution. Modern designs have ditched the old basket systems for safer, easier loading.

Your heat source will be either steam or electric. Electric units produce zero CO₂ emissions during operation. Steam systems can heat faster but require boiler infrastructure.

PLC controls handle temperature, pressure, pH, and timing automatically. Advanced units include remote diagnostics for troubleshooting without service calls.

The workflow is straightforward: load the remains, add the right amount of alkali (usually dry KOH flakes), start the cycle, and wait. Most systems can process their first case within 24 hours of delivery.

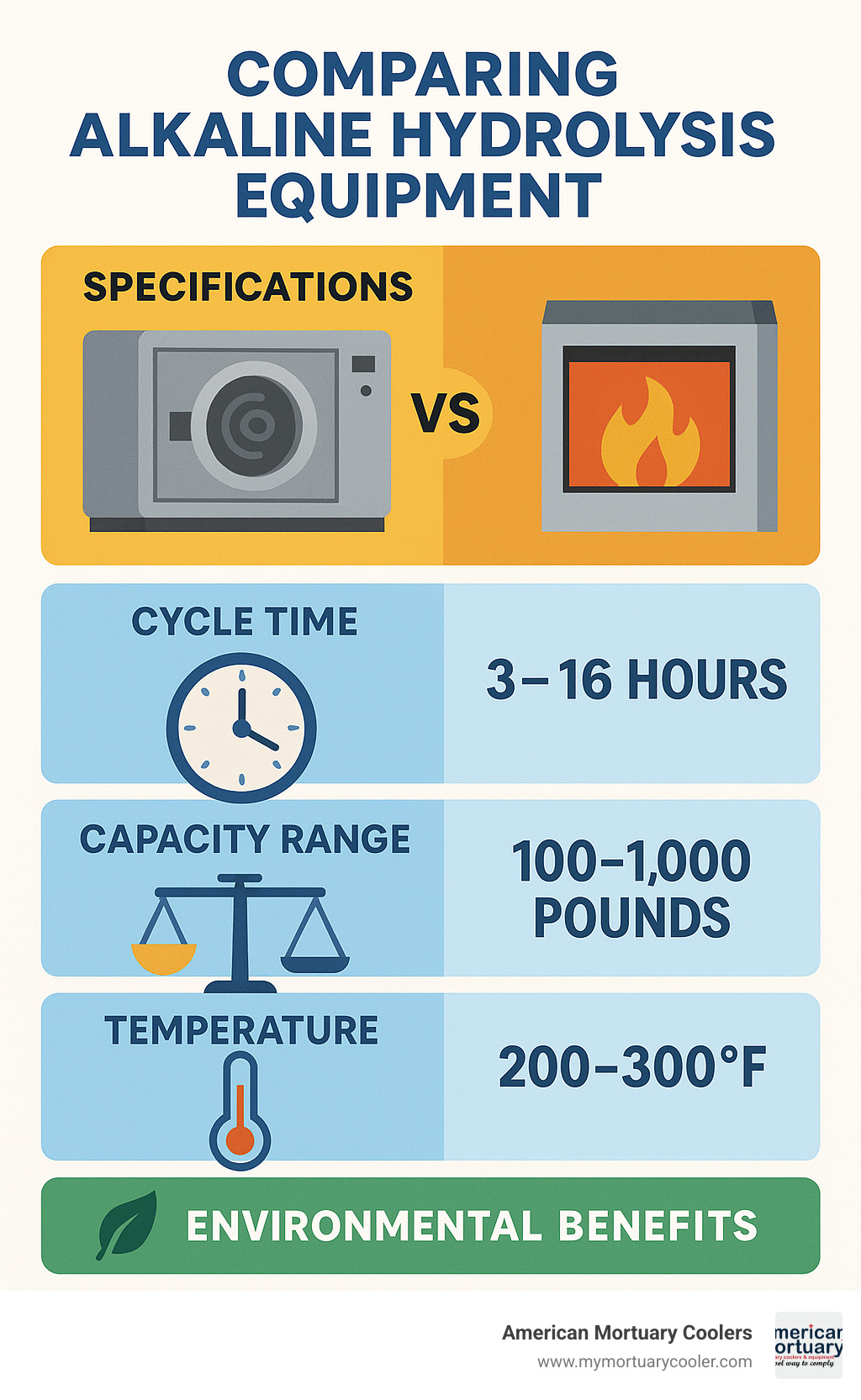

Comparing Specifications, Performance & Sustainability Metrics

When evaluating alkaline hydrolysis equipment, key performance metrics directly impact your operation's efficiency and environmental footprint. Capacity ranges from compact 65 lb units to massive 10,000 lb systems for high-volume operations.

Cycle times vary dramatically based on system design. The FC-600 system completes dissolution in about 3 hours with total cycle time of approximately 4.5 hours. Traditional systems may require 16 hours or more.

Water consumption represents a major sustainability advantage. Modern systems use 90% less water than older formulations, while the BioLiquidator uses 12× less water than legacy systems.

The effluent quality sets alkaline hydrolysis apart. The sterile liquid contains amino acids, peptides, sugars, and beneficial salts that municipal wastewater treatment facilities often welcome.

Capacity & Throughput Benchmarks

Small Systems (65-200 lb capacity):

- Ideal for: Small funeral homes, pet facilities

- Throughput: 1-2 cases per day

- Best for: Markets testing aquamation demand

Medium Systems (200-500 lb capacity):

- Ideal for: Established funeral homes

- Throughput: 2-4 cases per day with high-temp systems

- Best for: Facilities with steady aquamation demand

Large Systems (500-10,000 lb capacity):

- Ideal for: High-volume crematories, agricultural applications

- Throughput: Multiple cycles daily

- Best for: Regional processing centers

Temperature, Pressure & Water Consumption

Temperature Control:

- Low-temp systems: 93-98°C provide excellent safety margins

- High-temp systems: 150°C require pressure vessel certification

- Energy efficiency: Lower temperatures reduce utility costs

Water Consumption Facts:

- Modern systems: 90% reduction vs. traditional formulations

- Municipal impact: Reduced strain on water treatment facilities

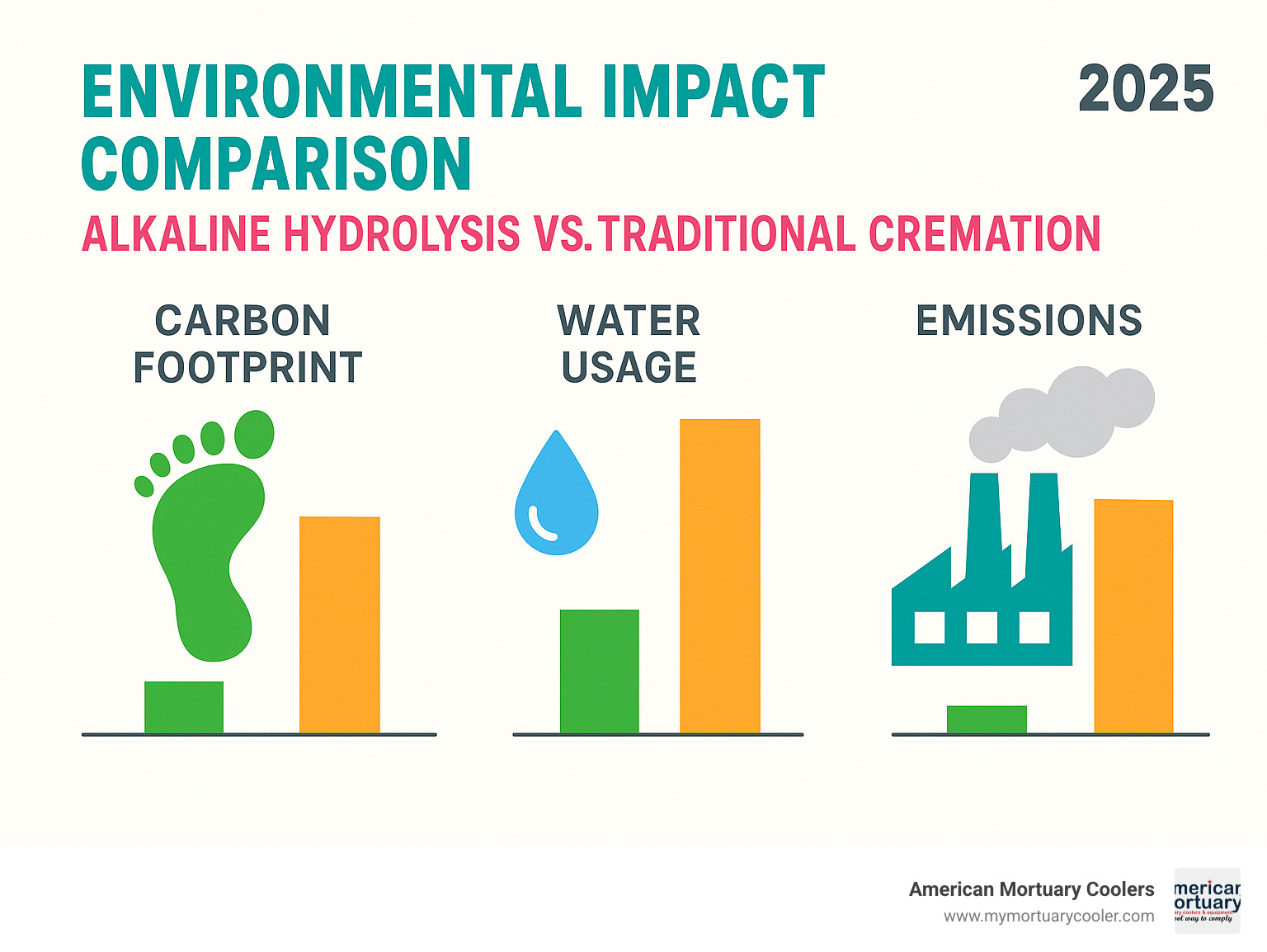

Energy Use, Carbon & Nutrient Outputs

Carbon Footprint Benefits:

- No direct CO₂ emissions during processing

- Lower energy requirements than flame cremation

- Eliminates mercury emissions from dental fillings

Nutrient Recovery:

- Sterile amino acids and peptides in effluent

- Beneficial salts improve municipal wastewater

- 33% more bone minerals recovered than flame cremation

Installation, Operation & Safety Requirements for Alkaline Hydrolysis Equipment

Getting alkaline hydrolysis equipment up and running is straightforward compared to installing flame crematories. Most systems arrive ready to operate within 24 hours - you just need electricity, water, and proper drainage. No special refractory materials, no high-temperature ducting, and no EPA air quality permits.

While traditional crematories operate at scorching 1800°F temperatures requiring extensive safety measures, alkaline hydrolysis works at gentle temperatures barely above boiling water. This eliminates most headaches funeral directors face with conventional cremation equipment.

Modern alkaline hydrolysis equipment prioritizes operator safety through thoughtful design. Features like basket-free loading eliminate wrestling with heavy metal baskets, while automatic pH control and safety interlocks protect both operators and equipment.

For detailed guidance on navigating the regulatory landscape, check out More info about regulatory steps which walks through the permitting process step by step.

Site Preparation, Utilities & Permitting

The compact footprint of alkaline hydrolysis equipment opens up installation possibilities that flame crematories simply can't match. We've helped funeral homes install systems in prep rooms, basements, and other spaces where traditional cremation would never get approval.

Foundation and space requirements are minimal - just a standard concrete pad and enough room for the unit itself. No special refractory materials or massive ventilation systems.

Utility connections keep things simple. Most systems need standard electrical service, municipal water with backflow prevention, and drainage to the municipal sewer system.

The permitting process varies by location, but it's generally much easier than getting approval for flame cremation. Building permits follow standard commercial equipment procedures. You won't need EPA Air Quality permits because there are no emissions.

The Scientific research on effluent safety provides compelling evidence that helps regulatory authorities feel confident about approving installations.

Handling Remains & Effluent

Alkaline hydrolysis equipment produces two distinct outputs, both surprisingly manageable compared to traditional cremation byproducts.

The bone mineral recovery process yields about 32% more material than flame cremation, and the fragments come out pure white and completely sterile. After proper drying, these process through standard cremated remains processors.

Effluent management involves pH adjustment from the alkaline processing solution back to neutral (7-8 range) before discharge. This sterile liquid contains beneficial amino acids, peptides, and nutrients that municipal wastewater treatment facilities often welcome.

Staff Training & Safety Protocols

Operating alkaline hydrolysis equipment safely is remarkably straightforward - most funeral directors master the basics in about an hour. Compare that to the extensive training required for safe flame crematory operation.

Training requirements focus on four key areas: basic system operation, proper alkali dosing procedures, safety protocols including appropriate PPE, and routine maintenance basics.

The safety advantages are substantial. Low operating temperatures virtually eliminate burn risks, there are no toxic combustion gases, atmospheric pressure systems eliminate explosion risks, and automated controls reduce operator error.

Legality & Compliance Map

The legal landscape for alkaline hydrolysis equipment continues expanding rapidly, with 28 U.S. states currently approving human alkaline hydrolysis and 4 Canadian provinces following suit. Nearly all jurisdictions permit pet alkaline hydrolysis.

Key approving states include California, Colorado, Florida, Georgia, Illinois, Minnesota, Nevada, Oregon, Washington, and Wyoming, plus 18 additional states with varying regulatory frameworks.

Canadian provinces that currently approve human alkaline hydrolysis include Ontario, Saskatchewan, Alberta, and Quebec, with provincial health authorities typically handling regulation.

Cost of Ownership & Manufacturer Comparison

When funeral directors ask me about alkaline hydrolysis equipment costs, I always start with the big picture. Yes, you're looking at a significant upfront investment - but while traditional crematories need expensive re-bricking every 5-10 years, these systems are built to run for well over 25 years with just routine maintenance.

The math gets interesting when you factor in operating costs. Take the Lab-50-KG model - it processes remains for as little as $0.30 per kilogram. Compare that to the ongoing fuel costs, maintenance headaches, and periodic rebuilds of flame cremation, and the numbers start working in your favor.

Most manufacturers understand that this represents a major decision for funeral homes. Financing options are readily available, and many provide lender education. Delivery typically takes 8-25 weeks from order, but most systems can process their first cycle within 24 hours of installation.

For a detailed breakdown of all ownership expenses, check out More info about water cremation costs - it covers everything from installation to long-term operating costs.

Up-Front Purchase, Installation & Retrofit Costs

Alkaline hydrolysis equipment pricing reflects the sophistication of these systems:

Equipment costs typically start around $150,000-$250,000 for smaller systems, moving into the $250,000-$400,000 range for medium-capacity units. Large systems designed for high-volume operations run $400,000 and up.

Installation expenses tell a different story than traditional crematories. Site preparation stays minimal since you're not dealing with extreme temperatures or complex refractory construction. Most manufacturers include training and startup support in the purchase price.

Financing has become much easier as lenders gain familiarity with the technology. Traditional equipment loans work well, and many manufacturers offer leasing programs.

Operating & Maintenance Expenses

The ongoing costs of alkaline hydrolysis equipment consistently surprise facility owners with how manageable they remain:

Chemical expenses stay remarkably low because you're working with simple materials. Dry KOH flakes for the alkali, basic neutralization chemicals for pH adjustment - nothing exotic or expensive.

The maintenance story gets even better. While flame crematories demand expensive re-bricking every 5-10 years, these systems just keep running. With minimal moving parts, mechanical failures stay rare. We're talking about equipment designed for 25+ year lifespans with routine maintenance only.

Top Alkaline Hydrolysis Equipment Brands Compared

The alkaline hydrolysis equipment market has matured into several strong manufacturers:

Bio-Response Solutions leads with over 35 years in the industry, focusing on both human and pet systems. Their regulatory expertise proves invaluable when navigating local approvals.

Resomation (Aquasolve) takes an innovative approach with pressure-free, low-temperature systems. What sets them apart is 100% electric operation with zero CO₂ emissions.

Fireless Cremation represents the newer generation with patent-pending chemical processes they call "alkaline hydrolysis 2.0." Their rapid dissolution times and water efficiency improvements are notable.

American Crematory brings traditional crematory manufacturing experience to the aquamation market with established service networks.

Water Cremation Systems specializes in pet cremation with strong Australian market expertise now expanding globally.

Consumer Perception, Business Impact & Future Outlook

The numbers don't lie - alkaline hydrolysis equipment is changing how families think about end-of-life care. When we talk to funeral directors who've made the switch, they consistently report the same surprising statistic: over 80% of families choose aquamation when it's offered as an option.

One director from our Tennessee region told us, "I was hoping maybe half our families would try it. Instead, we're seeing 90% of people choose water cremation over flame cremation." That's not just a trend - that's a fundamental shift in consumer preferences.

The appeal makes perfect sense. Families are increasingly concerned about their environmental impact, and alkaline hydrolysis equipment offers a gentler alternative that aligns with their values. The process feels more natural and peaceful, which resonates especially with families who found traditional cremation too harsh.

This shift creates real business opportunities for funeral homes willing to invest in the technology. The alkaline hydrolysis equipment gives you a competitive edge in markets where everyone offers the same basic services.

The pet sector shows even stronger growth patterns. In Australia, where 69% of households own pets, water cremation is becoming the preferred choice for beloved animal companions.

Environmental Marketing & Brand Differentiation

Alkaline hydrolysis equipment gives you authentic environmental benefits to market - not just green marketing fluff, but real measurable advantages that families can understand and appreciate.

The environmental story practically tells itself. You're using 90% less water than older methods, producing zero direct CO₂ emissions, and creating sterile effluent that actually benefits municipal water systems. The process recovers 32% more bone minerals for families.

Smart funeral directors are using carbon footprint calculators to show families exactly how much environmental impact they're avoiding. The "gentler choice" messaging resonates deeply with today's consumers.

Adoption Challenges & Opportunities for Funeral Homes

Installing alkaline hydrolysis equipment isn't without its challenges, but the opportunities far outweigh the problems for most funeral homes.

The biggest challenge is usually the initial investment. These systems require significant capital, though financing options are becoming more available. The good news is that unlike traditional crematories needing expensive re-bricking every few years, these systems are built to last decades.

Staff training matters more than you might expect. Your team needs to feel confident explaining the process to families and operating the equipment safely. Consumer education represents both a challenge and an opportunity - once families understand the process, adoption rates are remarkably high.

The market opportunities are substantial. You can differentiate yourself in competitive markets, command premium pricing for eco-friendly services, and potentially expand into pet cremation services.

Innovations on the Horizon

The alkaline hydrolysis equipment industry continues innovating at a rapid pace. Fully electric systems are eliminating the last traces of fossil fuel use, creating completely emission-free operation. Smart monitoring systems with AI-powered optimization are making the process even more efficient.

The policy landscape looks increasingly favorable. Additional states approve the technology almost every year, and international adoption is expanding globally. Market expansion beyond traditional funeral services offers exciting possibilities in healthcare facilities, agricultural applications, and laboratory waste processing.

Frequently Asked Questions about Alkaline Hydrolysis Equipment

The questions we hear most often from funeral directors considering alkaline hydrolysis equipment revolve around three main concerns: how it compares to traditional cremation, safety of the process, and regulatory requirements.

How does alkaline hydrolysis equipment differ from a flame cremator?

The differences between alkaline hydrolysis equipment and flame cremators are dramatic, starting with temperature. While flame cremation blasts remains at over 1800°F, alkaline hydrolysis works gently at just 93-302°F - about the temperature of a hot tub to boiling water.

Instead of fire, the process uses water mixed with alkali to break down tissue naturally. The cycle takes longer - anywhere from 3 to 16 hours compared to flame cremation's 2-3 hours - but families often see this as more respectful and less harsh.

The results tell an interesting story. You'll recover about 32% more bone minerals with alkaline hydrolysis, giving families more remains for memorialization. Instead of toxic emissions going into the air, you get sterile liquid that's actually beneficial to municipal water systems.

From a business perspective, alkaline hydrolysis equipment doesn't need the expensive refractory brick lining that flame cremators require rebuilding every 5-10 years. These systems are built to last well over 25 years with basic maintenance.

Is the effluent really safe to discharge into the sewer?

This question comes up in every conversation, and I understand why - it sounds too good to be true. But yes, the effluent from alkaline hydrolysis equipment is completely safe and often welcomed by municipal treatment facilities.

Here's what's actually in that liquid: sterile amino acids, peptides, sugars, and beneficial salts. No DNA, no pathogens, nothing harmful. The pH gets adjusted to neutral (between 7-8) before it goes down the drain.

Municipal water treatment managers often tell us something surprising - they actually prefer this effluent because the nutrients help their treatment processes work better. The sterility is complete. The process destroys everything organic, including prions and other pathogens.

What permits are required before installing a unit?

The permitting process for alkaline hydrolysis equipment is generally simpler than flame crematory approval, though it varies by location. You'll typically need three main permits: building permits for the equipment installation, sewer discharge permits for the effluent, and health department approval.

Here's the good news - you won't need EPA Air Quality permits because there are no emissions. The building permit is usually straightforward since you're not dealing with high-temperature combustion or special ventilation requirements.

The sewer discharge permit involves working with your local water authority to approve the effluent disposal. Most authorities are cooperative once they understand the sterile, beneficial nature of the liquid.

The NFDA and CANA have developed model guidelines that help standardize how regulators approach these permits. Most manufacturers provide regulatory guidance and can help you through the permitting process.

Conclusion

Alkaline hydrolysis equipment represents more than just another funeral service option - it's a genuine game-changer that's reshaping how we think about end-of-life care. When over 80% of families choose aquamation after learning about it, that tells us something important about what people really want.

The numbers speak for themselves. Alkaline hydrolysis equipment uses 90% less water than traditional methods, produces zero emissions, and lasts over 25 years without the expensive re-bricking that flame crematories need every 5-10 years. Plus, families get 32% more bone minerals for memorialization.

What really excites us at American Mortuary Coolers is how this technology opens doors that were previously closed. We've helped funeral directors install systems in historic downtown locations where traditional crematories simply couldn't get approval. That small footprint advantage isn't just convenient - it's a real business opportunity in urban markets.

The environmental benefits aren't just marketing fluff either. The sterile effluent actually helps municipal water treatment facilities instead of burdening them. That's the kind of circular economy thinking that makes sense for our future.

From our experience working with funeral directors across Tennessee, Georgia, Illinois, and beyond, we've learned that success with alkaline hydrolysis equipment comes down to three things: choosing the right system for your specific needs, getting proper training for your staff, and educating families about the gentle process.

The regulatory landscape keeps expanding too. What started with just a handful of pioneering states has grown to 28 states approving human alkaline hydrolysis, with more approvals coming regularly. Getting in early positions your facility as an innovation leader in your market.

Looking ahead, the trends all point in the same direction. Environmental regulations will keep tightening, consumer awareness will keep growing, and the technology will keep improving. The funeral directors who invest in alkaline hydrolysis equipment today are the ones who'll be best positioned for tomorrow's market demands.

This isn't just about adding another service to your menu - it's about future-proofing your business while serving families with genuine compassion. The gentler process resonates with people on an emotional level that goes beyond environmental benefits.

Whether you're considering your first aquamation system or thinking about expanding existing services, the key is working with people who understand both the technology and your unique market situation.

For more information about eco-friendly equipment solutions and how we can help you evaluate alkaline hydrolysis options for your facility, visit More info about eco-friendly equipment.