A Practical Guide to Finding the Right Walk In Cooler Threshold

Understanding Walk-In Cooler Thresholds: Essential Components for Cold Storage Integrity

A walk in cooler threshold is the transitional strip located at the bottom of a walk-in cooler or freezer doorway that creates a seal between the interior and exterior environments.

Quick Answer: Walk-In Cooler Threshold Basics

- Purpose: Seals the bottom of the door to prevent cold air loss and moisture ingress

- Standard Size: Typically 5" x 36" x 1/4"

- Common Materials: Aluminum ($43-$190) or stainless steel (up to $250)

- Load Rating: Designed for foot and hand truck traffic up to 500 lbs

- Key Feature: Often includes a 1/4" offset to protect door heater wires

The walk in cooler threshold serves as the critical boundary between your carefully controlled cold environment and the outside world. When properly installed and maintained, it prevents energy loss, reduces ice buildup, maintains food safety, and extends the life of your refrigeration equipment. A damaged or improperly installed threshold can lead to temperature fluctuations, higher energy costs, and even premature equipment failure.

For mortuary facilities, the threshold's integrity is particularly crucial. Unlike retail or restaurant applications, mortuary coolers demand unwavering reliability and specialized design considerations to maintain dignity and compliance with health regulations.

The temperature differential between your cooler (ideally 35°F to 41°F) and the outside environment creates a natural opportunity for energy loss and condensation. Your walk in cooler threshold works alongside door gaskets to create a complete seal, preventing the warm, humid air infiltration that leads to frost accumulation and increased compressor workload.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral directors select and maintain proper walk in cooler threshold components for their facilities. Having worked with countless funeral homes across America, I understand the unique requirements for maintaining dignity while ensuring reliable cold storage.

Basic walk in cooler threshold terms:

What Is a Walk-In Cooler Threshold and Why It Matters

A walk in cooler threshold (sometimes called a door sill) is that horizontal strip you see at the bottom of your walk-in cooler or freezer doorway. Don't let its simple appearance fool you – this modest component plays several vital roles in keeping your cold storage running efficiently and reliably.

Here at American Mortuary Coolers, we've witnessed how this small piece can make a world of difference in both operating costs and dependability. The walk in cooler threshold creates that crucial air-tight seal where your door gasket meets the floor. Without a properly installed threshold, cold air sneaks out while warm, humid air creeps in—creating perfect conditions for ice buildup, temperature swings, and higher energy bills.

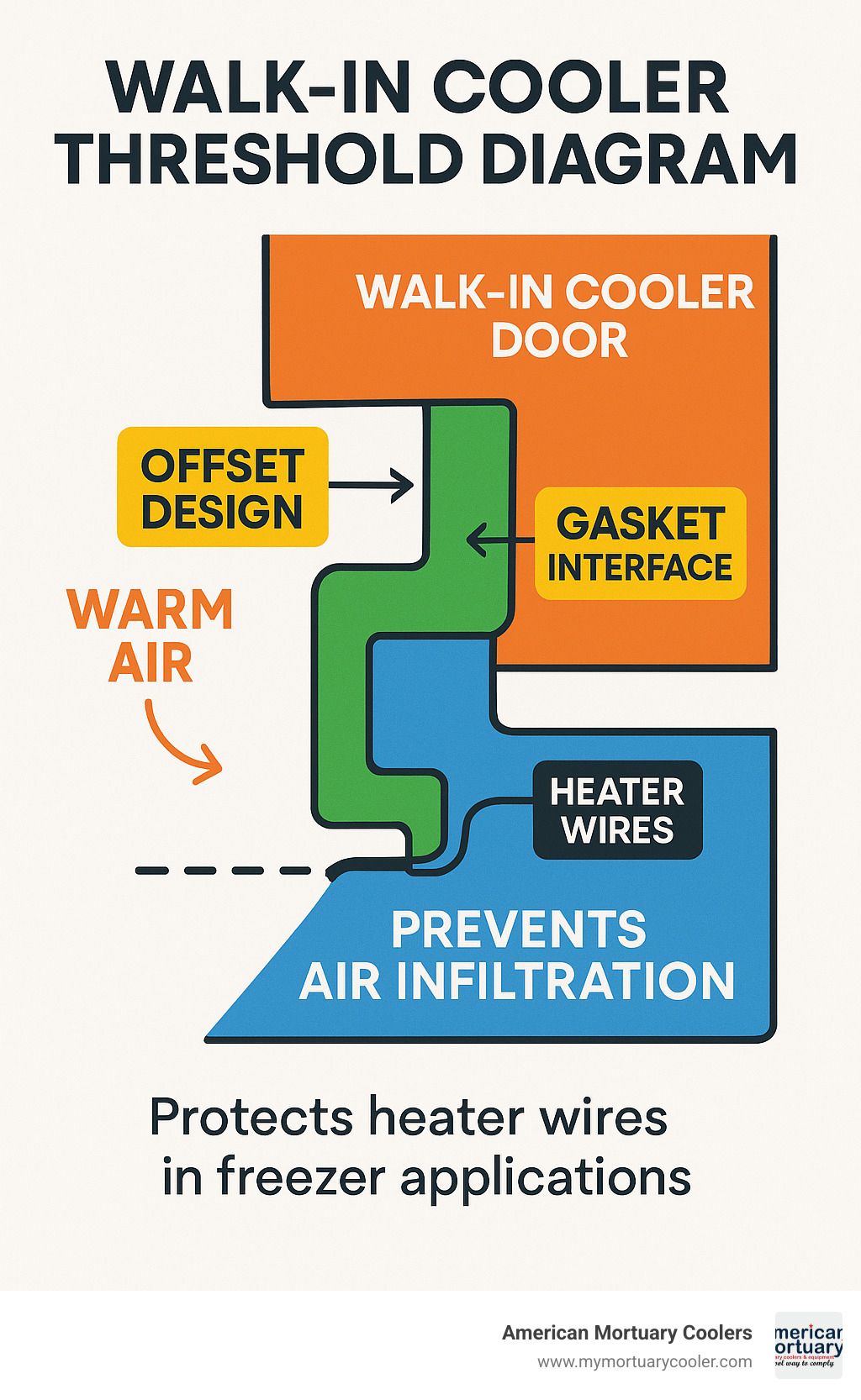

For freezer applications, your threshold often includes a clever design feature to protect door heater wires. These wires prevent frost from forming around the door frame, and the threshold's 1/4" offset keeps this system safe from damage. When heater wires become exposed or damaged, ice can prevent your door from closing properly, triggering a whole cascade of problems.

Beyond just sealing and protecting wires, your threshold provides that smooth transition between different flooring surfaces and helps distribute weight forces. This becomes particularly important in mortuary settings where carts carrying significant weight regularly cross this boundary.

The financial impact of a poorly functioning threshold shouldn't be underestimated. Industry data shows that damaged or worn door thresholds and gaskets are leading culprits behind warm air infiltration, directly increasing your energy consumption. For mortuary facilities running 24/7, these costs add up quickly, not to mention potential risks to the integrity of the cooler contents.

Anatomy of a Walk-In Cooler Threshold

Your typical walk in cooler threshold features several thoughtfully designed elements working together to create an effective seal:

The offset design includes that critical 1/4" lip creating the proper interface with your door gasket. This offset ensures the gasket compresses correctly when the door closes, forming that airtight seal you need.

The gasket interface provides a smooth, flat contact area for the door gasket. This meeting point is absolutely critical—any gaps or misalignment here will compromise your entire sealing system.

Many thresholds include a slight ramp transition on the exterior side, making it easier to wheel carts and equipment in and out. This gentle slope reduces jarring and potential damage when moving items across the threshold.

Some advanced designs incorporate a thermal break—a non-conductive material that interrupts heat transfer between warm and cold sides. This clever feature reduces condensation and energy loss at the threshold.

Quality thresholds include a secure mounting system, often with hooks that engage with cam-lock slots in the floor panel. This design keeps your threshold firmly in place despite frequent traffic.

For mortuary applications specifically, we often recommend thresholds with reinforced mounting systems and durable materials to withstand the unique conditions of mortuary environments.

Primary Functions of the Walk in Cooler Threshold

Your walk in cooler threshold serves four essential functions that directly impact cold storage performance:

Seal Integrity: First and foremost, it maintains that airtight seal at the bottom of your door. This seal prevents warm air from sneaking in and cold air from escaping, directly affecting your energy efficiency and temperature stability.

Accessibility: The threshold provides that smooth transition between the exterior floor and cooler interior, making it easier to move carts, trays, and equipment. In mortuary settings, this smooth transition is crucial for dignified and respectful handling.

Hygiene: A properly designed threshold eliminates crevices and gaps where moisture and debris might accumulate. This is particularly important in mortuary environments where sanitation is absolutely paramount.

Condensation Control: The threshold helps manage condensation that naturally forms at the boundary between warm and cold environments. By providing a controlled surface for this moisture, it prevents water from pooling on the floor and creating slip hazards or damaging surrounding structures.

At our facilities across the country, from our Johnson City, TN headquarters to our service centers in Atlanta, Chicago, and beyond, we've consistently observed that mortuary facilities with properly functioning thresholds experience fewer maintenance headaches and enjoy longer equipment lifespans.

Walk-In Cooler Threshold Types, Sizes & Materials

Shopping for a walk in cooler threshold for your mortuary facility can feel overwhelming with all the options available. After helping hundreds of funeral homes select the right components, I've found that understanding the basics of materials, designs, and sizes makes all the difference in making a smart choice.

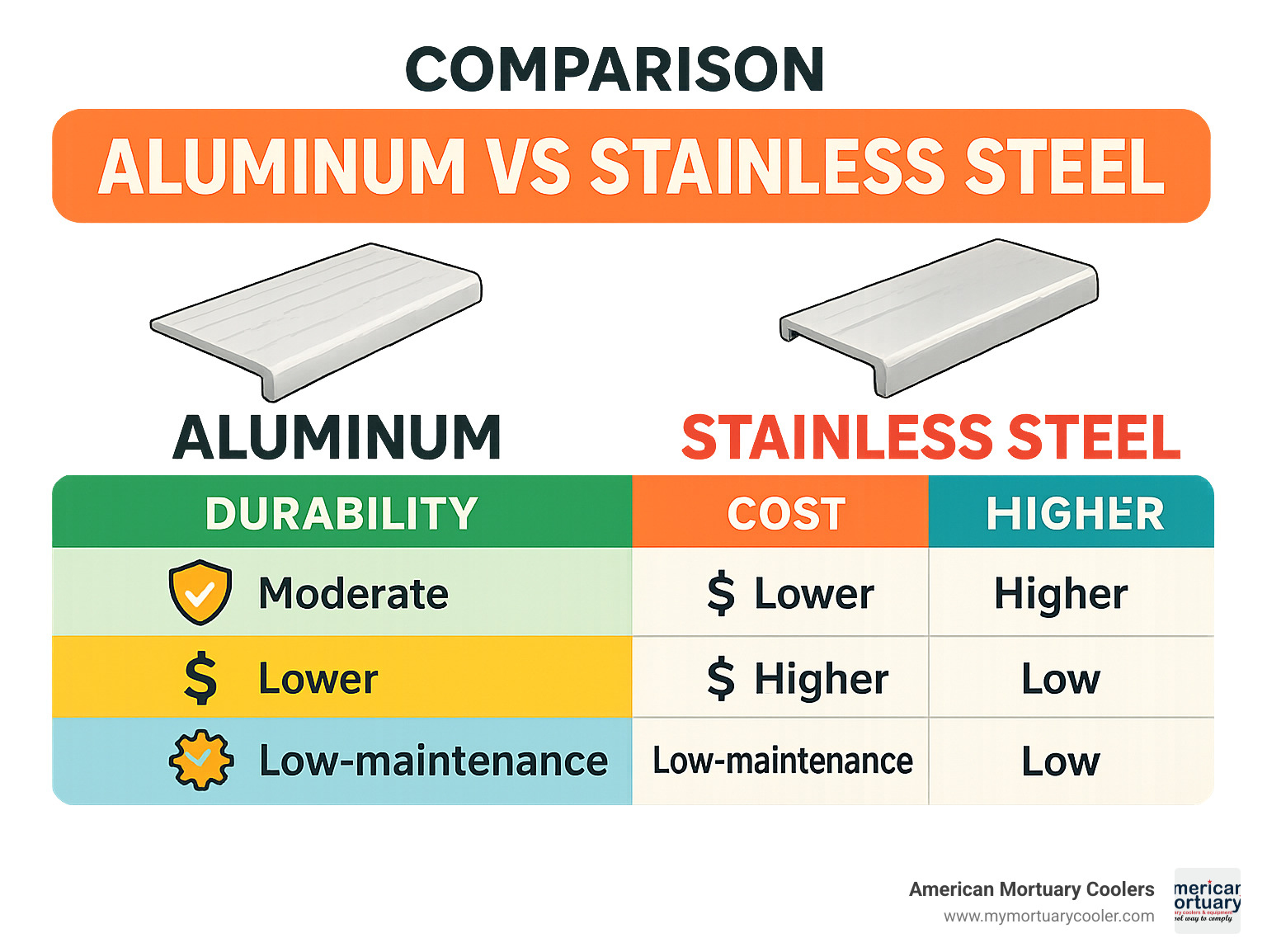

Let's talk materials first. Most of our customers choose between aluminum and stainless steel thresholds. Aluminum thresholds are our most popular option, typically priced between $43 and $190 depending on the specifics. They strike that sweet spot between weight, durability, and budget-friendliness. The anodized finish gives them decent corrosion resistance for everyday use.

For facilities that prioritize longevity and deal with strong cleaning agents, stainless steel thresholds are worth the investment at around $250. I've visited mortuary facilities where their stainless thresholds still look pristine after years of heavy disinfectant use. That resistance to harsh chemicals is invaluable in maintaining both appearance and function.

Some specialty applications might benefit from composite thresholds with their excellent thermal properties. These incorporate non-metallic materials to reduce cold transfer between environments, though they're less common in the mortuary industry.

When it comes to design, you'll encounter several variations. Raised tread thresholds feature textured surfaces that provide extra grip—a small detail that matters when staff are moving quickly in potentially damp conditions. Flush mount thresholds create that smooth, level transition that's ideal if you're frequently moving equipment with small wheels. The offset bar threshold design, with its critical ¼" lip, protects those essential door heater wires in freezer applications while creating the perfect interface for your door gaskets.

Most walk-in cooler doors fit perfectly with the industry standard walk in cooler threshold size of 5" × 36" × ¼". But don't worry if your setup is unique—custom lengths are readily available. We've crafted specialized thresholds for everything from compact units to oversized doorways.

Load ratings matter too, especially in mortuary settings where you're moving substantial weight. Standard thresholds handle foot and hand truck traffic up to 500 lbs, while reinforced versions support much more. Ideally, your threshold should match or exceed your floor system's rating, whether that's an economy floor (600 lbs/ft²), standard floor (1200 lbs/ft²), heavy duty floor (1500 lbs/ft²), or pallet jack floor (2600 lbs/ft²).

Raised vs Flush Walk in Cooler Threshold Options

The height difference between your cooler floor and exterior floor largely determines whether you need a raised or flush threshold.

Raised thresholds create a step-up ranging from ½" to 5" from the exterior floor. They're common in installations where the walk-in has an insulated floor. While they provide better thermal performance by creating a physical barrier against air movement, they often require a ramp for accessibility. In my experience visiting mortuary facilities across the country, raised thresholds with properly designed ramps offer the best balance of thermal efficiency and practical usability.

Flush thresholds, on the other hand, create that seamless transition between the exterior floor and cooler interior. They're typically used in "floorless box" installations where the cooler sits directly on an insulated concrete pad. While they eliminate the need for ramps and make cart traffic smoother, they may have slightly less effective sealing properties. Installation often requires recessing into the concrete, which needs to be planned during initial construction.

Material Pros & Cons for Walk-In Sills

After helping countless funeral directors select the right components, I've noticed that each material has its own personality and strengths.

Aluminum thresholds are the lightweights of the bunch—easy to handle, cost-effective, and resistant to everyday corrosion. They can be readily fabricated in custom sizes if your doorway has unusual dimensions. The downside? They show wear more quickly in high-traffic areas and can react poorly to certain cleaning chemicals commonly used in mortuary settings.

Stainless steel thresholds are the marathoners—built for the long haul with superior durability and excellent resistance to even the harshest cleaning regimens. While they come with a higher price tag and weigh more than their aluminum counterparts, they typically prove more economical over time due to their extended lifespan. The only real drawbacks are the initial cost and that they're harder to modify on-site if adjustments become necessary.

Composite thresholds are the specialists—excelling at creating thermal breaks that reduce condensation and heat transfer. Their non-conductive properties can be valuable in certain applications, but they generally lack the durability needed for heavy-duty mortuary use. They also have more limited availability and sometimes require special installation considerations.

For most mortuary applications, we recommend stainless steel despite the higher upfront investment. The superior durability and resistance to disinfectants make them the most cost-effective choice over the long term, especially when maintaining impeccable hygiene standards is non-negotiable. That said, plenty of our customers operate successfully with quality aluminum thresholds—it all depends on your specific needs and budget priorities.

Selecting, Sizing & Installing the Right Walk in Cooler Threshold

Choosing the appropriate walk in cooler threshold isn't just about picking a piece of metal—it's about finding the perfect match for your specific mortuary facility. At American Mortuary Coolers, we've guided countless funeral homes through this process, and we've seen how the right threshold makes all the difference.

When you're ready to select a threshold, start with a thorough site assessment. Take a good look at your facility's layout, noting the height difference between your exterior floor and cooler interior. Also consider your daily traffic patterns—are staff constantly moving carts in and out? The humidity levels in your area matter too, as they'll affect how much condensation you might face.

Your floor's load rating needs to play nicely with your threshold choice. For most mortuary applications, we recommend at least a standard floor (1200 lbs/ft²) or heavy-duty floor (1500 lbs/ft²). These ratings accommodate the specialized carts and equipment used in funeral homes without excessive wear and tear on your threshold.

Think about what crosses your threshold every day. Those specialized body carts with small wheels? They need a smooth transition and a durable threshold that won't buckle under repeated use. If you're using a freezer or very low-temperature cooler, make sure your threshold includes that critical offset design to protect your door heater wiring.

Don't forget to check your local building codes and health department regulations. Mortuary facilities often face stricter requirements, and the last thing you want is a compliance issue during your next inspection. If your facility serves the public, ADA compliance might require a ramp with a specific 1:12 slope for any raised threshold.

Budget-wise, you'll find options ranging from $43 for basic aluminum thresholds to $250+ for premium stainless steel. But think beyond the price tag—consider how long each option will last in your specific environment. Sometimes spending more upfront saves significant money down the road, especially in busy facilities.

For more comprehensive information on walk-in cooler features and pricing, check out our Complete Guide to Walk-In Cooler Features and Prices.

Step-by-Step Walk in Cooler Threshold Installation

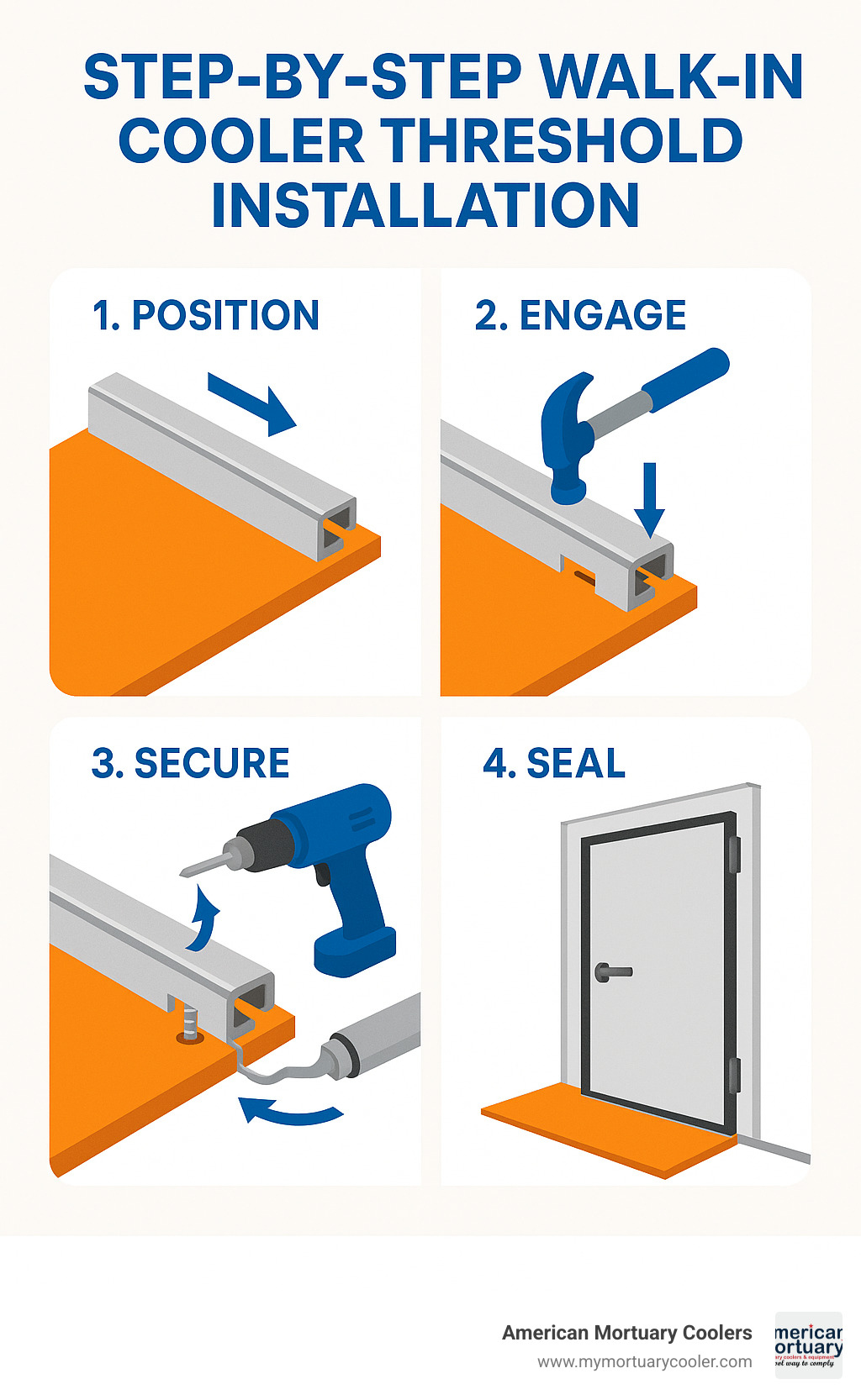

Installing a walk in cooler threshold properly is crucial—even the highest-quality threshold won't perform if it's not installed correctly. Here's our tried-and-true process:

Before you begin, gather everything you'll need: a cam-lock wrench, gloves (those edges can be sharp!), NSF-approved silicone caulk with a caulk gun, and a power drill with Phillips driver and 1/8" bit. Make sure the floor panel is clean and free of debris, and check that your cam-lock slots are accessible and in good shape.

Position your threshold bar so its hooks align with the cam-lock slots in the floor panel. The hooks should point in the same direction as the cam pins—this is a common mistake that can cause headaches later. Once aligned, gently tap the threshold until it moves about 1½" and you feel those hooks engage with the pins. That satisfying "click" means you're on the right track!

After the threshold is locked in position, secure it with self-tapping screws for extra stability. Then, apply a bead of NSF-approved silicone caulk along all seams to create a watertight seal. This step is especially important in mortuary settings where sanitation is paramount.

Finally, test the door operation to ensure proper gasket compression. The door should close smoothly, and the gasket should make full contact with the threshold. Verify that the threshold is level and firmly attached, making any necessary adjustments for smooth operation.

If you're replacing an existing threshold, take photos before removing the old one—they'll serve as valuable reference points during installation. And don't rush the removal process; careful extraction prevents damage to the surrounding floor panels.

When to Add a Ramp with Your Walk in Cooler Threshold

A well-designed ramp can be a game-changer for your walk in cooler threshold, especially in busy mortuary environments. But how do you know when you need one?

If your walk-in cooler floor creates a step-up of 2" to 5⅜" from the surrounding floor, a ramp isn't just nice to have—it's practically essential. I've visited facilities where staff struggle daily with this height difference, causing unnecessary strain and potential safety issues.

Equipment considerations should guide your decision too. If you're regularly using hand trucks, carts, or other wheeled equipment to transport items in and out of the cooler (as most mortuary facilities do), a proper ramp will make operations smoother and protect both your equipment and your threshold from damage.

Accessibility compliance isn't optional these days. ADA guidelines are clear: changes in level greater than 1/4" need a beveled edge with a slope no greater than 1:2. For changes greater than 1/2", you'll need a ramp with a slope no steeper than 1:12. These requirements ensure your facility remains accessible to everyone.

Your ramp must match your floor's load-bearing capacity. An economy floor (600 lbs/ft²) needs a different ramp design than a pallet-jack rated floor (2600 lbs/ft²). Using a ramp that's not rated for your traffic can lead to premature failure and potential safety hazards.

At American Mortuary Coolers, we often recommend stainless steel ramps with non-slip surfaces for mortuary applications. These can be thoroughly sanitized while providing smooth transitions for specialized mortuary carts. Whether installed as exterior additions or recessed into the floor for a more integrated appearance, the right ramp complements your threshold and improves your daily operations.

For more installation insights that might help with your threshold and ramp setup, take a look at our Walk-In Cooler & Freezer Installation Tips.

Accessibility, Safety & Energy-Efficiency Impacts

Your walk in cooler threshold might seem like a small detail, but it actually plays a huge role in how accessible, safe, and energy-efficient your cold storage becomes. At American Mortuary Coolers, we've seen how the right threshold design can transform a facility's operations.

Think about it - this small strip of metal is the literal bridge between two environments with completely different temperatures. Getting it right means smoother operations, fewer accidents, and lower utility bills.

Accessibility Considerations at the Walk in Cooler Threshold

Ever watched someone struggle to wheel a cart over an awkward threshold? It's not just frustrating - it can disrupt your entire workflow. A properly designed threshold creates a smooth transition that staff can steer easily, even when pushing carts or carrying items.

For mortuary facilities, this accessibility is particularly important during transfer operations where dignity and respect are paramount. The last thing you want is staff struggling with equipment when handling remains.

OSHA compliance requires workplaces to minimize trip hazards, and the ADA has specific requirements too. If your threshold creates a change in level greater than 1/4", you'll need a beveled edge or ramp. For mortuary facilities serving the public, these aren't just good practices - they may be legally required.

We've designed countless thresholds with the right slope (typically 1:12) to ensure smooth operations while meeting all regulatory requirements. The small investment in proper design pays huge dividends in operational efficiency.

Safety Considerations at the Walk in Cooler Threshold

Safety concerns at the threshold go beyond just tripping hazards. The meeting point of warm and cold environments creates unique challenges that smart design can address:

Slip-resistant surfaces are crucial where condensation might form. Quality thresholds incorporate textured surfaces or tread patterns that provide traction even when moisture is present. This simple feature can prevent serious accidents.

Visual cues at the threshold help alert staff to the transition. Some facilities benefit from thresholds with contrasting colors or materials that make the transition obvious even when staff are focused on other tasks.

Load distribution matters too. A properly designed threshold distributes weight evenly, preventing structural failures that could lead to accidents. This is especially important in mortuary settings where thresholds must safely support the weight of body carts without flexing or creating unstable transitions.

Some of our threshold designs include slightly raised edges to prevent wheel slip-off during cart movement - a small detail that can prevent major accidents.

How Threshold Design Cuts Utility Bills

Let's talk money. The financial impact of a proper walk in cooler threshold is significant, especially for facilities operating 24/7.

Did you know that air leakage around doors can account for up to 11% of a walk-in cooler's total energy consumption? A significant portion of this leakage occurs at the threshold if not properly sealed. When your threshold creates an airtight seal, your compressor doesn't have to work as hard, reducing energy consumption and extending equipment life.

The design directly affects how well the door gasket compresses when closed. When we install thresholds, we ensure they create the perfect surface for optimal gasket compression, dramatically reducing energy loss.

In freezer applications, poor threshold design leads to increased ice buildup around the door frame. This requires more frequent and longer defrost cycles - major energy consumers. By properly protecting heater wires and creating effective seals, quality thresholds minimize these costly cycles.

There's also the simple matter of door open time. Thresholds with well-designed transitions make it easier and faster to move items in and out of the cooler. This means doors stay open for shorter periods, reducing temperature fluctuations and recovery time.

For a typical mortuary cooler operating around the clock, these efficiency improvements can save hundreds or even thousands of dollars annually on energy bills. That makes investing in a quality threshold system not just good practice, but smart business.

At American Mortuary Coolers, we've refined our threshold designs based on feedback from funeral professionals across the country - from New York to Los Angeles and everywhere in between. We understand that in mortuary settings, every detail matters - not just for efficiency, but for the dignity and respect that families deserve.

Maintenance, Troubleshooting & Replacement Costs

Let's face it—even the best walk in cooler threshold won't last forever. At American Mortuary Coolers, we've seen how proper maintenance can extend the life of these critical components from just a few years to a decade or more. It's like taking care of your car—a little attention now saves a lot of money later.

Regular maintenance doesn't need to be complicated. A simple routine of cleaning your walk in cooler threshold with appropriate sanitizers keeps it functioning properly and looking professional. For our mortuary clients, we recommend using cleaning agents that both sanitize effectively and won't damage the threshold material—particularly important when working with aluminum components.

While you're cleaning, take a moment to check the door gasket where it meets the threshold. Look for any signs of wear, permanent compression, or tears. A damaged gasket can't create a proper seal, no matter how perfect your threshold is. Think of it like a pair of shoes with holes in the soles—no matter how nice they look, your feet still get wet.

"The most expensive threshold is the one you have to replace prematurely," our installation team often tells clients. Those few minutes spent checking fasteners and looking for corrosion can add years to your threshold's life. Vibration from daily use gradually loosens screws, while cleaning chemicals can accelerate corrosion if not properly rinsed.

With proper care, expect your walk in cooler threshold to serve you reliably for 8-10 years. Neglect it, and you might be shopping for a replacement in just 2-3 years. Given that replacement involves facility disruption and significant expense, the math clearly favors maintenance.

Impact of Damaged Thresholds

When a walk in cooler threshold fails, the problems cascade quickly. Think of it as a small leak in a boat—what starts as a minor issue can sink the whole operation if ignored.

Ice formation is often the first visible sign of trouble. When warm, humid air sneaks past a damaged threshold, it condenses and freezes around the door frame and on evaporator coils. This ice not only makes the door harder to open and close but forces your refrigeration system to work overtime.

Your utility bills will tell the story before long. Even small gaps at the threshold can increase energy consumption by 5-10%—a significant hit to your bottom line when compounded over months. For mortuary facilities operating 24/7, these costs add up quickly.

Temperature fluctuations follow as your refrigeration system struggles to maintain consistent cooling against the constant influx of warm air. In the mortuary setting, where temperature stability is non-negotiable, this can create serious concerns.

The strain on your cooling equipment leads to premature wear on compressors and fans—expensive components that might fail years earlier than designed. Meanwhile, moisture infiltrating around the damaged threshold can deteriorate your flooring, creating a widening circle of damage.

As one of our Nashville clients put it: "We thought we were just replacing a threshold, but ended up saving thousands in potential equipment damage." That's the hidden value of addressing threshold issues promptly.

Replacement Costs and Budgeting

When replacement becomes necessary, knowing what to budget helps avoid surprises. Material costs vary significantly based on your choice:

Aluminum thresholds run between $43-$190 depending on size and features. They're the most common choice and offer good value for typical applications.

Stainless steel thresholds start around $250 for standard sizes and climb higher for custom dimensions. While more expensive initially, their superior durability and corrosion resistance often make them more economical in the long run, especially in environments with frequent cleaning and disinfection.

Beyond the threshold itself, budget for professional installation (typically 1-2 hours of labor) and potential downtime. At American Mortuary Coolers, we understand that downtime isn't just an inconvenience—it's a serious operational concern. That's why we schedule installations to minimize disruption to your facility.

Smart facility managers often replace door gaskets at the same time as thresholds since these components typically wear at similar rates. Think of it like replacing both tires on the same axle—it ensures balanced performance.

For planning purposes, we recommend mortuary facilities budget for threshold inspection every 2-3 years and potential replacement every 5-7 years. High-traffic installations or harsh environments may require more frequent attention.

Common Walk in Cooler Threshold Problems to Avoid

Through years of servicing mortuary coolers from coast to coast, we've encountered some recurring threshold issues worth preventing:

Misaligned doors create uneven pressure on gaskets, preventing proper sealing. This often happens gradually as hinges settle or door frames shift slightly. Regular adjustment keeps everything aligned.

Worn heater wires in freezer applications can fail silently until ice formation makes the problem obvious—and by then, you're already losing energy and risking equipment damage. Inspection with a thermal camera can catch this early.

Bent threshold plates occur when load ratings are exceeded or impact damage occurs. We've seen everything from dropped equipment to improper floor cleaning machines cause this damage. Knowing your threshold's load rating and communicating it to staff prevents these costly accidents.

Missing or degraded caulk creates pathways for air and moisture infiltration. Silicone sealant naturally deteriorates over time, especially when exposed to cleaning chemicals. Reapplying quality, NSF-approved silicone caulk is a simple, inexpensive fix that pays big dividends.

Improper ramp slopes create both safety hazards and operational challenges. Too steep, and carts become difficult to manage; too shallow, and they don't effectively bridge the height difference. The ideal slope (typically 1:12 for ADA compliance) balances these concerns.

Our service teams provide comprehensive threshold evaluations as part of routine maintenance visits, catching these issues before they become expensive problems.

DIY vs Professional Replacement

While the DIY approach might seem appealing, walk in cooler threshold replacement is one area where professional installation often pays for itself. Here's why:

Professional installers bring specialized tools to the job—cam-lock wrenches and proper caulking equipment that most facilities don't have on hand. They also complete the work efficiently, minimizing cooler downtime that could compromise your operation.

Many manufacturers' warranties require professional installation, and for good reason. Improper installation can create hidden problems that emerge only after the installer has left. Our technicians perform thorough load testing after installation to verify the threshold meets specifications.

For clients who prefer handling their own maintenance, we provide detailed installation guides and ship replacement thresholds anywhere in the continental United States. However, for mortuary facilities where reliability is absolutely critical, professional installation provides both peace of mind and optimal performance.

As one of our Florida clients told us after a professional threshold replacement: "The difference was immediate—the door closes more smoothly, the cooler runs less often, and our monthly electric bill dropped noticeably." That's the kind of result that makes professional installation worth considering.

For more information on maintaining and repairing your walk-in cooler, check out our guide on How to Do Walk-In Cooler Repair Even If You've Never Tried It Before.

Frequently Asked Questions about Walk-In Cooler Thresholds

What load rating do I need for my threshold?

When folks call us at American Mortuary Coolers, this is often their first question. Choosing the right load rating isn't complicated once you understand what will be crossing your walk in cooler threshold day after day.

If your cooler only sees foot traffic, a standard 500 lb rating will serve you well. But in most funeral homes, you'll be moving more than just people. For hand trucks and lighter carts, look for a threshold that works with a standard floor (1200 lbs/ft²).

Many of our clients use specialized body carts that require more substantial support. In these cases, we recommend thresholds matching a heavy-duty floor rating (1500 lbs/ft²). And for those rare situations where you're using pallet jacks or exceptionally heavy equipment, you'll want a threshold designed for pallet jack floors (2600 lbs/ft²).

Your threshold should never be the weakest link in your floor system. We always recommend matching or exceeding the load rating of your walk-in cooler floor for peace of mind and lasting performance.

How often should I replace a walk-in cooler threshold?

There's no one-size-fits-all answer here, but we can give you some helpful guidelines based on our decades of experience with mortuary facilities nationwide.

Your walk in cooler threshold material makes a big difference in longevity. Those premium stainless steel thresholds we install typically reward you with 8-12 years of reliable service. Aluminum options, while more budget-friendly upfront, generally need replacement after 5-8 years.

Traffic volume plays a major role too. A busy facility with constant movement in and out of the cooler will naturally see faster wear than one with limited access. Similarly, environmental factors matter – harsh cleaning chemicals (common in mortuary settings) and high humidity can accelerate deterioration.

The care you give your threshold makes perhaps the biggest difference of all. Well-maintained thresholds with regular cleaning and inspection can last significantly longer than neglected ones.

We recommend having your threshold professionally inspected annually. Watch for these warning signs that replacement might be needed:

- Visible corrosion or pitting on the surface

- Bent or deformed areas that create gaps

- Loose mounting that allows movement

- Persistent ice formation despite good door gaskets

At American Mortuary Coolers, we help our clients develop sensible replacement schedules based on their specific usage patterns. This proactive approach prevents unexpected failures and the disruptions they cause.

Are ramps required by code for every raised threshold?

This question touches on both legal requirements and practical considerations. The short answer: it depends on your specific situation, but ramps often make good sense regardless of code requirements.

From a regulatory standpoint, several factors come into play. If your facility serves the public, the Americans with Disabilities Act (ADA) requires ramps for level changes greater than 1/4 inch. While OSHA doesn't always explicitly mandate ramps, their guidelines strongly promote eliminating trip hazards – which often means adding ramps to raised thresholds.

Local building codes add another layer of complexity. Some municipalities have specific requirements for commercial refrigeration installations, including how threshold transitions must be handled. We're familiar with these variations and can help steer them.

Beyond legal compliance, ramps offer tremendous practical benefits for mortuary operations. They improve staff safety by reducing trip hazards, allow smoother movement of carts and equipment, protect your valuable equipment from jarring transitions, and reduce physical strain on your team members.

For most funeral homes we work with, we typically recommend installing ramps with any threshold height greater than 1/2 inch. This ensures smooth, dignified transport operations while keeping your staff safe and efficient.

When you're ready to explore options for your facility, our team can help determine exactly what your local codes require and what practical solutions make the most sense for your specific needs.

Conclusion

Selecting the right walk in cooler threshold might seem like a small detail in your cold storage system, but as we've explored throughout this guide, it's actually a crucial component that affects everything from your energy bills to the safety of your staff.

At American Mortuary Coolers, we've built our reputation on understanding these "small details" that make a big difference. Working with funeral homes across the country—from our home base in Tennessee to facilities in California, from Chicago to Atlanta—we've seen how the right threshold can transform a walk-in cooler's performance.

Think of your walk in cooler threshold as the guardian of your cooler's efficiency. It's where the outside world meets your carefully controlled environment—and where problems often begin when this component isn't given proper attention. A quality threshold, properly installed and maintained, pays for itself many times over through improved energy efficiency, reduced maintenance headaches, and longer equipment life.

We understand that in the funeral industry, reliability isn't just convenient—it's essential. That's why we focus on creating durable, thoughtfully designed solutions that stand up to the unique demands of mortuary environments. From the materials we select to the installation methods we recommend, every decision is made with your specific needs in mind.

The beauty of working with our team is that we deliver this expertise directly to your doorstep, anywhere in the contiguous 48 states. We're not just shipping equipment—we're delivering peace of mind, backed by decades of specialized experience in the funeral industry.

Whether you're building a new facility or upgrading an existing one, we encourage you to give your walk in cooler threshold the attention it deserves. It's an investment that affects your daily operations in countless ways, from the smoothness of your workflow to the consistency of your cooler's temperature.

Ready to find the perfect threshold solution for your mortuary cooler? Our team is just a phone call away, ready to help you steer the options and find the perfect fit for your facility's unique needs. With American Mortuary Coolers, you're choosing a partner who understands the critical nature of your work and the equipment that supports it.

Choose the right walk-in cooler threshold today, and you'll enjoy smoother operations, lower energy bills, and more reliable performance for years to come. That's not just good for business—it's essential for the dignified service you provide to families in their time of need.