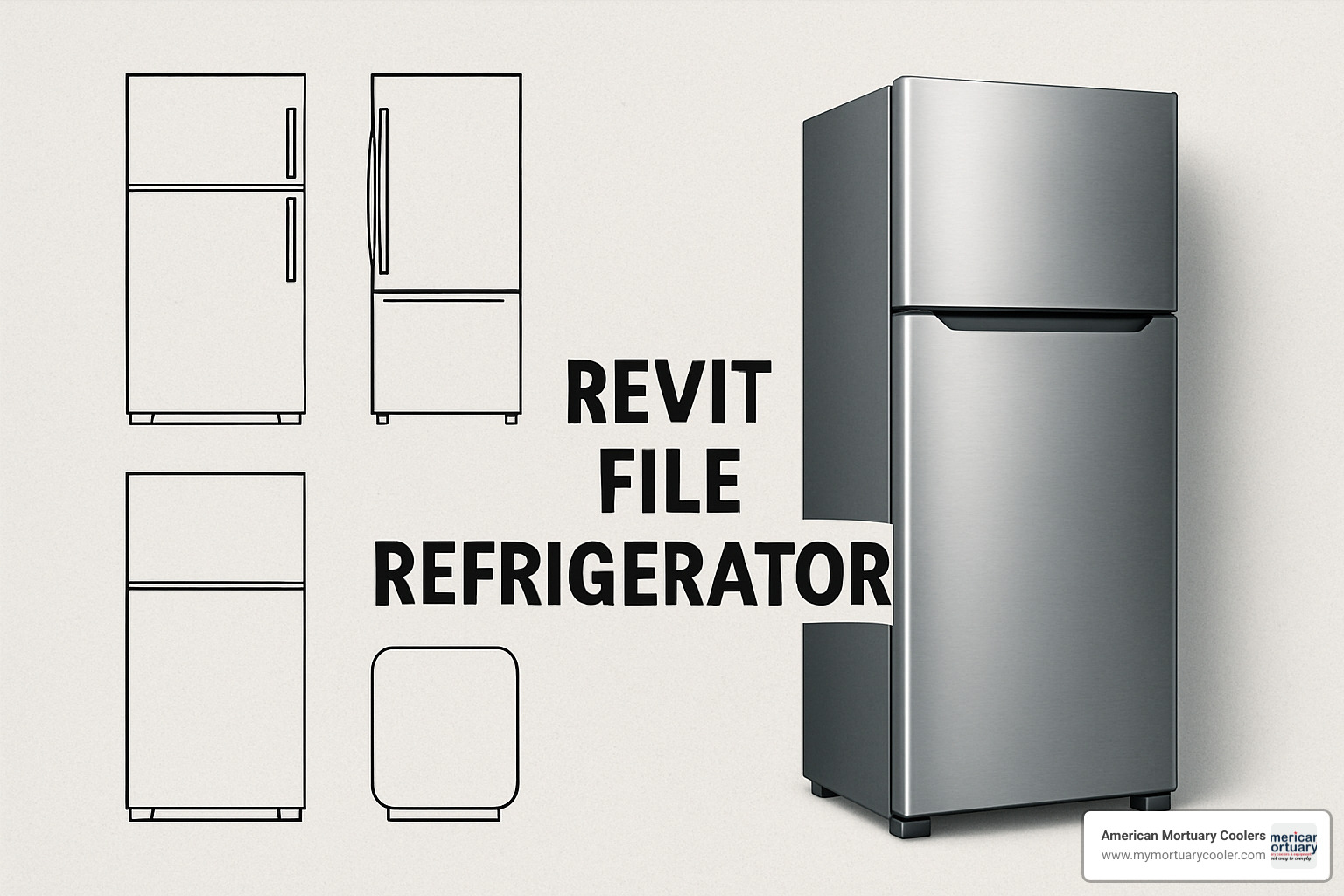

Simplifying BIM Integration with Revit File Refrigerators

Looking for revit file refrigerator resources? Here's what you need to know:

| Quick Answer | Description |

|---|---|

| Definition | A Revit file refrigerator is a parametric 3D model (.rfa or .rvt format) used in Building Information Modeling (BIM) to represent refrigeration units in architectural designs. |

| Common Types | Walk-in, reach-in, built-in, column, counter, commercial, residential |

| Key Parameters | Dimensions, door swing, material options, finishes, electrical data |

| Where to Find | ARCAT, BIMsmith, manufacturer websites, DesignsCAD |

| File Formats | RFA, RVT, DWG, SKP, IFC, GLB |

Revit file refrigerator models are essential components for architects, engineers, and contractors working on Building Information Modeling (BIM) projects. These parametric families allow design professionals to accurately represent refrigeration units in their digital designs, ensuring proper space planning, systems coordination, and visual presentation. Whether you're working on a commercial kitchen, residential project, or specialized facility like a mortuary, having access to the right refrigerator Revit families can streamline your workflow and improve project documentation.

The value of quality refrigerator Revit files cannot be overstated. They save countless hours of modeling time while providing accurate representations that include crucial data like dimensions, clearance requirements, and electrical specifications. From simple residential units to complex walk-in coolers, the right Revit family ensures your design accounts for all necessary considerations before construction begins.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience working with revit file refrigerator models for specialized preservation environments. My expertise includes helping funeral directors and architects integrate precise refrigeration units into their BIM workflows for optimal space utilization and compliance.

Revit File Refrigerator 101: Definition, Parameters & Types

Let's talk about what a revit file refrigerator actually is. At its core, it's a smart digital twin of a real refrigerator that lives inside your Autodesk Revit software. These digital models (typically saved as .rfa files) aren't just static 3D shapes – they're intelligent, data-rich families that respond and adapt based on how you configure them. Think of them as virtual refrigerators that know how to behave like their real-world counterparts.

The beauty of these parametric families is how they span the entire refrigeration universe. Whether you need a sleek built-in unit for a luxury home kitchen or a massive walk-in cooler for a commercial space, there's a revit file refrigerator for that:

Reach-in refrigerators stand tall and proud with single or multiple doors – the workhorses of commercial kitchens everywhere. Their built-in cousins nestle perfectly flush with surrounding cabinetry, creating that seamless look clients love. For the high-end residential project, column refrigerators offer that sophisticated, modular approach when paired with matching freezer units.

When counter space is precious (isn't it always?), under-counter refrigeration units maximize workspace while keeping essentials close at hand. And of course, the mighty walk-in coolers serve as refrigerated rooms for everything from restaurant supply storage to specialized preservation environments – something we know quite well at American Mortuary Coolers!

Each refrigerator family comes with options to personalize its look and function. Door swing direction (critical for tight spaces), handle styles, and various finishes can transform the same basic unit to match any design aesthetic. From commercial-grade stainless steel to custom panel-ready models that disappear into cabinetry, the possibilities are nearly endless.

Why a revit file refrigerator matters in BIM

Including accurate revit file refrigerator models in your BIM workflow isn't just about making pretty pictures – it delivers real-world benefits that save time, money, and headaches.

First, there's coordination. Refrigeration units aren't standalone islands – they need specific clearances, ventilation space, and connections to building systems. As one kitchen design specialist told me, "Using manufacturer-specific refrigerator Revit models has saved us countless hours in coordination meetings. When we can show exact clearance requirements and utility connection points in our BIM model, we avoid expensive field modifications during construction."

Clash detection might be my favorite BIM superpower. Nothing ruins your day quite like finding on-site that your perfectly planned refrigerator won't fit because of an inconveniently placed duct. Quality revit file refrigerator families help catch these conflicts before the first nail is hammered.

The visualization aspect shouldn't be underestimated either. When clients can see realistic representations of their space – complete with accurately modeled equipment – approvals come faster and change orders decrease. This is particularly crucial in specialized environments like mortuaries, where equipment placement and workflow are absolutely critical.

Looking beyond construction, these data-rich models continue providing value through facility management integration. When it's time for maintenance or replacement, having detailed refrigeration information already in your building's digital twin is invaluable. Some advanced models even include energy consumption data to help with sustainability goals and operational cost projections.

Key parameters every revit file refrigerator should include

A truly useful revit file refrigerator isn't just a pretty 3D shape – it's packed with parameters that make it function realistically in your digital environment.

The dimensional parameters form the foundation: width, depth, and height tell the basic story, but don't forget clear space requirements for door swing and interior dimensions that affect capacity. Getting these right prevents nasty surprises during installation.

Functional parameters bring your refrigerator to life in the model. Door hinge location (left, right, or both for double-door units) might seem minor until you try to open a door into a wall! Door swing angle, shelf count, and even refrigerant type (increasingly shifting toward environmentally friendly options like R290) all impact how the unit functions in the real world.

Technical parameters matter tremendously for coordination with other disciplines. Power requirements, connection points, ventilation needs, and weight all affect how other systems interact with your refrigeration. Missing these can lead to expensive field modifications.

For public spaces, accessibility parameters ensure ADA compliance with proper reach ranges for controls and adequate clear floor space. These aren't just nice-to-haves – they're often code requirements.

Here's how manufacturer-specific and generic refrigerator models typically compare:

| Parameter | Manufacturer-Specific Models | Generic Models |

|---|---|---|

| Accuracy | Exact dimensions and specifications | Approximate dimensions |

| Detail Level | High (includes brand-specific details) | Medium to low (simplified) |

| File Size | Larger (more geometry) | Smaller (optimized) |

| Customization | Limited to manufacturer options | Highly customizable |

| Data Richness | Includes specific model numbers, warranty info | Basic parameters only |

| Visual Fidelity | Matches actual product exactly | Representational |

| Best Use Case | Final documentation, client presentations | Early design, space planning |

At American Mortuary Coolers, we've learned how valuable accurate Revit families are to our clients. When architects can confidently integrate our specialized refrigeration units into their designs – complete with precise clearance requirements and connection points specific to mortuary applications – projects move forward smoothly. That's why we invest in creating detailed, parameter-rich revit file refrigerator models that truly represent our custom cooling solutions.

How to Select the Ideal Refrigerator Family for Your Project

Picking the perfect revit file refrigerator for your project isn't just about finding any refrigerator model—it's about finding the right match for your specific needs. Let's walk through how to make this important decision together.

When I work with architects and designers, I always start by asking about their project type. A busy commercial kitchen needs industrial-strength refrigeration that can handle constant opening and closing, while a high-end residential kitchen might prioritize sleek integration with cabinetry. For hospitality projects like hotels or restaurants, you'll want that sweet spot between durability and aesthetics that impresses guests while standing up to daily use.

Project types really do dictate your refrigerator needs. For specialized facilities like mortuaries, standard refrigerator families simply won't cut it—you need models designed specifically for preservation with precise temperature control and specialized access features. As we often tell our clients at American Mortuary Coolers, "The right cooling solution isn't just about temperature—it's about dignity and respect."

Style considerations matter tremendously, especially in visible spaces. For upscale residential projects, you might need panel-ready refrigerator families that can accept custom cabinet fronts to blend seamlessly with surrounding millwork. Commercial spaces typically favor stainless steel finishes—they're durable, easy to clean, and have that professional look clients expect.

Size constraints are non-negotiable in most projects. I've seen too many last-minute panics when a beautiful refrigerator model won't fit the allocated space. Measure carefully, then double-check that your selected Revit family accurately represents the planned unit's dimensions—including door swing clearances!

"When we're designing a mortuary facility," our lead designer often explains, "we recommend architects start with our specialized Revit families early in the design process. Generic families might miss critical details like door clearances and ventilation requirements that are unique to mortuary refrigeration."

The manufacturer-specific versus generic family debate has a simple answer: use what makes sense for your current design phase. Early in conceptual design, generic families work perfectly for space planning. As your project moves toward construction documentation, switching to manufacturer-specific models ensures you're working with the exact dimensions and connection points you'll encounter in the field.

For specialized applications like walk-in coolers, be sure your Revit family includes critical details like panel thickness options (typically 4" or 5.375"), door configurations, viewport windows, kickplate options, and floor configurations. These details matter tremendously for both function and installation.

Commercial vs. Residential Revit File Refrigerators

The differences between commercial and residential revit file refrigerator families reflect their real-world counterparts in meaningful ways.

Capacity is perhaps the most obvious distinction. Commercial refrigerator families typically represent units with significantly larger storage capacity. While your average home refrigerator might offer 18-30 cubic feet of storage, commercial units like our RI18HC-G Reach-In Refrigerator provides a generous 16.85 cubic feet in a much more compact footprint because it's designed for efficient food storage rather than home convenience features.

Commercial units are built for duty cycles that would overwhelm residential models. Their Revit families should include data reflecting this durability—like recovery time after door openings and the ability to maintain consistent temperatures under frequent use. This information matters when creating accurate facility management documentation.

When it comes to finishes, residential refrigerator families offer a rainbow of options to match home décor—everything from classic white to trendy matte black or custom panels. Commercial units prioritize practicality, with stainless steel dominating for its durability and easy cleaning. These finish options should be readily accessible parameters in your refrigerator family.

Don't overlook warranty information when selecting a refrigerator family. Commercial models often include substantial coverage—like the 7-year warranty on parts, labor, and compressor included in our RI18HC-G family—that can be extracted directly from the family into project specifications.

For specialized applications like mortuary refrigeration, our Revit families include parameters beyond what you'd find in standard commercial units, such as body capacity configurations, temperature monitoring systems, specialized door hardware, and reinforced flooring designed for the unique demands of this sensitive application.

Accessibility, energy & code considerations

Regulatory compliance isn't the most exciting part of design, but it's absolutely critical when selecting a revit file refrigerator family.

For ADA compliance, your refrigerator family should include clear floor space parameters that ensure adequate maneuvering room, reach range data for controls so you can verify they fall within accessible heights, door swing clearances that accommodate wheelchair access, and handle types that comply with ADA operation requirements. These parameters let you quickly verify compliance without constant cross-referencing to code books.

Energy efficiency considerations continue to gain importance. Look for Revit families that include ENERGY STAR certification data, Department of Energy (DOE) compliance information, and annual energy consumption metrics that can be integrated into whole-building energy analysis. These data points help substantiate green building certification efforts.

"One often overlooked aspect of refrigerator Revit families is refrigerant data," our engineering team frequently points out. "With regulations rapidly shifting toward environmentally friendly options like R290, having this information embedded in your Revit family helps ensure compliance and future-proofs your documentation."

Health and safety codes add another layer of consideration. For food service applications, look for NSF certification information in your Revit family. California Air Resources Board (CARB) compliance for refrigerants and SNAP (Significant New Alternatives Policy) compliance data help ensure your specified equipment meets increasingly stringent environmental regulations.

At American Mortuary Coolers, we understand that selecting the right refrigeration solution—and the right Revit family to represent it—requires balancing technical requirements with human needs. Whether you're designing a commercial kitchen, residential space, or specialized facility like a mortuary, the right refrigerator family helps ensure your project succeeds both digitally and in the real world.

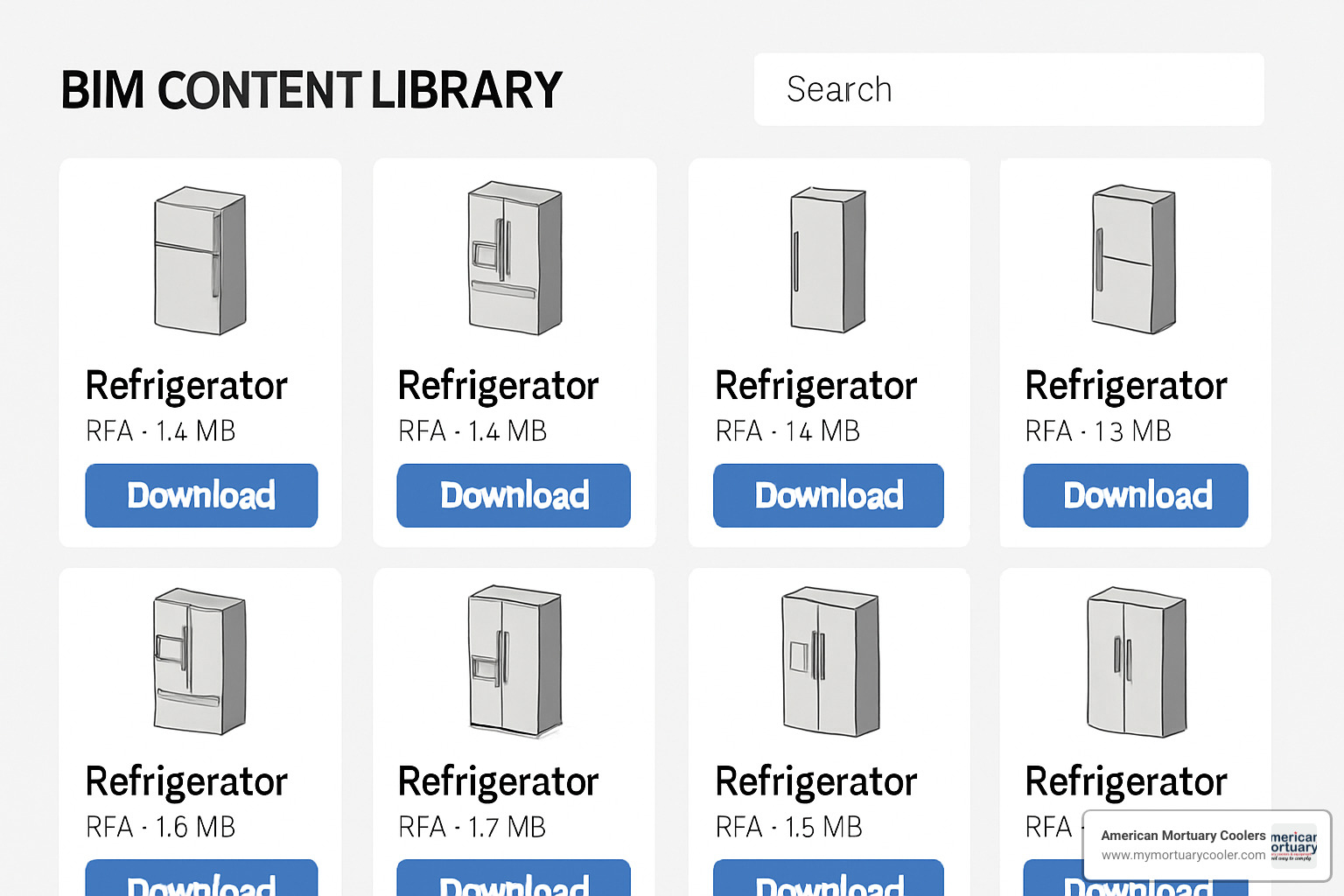

Where & How to Download Revit File Refrigerators

Finding high-quality revit file refrigerator models doesn't have to be a treasure hunt. There are several excellent resources where you can find everything from basic generic families to manufacturer-specific models with all the bells and whistles.

BIM Content Libraries have become the go-to destinations for many architects and designers:

- BIMsmith Market offers a wonderfully curated collection of refrigerator families - both manufacturer-specific and generic options that can save you hours of modeling time.

- ARCAT remains one of my personal favorites, providing free access to numerous refrigerator families without even requiring registration. Their "no strings attached" approach is refreshing.

- DesignsCAD provides both free and budget-friendly paid options if you need something specific.

Many refrigerator manufacturers have recognized the importance of BIM and now offer Revit content directly through their websites. Sub-Zero/Wolf, True Refrigeration, Traulsen, and KitchenAid/Whirlpool all maintain libraries of their product families, often with multiple configuration options to match what you'd find in their catalogs.

For specialized applications like mortuary refrigeration, companies like us at American Mortuary Coolers provide custom Revit families designed specifically for these unique applications. These specialized families include parameters that generic refrigerators simply don't account for.

When downloading refrigerator content, you'll encounter various file formats. The native RFA (Revit Family) format is ideal, but you might also find RVT (Revit Project files containing multiple families), DWG (AutoCAD files you can import), SKP (SketchUp files requiring conversion), IFC (the open BIM format), or GLB (binary glTF files for web viewing).

Best sources for a revit file refrigerator download

After years of helping architects implement mortuary refrigeration into their projects, we've developed some strong opinions about the best places to find quality refrigerator Revit content:

For free libraries, ARCAT stands head and shoulders above the rest with their extensive collection of manufacturer-specific families and no registration hoops to jump through. RevitCity offers a community-driven approach with both generic and manufacturer content that often includes helpful user reviews. BIMobject rounds out the top three with their large collection of manufacturer-approved content that's regularly updated.

If you're willing to invest a few dollars for premium content, paid marketplaces like DesignsCAD offer high-quality refrigerator models starting around $4 - often a bargain compared to the time you'd spend creating them yourself. TurboSquid provides professional 3D models that import nicely into Revit, while FormFonts offers a subscription-based service with carefully curated content.

For the most accurate representation of what will actually be installed, manufacturer BIM hubs are hard to beat. True Refrigeration provides a comprehensive library of commercial refrigeration families with accurate connection points. Sub-Zero/Wolf offers beautiful high-end residential refrigerator families with detailed finish options. Arctic Industries specializes in walk-in cooler and freezer Revit families with parametric controls that make them adaptable to various configurations.

"We've found that using manufacturer-specific Revit content whenever possible provides the most accurate representation of the final installation," notes our BIM coordinator. "The Arctic Walk-In Revit family, for example, includes parametric controls for all square and rectangular boxes, including coolers, freezers, and combo units with multiple doors—making it suitable for a wide range of commercial and mortuary applications."

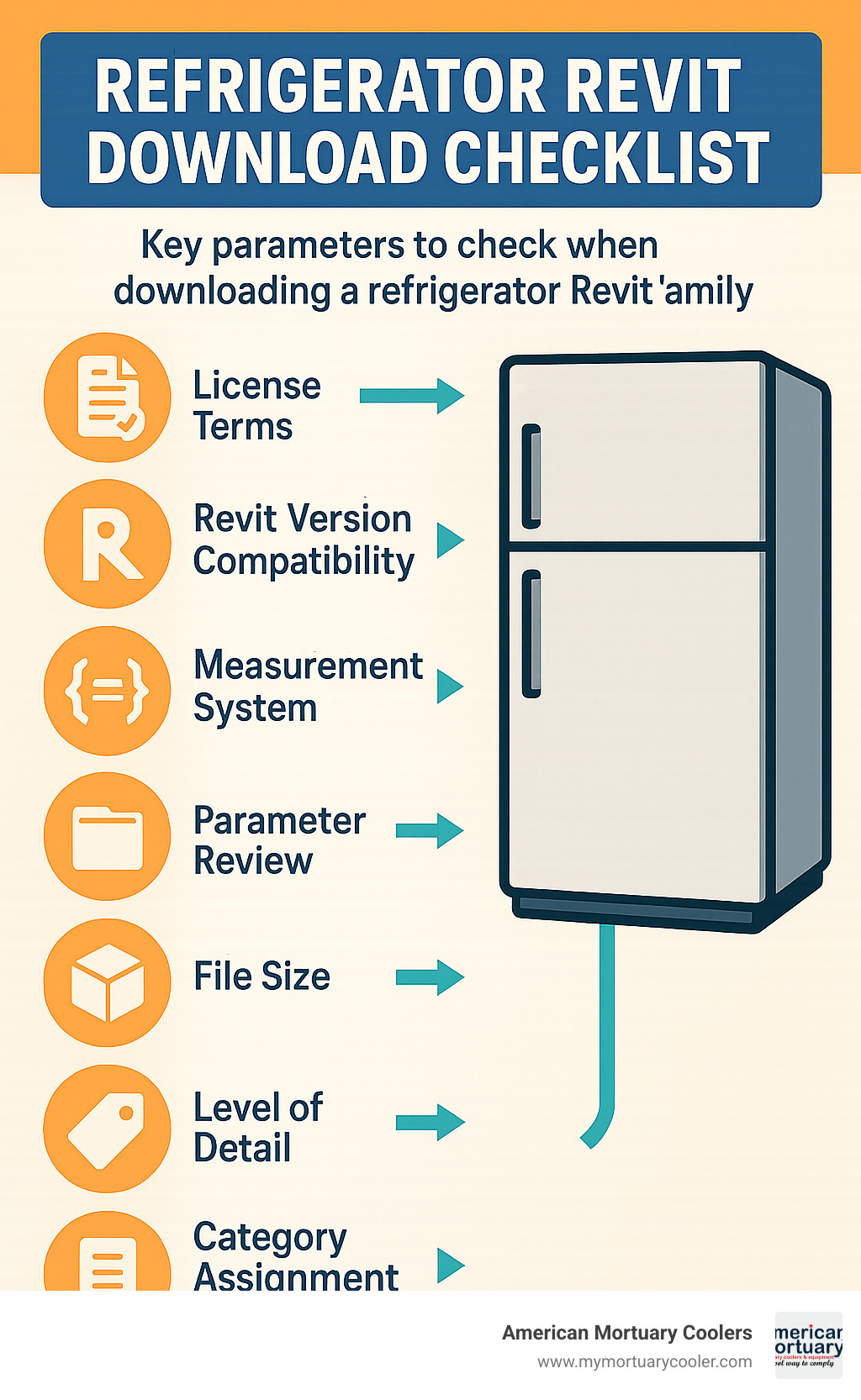

revit file refrigerator download checklist

Before you click that download button and bring a revit file refrigerator into your project, take a moment to verify a few critical details:

First, check the license terms to ensure you can use the family for your commercial project. Nothing's worse than getting deep into documentation only to find you can't legally use that perfect refrigerator model.

Verify Revit version compatibility with your current software. While newer versions can usually open older families, the reverse isn't true, and compatibility issues can cause frustrating workflows.

Confirm the measurement system matches your project standards. Converting from metric to imperial (or vice versa) can introduce rounding errors that cause headaches during construction.

Perform a thorough parameter review to ensure the family includes all the data you'll need: dimensional parameters for width, depth, and height; door swing direction and clearance zones; appropriate material options; and MEP connection points if you're coordinating with engineering disciplines.

Don't overlook the file size - overly detailed families with excessive geometry can dramatically slow down your project performance. Similarly, verify the level of detail is appropriate for your current project phase. You don't need photorealistic renders of the ice maker during schematic design!

Finally, check the category assignment to make sure the family is properly categorized in Revit. An incorrectly categorized refrigerator won't schedule properly and might not appear in the appropriate views.

At American Mortuary Coolers, we've optimized our Revit families to balance detail with performance, ensuring you get accurate representations of our specialized refrigeration units without bogging down your BIM workflow. We understand that every project has unique requirements, which is why our custom approach extends from our physical products to our digital assets.

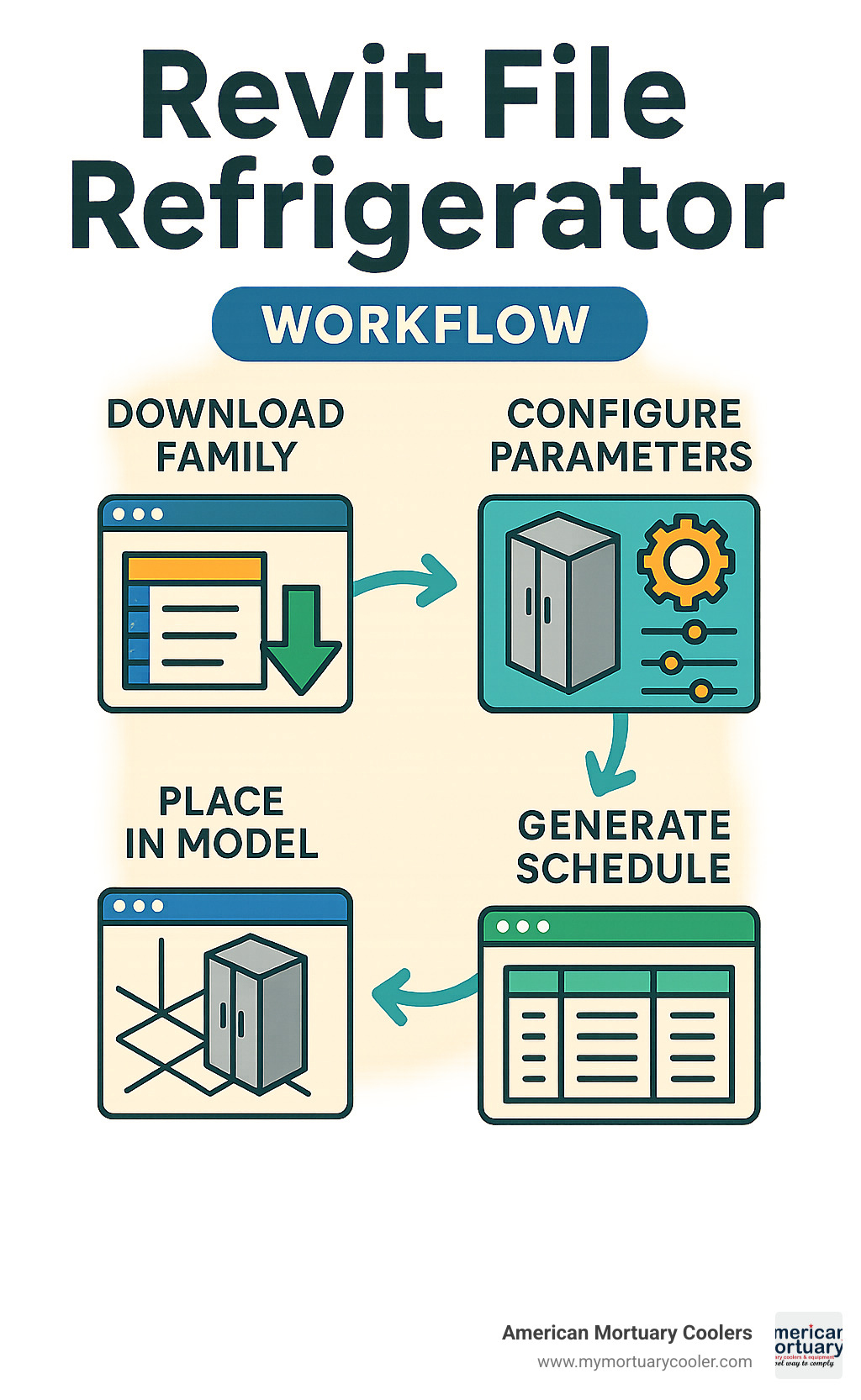

Integrating, Customizing & Scheduling Refrigerators in Revit

So you've found and downloaded the perfect revit file refrigerator – now what? Getting this family to work seamlessly in your project requires a few key steps that will save you headaches down the road.

Let's start with bringing your refrigerator into your project. Use the "Load Family" command to import your refrigerator, and take a moment to organize it logically in your project browser. This small bit of housekeeping pays dividends later when you're rushing to make deadline changes. Many experienced BIM managers actually create project templates with commonly used refrigerator families already loaded – a real time-saver if you frequently work on kitchen designs or specialized facilities.

When placing your revit file refrigerator, pay attention to the elevation – floor-mounted units need proper positioning to avoid floating refrigerators (a common rookie mistake). Always maintain the manufacturer's recommended clearances, which are often included as reference lines in well-built families. Cabinet-mounted refrigerators typically work best as face-based families for easier positioning.

One of Revit's most powerful features is its ability to generate detailed equipment schedules. For refrigeration units, create a dedicated schedule that includes type mark, model, manufacturer, dimensions, electrical requirements, and any special clearance notes.

"In our mortuary projects, we've learned that creating specialized equipment schedules just for refrigeration units prevents critical details from slipping through the cracks," explains our project coordinator. "These specialized coolers have unique requirements standard schedules might miss."

For walk-in coolers, families like the Arctic Walk-In Revit family are structured specifically to streamline scheduling. The door components are designated as Specialty Equipment with manufacturing numbers and electrical details already embedded, making your equipment lists comprehensive and accurate for both procurement and installation.

Modifying geometry & materials without breaking the family

Customizing a revit file refrigerator can be like performing surgery – you need to know what you're doing to avoid killing the patient. Here's how to make changes while preserving the family's parametric intelligence:

Use sub-category controls to manage elements like handles and logos through visibility parameters rather than deleting them outright. Creating custom subcategories gives you more flexibility to hide certain elements in specific views without losing them completely.

When working with nested components (families within families), understand the hierarchy before diving in. Always edit in Family Editor rather than trying to modify components in the project environment, which often leads to broken parameters. Be particularly cautious with nested families since changes can have ripple effects on parameters.

For materials and finishes, use material parameters instead of direct material assignments. This approach maintains flexibility and allows for project-wide updates. Create custom materials in your project library, and for those client presentations, consider adding realistic textures to refrigerator surfaces to improve your renderings.

The Arctic Walk-In Revit family exemplifies this flexible approach, allowing customization of panel finishes while preserving parametric functionality. You can easily adjust door kickplates, hinge placement (right or left), hinge configurations (2 or 3), and viewport sizes without breaking the family structure.

Common mistakes & troubleshooting tips

Even seasoned Revit users encounter obstacles with refrigerator families. Here are the usual suspects and how to handle them:

Missing connectors frustrate MEP coordination efforts. If your electrical or plumbing connectors aren't visible or connecting properly, check connector visibility in View Properties and verify proper placement within the family. Sometimes they're there but hidden!

Scale issues can make your refrigerator look comically large or disappointingly tiny. When this happens, check unit settings in both the family and project. Many refrigerator families are created in a different unit system than your project is using, causing unexpected scaling.

Wrong category assignments cause headaches with schedules and visibility. Verify your refrigerator is assigned to the appropriate category – typically Specialty Equipment or Mechanical Equipment – to ensure proper filtering and scheduling.

Schedule mismatches occur when parameters don't appear where expected. Ensure you're using shared parameters or project parameters, not just family parameters, if you want them to appear in schedules.

"A common mistake we see with the Arctic Walk-In Revit family," our technical support team points out, "is architects trying to edit individual components separately. This family must be used as a complete unit to preserve parameter relationships. The door is intentionally nested as a specialty equipment family so it automatically appears in equipment schedules."

Mini-FAQ (3 quick answers)

How do I swap a generic to a manufacturer revit file refrigerator later?

Replacing a placeholder with the real deal is straightforward: select your generic refrigerator, use the "Replace Family" command from the Modify tab, choose your manufacturer-specific model, and map the parameters between them. Always verify placement and connections afterward, as these can shift during replacement. For best results, use families with similar parameter names and placement elevations.

What's the safest way to show door swing in plans?

Door swing representation matters, especially in tight spaces. Use the built-in door swing parameter in your revit file refrigerator and consider creating a dedicated floor plan view optimized for showing clearances. Dashed lines for door swings help distinguish them from other elements. For clarity, include a clearance zone and note swing direction in your refrigerator schedules.

"In mortuary applications," our design team emphasizes, "door swing clearance isn't just about convenience – it's essential for dignified and efficient operations. We recommend showing both the swing arc and a clearance rectangle in plan views."

Can I batch-update finishes across multiple placed refrigerators?

Yes! You have several options for updating finishes across multiple refrigerators without tedious one-by-one editing. If your families use global parameters for finishes, you can update all instances at once. Alternatively, create a selection set of all refrigerators and use the Properties panel to change shared parameters. Some finishes can be updated directly through schedules with editable fields. For the power users, Dynamo scripts can perform sophisticated batch updates of family parameters.

Just be sure you're modifying the correct parameter controlling the finish appearance, especially with manufacturer-provided models that might handle finishes differently than generic families.

Conclusion

Finding and using the right revit file refrigerator models can transform your BIM workflow from headache-inducing to surprisingly smooth. I've seen how quality refrigerator families save countless hours while dramatically improving project outcomes – from initial space planning all the way through construction documentation.

Here at American Mortuary Coolers, we've developed a deep understanding of specialized refrigeration needs. Our mortuary coolers aren't just another appliance – they're essential infrastructure with unique requirements that standard models simply don't address. That's why we provide custom-custom Revit families alongside our durable cooling solutions, ensuring seamless integration into your BIM projects whether you're designing a commercial kitchen, residential space, or specialized facility.

The benefits of using proper refrigerator Revit families extend throughout the project lifecycle:

When you use accurate, parameter-rich refrigerator families, you're essentially future-proofing your design. You'll catch potential issues before they become expensive field modifications. Your coordination meetings become more productive since everyone can visualize exactly where utilities need to connect. And perhaps most importantly, your documentation reflects reality – not wishful thinking.

"Having accurate Revit content has completely changed how we approach specialized refrigeration," one architect recently told me. "We used to leave generic boxes as placeholders until late in the design, but that always created headaches. Now we integrate manufacturer-specific models early, and it's made a world of difference."

The refrigeration industry continues evolving rapidly – with new energy standards, environmental regulations, and technologies emerging constantly. Using current, manufacturer-provided Revit content ensures your projects stay compliant with these changes while incorporating best practices.

For those working on mortuary projects specifically, I'd recommend exploring our in-depth resources on comparing mortuary refrigeration systems. And if you're looking to upgrade existing facilities, our guide to changing your mortuary cooler provides valuable insights on optimization.

With the guidelines we've covered in this guide, you're now equipped to find, download, and implement the perfect revit file refrigerator for your next project. No more generic boxes or inaccurate models – just seamless coordination, precise documentation, and ultimately, a more successful project delivery.

We're always here to help if you have questions about integrating our specialized cooling solutions into your BIM workflow. After all, getting the details right in digital design means fewer surprises when it matters most – during construction and beyond.