The Complete Guide to Commercial Walk-In Freezer Cost

Why Commercial Walk-In Freezer Cost Matters for Your Business

Understanding commercial walk in freezer cost is crucial before making this significant investment for your business. Whether you're running a restaurant, pharmacy, or funeral home, the sticker price is just the beginning of your total investment.

Quick Answer: Commercial Walk-In Freezer Cost Ranges

- Small units (6×6 feet): $5,000 - $10,000

- Medium units (10×10 feet): $8,000 - $15,000

- Large units (20×20+ feet): $25,000 - $40,000+

- Cost per square foot: $100 - $150 (including basic refrigeration)

- Installation costs: $2,000 - $7,000 additional

- Monthly operating costs: $70 - $240+ depending on size

Commercial walk-in freezers serve as the backbone of cold storage operations across multiple industries. Restaurants rely on them to store bulk ingredients and preserve food safety. Pharmacies use them for temperature-sensitive medications. Funeral homes depend on them for dignified preservation services.

The true cost extends far beyond the initial purchase price. You'll need to factor in installation, ongoing energy consumption, maintenance, and potential customization requirements. A walk-in freezer typically runs 16-18 hours per day, making energy efficiency a critical cost consideration over its 15-20 year lifespan.

As one industry expert noted in our research: "The short answer is 'it depends.' But I know that's not the answer you came here for, so I'll break down some general pricing guidelines."

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping businesses steer commercial walk in freezer cost decisions. My background as a specialized cold storage equipment provider has given me deep insights into the true total cost of ownership for these critical business investments.

How Much Does a Commercial Walk-In Freezer Cost?

Let's get straight to the numbers you're looking for. The commercial walk in freezer cost depends heavily on size, but here's what most businesses can expect to invest:

Small freezers (around 6×6 feet) typically run $5,000 to $10,000. These work great for smaller restaurants or specialty shops that need reliable cold storage without breaking the bank.

Medium-sized units (think 10×10 feet) will cost you $8,000 to $15,000. This sweet spot handles most mid-sized restaurant operations comfortably.

Large industrial freezers (20×20 feet and up) jump to $25,000 to $40,000 or more. These heavy-duty units serve big operations, large restaurants, or specialized facilities like funeral homes.

Here's the thing though – that sticker price is just the beginning. Your lifetime costs include installation, monthly electricity bills, and maintenance over the unit's 15-20 year lifespan.

| Size | Cubic Feet | Price Range |

|---|---|---|

| 6×6 feet | ~288 cu ft | $5,000 - $10,000 |

| 8×10 feet | ~640 cu ft | $7,000 - $12,000 |

| 10×10 feet | ~800 cu ft | $8,000 - $15,000 |

| 20×20 feet | ~3,200 cu ft | $25,000 - $40,000+ |

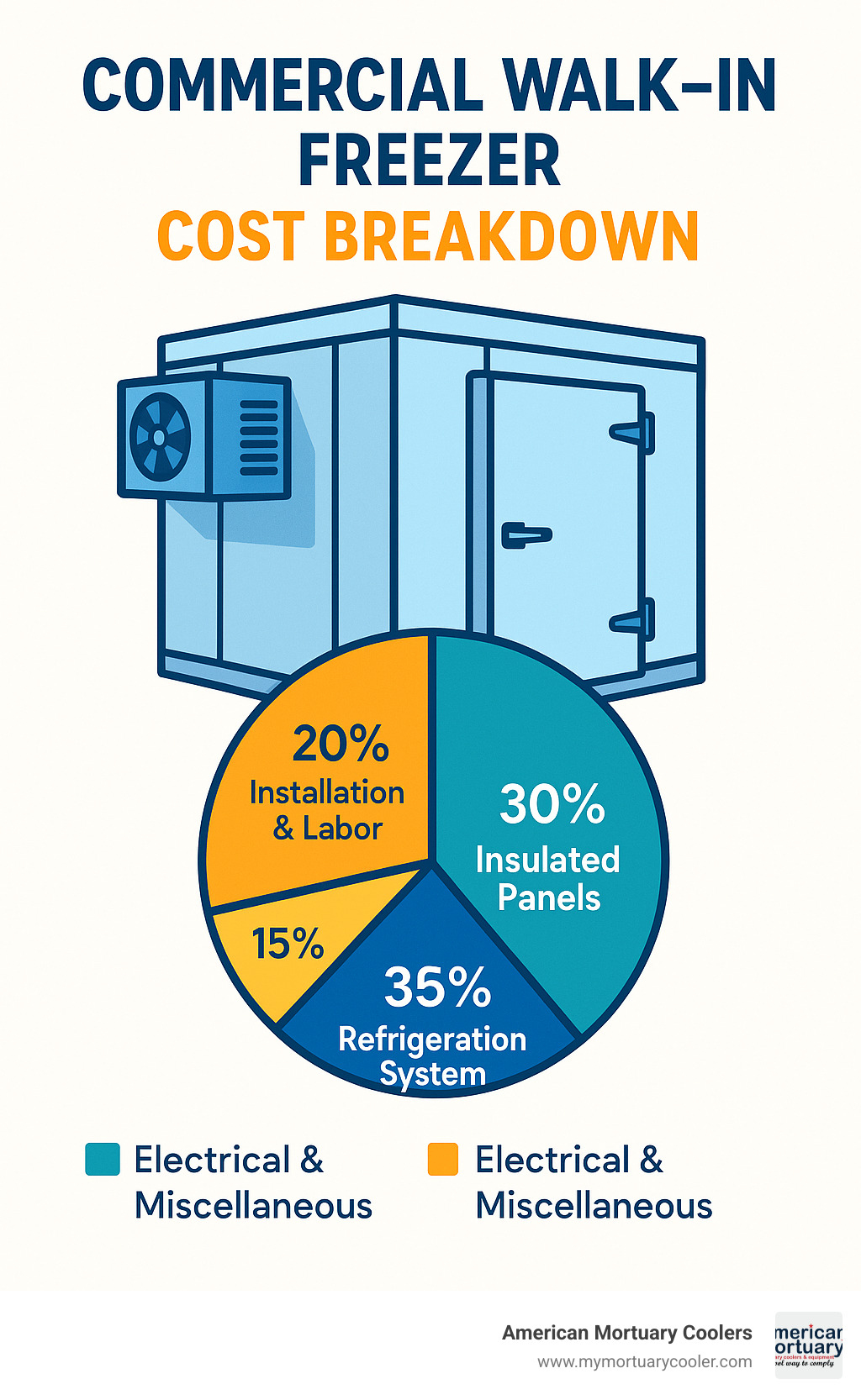

The refrigeration system alone eats up about 35% of your total cost – making it the biggest single expense.

Average Commercial Walk-In Freezer Cost by Size

A 6×6 foot freezer costs $5,000 to $8,000 for the equipment itself. You'll spend roughly $244 monthly on electricity to keep it running. These compact units work perfectly for small restaurants, cafes, or specialty food shops.

8×10 foot units bump up to $7,000 to $12,000 for equipment. Medium-sized restaurants and retail operations love this size for its versatility.

10×10 foot freezers range from $8,000 to $15,000. The 100 square feet of floor space handles larger foodservice operations or facilities that need multi-purpose cold storage.

20×20 foot units and larger start at $25,000 and can easily hit $40,000 or more. Monthly electricity bills often exceed $400, depending on your specific setup and local rates.

You'll also need to decide between quick-ship and custom options. Quick-ship units cost $8,000 to $30,000 and arrive in 1-6 weeks. Custom units run $10,000 to $40,000 but take 10-12 weeks.

Commercial Walk-In Freezer Cost per Square Foot

Here's a handy budgeting rule: expect to pay $100 to $150 per square foot for your freezer, including panels and basic refrigeration equipment.

Your budgeting formula: Floor area × $100-150 = Base equipment cost

So that 10×10 unit (100 square feet) should cost roughly $10,000 to $15,000 for basic equipment. This doesn't cover installation, electrical work, or site prep – those are separate line items.

Panel pricing breaks down to about $50 to $100 per linear foot, depending on insulation thickness and construction quality.

Factors That Influence Your Final Price Tag

Several key variables can dramatically swing your commercial walk in freezer cost from the lower end of our price ranges to the higher end—or even beyond. Think of it like buying a car: the base model gets you where you need to go, but every upgrade adds to the final bill.

The biggest surprise for many buyers? Operating costs vary wildly by location. The latest research on commercial electricity rates shows that businesses in Hawaii pay nearly three times more per kilowatt-hour than those in Louisiana.

Size & Layout Choices

Standard modular sizes offer the sweet spot for value—manufacturers build tons of 6×6, 8×10, and 10×10 units, so you get economy of scale pricing. Step into custom territory, and you're looking at 10-20% premium on your base cost.

Combination cooler-freezer units can actually save you money if you need both. Instead of buying two separate units, a combo design typically costs 10-15% less than purchasing individually.

Think about tomorrow, not just today. Expanding an existing walk-in later costs significantly more than sizing up initially. As a rule of thumb, one cubic foot holds about 28 pounds of frozen food—use that to calculate your true capacity needs.

Insulation & Panel Construction

Polyurethane insulation starts strong with an R-value of 32, but degrades over time. After five years, you're looking at an effective R-value of just 8.

Extruded polystyrene costs more upfront but maintains performance. It starts at R-32 and still delivers R-24 after five years. That sustained insulation performance translates to lower energy bills year after year.

Panel thickness matters too. Standard 4-inch panels handle most applications, while 6-inch panels are essential for extreme temperature requirements.

Refrigeration System Options

Self-contained units mount everything right on the walk-in. They're simpler to install and cost less upfront, but often come with higher operating costs and more interior noise.

Remote systems locate the noisy condenser outside your building. Installation gets more complex, but you'll often see better energy efficiency and quieter operation.

Top-mount systems split the difference—literally. They offer balanced performance and moderate installation requirements.

Installation & Permitting

Budget $2,000 to $7,000 beyond your equipment cost, depending on your site's complexity.

Your installation includes site preparation and concrete pad work, 208-230V electrical service, plumbing connections for condensate drainage, and panel assembly.

Health department approvals add time and sometimes cost, but they're non-negotiable for food service applications. For detailed installation planning, check our guide on Walk-In Cooler Installation Cost.

Indoor vs Outdoor Packages

Outdoor installation might sound like more work, but it can actually save money by avoiding building modifications. Outdoor packages add about 10-15% to base costs but include everything needed for weather protection.

Outdoor packages come with weather-resistant housing, low-ambient refrigeration kits, rain hoods and vinyl roofs, and improved insulation barriers.

Indoor installations skip the weather protection but offer easier maintenance access and better integration with existing workflows.

Operating Costs & Energy Efficiency

Walk-in freezers typically run 16-18 hours daily, making efficiency crucial for your bottom line. Small efficiency improvements compound into significant savings over a 15-20 year lifespan.

Door opening frequency dramatically affects energy consumption. Strip curtains help retain cold air and typically pay for themselves within months through energy savings.

Proper temperature settings matter too. Running your freezer at -15°F instead of the recommended -10°F might seem safer, but those extra 5 degrees can increase energy consumption by 15-20%. Follow scientific research on safe cold storage guidelines for optimal efficiency.

Beyond Purchase Price: Installation, Energy & Maintenance

The true commercial walk in freezer cost extends far beyond the initial purchase. Smart buyers understand that the sticker price is just the beginning of their investment journey.

Installation Cost Breakdown

Professional installation typically adds $2,000-$7,000 to your project cost. While this might seem steep, proper installation is crucial for optimal performance and warranty coverage.

The equipment off-loading and positioning phase often requires specialized equipment like cranes or forklifts, costing $200-$500.

Panel assembly represents the most labor-intensive portion. Technicians use specialized tools to connect the cam-lock panels, ensuring proper gasket compression and seal verification.

Refrigeration hookup involves electrical connections (often requiring upgrading to 208-230V service, which can add $500-$1,500), refrigerant line installation for remote systems, condensate drain plumbing, and system startup testing.

Code compliance and inspections include building permit fees ($100-$500) and health department approvals for food service applications.

For comprehensive installation guidance, check our Walk-In Cooler Pricing 101 guide.

Energy Consumption & Operating Bills

Energy costs represent a significant ongoing expense that many buyers underestimate. A 6×6 freezer typically costs approximately $244 per month to operate, while an 8×10 cooler runs about $132 monthly.

The Average Kilowatt Hours (AKWH) method provides a reliable way to estimate your monthly costs. Simply multiply your unit's AKWH rating by your local electricity rate.

Many utilities offer rebates for energy-efficient commercial refrigeration equipment, potentially reducing both upfront and operating costs by $200-$2,000.

Maintenance & Repair Budget

Annual maintenance costs typically range from $300-$500 for preventive care. Regular maintenance prevents costly breakdowns and extends equipment life.

Routine maintenance tasks include gasket and door seal replacement ($50-$150), evaporator and condenser coil cleaning ($100-$200), and control system calibration ($100-$200).

Major repairs can be expensive when they occur. Compressor replacement costs $2,000-$5,000, while panel repair runs $500-$2,000. Electrical component upgrades typically cost $300-$1,000.

Lifespan & Warranty Considerations

Well-maintained walk-in freezers typically last 15-20 years, making them excellent long-term investments. This longevity helps justify the initial investment and ongoing maintenance costs.

Warranty coverage varies significantly between components. Panels often come with 10-year structural warranties, while refrigeration components typically include 1-year standard coverage with options for 3-5 year extended warranties.

Extended service plans provide peace of mind and budget predictability. These plans typically cost 5-10% of the equipment value annually but can save thousands if major repairs are needed.

Money-Saving Strategies & Financing Options

Nobody likes spending more than they have to, especially on big-ticket items like commercial refrigeration. The good news? There are plenty of ways to reduce your commercial walk in freezer cost without sacrificing quality or performance.

Proper sizing is your first line of defense against overspending. A unit that's too large wastes energy every single day, while one that's too small forces you to buy a second unit sooner than planned.

Energy-efficient models cost more upfront but pay for themselves through lower operating costs. When a freezer runs 16-18 hours daily for 15-20 years, those monthly savings really add up.

Don't overlook rebate programs. Many utilities offer substantial incentives for energy-efficient commercial refrigeration equipment. Federal tax credits and local utility rebates can reduce your net cost by thousands of dollars.

New vs Used Commercial Walk-In Freezers

The used equipment market tempts many buyers with 30-50% upfront savings, but proceed with caution. As one industry expert noted: "Used walk-in coolers often lead to larger expenses and headaches."

New equipment brings full manufacturer warranties, the latest energy efficiency technology, and customizable specifications. You'll also get a predictable maintenance schedule and peace of mind.

Used equipment can offer significant savings, but comes with unknown maintenance history, limited warranty coverage, and potential for costly hidden repairs. If you go the used route, budget extra for unexpected repairs and have the unit thoroughly inspected.

Financing & Leasing Paths

You don't have to pay cash upfront for your walk-in freezer. Several financing options can help spread the cost while preserving your working capital.

Capital leases let you own the equipment at lease end while enjoying tax depreciation benefits. These typically run 3-7 years and work well for businesses that want to eventually own their equipment.

Operating leases offer lower monthly payments and often include maintenance coverage. They're perfect for businesses that prefer to refresh their equipment regularly.

The Section 179 tax deduction allows profitable businesses to immediately expense qualifying equipment rather than depreciating it over time. This can create significant tax savings in the year of purchase.

Cutting Operating Costs

Smart operational choices can dramatically reduce your monthly expenses. LED lighting cuts both energy consumption and heat load inside the freezer. Door alarms prevent costly temperature loss from accidentally leaving doors open. Smart controls optimize defrost cycles to run only when needed.

Strip curtains are one of the most cost-effective upgrades you can make. They dramatically reduce cold air loss during loading and unloading.

Train your staff on energy-saving practices. Simple habits like minimizing door opening frequency, allowing hot items to cool before refrigeration, and keeping door seals clean can reduce operating costs by 10-15%.

Regular maintenance prevents small problems from becoming expensive repairs. Check with your local utility company about available rebate programs for ongoing incentives.

Expert Tips for Selecting the Right Walk-In Freezer

Choosing the right walk-in freezer involves much more than comparing commercial walk in freezer cost figures. After years of helping businesses across Tennessee, Atlanta, Chicago, and beyond, I've learned that the smartest buyers focus on getting the right fit for their specific needs rather than just the lowest price.

The key is conducting a thorough needs assessment before you start shopping. This means honestly evaluating your current storage requirements, understanding your peak demand periods, and planning for future growth.

Load calculations matter more than you might think. One cubic foot of freezer space holds approximately 28 pounds of food, but you'll also need space for proper air circulation and staff movement. Don't forget to account for seasonal fluctuations.

Proper Sizing & Capacity Planning

Getting the size right from the start saves you money and headaches down the road. I always recommend starting with your product turnover analysis. How much inventory do you move through weekly? What's your delivery schedule like?

Peak season planning is where many businesses get caught off guard. That busy holiday period or summer rush isn't just a nice problem to have – it's a reality your freezer needs to handle. Build in a 20-30% buffer above your normal capacity.

Think about future expansion too. It's much more cost-effective to install a slightly larger unit now than to add a second unit or upgrade entirely in a few years.

Allow for 40-inch aisles between shelving units so staff can work efficiently. You'll also need proper clearances around refrigeration equipment – at least 2 feet for packaged units and 2 inches for remote condensers.

Supplier & Manufacturer Checklist

Supplier vetting can make or break your walk-in freezer experience. The lowest bidder isn't always your best choice, especially when you consider long-term support and reliability. Look for suppliers with solid certifications like NSF approval and UL listing.

Check their lead times honestly. Can they deliver when you need it? Quick-ship units typically arrive in 1-6 weeks, while custom builds take 10-12 weeks.

The service network matters tremendously after installation. When your freezer needs repair at 2 AM on a Saturday, you want a supplier with local service coverage and emergency response capability.

Don't skip checking references from similar businesses in your area. A supplier might be great for restaurants but struggle with funeral home requirements, or vice versa.

For a comprehensive evaluation framework, check out our Ultimate Checklist for Choosing a Walk-In Freezer Supplier guide.

Compliance & Permitting Mistakes to Avoid

Regulatory codes trip up more businesses than you'd expect. The permitting process isn't just bureaucratic paperwork – it's about ensuring your installation is safe, legal, and won't cause expensive problems later.

Common pitfalls include underestimating electrical requirements. Most walk-in freezers need 208-230V service, which might require electrical upgrades to your facility.

Building codes vary significantly by location, but most require proper structural support calculations, adequate ventilation for refrigeration components, and fire safety considerations.

Health department approvals follow their own timeline and requirements. Schedule your pre-approval meetings early in the process, not the week before installation.

The electrical permit process alone can take weeks in some jurisdictions. Missing this step can shut down your project entirely. Always confirm permit requirements with your local building department before ordering equipment.

Working with experienced suppliers helps you steer these regulatory waters more smoothly. At American Mortuary Coolers, we've guided countless businesses through the compliance process, helping them avoid costly delays and ensure their installations meet all applicable codes from day one.

Frequently Asked Questions about Commercial Walk-In Freezer Cost

Let's tackle the three most common questions we hear from customers considering their first walk-in freezer investment. These answers come from years of helping businesses across the country steer their cold storage decisions.

What is the typical commercial walk-in freezer cost per square foot?

You can expect to pay $100 to $150 per square foot for a commercial walk-in freezer, including basic panels and refrigeration equipment. This gives you a solid starting point for budgeting, though your final cost depends on several factors.

Here's how the math works: multiply your floor area by this range to get your baseline equipment cost. A 10×10 foot unit (100 square feet) would run approximately $10,000-$15,000 for the equipment itself.

But here's the catch – that square footage price doesn't include everything you'll need. Installation, electrical work, and site preparation typically add another $2,000-$7,000 to your total investment. The commercial walk in freezer cost per square foot is just your starting point, not your finish line.

Insulation type, refrigeration system choice, and any custom features will push your final cost higher or lower within that range. Indoor units typically cost less than outdoor packages, which need weatherproofing.

How long does installation usually take and what's included?

Most standard walk-in freezer installations take 1-3 days from start to finish. The timeline depends on your unit's complexity and site conditions, but here's what you can expect during those days.

Day one usually involves panel assembly using cam-lock connections – those specialized fasteners that hold your freezer walls together. Your installation team will also handle door alignment and hardware adjustment to ensure everything seals properly.

The refrigeration system hookup and startup typically happens on day two, along with electrical connections and testing. This is when your freezer actually becomes functional, though it needs time to reach proper temperature.

Day three covers system commissioning and temperature verification – basically making sure everything works correctly before your installer leaves. Some installations finish faster, especially with pre-assembled units that reduce on-site work.

Installation costs ($2,000-$7,000) often require additional work like electrical upgrades, concrete pad preparation, and permit fees. Many customers are surprised by these "extras," but they're essential for a proper installation.

What is the expected lifespan of a well-maintained unit?

A well-maintained commercial walk-in freezer should serve your business for 15-20 years, making it one of the better long-term investments you can make. The key phrase here is "well-maintained" – neglect will cut that lifespan significantly.

Regular maintenance is your secret weapon for reaching that 20-year mark. This means monthly coil cleaning, checking refrigerant levels, and replacing door seals when they show wear. Think of it like maintaining a vehicle – small investments in upkeep prevent major breakdowns.

Some components will need replacement during your freezer's lifetime. Compressors typically last 10-15 years, while door hardware might need updates every 5-7 years depending on usage. Panel construction usually outlasts everything else when properly maintained.

Quality manufacturers offer extended warranties and service plans to protect your investment beyond the standard coverage. These plans often pay for themselves by catching small problems before they become expensive repairs.

The funeral industry equipment we specialize in at American Mortuary Coolers often exceeds these lifespan expectations because our customers understand the importance of reliable temperature control. Proper care and professional service make all the difference in maximizing your freezer's working life.

Conclusion

Making smart decisions about commercial walk in freezer cost means thinking beyond that initial price tag. Over the 15-20 year lifespan of your unit, you'll invest in installation, energy bills, and maintenance – and these costs can really add up if you don't plan carefully.

The good news? Smart planning saves thousands while giving you reliable cold storage that actually works when you need it most. The secret is choosing quality insulation that won't lose efficiency over time, properly sizing your unit so you're not overpaying or running out of space, and investing in energy-efficient refrigeration that qualifies for utility rebates.

Professional installation might seem like an extra expense, but it's actually an investment in optimal performance. And here's something many business owners overlook: regular maintenance is way cheaper than emergency repairs. A little preventive care goes a long way toward maximizing your equipment's lifespan.

At American Mortuary Coolers, we've learned that every cold storage situation is different. Based in Tennessee and serving businesses across all 48 contiguous states, we specialize in crafting durable, custom solutions that fit your exact needs. Our background in specialized cold storage applications has taught us how to optimize total cost while delivering the reliability you depend on.

Whether you're expanding your restaurant, upgrading pharmacy storage, or designing specialized preservation facilities, investing in quality walk-in freezer equipment pays off in reliability, efficiency, and long-term value. The peace of mind alone is worth it.

For more insights into commercial refrigeration solutions, check out our guide to Commercial Walk-In Freezers That Are Cooler Than Cool.

Here's the bottom line: the cheapest upfront cost rarely gives you the best value. Focus on total cost of ownership, energy efficiency, and reliable performance. Your future self (and your accountant) will thank you for making the smart investment in your business's future.