What Is a Commercial Walk In Freezer and Why Do Businesses Need One?

A commercial walk in freezer is a large, insulated cold storage room designed to keep food or other perishables safely frozen, typically at –10°F or lower. Used in restaurants, grocery stores, mortuaries, and more, these freezers offer much more space and reliability than standard reach-in units.

Quick facts about commercial walk in freezer:

| Feature | Details |

|---|---|

| Purpose | Stores bulk items at –10°F or below |

| Typical Sizes | 6′×8′ to 40′×40′+ (custom available) |

| Industries | Foodservice, florists, pharmacies, mortuaries |

| Insulation | 4" polyurethane panels, R-32 & up |

| Average Lifespan | 15+ years with good maintenance |

| Energy Tips | LED lights, thick insulation, tight gaskets |

| Compliance | NSF, UL, EISA (energy/code standards) |

"Walk-in freezers are a staple in many industries, offered in a variety of sizes and designs to meet different operational needs."

If you’re searching for a commercial walk in freezer, you want cold storage that is tough, energy efficient, customizable, and compliant with industry regulations. You’ll also need to choose options custom for your space—indoor or outdoor, self-contained or remote refrigeration, and the right warranty for peace of mind.

I'm Mortuary Cooler, a national mortuary cooler supplier and U.S. cooler expert. With years helping businesses and funeral homes select the ideal commercial walk in freezer for reliability and efficiency, I know what matters most: straightforward choices, fast delivery, and lasting results.

Basic commercial walk in freezer glossary:

Anatomy & Key Specs Every Buyer Should Know

When you're shopping for a commercial walk in freezer, you're not just buying a big cold box. You're investing in a sophisticated piece of equipment that needs to keep your products safe, your energy bills reasonable, and your business compliant with health codes.

Think of it like buying a car—you wouldn't just look at the color and price. You'd want to know about the engine, safety features, and how long it'll last. The same goes for commercial freezers.

Main Components & Features

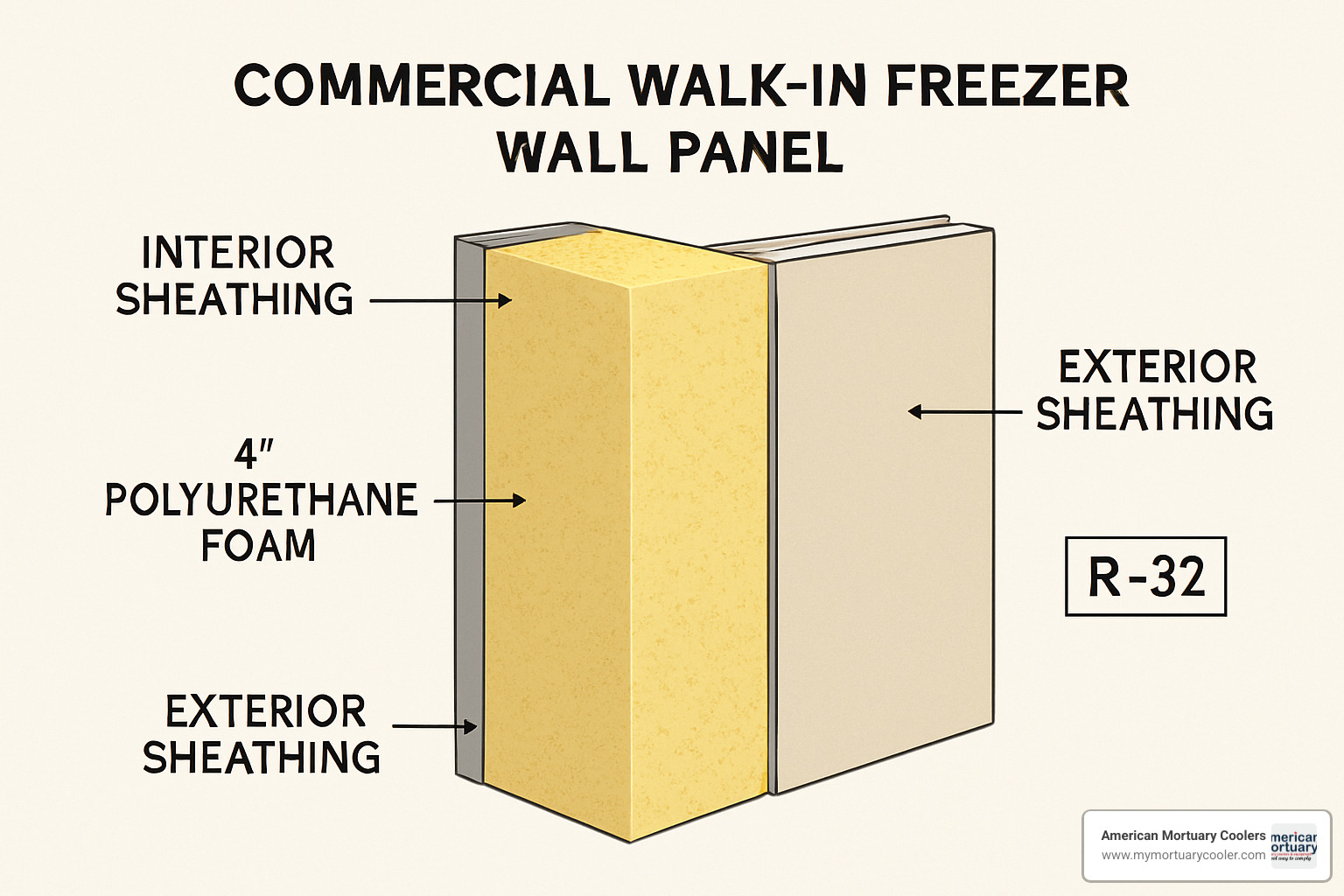

The heart of any commercial walk in freezer starts with insulated panels. These aren't your average wall panels—they're typically 4 inches thick, packed with polyurethane foam that delivers an R-value of 32 or higher. That's what keeps the Arctic air inside and the summer heat outside, even when it's blazing hot in Tennessee.

Doors might seem simple, but they're doing heavy lifting. Most are 34" x 78" or 36" x 78", built with industrial-strength hinges and self-closing mechanisms. The real magic happens with the magnetic gaskets—they seal tight like a refrigerator door, but sized for commercial use. Many doors get diamond kick-plates too, because let's face it, things get bumped in busy kitchens.

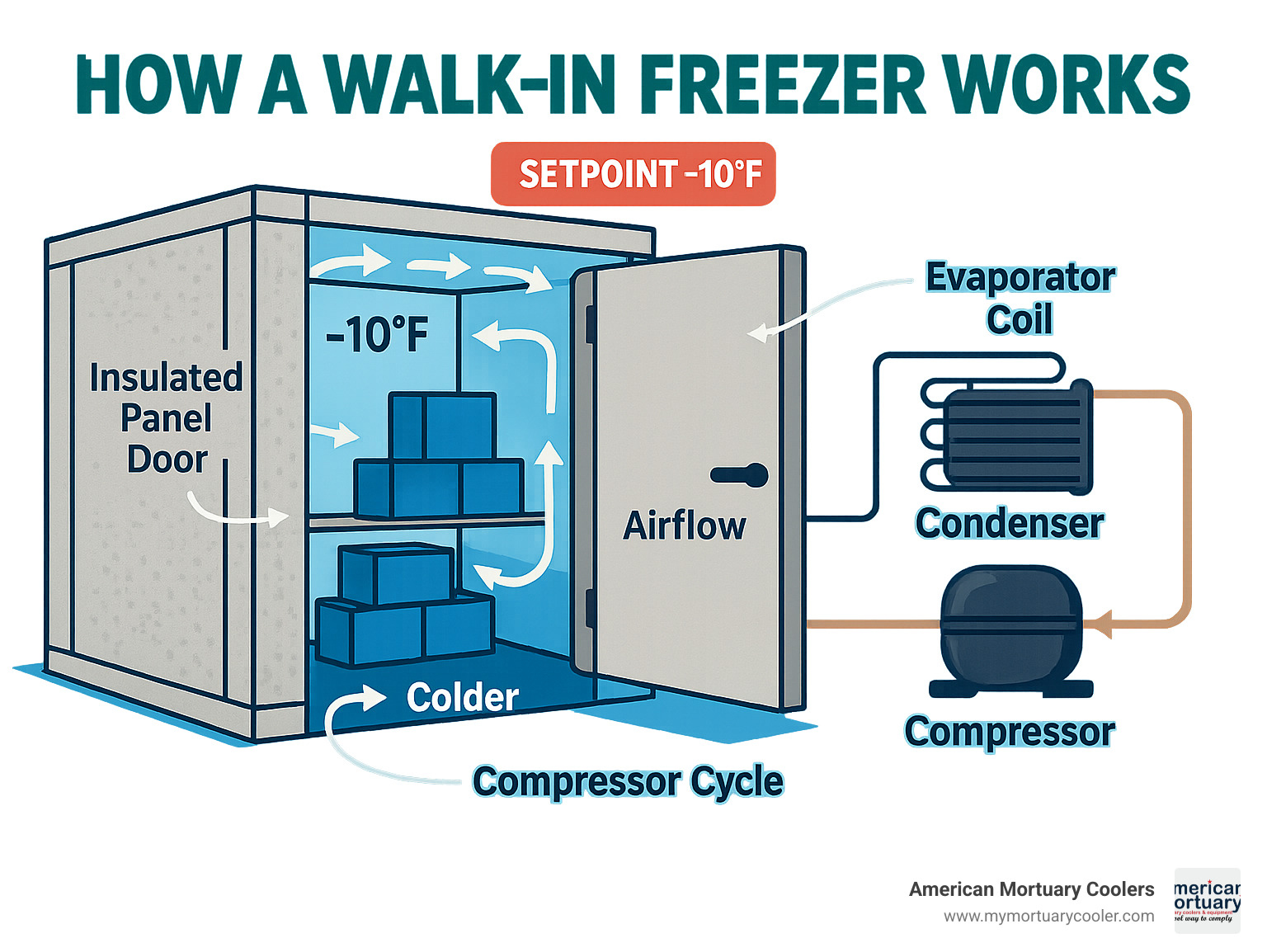

The evaporator and compressor work as a team. The evaporator pulls heat from inside your freezer, while the compressor dumps that heat outside. You can get these as self-contained units (everything in one package) or remote systems (compressor outside, evaporator inside). We'll dig deeper into that choice in a moment.

Flooring is crucial for freezers. Unlike coolers, freezers need insulated floors to prevent the ground from warming things up. Most use diamond-tread steel or NSF-approved fiberglass—both tough enough for daily use and easy to clean.

Defrost cycles run automatically to prevent ice buildup on the coils. Modern systems use electric or hot-gas defrost, with smart controls that wait until coil temperatures drop to 20°F after defrost before starting the fans again.

You'll also get vapor-proof LED lighting (moisture and cold don't mix well with regular bulbs) and relief ports. Those little ports might seem minor, but they prevent pressure buildup that makes doors impossible to open—your back will thank you.

Modern engineering keeps improving these systems. Latest research on thermal conductivity shows that fiberglass exteriors can achieve thermal conductivity as low as 0.04 BTUs—far better than aluminum or steel panels.

For more details on features and pricing, check out our complete guide to walk-in cooler features.

Common Components Glossary

Cam-lock panels connect your walls, ceiling, and floor with heavy-duty locks that create airtight seals. They make assembly easier and ensure everything stays put for years.

Magnetic gaskets work like your home refrigerator door seal, but built for commercial punishment. They use magnetic strips to keep doors sealed tight.

Vapor-proof LED lighting handles moisture and cold without shorting out. These fixtures are designed specifically for freezer environments.

Relief ports are small vents that equalize pressure when doors open and close frequently. Without them, you'd need superhuman strength to open the door after busy periods.

Why Temperature Matters in a Commercial Walk-In Freezer

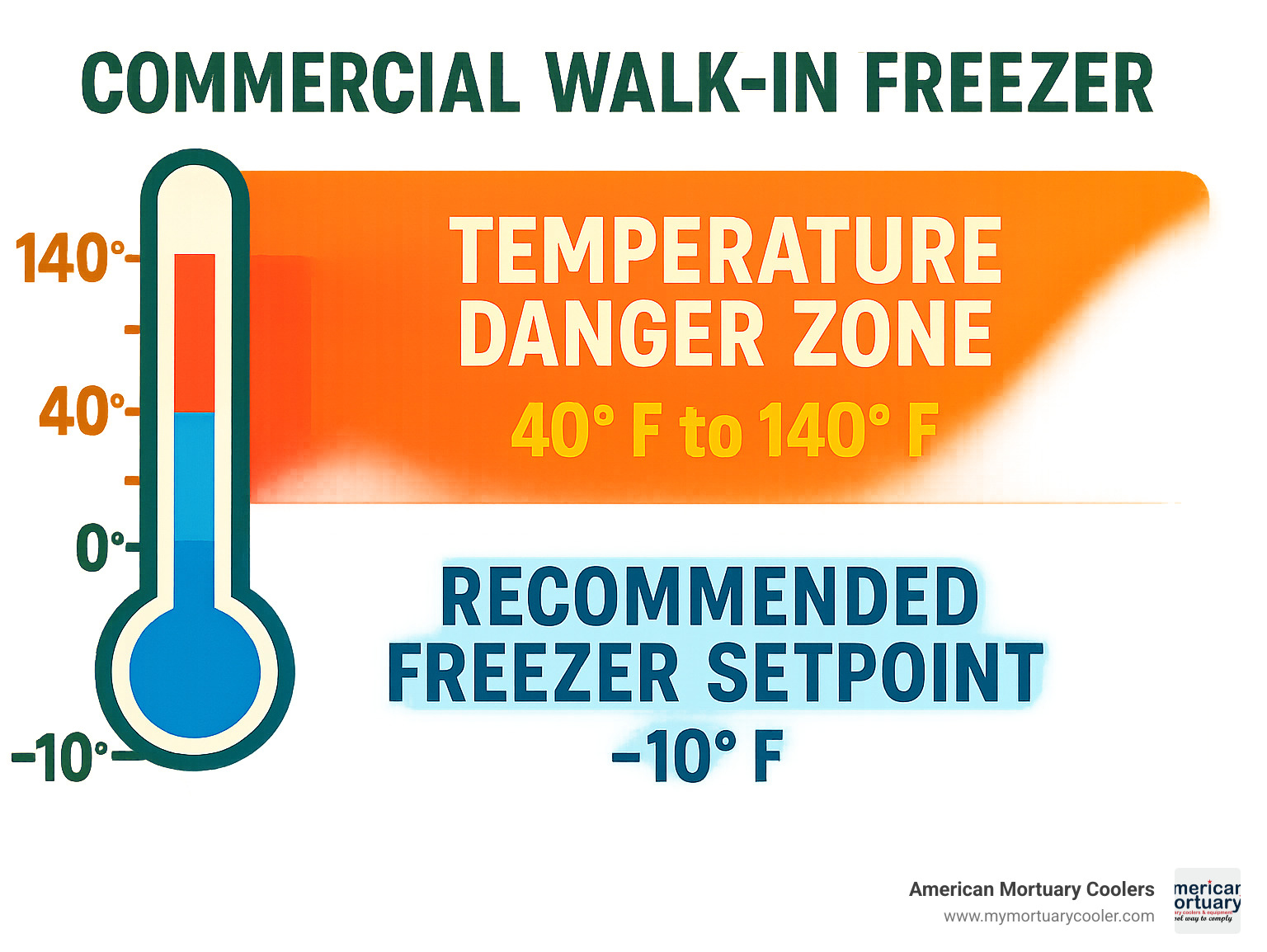

The standard -10°F setpoint isn't just a random number—it's based on food safety science and regulations. At this temperature, bacteria can't grow, and food quality stays locked in for months instead of days.

Food safety requires temperatures below 0°F according to FDA guidelines, but -10°F gives you that extra safety margin. It's like wearing a seatbelt—you hope you won't need it, but you're glad it's there.

Product quality improves dramatically at proper temperatures. Less freezer burn, longer shelf life, and better texture when you thaw items. Whether you're storing wedding cakes or prime rib, proper temperature control makes the difference.

For specialty applications like pharmaceuticals, blood plasma, or mortuary storage, temperature control becomes even more critical. Some applications need blast freezing down to -40°F for rapid temperature reduction.

The choice between self-contained and remote refrigeration affects your entire operation:

| System Type | Pros | Cons | Best For |

|---|---|---|---|

| Self-Contained | Easy install, all-in-one design | Louder, more heat inside, size limits | Small to medium units |

| Remote | Quieter, less heat indoors, scalable | Needs line-set install, higher upfront | Large/industrial, outdoor |

Self-contained systems put everything in one package—perfect for smaller operations or indoor installations where simplicity matters most. Remote systems separate the noisy compressor from your workspace, making them ideal for larger facilities or noise-sensitive environments.

Best Commercial Walk-In Freezer Models for Every Industry

Finding the right commercial walk in freezer feels a bit like dating—you need the perfect match for your space, your budget, and your industry's quirks. Whether you're storing wedding cakes or maintaining the cold chain for pharmaceuticals, we've rounded up the top models that deliver reliability across restaurants, breweries, funeral homes, and beyond.

Each of these freezers brings something special to the table, from lightning-fast installation to warranties that outlast most marriages. Let's explore what makes each one shine.

Polar King Outdoor Commercial Walk-In Freezer

When Mother Nature throws her worst at your freezer, the Polar King laughs it off. This outdoor powerhouse features a seamless fiberglass shell that's been torture-tested in 175°F desert heat and arctic winters alike. No rust, no leaks, no worries.

The 12-year structural warranty speaks volumes about build quality. With 4-inch urethane insulation delivering R-32+ performance, your frozen goods stay put whether you're in Phoenix or Fairbanks. Available in widths from 6 to 16 feet and lengths up to 60 feet, it handles everything from small restaurant needs to warehouse-scale storage.

The real magic? It arrives pre-assembled and pre-wired—just hook up power and you're freezing. Perfect for businesses that need reliable outdoor storage without the headache of complex installation.

American Walk-In Coolers Quick-Ship Freezer

Sometimes you need cold storage yesterday, and that's where American Walk-In Coolers delivers. Their Quick-Ship Freezer lives up to its name with fast turnaround times and an instant online quote system—no waiting for callback tag.

Built right here in the USA, these units come with a 20-year panel warranty and 5-year coverage on doors and compressors. The modular cam-lock panels with 4-inch polyurethane insulation meet all NSF and UL requirements, so you're code-compliant from day one.

Standard features include LED lighting and PVC strip curtains to minimize cold loss during busy periods. Plus, they offer nationwide installation to get you up and running professionally.

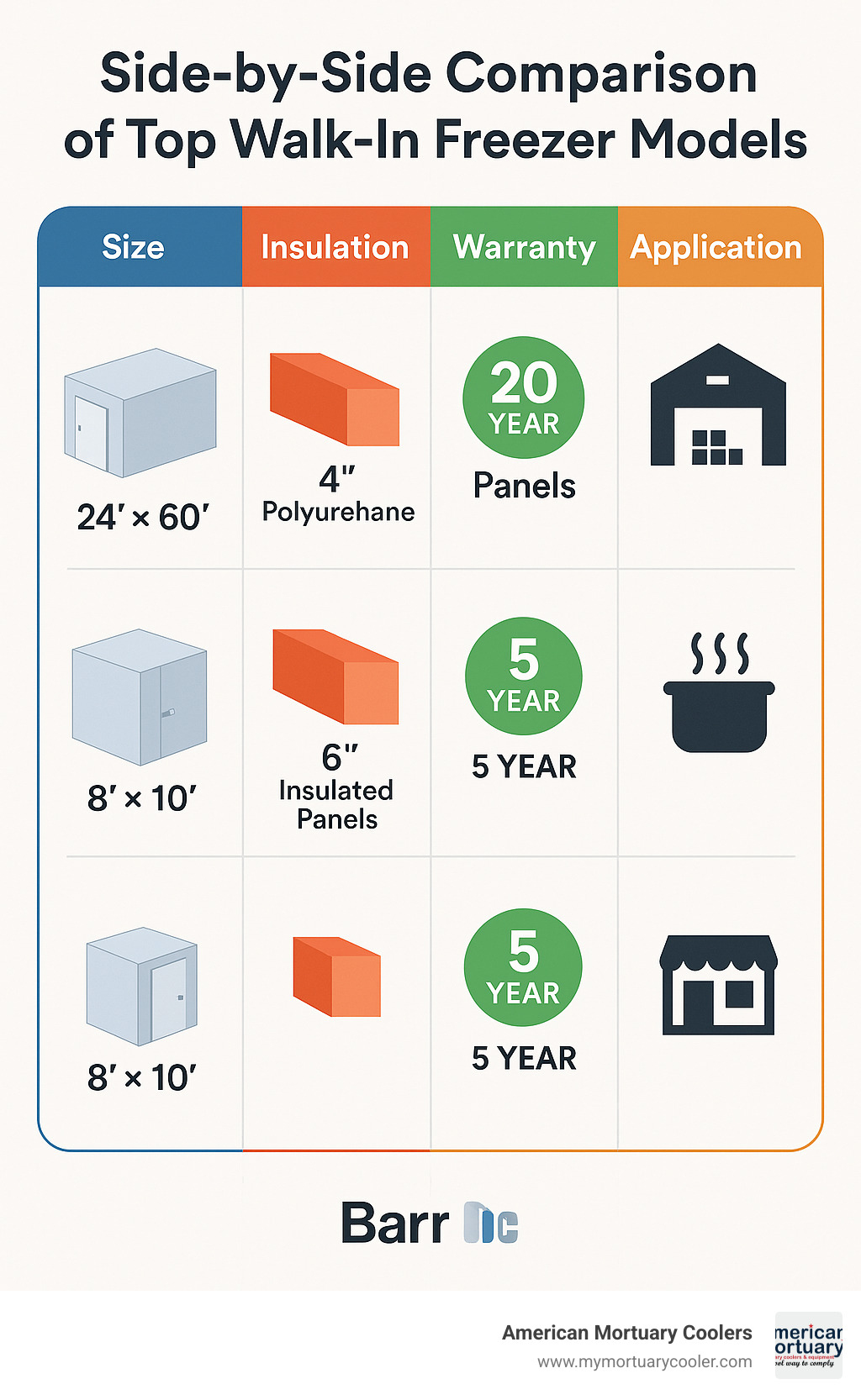

Barr Inc. Industrial Freezer (24′×60′)

When you need serious cold storage space, the Barr Inc. Industrial Freezer doesn't mess around. This beast offers 1,440 square feet of freezer space with forklift-sized doors and custom floor loads up to 7,200 pounds per square foot.

Built for large-scale distribution and food manufacturing, it features multiple access points and heavy-duty flooring that can handle whatever you roll through those doors. The custom design flexibility means it works for everything from ice cream warehouses to pharmaceutical cold storage—and yes, it's excellent for mortuary applications too.

This isn't just storage; it's cold-chain infrastructure that grows with your operation.

DOLUYO EVI Blast Freezer Room

Speed matters in food processing, and the DOLUYO EVI Blast Freezer delivers rapid temperature pull-down that would make a Formula 1 pit crew jealous. The monoblock design installs in just 20 minutes, while Improved Vapor Injection compressors reach -40°C for serious blast freezing power.

The 150mm insulated panels and hot-gas defrost system keep operations running smoothly, while automatic load adjustment adapts to your production needs. The side-embedded installation keeps your workflow lean and efficient.

Perfect for seafood processors, ice cream manufacturers, or any operation where fast freezing preserves product quality and profits.

8′×10′ Starter Commercial Walk-In Freezer Box

Not every business needs warehouse-scale freezing. This entry-level freezer delivers industry-standard performance at a startup-friendly price. The 8×10×8'2" footprint with 4-inch urethane insulation and R-32 rating meets all code requirements without breaking the bank.

The 34×78-inch self-closing door and simple cam-lock installation mean you can get cold storage up and running quickly. As your business grows, these modular systems expand easily—making it a smart investment for bakeries, small restaurants, and test kitchens.

Sometimes the best commercial walk in freezer is the one that gets you started without overwhelming your budget or your space.

Each of these models brings proven performance to different industries and applications. The key is matching your specific needs—space, budget, installation requirements, and industry compliance—with the right freezer's strengths. Whether you're preserving dignity in mortuary care or keeping the perfect scoop ready for summer crowds, there's a commercial walk in freezer built for your success.

Selecting & Installing the Perfect Unit

Choosing the right commercial walk in freezer isn't rocket science, but it does require some thoughtful planning. Think of it like buying a car—you wouldn't pick a two-seater sports car for a family of six, right?

How to Right-Size Your Commercial Walk-In Freezer

The golden rule for sizing is 28 pounds per cubic foot—that's the industry standard for frozen storage density. So if you're storing 1,000 pounds of frozen goods, you'll need about 36 cubic feet of space. But here's where it gets interesting.

Your delivery frequency makes a huge difference. Getting daily deliveries? You can get away with a smaller unit since you're not stockpiling for weeks. But if you're like most businesses and get weekly or bi-weekly deliveries, you'll need more breathing room.

When planning your space, remember to leave 40-inch aisles for rolling carts—trust me, your staff will thank you when they're not playing Tetris with a fully loaded cart. Perimeter shelving maximizes your usable area without blocking traffic flow.

Don't forget about future growth. If you're expanding your menu or expect business to grow, consider modular systems that can expand with you. Some businesses find combo units (cooler and freezer in one footprint) work perfectly for their mixed storage needs.

Save on business energy costs

Installation Checklist & Timeline

Getting your commercial walk in freezer installed smoothly starts with good preparation. Here's what you need to know to avoid any "cool" surprises.

Site preparation is crucial. Your slab needs to be level within 1/4 inch per 10 feet—any more and your door won't seal properly. For outdoor units, concrete is non-negotiable. Check overhead clearance too, because you'll need access for cranes or forklifts during delivery.

Most units arrive either pre-assembled or in modular panels. The cam-lock panel systems are actually pretty clever—they connect easily with just a cam wrench and some muscle. If you're going with a remote condensing unit, you'll need line-set runs (standard up to 35 feet, longer runs cost extra).

Electrical hookup requires a licensed electrician for final power connections. Most systems run on 208-230V single phase, though larger industrial units need 3-phase power. Don't try to DIY this part—it's not worth the risk.

The startup and testing phase is where everything comes together. Verify your door seals are tight, set your temperature controls to that crucial -10°F setpoint, and check that lighting and alarms work properly. Run a defrost cycle and make sure drainage is working correctly.

Finally, make sure you're code compliant. UL, NSF, and EISA compliance aren't just nice-to-haves—they're must-haves for food safety and energy rebates. Check local requirements for seismic, hurricane, or snow-load specs too.

More info about refrigeration units

Maintenance & Cost-Cutting Hacks to Hit 15+ Years

Your commercial walk in freezer is a workhorse—treat it right, and it'll keep your products frozen solid for 15+ years. Skip the maintenance, and you'll be shopping for a replacement sooner than you'd like (and explaining to your boss why the ice cream melted).

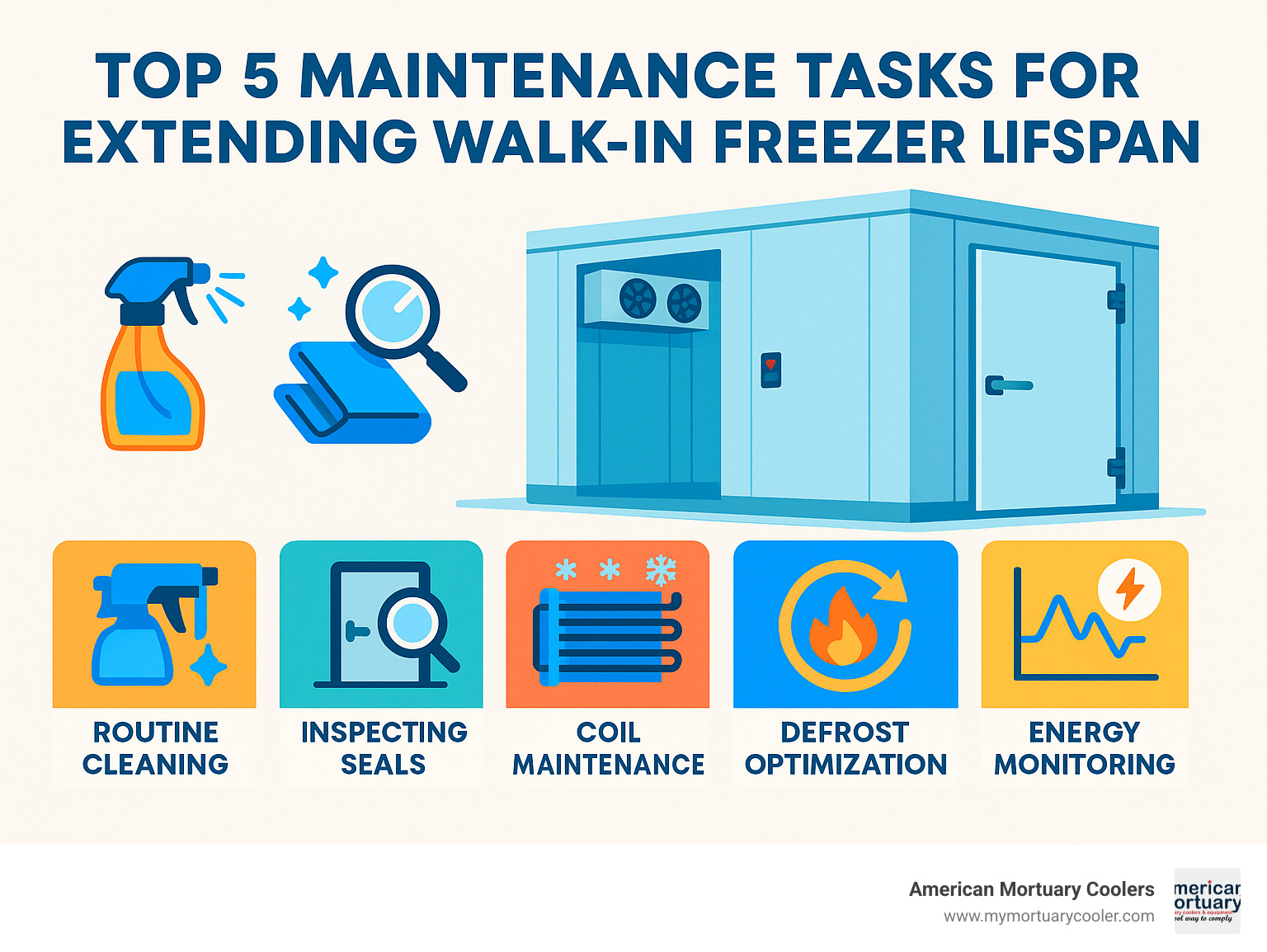

The secret to longevity isn't complicated: routine cleaning, smart energy monitoring, and catching small problems before they become expensive headaches.

Start with weekly cleaning of walls, floors, and shelving. It's not glamorous, but clean surfaces stay colder and last longer. Monthly, give those door gaskets some love—wipe them down and check for cracks or tears. A worn gasket is like leaving your front door open in January.

Coil maintenance is where the real money-saving magic happens. Keep your evaporator and condenser coils free of ice, dust, and that mysterious fuzzy stuff that accumulates over time. Set your defrost cycles correctly—typically three times daily for electric defrost systems. When those coils get clogged, your compressor works overtime, and your electric bill shows it.

Here's a pro move: install PVC strip curtains on high-traffic doors. They're like a bouncer for warm air—keeping the cold in while your staff moves in and out. Your compressor will thank you with lower runtime hours (most walk-ins run 16–18 hours daily, but efficient ones can do less).

Energy monitoring might sound fancy, but it's just paying attention to how hard your system works. Track those runtime hours and watch for spikes that signal trouble. Modern systems even send alerts to your phone—technology making your life easier for once.

Don't ignore moisture control. Check regularly for condensation and ice buildup in weird places. Water where it shouldn't be means your insulation's R-value is taking a hit, and wet insulation is about as useful as a screen door on a submarine.

Defrost optimization is all about timing. Set your fan delay so fans restart when coil temperature hits 20°F after defrost, with a 5–7 minute drip time. Get this wrong, and you'll have ice castles growing on your coils.

More info about gasket replacement

Troubleshooting Common Issues

When your freezer starts acting up, don't panic. Most problems have simple solutions—if you catch them early.

Ice buildup is the most common complaint, and it's usually telling you about door leaks, failed defrost cycles, or too much warm air sneaking in. Check those gaskets first, then your strip curtains, then the defrost timer. Nine times out of ten, it's one of these three culprits.

Warm spots in your freezer mean uneven temperatures, which means unhappy health inspectors. Usually, this points to blocked airflow from overloaded shelves or failing circulation fans. Give your products some breathing room, and make sure nothing's blocking the air vents.

A high amp draw on your compressor means it's working too hard. Dirty condenser coils or low refrigerant are the usual suspects. This is when you call in a professional—don't try to be a hero with refrigerant.

Noisy compressors are like cars—a normal hum means everything's fine, but screeching, grinding, or banging means trouble. When in doubt, call your service tech. It's cheaper than a new compressor.

Most of these headaches disappear with monthly visual checks and a yearly professional tune-up. Think of it as preventive medicine for your freezer—a little attention now saves a lot of money later.

Frequently Asked Questions about Commercial Walk-In Freezers

Let's tackle the three questions we hear most often from businesses shopping for their first commercial walk in freezer—or upgrading their current setup.

How cold should a commercial walk-in freezer be?

Your commercial walk in freezer should maintain –10°F for optimal food safety and quality. This isn't just a suggestion—it's the industry gold standard that keeps your products safe from harmful bacteria while preserving taste and texture for months.

Some specialized applications need even colder temperatures. Blast freezers can reach –40°F for rapid freezing of delicate items like seafood or baked goods. But for most restaurants, grocery stores, and food service operations, that reliable –10°F setpoint is exactly what you need.

The key is consistency. Temperature swings can cause freezer burn, compromise food safety, and cost you money in spoiled inventory. A quality unit with proper insulation and regular maintenance will hold that –10°F like a champ.

What's the average lifespan and how can I extend it?

A well-built commercial walk in freezer typically lasts 15 years—and with proper care, many units keep running strong well beyond that. We've seen units from the 1990s still humming along in busy kitchens.

The secret to longevity? Stick to a maintenance schedule. Clean those coils monthly, replace door gaskets when they show wear, and don't ignore small issues before they become big problems. Think of it like your car—regular oil changes and tune-ups prevent expensive breakdowns.

Simple habits make a huge difference. Keep the interior clean, don't overload shelves (which blocks airflow), and train your staff to close doors promptly. These little steps can add years to your freezer's life and keep your energy bills reasonable.

Self-contained vs remote systems—what's better?

The answer depends on your space, noise tolerance, and service access needs. Both systems have their sweet spots.

Self-contained units are the plug-and-play option. Everything's built into one compact package, making installation quick and straightforward. They're perfect for smaller operations or tight spaces where you can't run refrigeration lines. The downside? They're noisier since the compressor sits right on top of the unit, and they generate more heat inside your building.

Remote systems separate the noisy compressor from the freezer box, keeping your workspace quieter and cooler. They're easier for technicians to service (no crawling around in cramped spaces), and they handle larger capacities better. The trade-off is more complex installation—you'll need refrigeration lines run between the indoor and outdoor components, plus higher upfront costs.

For most small to medium businesses, self-contained wins on simplicity and budget. But if you're planning a large installation or noise is a concern, remote systems are worth the extra investment.

Conclusion

Your commercial walk in freezer journey doesn't end when the unit arrives—it's just the beginning of years of reliable cold storage that keeps your business running smoothly. Whether you're storing prime rib for Saturday's dinner rush, preserving delicate flowers for wedding season, or maintaining the dignity we specialize in at American Mortuary Coolers, the right freezer becomes part of your daily success story.

The key takeaways that matter most? Right-sizing your unit means calculating that 28-pounds-per-cubic-foot rule while planning for future growth—nobody wants to outgrow their freezer in year two. Energy savings come from smart choices like thick insulation (R-32 minimum), LED lighting that won't burn out in the cold, and magnetic gaskets that seal tight every single time.

But here's what really counts: long-term ROI. A well-chosen commercial walk in freezer with proper maintenance easily hits that 15-year mark, often stretching to 20 years or more. When you break down the numbers, that's pennies per day for reliable cold storage that never takes a sick day.

At American Mortuary Coolers, we've seen how the right cold storage solution transforms operations—from small funeral homes to large facilities across all 48 contiguous states. Compliance matters too, and every unit we deliver meets NSF, UL, and EISA standards, so you're covered for inspections and eligible for energy rebates that put money back in your pocket.

Ready to take the next step? We're here to help you steer everything from initial sizing to final installation, with direct delivery from our Tennessee facility to your front door.

See more walk-in coolers & freezers solutions or get in touch for a custom quote that fits your space, your budget, and your business perfectly.