A Comprehensive Guide to 404A Pressure Temperature Charts

Why 404A Pressure Temperature Charts Are Essential for Reliable Refrigeration

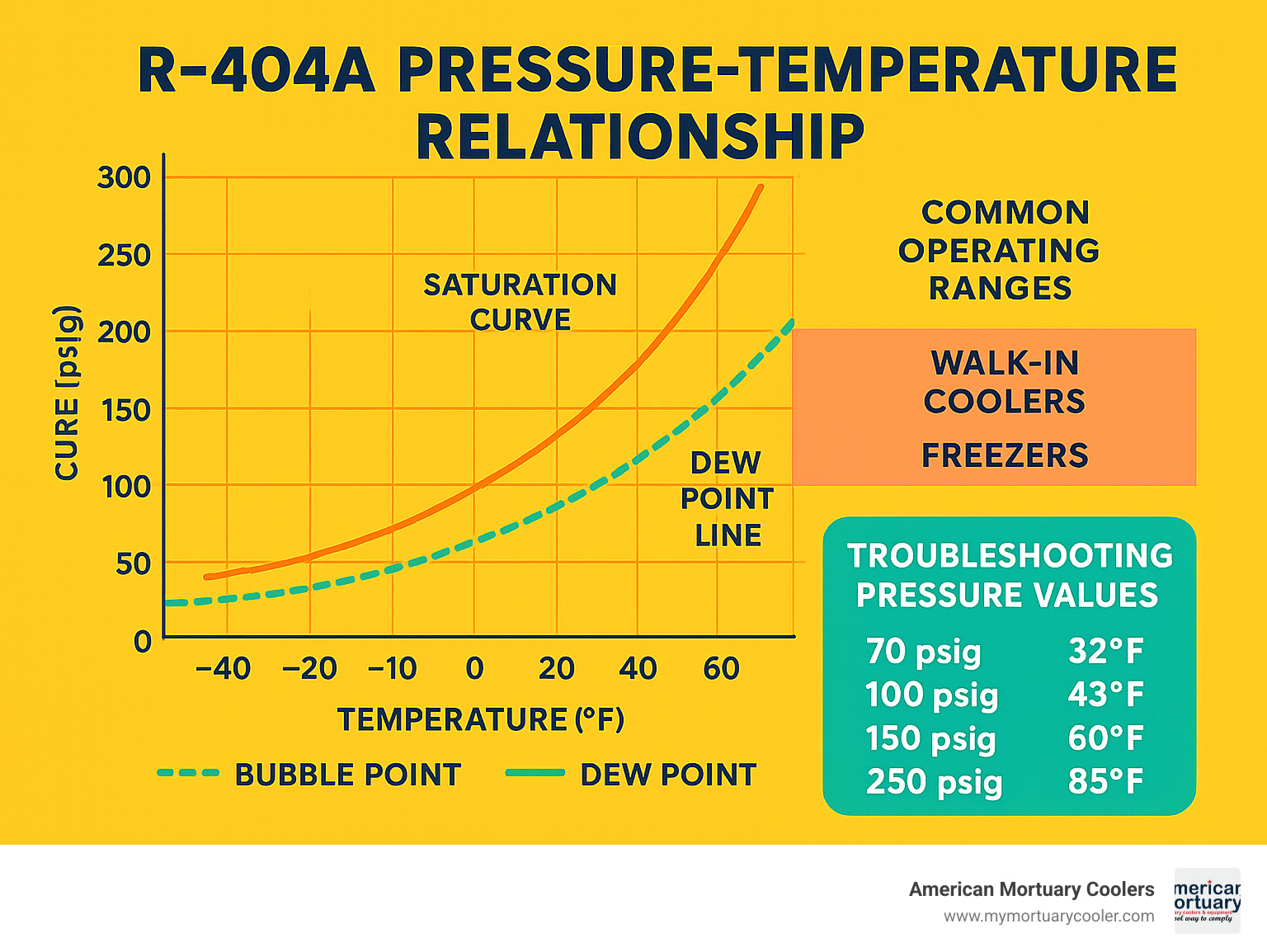

The 404a pressure temperature chart is your roadmap to proper refrigeration system operation. This chart shows the exact relationship between pressure and temperature for R-404A refrigerant, helping you diagnose problems, set controls, and ensure your cooling systems run efficiently.

Quick Reference for 404A Pressure Temperature Values:

- At 0°F: 33.7 psig (liquid) / 32.6 psig (vapor)

- At 40°F: 86.9 psig (liquid) / 85.4 psig (vapor)

- At 100°F: 236.8 psig (liquid) / 234.6 psig (vapor)

- Critical Temperature: 161.7°F

- Critical Pressure: 540.8 psi

R-404A remains widely used in commercial refrigeration, especially in walk-in coolers, freezers, and mortuary cooling systems. This HFC blend consists of 44% R-125, 4% R-134a, and 52% R-143a by weight. While it has a high Global Warming Potential of 3922, it's still legal to use and service existing systems.

Understanding pressure-temperature relationships helps you troubleshoot system issues quickly. When your gauges show 70 psig suction pressure, the chart tells you the refrigerant is saturating at about 32°F. If your evaporator should be running at 20°F, you know something's wrong.

The chart becomes especially critical in mortuary applications where precise temperature control protects sensitive materials and ensures regulatory compliance. Whether you're setting up a new walk-in cooler or diagnosing why your freezer isn't holding temperature, the PT chart gives you the data you need.

I'm Mortuary Cooler, and I've spent years helping funeral homes optimize their refrigeration systems using 404a pressure temperature chart data to ensure reliable operation. My experience with mortuary cooling applications has shown me how critical proper PT relationships are for maintaining consistent temperatures in sensitive environments.

Relevant articles related to 404a pressure temperature chart:

Why R-404A Still Matters in Commercial & Mortuary Refrigeration

You might wonder why we're still talking about R-404A when everyone's focused on environmental concerns. The truth is, this refrigerant blend isn't going anywhere anytime soon – especially in the specialized world of mortuary cooling.

R-404A earned its place in commercial refrigeration because it simply works. When your walk-in cooler needs to maintain 35°F consistently, or your mortuary cooler must hold precise temperatures for days, R-404A delivers reliable performance. That's why we still see it powering everything from supermarket display cases to the custom mortuary equipment we build here in Tennessee.

The blend's zero ozone depletion potential made it a hero when it replaced older refrigerants like R-502. Its Global Warming Potential of 3922 presents challenges today, but existing systems continue operating legally and effectively. For funeral homes investing in quality equipment, understanding R-404A remains essential.

What Is R-404A and Where Is It Used?

R-404A is a carefully engineered blend containing 52% R-143a, 44% R-125, and 4% R-134a by weight. This specific composition creates excellent thermodynamic properties for medium and low-temperature applications – exactly what mortuary cooling demands.

Walk into any funeral home, and you'll likely encounter R-404A working behind the scenes. Mortuary coolers rely on this refrigerant's ability to maintain consistent temperatures even when doors open frequently or ambient conditions change. The same reliability makes it popular in supermarket frozen food sections, ice cream manufacturing facilities, and vaccine storage applications.

Cold storage warehouses and commercial kitchens depend on R-404A's performance in their walk-in freezers. When your 404a pressure temperature chart shows the refrigerant saturating at exactly the right temperature, you know your system is running as designed.

In our mortuary applications, we've seen R-404A handle the demanding requirements of body storage and preparation areas. The refrigerant's consistent performance ensures proper preservation conditions, giving funeral directors confidence in their equipment.

Environmental & Regulatory Landscape

The regulatory landscape around R-404A keeps evolving, but it's not disappearing overnight. The Kigali Amendment to the Montreal Protocol targets high-GWP refrigerants for gradual phasedown, while the EPA's SNAP program restricts certain new applications while allowing continued service of existing systems.

Here's what funeral homes need to know: 2020 brought restrictions on R-404A in new supermarket systems, and the HFC phasedown began in 2021. More restrictions arrived in 2024, with an 85% reduction in HFC consumption projected by 2036.

For mortuary facilities, this means planning ahead for eventual system retrofits or replacements. However, your existing R-404A equipment can continue operating and receiving service with proper refrigerant management. The key is working with suppliers who understand both current regulations and future compliance requirements.

Smart funeral home operators are already discussing retrofit planning with their service technicians. Understanding your current system's 404a pressure temperature chart data helps determine the best timing for upgrades while maximizing your equipment investment.

How to Read and Apply a 404A Pressure Temperature Chart

Think of a 404a pressure temperature chart as your refrigeration system's translator. It tells you exactly what your pressure readings mean in terms of temperature, and vice versa. Every technician working with R-404A systems needs to understand this fundamental relationship.

The chart shows you the saturation point where liquid and vapor phases meet. This is where the magic happens in your refrigeration cycle. For R-404A, you'll see two key columns: the bubble point (where liquid starts to vaporize) and the dew point (where vapor starts to condense). Since R-404A is a near-azeotropic blend, these numbers stay very close together, making your job easier.

Most charts display pressure in psig (pounds per square inch gauge), which measures pressure above atmospheric pressure. Red numbers typically indicate vacuum conditions below atmospheric pressure, while black numbers show positive gauge pressure. Temperature readings appear in both Fahrenheit and Celsius.

Here's something important to remember: pressure increases exponentially with temperature. A small temperature change creates a big pressure difference, especially at higher temperatures. This relationship becomes critical when you're troubleshooting system problems.

Interpreting the 404A pressure temperature chart in Walk-In Coolers

Walk-in coolers typically operate in the medium-temperature range between 32°F and 40°F. At American Mortuary Coolers, we see this range constantly in our funeral home installations where precise temperature control matters most.

When your 404a pressure temperature chart shows these key temperatures, here's what to expect:

At 32°F, you'll see about 73.8 psig for liquid saturation and 72.4 psig for vapor. Move up to 35°F, and those numbers jump to 79.2 psig and 78.0 psig respectively. At 40°F, you're looking at 86.9 psig and 85.4 psig.

Your suction pressure should match your desired evaporator temperature, minus any pressure drop in the suction line. Let's say you want your mortuary cooler to hold 35°F. If you need a 5°F temperature difference across the evaporator coil, your evaporator runs at about 30°F. Check your chart, and you'll find that corresponds to roughly 67 psig suction pressure.

Subcooling plays a huge role here too. This happens when liquid refrigerant cools below its saturation temperature. Proper subcooling (usually 10-15°F) ensures liquid refrigerant reaches the expansion valve, boosting both efficiency and cooling capacity. Without it, your system struggles to maintain consistent temperatures.

Calculating Superheat with a 404A pressure temperature chart

Superheat calculation keeps your expansion valve happy and your system running smoothly. The process is straightforward once you get the hang of it.

First, measure the suction line temperature right at the evaporator outlet using your thermometer. Next, read the suction pressure on your manifold gauge. Take that pressure reading to your 404a pressure temperature chart and find the corresponding saturation temperature.

Now comes the simple math: Superheat equals actual temperature minus saturation temperature.

Here's a real-world example from one of our mortuary cooler installations. Your suction pressure reads 70 psig, and your suction line temperature measures 45°F. Looking at the PT chart, 70 psig corresponds to about 31°F saturation temperature. So your superheat is 45°F minus 31°F, which equals 14°F.

Most systems run best with superheat between 8-12°F, though this varies based on your specific system design and operating conditions. Too little superheat risks liquid refrigerant entering your compressor. Too much superheat reduces system capacity and efficiency.

Diagnosing Common System Issues Using PT Data

Your 404a pressure temperature chart becomes a detective tool when systems act up. Pressure readings that don't match expected temperatures tell you exactly where to look for problems.

Low suction pressure often points to a low refrigerant charge, liquid line restriction, or expansion valve hunting. Compare your actual suction pressure to what you'd expect for your desired evaporator temperature. If it's significantly low, start checking for leaks or restrictions.

High suction pressure suggests different problems: system overcharge, oversized expansion valve, or compressor valve issues. Verify your superheat and subcooling measurements to narrow down the cause.

High discharge pressure typically means a dirty condenser, system overcharge, or non-condensable gases in the system. Compare your discharge pressure to expected pressure for current ambient temperature. If it's running high, clean that condenser first.

Low discharge pressure usually indicates low refrigerant charge, compressor inefficiency, or liquid line restrictions. Check your subcooling and overall system capacity to confirm the diagnosis.

In mortuary applications, these diagnostic skills become especially important. Temperature fluctuations can't be tolerated, so quick, accurate troubleshooting using PT data keeps systems running reliably when it matters most.

Operating Pressures, Temperature Ranges & Field Benchmarks

When you're out in the field with your gauges connected to an R-404A system, knowing what pressures to expect saves you time and helps you spot problems quickly. After years of working with mortuary cooling systems, I've learned that having solid benchmarks makes troubleshooting much more straightforward.

For suction pressures, you'll typically see 15-25 psig in low-temperature applications running between -20°F to 0°F. When you're working with medium-temperature systems like walk-in coolers operating from 20°F to 40°F, expect suction pressures in the 40-90 psig range.

Discharge pressures tell a different story and fluctuate more with conditions. On a normal day with ambient temperatures between 70-90°F, you should see 150-250 psig on your high-side gauge. When it's hot outside and ambient temperatures climb to 90-110°F, those discharge pressures can jump to 250-350 psig or higher.

Several factors affect these pressure readings beyond just the 404a pressure temperature chart values. Ambient temperature has the biggest impact - a hot summer day will drive your head pressures up significantly. Altitude matters too, especially if you're servicing equipment in mountainous areas where lower atmospheric pressure affects your gauge readings.

System design plays a crucial role as well. A properly sized condenser will maintain lower head pressures than an undersized one. Similarly, evaporator load and piping configuration influence what you'll see on your gauges. Most importantly, refrigerant charge level affects both suction and discharge pressures - undercharge typically drops both readings while overcharge usually raises them.

Scientific research on saturation data confirms these field observations match laboratory testing across various operating conditions.

Recommended Settings for Walk-In Coolers & Freezers

Setting up controls properly from the start prevents most service calls later. For walk-in coolers maintaining 35-38°F box temperatures, I recommend a low-pressure cut-out at 15-20 psig with the cut-in set at 25-30 psig. This protects the compressor from low charge conditions while allowing normal cycling.

Set your high-pressure cut-out at 300-350 psig to protect against condenser problems or overcharge situations. For defrost timing, most cooler applications need 2-4 defrost cycles per day, depending on door openings and humidity levels.

Walk-in freezers operating at 0 to -10°F box temperatures need different settings. Drop your low-pressure cut-out to 5-10 psig with the cut-in at 15-20 psig. Keep the same high-pressure cut-out at 300-350 psig, but increase defrost frequency to 4-6 times per day since frost buildup happens faster at lower temperatures.

These control settings ensure proper system protection while maintaining efficient operation. The low-pressure controls prevent compressor damage from refrigerant loss, while high-pressure controls protect against condenser fouling or overcharge conditions.

At American Mortuary Coolers, we pre-set these controls on our custom units because proper settings are critical for the reliable operation funeral homes depend on. Temperature fluctuations in mortuary applications can have serious consequences.

Troubleshooting Checklist for Technicians

A systematic approach saves time and prevents missed problems. Start with gauge comparison - connect your manifold set and compare actual readings to what the 404a pressure temperature chart says you should see for your operating conditions.

Check the liquid line sight glass next. Bubbles usually indicate low charge or a restriction upstream. Moisture indicators help identify contamination problems that affect system performance.

Compressor amperage tells you a lot about system health. Compare your clamp-on meter reading to the nameplate rating. High amperage often indicates system problems, while low amperage might suggest reduced capacity or electrical issues.

Don't forget leak detection during every service call. Even small leaks affect system performance over time and waste expensive refrigerant. Electronic leak detectors work well with R-404A, but soap bubbles still catch leaks that electronic units sometimes miss.

Quick fixes that solve many common problems include cleaning the condenser coil when discharge pressures run high, checking the filter drier when subcooling is low, and adjusting TXV superheat when it's outside normal range. Always verify defrost operation if you see ice buildup on the evaporator - many "refrigeration problems" are actually defrost issues.

Beyond 404A: Alternatives, Retrofits & Preparing for the Future

The writing is on the wall for R-404A. While your existing systems can keep running for years to come, smart facility managers are already planning their next moves. Environmental regulations are tightening, and refrigerant costs are climbing. The good news? You have solid alternatives that won't break the bank or require a complete system overhaul.

R-448A has become the go-to replacement for most R-404A systems. With a much lower Global Warming Potential of 1274 (compared to R-404A's 3922), it can retrofit into existing systems with minimal fuss. You'll need about 105% of your original R-404A charge, and the refrigerant has a 7°F temperature glide that affects charging procedures.

R-449A offers similar benefits with a GWP of 1282. Both of these alternatives give you comparable cooling performance while dramatically reducing your environmental footprint. The efficiency improvements can even help offset the higher refrigerant costs.

For those looking further ahead, CO₂ (R-744) represents the ultimate low-impact solution with a GWP of just 1. However, CO₂ systems operate at much higher pressures and require significant equipment changes. Hydrocarbons like propane (R-290) offer excellent efficiency but bring flammability concerns that require special safety measures.

The retrofit process itself is straightforward for most R-404A alternatives. You'll recover the existing refrigerant, replace filter driers and rubber seals, evacuate the system thoroughly, charge with the new refrigerant, and adjust controls. Most systems can be converted in a day with minimal downtime.

At American Mortuary Coolers, we're seeing more funeral homes ask about future-ready refrigeration systems. The mortuary industry values reliability above all else, so we typically recommend proven alternatives like R-448A for existing systems while designing new installations with long-term refrigerant availability in mind.

PT-Curve Differences Between 404A and Its Replacements

Here's where your 404a pressure temperature chart knowledge really pays off. While R-448A operates similarly to R-404A, the pressure relationships aren't identical. Understanding these differences prevents costly mistakes during retrofits.

R-448A runs at slightly higher pressures across the temperature range. At 0°F, R-448A liquid pressure hits 34.2 psig compared to R-404A's 33.7 psig. At normal walk-in cooler temperatures around 40°F, you're looking at 87.5 psig for R-448A versus 86.9 psig for R-404A. The differences seem small, but they add up.

The bigger challenge comes from R-448A's 7°F temperature glide. Unlike R-404A, which behaves almost like a single-component refrigerant, R-448A has different bubble point and dew point temperatures. This affects how you charge the system and diagnose problems.

You'll need to recalibrate your pressure controls and safety switches for the new operating pressures. Expansion valve settings often need adjustment too. Many technicians overlook alarm setpoints, leading to nuisance shutdowns when the system is actually running fine.

The glide also means you must charge R-448A as liquid to prevent the blend components from separating. If you charge vapor like you might with R-404A, you'll end up with the wrong refrigerant composition in your system.

Latest data sheet on Forane 404A

Keeping Systems Efficient During the Transition

Smart maintenance becomes even more critical as the industry transitions between refrigerants. Your facility might be running multiple refrigerant types, each with different service requirements. Staying organized and maintaining peak efficiency requires a systematic approach.

Clean condensers remain your best bang for the buck. A dirty condenser coil forces higher discharge pressures regardless of which refrigerant you're using. We recommend monthly cleaning for most commercial applications, weekly during heavy pollen seasons.

Proper refrigerant charge verification using PT charts becomes more complex with glide refrigerants. Traditional subcooling measurements need adjustment for the temperature glide. Many technicians find electronic superheat and subcooling calculators helpful for the newer refrigerants.

Electronic expansion valves adapt better to alternative refrigerants than mechanical TXVs. They can automatically adjust for different refrigerant properties and maintain optimal superheat across varying load conditions. The investment often pays back through improved efficiency and reduced service calls.

Smart controls really shine during the transition period. Modern controllers can store operating parameters for different refrigerants, automatically adjusting setpoints when you switch refrigerant types. They also provide better diagnostic information, helping you spot problems before they cause downtime.

Training your service team on the new refrigerants prevents expensive mistakes. Each alternative has its quirks, and proper charging procedures vary significantly from R-404A practices.

Frequently Asked Questions about 404A PT Charts

When working with R-404A systems, technicians often have the same questions about pressure-temperature relationships. Let me address the most common ones I've encountered over the years helping funeral homes optimize their refrigeration systems.

What is the temperature glide of R-404A?

R-404A has an incredibly small temperature glide of just 0.5°F. This is one of the reasons it became so popular in commercial refrigeration applications. Unlike some newer refrigerant blends that can have glides of 5°F or more, R-404A behaves almost exactly like a single-component refrigerant.

What does this mean for you? Charging is straightforward - you can add refrigerant as liquid or vapor without worrying about changing the blend composition. The 404a pressure temperature chart shows bubble point and dew point temperatures that are practically identical, making your calculations simple and reliable.

This minimal glide also means your system operates more predictably. You won't see the shifting pressures during operation that can complicate diagnostics with high-glide refrigerants. For mortuary cooling applications where consistency is critical, this characteristic has made R-404A a trusted choice.

What are normal suction and discharge pressures for 404A?

Normal operating pressures vary significantly based on your application and environmental conditions. Here's what I typically see in properly operating systems:

For suction pressures, your readings should align with your desired evaporator temperature. Walk-in coolers maintaining 35°F typically show 70-80 psig suction pressure. Walk-in freezers operating at 0°F usually run around 25-35 psig. Low-temperature mortuary applications at -10°F often see 15-25 psig.

Discharge pressures depend heavily on ambient temperature. On a mild 70°F day, expect 150-180 psig. When it's 90°F outside, pressures climb to 220-250 psig. During hot summer days reaching 110°F, discharge pressures can hit 300-350 psig.

These ranges assume your equipment is properly sized and maintained. If your pressures fall outside these ranges, it's time to investigate. Low suction pressure often indicates insufficient refrigerant charge or a restriction. High discharge pressure usually points to condenser problems or overcharge conditions.

How does ambient temperature affect system pressures?

Ambient temperature has a dramatic effect on your system's discharge pressure, and understanding this relationship is crucial for proper operation. For every 10°F increase in outdoor temperature, discharge pressure typically jumps 15-25 psig.

This happens because your condenser must reject heat to the surrounding air. When it's hotter outside, the condenser works harder to achieve the same temperature difference needed for proper heat transfer. The 404a pressure temperature chart shows you exactly what pressure corresponds to your condensing temperature.

This relationship affects several critical aspects of your system. First, you need to size condensers appropriately for your local climate. A condenser that works fine in Minnesota might struggle in Arizona. Second, your high-pressure cutout controls must account for peak ambient conditions to prevent nuisance shutdowns.

In our mortuary cooling applications, we often work with facilities that have both indoor and outdoor equipment. Indoor units benefit from more stable ambient conditions, while outdoor condensers must handle seasonal temperature swings. Understanding these pressure variations helps ensure your cooling systems keep running reliably when you need them most.

The key is planning ahead. If you know your area regularly sees 100°F+ summer days, your system design and control settings need to accommodate the resulting high discharge pressures. This foresight prevents emergency service calls during the hottest weather.

Conclusion

Mastering the 404a pressure temperature chart has been your gateway to understanding reliable refrigeration operation throughout this guide. From troubleshooting that stubborn walk-in cooler to setting up a precision mortuary cooling system, these PT relationships form the foundation of everything we do in commercial refrigeration.

Here at American Mortuary Coolers, we've spent years perfecting mortuary cooling solutions that honor these precise PT requirements. Every custom system we craft in Tennessee gets designed with proper refrigerant management at its core. Whether we're shipping to a funeral home in California or delivering locally, our equipment reflects decades of understanding how pressure and temperature work together.

The industry is changing, and R-404A won't be around forever. But here's the thing - the fundamental principles you've learned reading these charts transfer directly to every replacement refrigerant. Whether you're working with R-448A tomorrow or something completely different in five years, you'll still be reading pressure, checking temperature, and calculating superheat.

Your path forward starts with keeping current PT charts in your toolbox and regularly checking system pressures against expected values. Plan ahead for refrigerant transitions by investing in proper training and quality instruments. Document everything for regulatory compliance - trust me, you'll thank yourself later when the inspector shows up.

The funeral industry demands reliability above all else. When families are counting on you, equipment failure isn't an option. That's why we build our mortuary coolers around these proven refrigeration principles, incorporating the latest technology while maintaining the rock-solid dependability that sensitive applications require.

Change is coming to commercial refrigeration, bringing new refrigerants and smarter technologies. But some things never change - understanding pressure-temperature relationships will always be your key to efficient, reliable cooling systems. Whether you're maintaining today's R-404A equipment or preparing for tomorrow's innovations, these fundamentals remain your most valuable tools.