Everything You Need to Know About the Coolbot Product

Why Affordable Cold Storage Matters for Every Business

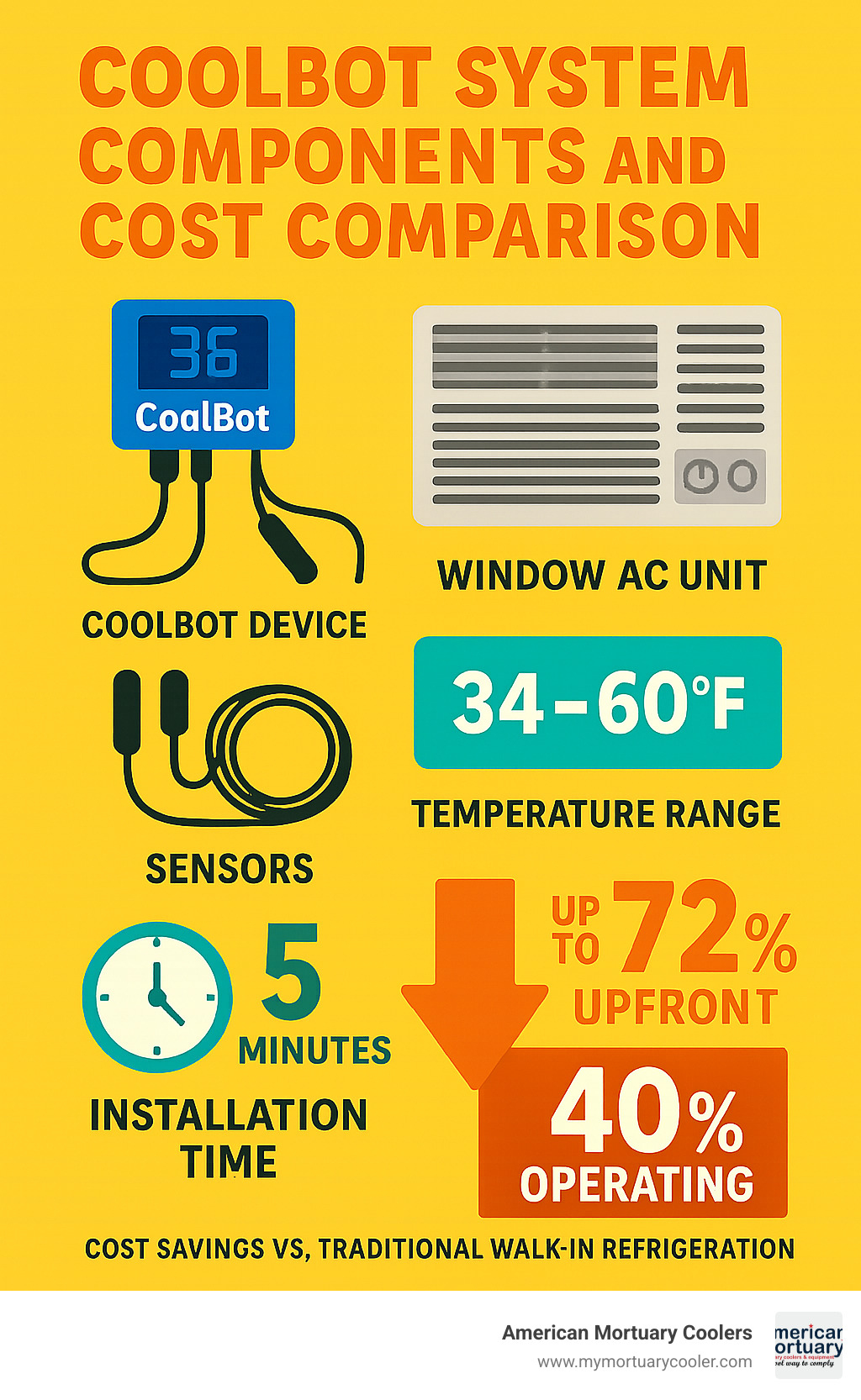

CoolBot is a micro-controller device that transforms any standard window air conditioner into a walk-in cooler capable of reaching temperatures as low as 34°F. Here's what you need to know:

- What it is: Electronic device that overrides A/C temperature limits

- How it works: Uses sensors and heating elements to prevent freeze-up

- Cost savings: Up to 72% less upfront costs, 40% lower operating expenses

- Applications: Farms, florists, restaurants, breweries, hunters, mortuaries

- Temperature range: 34°F to 60°F in any climate

- Installation: 5-minute setup, no tools or rewiring required

Over 125,000 CoolBot units have been sold worldwide, helping businesses save thousands on refrigeration costs while maintaining professional-grade cooling performance.

Traditional walk-in coolers can cost $7,000 or more to install. The CoolBot changes this equation completely. By pairing a $374 controller with a standard $600 window air conditioner, you can build effective cold storage for a fraction of the price.

"The CoolBot is amazing, it was a total game changer for our business," reports one florist who uses the system to extend the sales window for cut flowers.

The impact goes beyond cost savings. In developing countries, CoolBot has directly helped over 20,000 smallholder farmers reduce post-harvest losses through USAID partnerships. One milk collection center increased production from 3,000 to 17,000 pounds per week within six months of installing their CoolBot system.

As American Mortuary Coolers and a national supplier of mortuary cooling solutions, we've seen how the CoolBot technology provides reliable, cost-effective refrigeration for funeral homes and other businesses requiring precise temperature control.

Why Affordable Cold Storage Matters

In many developing countries, postharvest loss for fruits and vegetables exceeds 50 percent due to lack of affordable refrigeration. Even in developed markets, small businesses struggle with the high costs of traditional walk-in coolers. The CoolBot addresses this critical need by making professional-grade cold storage accessible to:

- Farmers storing produce from harvest to market

- Florists preserving cut flowers at optimal temperatures

- Brewers maintaining fermentation temperatures in beer caves

- Hunters processing and storing wild game

- Small restaurants creating affordable walk-in refrigeration

- Funeral homes requiring reliable mortuary cooling solutions

How the CoolBot Works & Why It's Different

Think of the CoolBot as a clever electronic trick that makes your regular window air conditioner think it's working normally while secretly allowing it to cool much colder than it was ever designed to do.

Here's the problem every air conditioner faces: when you try to cool below about 60°F, ice starts forming on the metal coils inside the unit. This ice blocks airflow and can actually destroy the compressor. That's why your home A/C won't let you set the thermostat to 45°F no matter how hot it gets outside.

The CoolBot solves this with what's essentially a sophisticated sensor hack. It uses a micro-controller to monitor multiple temperature points and tricks the air conditioner into thinking everything is fine while preventing the deadly ice buildup that would normally occur.

The beauty of this approach is that it leverages mass-produced window units instead of expensive commercial compressors. You can walk into any big box store, buy an Energy Star air conditioner, and transform it into professional-grade refrigeration equipment.

Core Components Inside a CoolBot

Every CoolBot system relies on four key components working together.

The room sensor acts as your eyes inside the cooler, constantly monitoring the actual air temperature and communicating with the brain of the system to maintain your desired temperature.

The fin sensor is the real hero of the operation. This component watches the temperature of the air conditioner's evaporator coils. When those coils start approaching the danger zone where ice would form, it immediately alerts the system to take action.

The heater wire is where the magic happens. This small heating element warms up the air conditioner's factory temperature sensor, essentially lying to it about how cold things are getting. This keeps the A/C running even when it would normally shut down to protect itself.

The micro-processor serves as the brain that coordinates everything. It's constantly making decisions about when to cycle the compressor on and off, when to activate the heater, and how to maintain your target temperature without destroying the equipment.

CoolBot vs Traditional Walk-In Refrigeration

The cost difference between CoolBot systems and traditional walk-in coolers is frankly shocking. While a conventional system might run you $7,000 or more before installation, you can build a CoolBot-powered cooler for under $2,000 including the air conditioner.

But the savings don't stop at purchase price. CoolBot systems typically use 40% less energy than traditional commercial units because they leverage the efficiency improvements built into modern Energy Star air conditioners.

Installation is where the CoolBot really shines. Instead of waiting weeks for a commercial refrigeration technician and paying thousands in labor costs, you can have your system running in about five minutes. The same simplicity extends to maintenance—any HVAC technician can service a window air conditioner, but commercial walk-in systems require specialized knowledge and expensive parts.

CoolBot Temperature Logic Explained

The CoolBot's approach to temperature control is surprisingly smart for such a simple-looking device. When you set your target temperature to 34°F, the system doesn't just run the air conditioner constantly and hope for the best.

Instead, it uses an intelligent cycling approach that prevents problems before they start. During the cooling phase, your A/C runs normally while the fin sensor keeps a close eye on coil temperature. The moment those coils approach 33°F, the anti-freeze prevention kicks in—the heater wire activates to prevent ice formation without stopping the cooling process.

Once your room reaches the target temperature, the system cycles off to prevent overcooling and save energy. If minor icing does occur despite all precautions, the CoolBot runs a brief defrost cycle to clear any frost buildup and get back to normal operation.

Benefits & Real-World Applications of CoolBot

The CoolBot has quietly revolutionized how businesses think about refrigeration. With over 125,000 units humming away in coolers worldwide, this little device has proven that you don't need to break the bank for professional-grade cold storage.

Let's talk numbers that matter to your bottom line. Users consistently report 72% savings in upfront costs compared to traditional walk-in coolers. But the savings don't stop there—operating expenses drop by 40% thanks to the system's smart energy management. One Connecticut grower was thrilled to see his monthly electricity bill drop by over $500 after switching to a CoolBot system.

The secret sauce lies in energy efficiency. Modern window air conditioners often outperform older commercial compressors, especially those with Energy Star ratings. The CoolBot's intelligent cycling takes this natural advantage and optimizes it further.

Beyond individual businesses, the global impact tells an inspiring story. Through partnerships with USAID, Feed the Future, and Fintrac, CoolBot technology has directly helped over 20,000 smallholder farmers in Honduras and Guatemala. In regions where postharvest losses can exceed 50% due to lack of refrigeration, this affordable technology is literally putting food on tables and money in farmers' pockets.

Industry Snapshots

Produce farms have found their sweet spot with CoolBot systems. Small-scale growers use them to bridge that critical gap between harvest and market, maintaining 38°F to 40°F temperatures that keep mixed produce fresh for CSA pickups.

Craft breweries found that perfect fermentation doesn't require expensive equipment. CoolBot systems create affordable "beer caves" that maintain rock-steady 55°F temperatures. Whether you're fermenting your latest IPA or storing finished kegs, consistent temperature control makes all the difference.

Wild-game processing operations rely on CoolBot systems in converted sheds and insulated spaces. Hunters and processors know that reaching 34°F quickly isn't just about quality—it's about food safety.

Floral studios have perhaps seen some of the most dramatic results. Cut flowers are incredibly temperature-sensitive, and florists report significantly extended sales windows when they can hold blooms at optimal temperatures between delivery and sale.

Case Studies & Testimonials

The Jocón Milk Collection Center in Guatemala showcases what's possible when affordable technology meets real need. Within just six months of installing their CoolBot system, production jumped from 3,000 to 17,000 pounds per week. The reliable cold storage didn't just maintain milk quality—it allowed them to expand their entire collection network.

Closer to home, a Connecticut grower turned his insulated garage into a professional-grade walk-in cooler using nothing more than a CoolBot and a standard window air conditioning unit. The system maintained a steady 38°F throughout brutal summer heat while saving him over $500 monthly on electricity compared to his previous commercial setup.

Field testing has taken CoolBot systems to some challenging places. From Papua New Guinea to Bangladesh, Thailand to Equatorial Africa, USAID development projects have validated the technology's performance across three continents and countless climate conditions.

One Australian flower farm owner summed it up perfectly: "Installing a CoolBot has been the perfect solution for our coolroom requirements. Easy to install - a cheap, reliable and effective way to store our cut flowers post harvest."

At American Mortuary Coolers, we've integrated CoolBot technology into several custom cooling solutions for funeral homes seeking reliable, cost-effective refrigeration. The technology's proven track record gives us confidence in recommending it for operations where precise temperature control matters most.

For a deeper dive into the energy savings potential, this detailed analysis breaks down the numbers: Lower Your Electric Bill With CooLBot.

Installation, Sizing & Insulation Guide

Setting up a CoolBot system is refreshingly simple—no electrician required, no complex wiring, and you'll be up and running in about five minutes. The real secret to success isn't in the installation itself, but in the planning that happens before you even unbox your CoolBot.

Think of it this way: traditional commercial refrigeration can muscle through poor insulation by throwing more energy at the problem. Your CoolBot system is smarter than that. It works best when you give it a well-insulated space and properly sized air conditioner to work with.

CoolBot Compatibility Chart

Your CoolBot plays well with most standard window air conditioners, though some work better than others. The good news is that you'll find compatible units at any big box store or appliance dealer.

Window A/C units from major brands like LG, GE, and Frigidaire typically work great with the CoolBot. Energy Star rated units are your best bet—they're more efficient and usually have the electronic controls that work smoothly with the system.

The sweet spot for BTU capacity falls between 6,000 and 25,000 BTU. An 18,000 BTU window unit hits the perfect balance for many applications, providing plenty of cooling power while maintaining excellent efficiency.

Mini-split systems can work, but compatibility varies significantly by model. If you're considering this route, check with the manufacturer first to avoid headaches later.

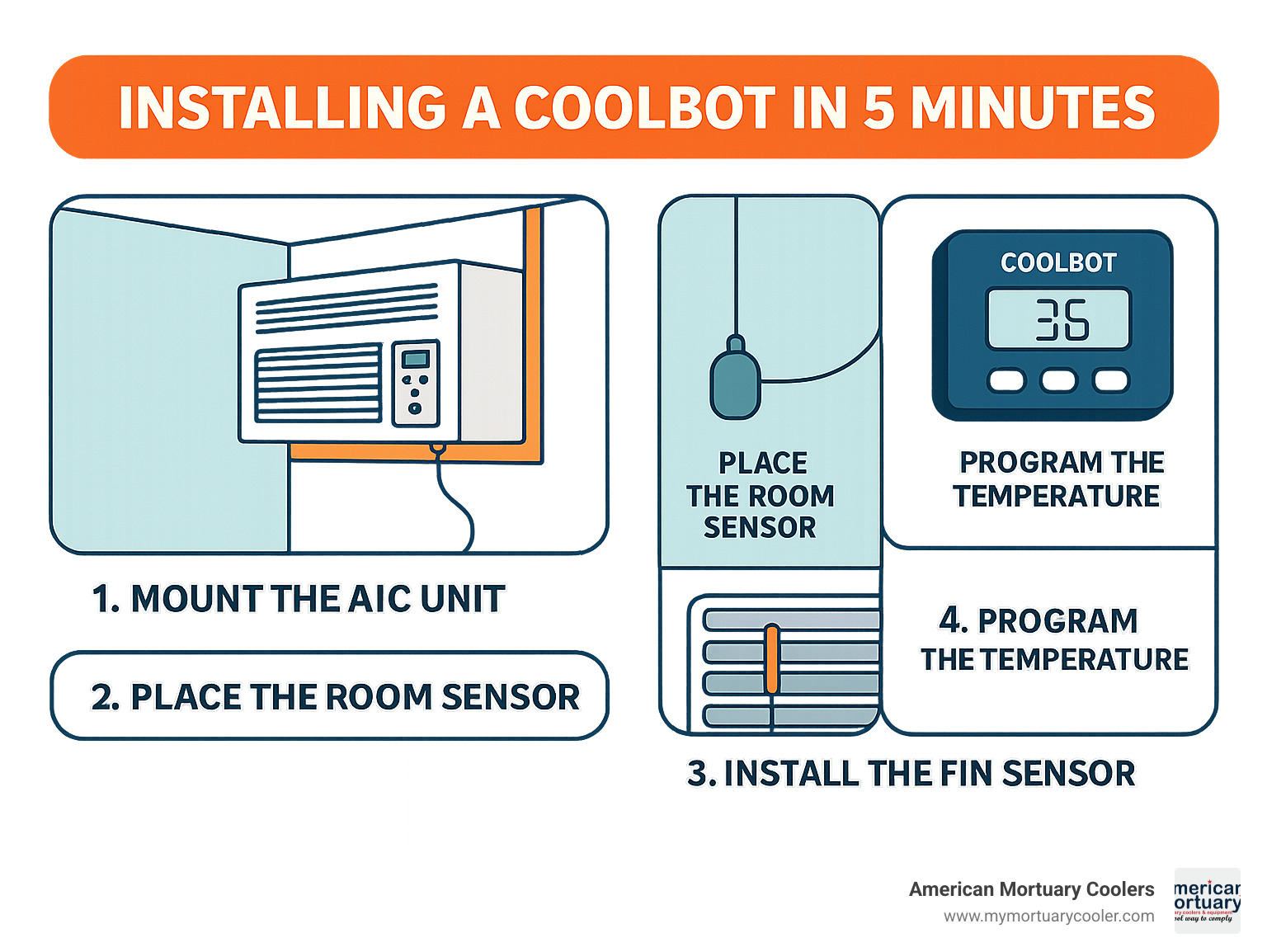

Step-by-Step Setup

The actual installation really does take just minutes once your space is ready. Mount your A/C unit first, making sure to seal around it completely with expanding foam—every air leak works against you.

Place the room sensor a few inches away from the A/C unit on an interior wall. This little guy monitors your actual air temperature and tells the system when you've hit your target.

The fin sensor is where the magic happens. Wedge this probe right into the evaporator coil fins where the factory temperature sensor sits. This prevents the freeze-up that would normally destroy a standard air conditioner running at low temperatures.

Connect the heater wire by wrapping it alongside the A/C's original temperature sensor and securing with aluminum foil. This creates the thermal contact needed to trick the unit into running below its normal limits.

Program your target temperature using the three simple buttons on the CoolBot unit. You can set anything between 33°F and 60°F depending on what you're storing.

Room Size & BTU Recommendations

Getting the sizing right is crucial because the CoolBot works by intelligently cycling your A/C unit rather than running it flat-out all the time. You need adequate cooling capacity to handle the load.

A 6' x 8' room needs at least 10,000 BTU to maintain proper temperatures. Step up to an 8' x 10' space and you'll want 15,000 BTU for reliable performance. Larger 10' x 14' rooms require 25,000 BTU to handle the increased volume effectively.

Hot climates demand extra consideration—add about 20% to these base requirements if you're dealing with summer temperatures above 90°F regularly.

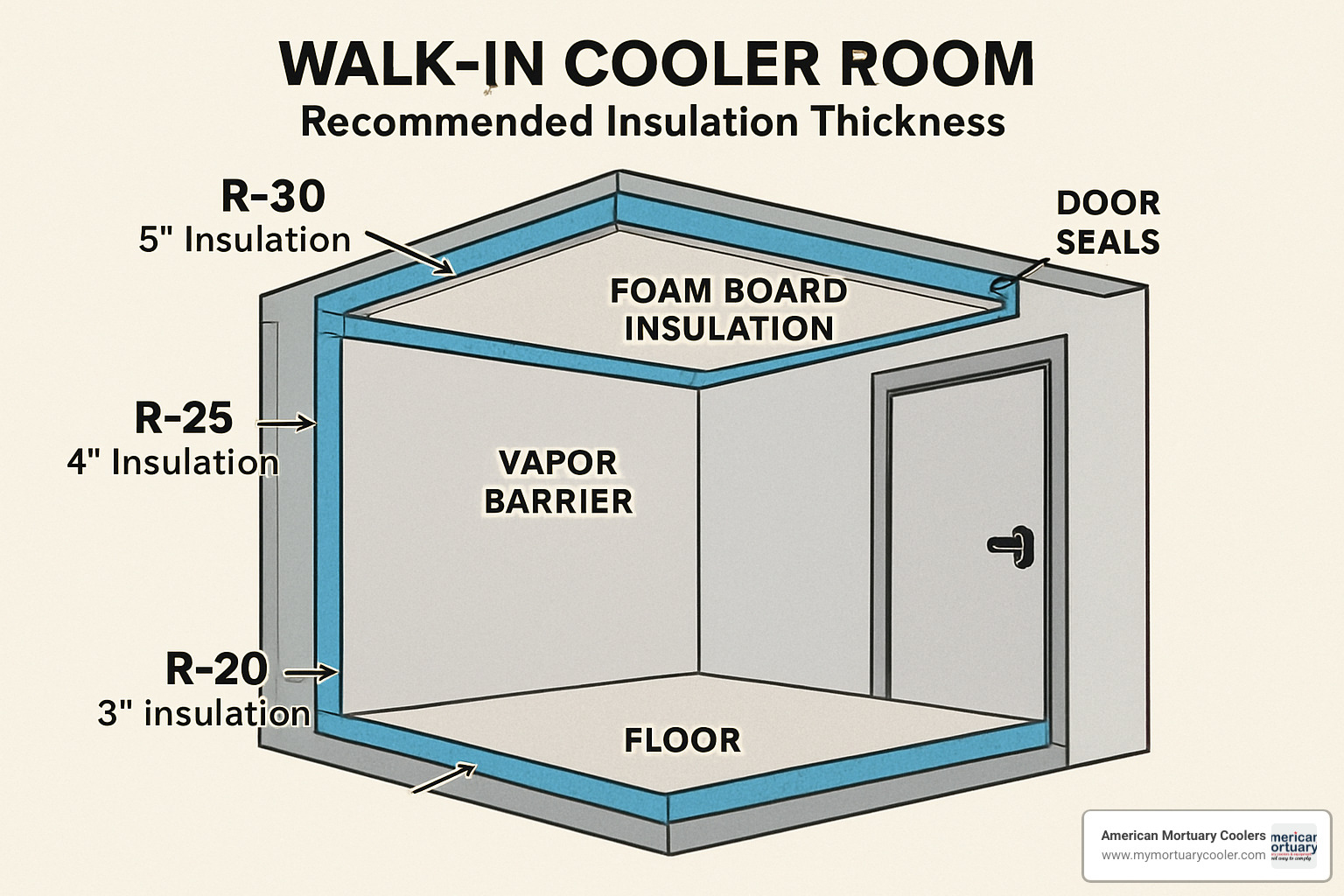

Insulation & Vapor Barriers

Poor insulation is the enemy of any refrigeration system, but it's especially critical with CoolBot setups. The good news is that proper insulation isn't rocket science—it just requires attention to detail.

Wall insulation should hit R-24 minimum, with 4-inch solid foam board being the gold standard. Ceiling insulation needs R-30 or better to prevent heat from radiating down into your cooler space.

Don't forget the floor—a sealed vapor barrier with foam board underneath prevents ground moisture and temperature transfer that can work against your system.

Quality door seals and proper closure mechanisms make a huge difference. A door that doesn't seal properly can double your energy costs and make temperature control nearly impossible.

Poor insulation forces any refrigeration system to run continuously, reducing efficiency and potentially causing premature failure. As we explain in our A Quick Start Guide to Understanding Walk-In Coolers, proper insulation is the foundation that makes everything else work properly.

Maintenance, Troubleshooting & Limitations

The beauty of CoolBot systems lies in their simplicity. Unlike traditional commercial refrigeration that requires specialized technicians, most CoolBot maintenance involves basic A/C unit care that any business owner can handle.

Routine Care Schedule

Monthly maintenance keeps your CoolBot running smoothly. Clean those condenser coils with a soft brush or shop vacuum - dirty coils force the system to work harder and waste energy. Check your door gaskets for wear, and make sure all sensor connections stay secure.

Seasonal tasks dig a bit deeper. Inspect your insulation for any damage or settling that might compromise performance. Test sensor calibration using the simple ice water method described in your manual.

Annual service might include professional A/C maintenance if you're not comfortable doing it yourself. This is also a good time to calibrate sensors, check for firmware updates, and document energy usage to track your savings over time.

Common CoolBot Issues & Fixes

Temperature swings frustrate many users initially. If your CoolBot bounces between 49°F and 55°F instead of holding steady at 34°F, sensor calibration is usually the culprit. The ice water calibration test takes five minutes and solves most temperature control issues.

Icing problems typically point to sensor placement errors. That fin sensor must be wedged properly into the evaporator coil fins - not just stuck near the cold air outlet. Double-check that your heater wire is wrapped snugly against the A/C's factory temperature sensor with aluminum foil for good thermal contact.

Oversized heat loads can overwhelm even properly sized systems. Living organisms generate significant heat - a single large animal can produce 5,000-6,000 BTU of heat. If your cooler struggles to reach target temperatures, calculate your actual heat load before adjusting settings.

Error codes provide helpful diagnostics when they appear. "Er" indicates room sensor problems, while "Ef/Er" points to fin sensor issues. Most sensor problems resolve with cleaning connections or repositioning sensors according to the installation guide.

A factory reset often clears mysterious glitches or erratic behavior. Don't hesitate to try this simple fix before diving into complex troubleshooting.

When CoolBot Isn't the Best Fit

CoolBot technology works brilliantly within its design parameters, but certain applications call for different solutions.

Freezer temperatures below 32°F exceed CoolBot capabilities. The system is engineered for cooler applications in the 34°F to 60°F range. True freezing requires specialized equipment designed for those extreme temperatures.

Very large spaces requiring multiple high-capacity units may actually cost more than commercial systems when you factor in electrical requirements and complexity. At some point, traditional refrigeration becomes more economical.

Poor insulation situations doom any CoolBot installation. If you can't achieve minimum R-24 insulation levels, the system will run continuously and struggle to maintain temperatures.

For more insights into temperature control fundamentals, check out our guide: How to Control Temperature in 5 Simple Steps.

The key is matching the technology to your specific needs. CoolBot excels in most cooling applications, but knowing its boundaries helps you make informed decisions about your refrigeration investment.

Frequently Asked Questions about CoolBot

What types of air conditioners work with a CoolBot?

Good news - the CoolBot plays well with most standard window air conditioners you'll find at your local hardware store. We're talking about the major brands like LG, GE, and Frigidaire that you already know and trust.

Energy Star-rated units are your best bet for keeping those electricity bills in check. Most folks find success with BTU ratings between 6,000 and 25,000, with the sweet spot being around 18,000 BTU for many applications.

Here's where it gets a bit trickier: mini-split systems can be finicky with CoolBot compatibility. Before you invest in one, definitely check with the manufacturer first. You'll also want to stick with newer units that have electronic controls rather than those old-school mechanical thermostats.

The most important thing? Your A/C unit needs accessible evaporator coils where you can properly place the fin sensor. Without that, the whole system won't work properly.

How much money will I save compared to conventional systems?

Let's talk numbers - and they're pretty impressive. CoolBot users typically slash their upfront costs by up to 72% and cut operating expenses by 40% compared to traditional walk-in coolers.

Here's the math: A complete CoolBot system runs you about $1,000 to $2,000 total. That includes the $374 controller and a decent $600 window A/C unit. Compare that to conventional systems that start at $7,000 and go up from there.

The savings don't stop at installation. That intelligent cycling system we talked about earlier? It really works. One Connecticut grower reported monthly electricity savings exceeding $500 after switching to CoolBot. Your exact savings will depend on your local electricity rates, how much you use the system, and how well your space is insulated.

At American Mortuary Coolers, we've seen funeral homes significantly reduce their cooling costs by incorporating CoolBot technology into their operations, especially for smaller preparation areas or temporary storage needs.

Is CoolBot reliable in hot or tropical climates?

Absolutely. The CoolBot has been put through its paces in some seriously challenging conditions. We're talking about Papua New Guinea, Bangladesh, Thailand, and Equatorial Africa - places where the heat doesn't quit.

Arizona users report successful operation even when starting temperatures exceed 109°F. Yes, it takes longer to reach target temperatures when you're fighting that kind of heat, but it gets there. The system has proven itself reliable in extreme conditions time and time again.

The secret sauce for hot climates? Increase your A/C unit size by 20% and make sure your insulation game is on point. A well-insulated room with adequate cooling capacity will maintain target temperatures no matter what Mother Nature throws at it outside.

Think of it this way - if your CoolBot can handle the blazing heat of equatorial Africa, it can probably handle whatever climate you're working with. The key is giving it the tools it needs to succeed through proper sizing and excellent insulation.

Conclusion

The CoolBot has genuinely changed the game for anyone who needs reliable cold storage without breaking the bank. What started as a clever engineering solution has grown into a worldwide movement, with over 125,000 units helping businesses save money while keeping their products perfectly chilled.

The numbers speak for themselves - 72% savings upfront and 40% lower operating costs compared to traditional systems. But the real story goes deeper than dollars and cents. We're talking about small farmers finally being able to preserve their harvest, florists extending the life of beautiful blooms, and craft brewers maintaining perfect fermentation temperatures without taking out a second mortgage.

At American Mortuary Coolers, we've seen this technology work wonders across our service areas from Tennessee to Atlanta to Chicago and beyond. When funeral homes need dependable mortuary cooling on a budget, CoolBot systems integrated into our custom designs deliver professional results every single time.

The beauty of CoolBot technology lies in its simplicity. Take something everyone can buy at Home Depot, add some smart sensors and a microprocessor, and suddenly you have cold storage that rivals systems costing ten times more.

Success comes down to doing the basics right - proper insulation, correct sizing, and careful installation. Skip these fundamentals, and you'll struggle with any cooling system. Get them right, and your CoolBot will run reliably for years while saving you thousands.

Whether you're preserving flowers, storing produce, cooling beer, or maintaining mortuary temperatures, this technology has proven itself in every climate and application imaginable. From tropical Guatemala to frozen Minnesota, CoolBot systems just keep working.

For businesses ready to explore custom solutions that blend CoolBot technology with professional design, we're here to help. Every project is different, but the goal stays the same - maximum cooling performance at minimum cost. Our comprehensive guide How to Master Walk-In Cooler Design in 5 Simple Steps walks you through everything you need to know.

The CoolBot proves that the best innovations often come from thinking differently about everyday problems. Sometimes the most neat solution is also the most practical one.