Why Walk-In Coolers Are Essential for Modern Cold Storage

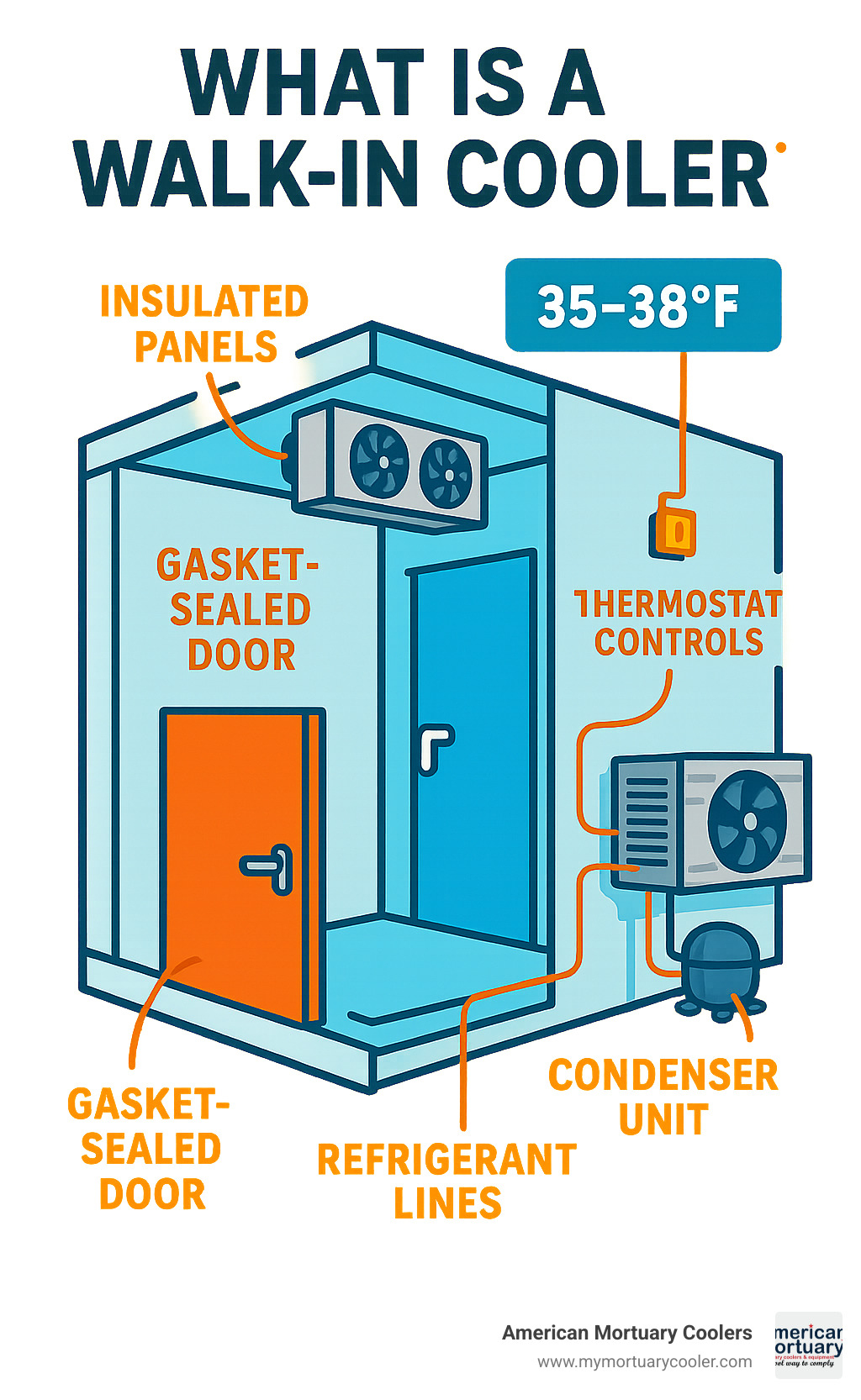

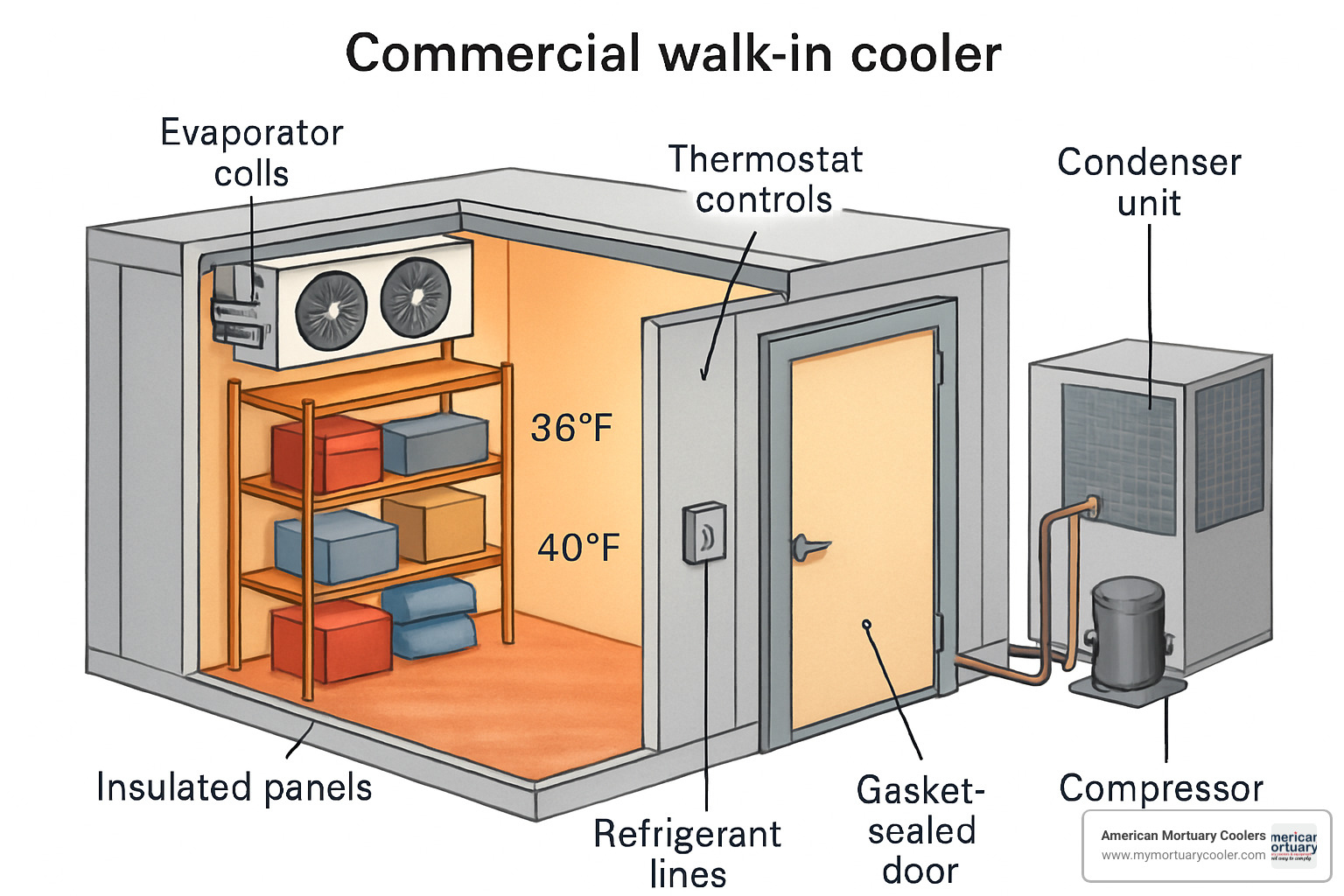

What is a walk-in cooler - it's a large refrigerated storage room that you can physically enter, designed to maintain temperatures between 35-38°F for preserving perishable goods. Unlike standard refrigerators, these units offer massive storage capacity and are built for commercial and industrial use.

Key Features of Walk-In Coolers:

- Temperature Range: 35-38°F (1.7-3.3°C) for optimal preservation

- Size: Typically under 3,000 square feet with various custom dimensions

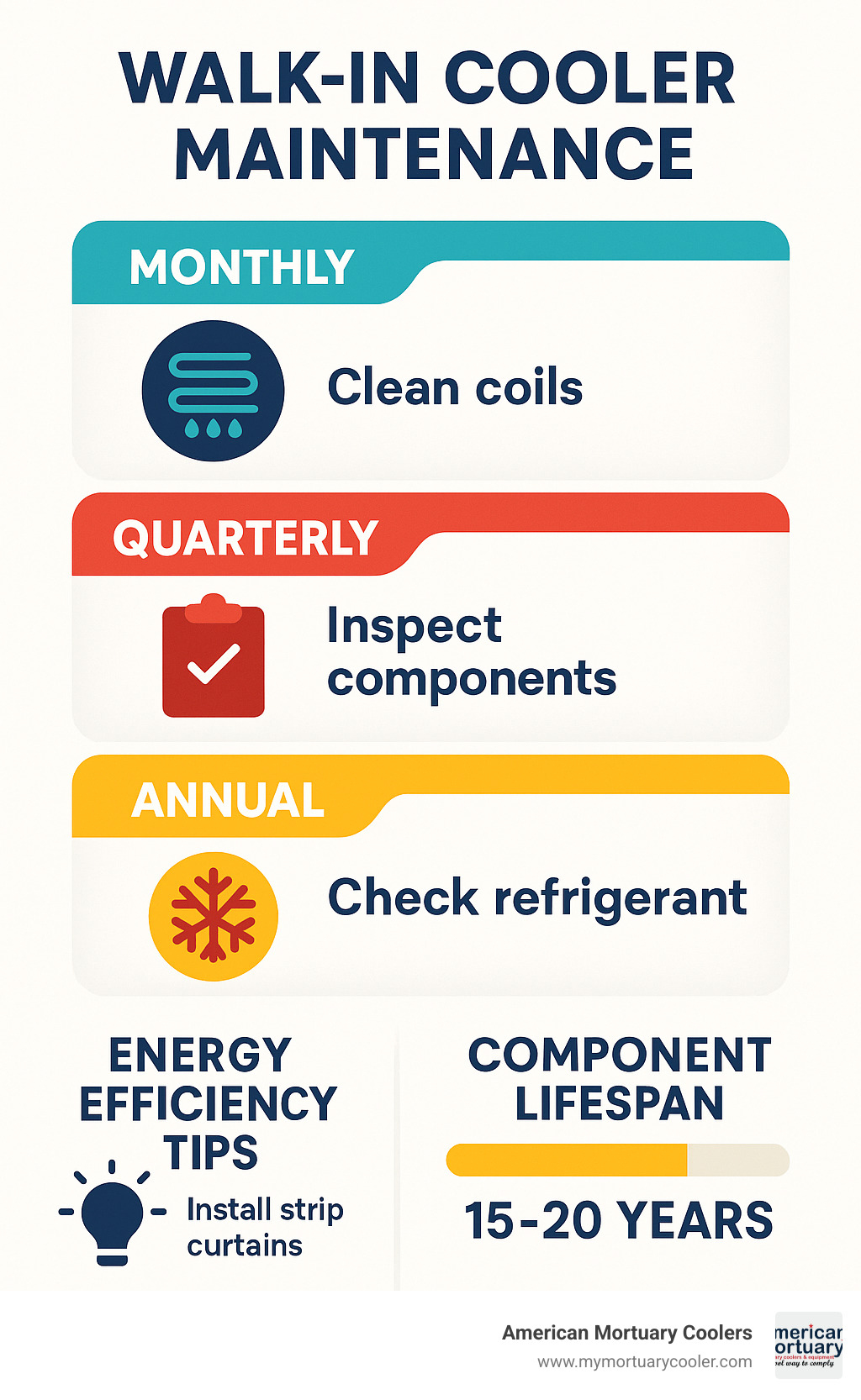

- Lifespan: 15-20 years with proper maintenance

- Applications: Restaurants, grocery stores, funeral homes, pharmaceuticals

- Components: Insulated panels, refrigeration system, sealed doors, temperature controls

Walk-in coolers serve as the backbone of cold chain management across essential industries. From restaurants preserving fresh ingredients to funeral homes maintaining dignified services, these units bridge the gap between standard refrigeration and large-scale warehouse storage.

The refrigeration cycle works through four key stages: compression, condensation, expansion, and evaporation. This process continuously removes heat from the interior space while specialized insulation and gasket-sealed doors maintain consistent temperatures.

Modern walk-in coolers come in several configurations:

- Self-contained units with all components integrated

- Remote systems with outdoor condensers

- Indoor vs outdoor installations

- Combination cooler-freezer units

As American Mortuary Coolers, we've spent years helping funeral directors understand walk-in cooler technology and select the right equipment for their facilities. Our expertise in what is a walk-in cooler comes from working directly with mortuary professionals who need reliable, space-efficient cooling solutions that meet their unique requirements.

What is a Walk-In Cooler? Definition, Temperature & Key Components

What is a walk-in cooler? Think of it as a room-sized refrigerator that you can actually walk into. These commercial-grade cooling systems are designed specifically for medium-term storage of temperature-sensitive items, maintaining that sweet spot between 35-38°F (1.7-3.3°C) where things stay fresh without freezing solid.

Unlike your kitchen refrigerator, walk-in coolers are built tough for heavy-duty use. They're constructed from prefabricated insulated panels that lock together like giant puzzle pieces using cam-action devices and heavy-duty gaskets. This creates an airtight seal that keeps the cold in and the warm air out.

The magic happens through several key components working together. The compressor acts as the heart of the system, pressurizing refrigerant to start the cooling process. The condenser releases heat from the refrigerant to the outside air, while the evaporator does the opposite—absorbing heat from inside your cooler. A thermostat keeps everything running smoothly by cycling the compressor on and off to maintain your target temperature.

What really sets walk-in coolers apart is their construction. You'll find 4-6 inches of insulation—usually polyurethane or extruded polystyrene foam—sandwiched between steel panels that protect the insulation core. The gasketed doors are specially designed to prevent warm air from sneaking in every time someone opens them.

These systems are built to last. With proper care, you can expect 15-20 years of reliable service from a quality walk-in cooler. The industry standard keeps footprints generally under 3,000 square feet, though custom sizes can accommodate whatever space you're working with.

Walk-in coolers serve an impressive range of industries. You'll find them in restaurants, hotels, grocery stores, pharmaceutical facilities, laboratories, and funeral homes. Each application has its own specific needs for temperature control and storage capacity.

What is a Walk-In Cooler for Food Safety?

When it comes to foodservice, understanding what is a walk-in cooler means recognizing it as your first line of defense against foodborne illness. The USDA doesn't mess around here—they require business refrigeration systems to maintain internal temperatures of 40°F or below to prevent dangerous bacterial growth and spoilage.

Walk-in coolers excel at this job because they maintain consistent temperatures across large storage volumes. Unlike smaller units that can have hot spots, a properly functioning walk-in cooler keeps everything at the right temperature from floor to ceiling.

The bigger capacity also means better temperature recovery. When someone opens the door of a small refrigerator, it can take a while for temperatures to stabilize again. Walk-in coolers bounce back much faster, keeping your food safer.

Restaurants, supermarkets, and catering facilities count on these units to store fresh produce, dairy products, meats, and prepared foods safely. The organized storage space also promotes proper airflow, which is crucial for maintaining consistent temperatures throughout the unit.

What is a Walk-In Cooler in Mortuary Applications?

For funeral homes, what is a walk-in cooler takes on a more specialized meaning. These units provide dignified body holding with precise temperature and humidity control that goes beyond basic refrigeration needs.

Mortuary walk-in coolers operate under different parameters than food storage units. The focus shifts to preservation while maintaining respectful conditions for families during their difficult time.

At American Mortuary Coolers, we understand the unique requirements funeral service providers face. Our custom mortuary coolers feature precise temperature control systems and humidity management capabilities built into durable construction designed for long-term reliability. We offer customizable interior configurations and provide direct delivery across the contiguous 48 states.

More info about Walk-In Coolers and Freezers: Essential Solutions for Your Mortuary Needs

How Does a Walk-In Cooler Work? The Refrigeration Cycle Demystified

When people ask what is a walk-in cooler, they're often curious about the magic happening behind those insulated walls. The truth is, it's not magic at all—it's a beautifully simple process that's been keeping things cold for over a century.

Your walk-in cooler works on the same basic principle as your home air conditioner, just with a few tweaks to handle the demands of commercial cold storage. The heart of the system is the refrigeration cycle, a continuous loop that moves heat from inside your cooler to the outside world.

Here's how the four-stage process works: Compression starts when your compressor pressurizes the refrigerant gas, which heats it up and increases the pressure. Think of it like squeezing a balloon—the gas gets hot and compressed.

Next comes condensation. That hot, high-pressure refrigerant flows through the condenser coils (usually located outside or on the roof), where it releases all that heat to the outside air and turns into liquid. It's like steam cooling down and becoming water again.

The expansion stage is where things get interesting. The liquid refrigerant passes through an expansion valve, and suddenly the pressure and temperature drop dramatically. This is the cooling magic happening right before your eyes.

Finally, evaporation completes the cycle. That cold, low-pressure refrigerant absorbs heat from inside your cooler through the evaporator coils, turning back into gas and starting the whole process over again.

Your cooler's brain is the thermostat, typically set around 35°F with cut-in points at 38-39°F. When the temperature rises, it signals the compressor to kick on. When it drops to the target temperature, everything shuts down for a well-deserved break.

The system also includes safety features like low-pressure switches that protect your compressor from damage, and pump-down cycles that automatically move refrigerant into the condenser during off periods.

One thing that makes walk-in coolers special is their off-cycle defrost system. Instead of using heaters like freezers do, your cooler uses the natural above-freezing air temperature. The blower fans keep running even when the compressor is off, circulating warm air over the coils to melt any frost buildup.

Those evaporator fans are the unsung heroes of your walk-in cooler. They run continuously, ensuring consistent air circulation and temperature distribution throughout your storage space. Without them, you'd have warm spots and cold spots that could compromise your stored items.

Modern systems use various refrigerants designed for efficiency and environmental responsibility. The whole system is engineered to run reliably for years with minimal maintenance.

Scientific research on cold food storage

Types, Sizes & Installation Options

When you're exploring what is a walk-in cooler for your facility, you'll find there's no one-size-fits-all solution. The beauty of modern walk-in coolers lies in their flexibility to adapt to your specific needs and space constraints.

Most businesses start with prefabricated modules that offer quick installation and reliable performance. The 10×10 foot and 8×10 foot sizes have become industry favorites because they strike the perfect balance between storage capacity and manageable installation. These standard dimensions make ordering straightforward and keep costs reasonable.

But here's where it gets interesting – custom dimensions open up a world of possibilities. Maybe you have an awkward corner space or need maximum storage in a tight footprint. Custom sizing ensures you're not wasting valuable real estate or compromising on the storage you actually need.

Combo cooler-freezer units deserve special mention because they're brilliant space-savers. These integrated systems give you both refrigerated and frozen storage in one efficient package, perfect for facilities that need both temperature ranges but don't have room for separate units.

Now, let's talk about where you'll put your cooler. Indoor installations are the most common choice because they're protected from weather and easier to access. You can often use your existing floor, which saves on foundation costs. Outdoor installations require more planning – you'll need a proper concrete pad with drainage and possibly a weather kit with additional insulation and protective features.

| Feature | Indoor Coolers | Outdoor Coolers |

|---|---|---|

| Installation | Inside existing buildings | Standalone outdoor units |

| Insulation | Standard 4" thickness | Improved with weather protection |

| Foundation | Existing floor surface | Concrete pad required |

| Accessibility | Easy staff access | May require weather protection |

| Energy Use | Stable ambient conditions | Variable with weather |

| Maintenance | Protected environment | More frequent due to exposure |

The refrigeration system itself comes in two main flavors. Self-contained units have everything built into one package – compressor, condenser, evaporator, and controls all integrated together. They're simpler to install and maintain, making them popular for smaller operations.

Remote condensing systems separate the condenser from the cooler itself, typically placing it on a rooftop or outside wall. This arrangement offers several advantages: quieter operation inside your building, better heat rejection in hot climates, and easier maintenance access to the condenser.

Panel thickness matters more than you might think. Standard 4-inch panels work fine for most applications, but 6-inch panels provide better insulation and energy efficiency, especially for outdoor installations or challenging environments.

The insulation core itself comes in two main types. Polyurethane foam bonds well during manufacturing but loses some insulating value over time. Extruded polystyrene resists moisture better and maintains its insulating properties longer – it retains about 47% of its initial R-value compared to polyurethane's 19%.

For outdoor installations, don't forget about those winter kits. These include compressor heaters and other cold-weather protection that keeps your system running smoothly when temperatures drop. A proper rain roof and weatherproofing complete the package.

At American Mortuary Coolers, we understand that funeral homes have unique space and operational requirements. Whether you need a compact 8×10 unit tucked into an existing prep room or a custom-sized outdoor installation, we'll help you steer these options to find the perfect solution for your facility.

More info about Ultimate Guide to Walk-In Coolers

Maintenance, Troubleshooting & Lifespan Optimization

When you understand what is a walk-in cooler, you quickly realize that proper maintenance is what separates a 15-year investment from a 20-year one. Think of it like caring for a car - regular attention prevents those midnight emergency calls that nobody wants to deal with.

Daily care starts simple. Check your temperature logs religiously, because consistency tells you everything about your cooler's health. While you're at it, give those door seals a quick visual inspection for cracks or debris. Food particles love to hide in gaskets, and they're surprisingly good at breaking down rubber over time.

The interior cleaning routine doesn't need to be complicated. Use gentle, non-abrasive cleaners and focus on maintaining proper airflow around stored items. Make sure doors close completely - it sounds basic, but a door that doesn't seal properly can double your energy costs.

Monthly maintenance is where the real magic happens. This is when you break out the soft brushes and vacuum to clean those evaporator and condenser coils. Dirty coils are probably the number one cause of premature system failure, yet they're completely preventable with regular attention.

During these monthly sessions, inspect refrigerant lines for leaks and check drain pans for clogs. Test your thermostat calibration and examine fan motors for unusual wear. These small steps catch problems before they become expensive emergencies.

Common problems have predictable patterns. Ice build-up usually means poor airflow, defrost system issues, or damaged door seals. Temperature inconsistencies often point to dirty coils, low refrigerant, or thermostat problems. The good news is that most issues give you warning signs if you're paying attention.

Warm spots in your cooler typically indicate blocked air circulation or failing fans. Strange noises usually mean mechanical components need attention. High energy bills often signal that your system is working harder than it should, which points to maintenance needs.

The DIY versus professional service question comes up constantly. Daily cleaning and basic inspections are perfect for in-house staff. But when you're dealing with refrigerant work, electrical repairs, or major component replacement, call in licensed professionals. Your warranty depends on it, and frankly, so does your safety.

Regular professional inspections are like preventive medicine for your cooler. A trained technician can spot failing timers, damaged valves, or refrigerant leaks before they cause complete system failure. The cost of a maintenance visit is always less than the cost of replacing spoiled inventory or emergency repairs.

Temperature logs become your best friend for troubleshooting. They reveal patterns that help technicians diagnose problems quickly. Digital thermostat upgrades can provide more precise control and better data tracking than older mechanical systems.

The 15-20 year life expectancy isn't just a suggestion - it's achievable with consistent care. Replace worn parts promptly, keep detailed maintenance records, and don't ignore small problems. Your future self will thank you when your cooler is still running strong after two decades.

Scientific research on digital thermostat upgrades

Energy Efficiency, Regulations & Future Innovations

When we talk about what is a walk-in cooler today, we're really talking about sophisticated energy-saving machines that would make your grandfather's old icebox jealous. Modern walk-in coolers have come a long way from the power-hungry units of decades past, and the improvements are showing up in monthly utility bills across the country.

The secret starts with high R-value insulation packed into those 4-6 inch thick panels. This isn't your average house insulation – it's specially engineered foam that creates an incredibly effective barrier against heat transfer. Think of it as a really good winter coat for your cooler, keeping the cold in and the heat out.

LED lighting systems have revolutionized walk-in cooler efficiency. These motion-activated fixtures use a fraction of the energy that old fluorescent bulbs consumed, and they generate virtually no heat. That means your compressor doesn't have to work overtime fighting against light bulb heat – a win-win situation.

One of the simplest yet most effective innovations is the humble strip curtain. These plastic barriers hang at doorways and dramatically reduce cold air loss when staff enter and exit. It's amazing how such a basic solution can cut energy costs by 10-15% in busy facilities.

Smart IoT controls represent the cutting edge of walk-in cooler technology. These systems learn your facility's patterns and optimize compressor cycles accordingly. They can even send alerts to your phone if temperatures drift out of range – no more finding problems during your morning coffee.

The regulatory landscape keeps pushing the industry toward better efficiency. EISA compliance now mandates high-efficiency motors and improved insulation standards. NSF approval remains essential for food service applications, while UL listing ensures electrical safety. The ASTM84 standards cover smoke and flame spread ratings, keeping everyone safe.

Looking ahead, natural refrigerants like CO2 and ammonia are gaining ground as environmentally friendly alternatives. Variable-speed compressors adjust their output to match cooling demand instead of cycling on and off like traditional systems. Advanced defrost controls minimize energy waste, and remote monitoring capabilities let you track performance from anywhere.

Here's something that might surprise you: ambient temperature changes can dramatically impact your energy costs. When outside temperatures climb from 80°F to 100°F, your refrigeration load can increase by up to 30%. That's why proper installation location matters so much for long-term operating costs.

Modern systems also feature automatic pump-down cycles that protect outdoor condensing units from low ambient temperatures. The system evacuates refrigerant into the condenser when the cooler reaches its setpoint, preventing damage during cold weather.

At American Mortuary Coolers, we stay current with these efficiency innovations because we know funeral directors need reliable, cost-effective cooling solutions. Our custom units incorporate the latest energy-saving technologies while maintaining the precise temperature control that mortuary applications demand.

More info about How to Master Walk-In Cooler Design

Scientific research on energy efficiency

Frequently Asked Questions about Walk-In Coolers

When people first start researching what is a walk-in cooler, they usually have three main concerns: sizing, efficiency, and longevity. Let's tackle these head-on with practical answers based on real-world experience.

What size walk-in cooler do I need?

Getting the size right is crucial because you can't easily expand later. The industry uses a handy rule of thumb: 28 pounds of product per cubic foot of storage space. But that's just the starting point.

Think about your current storage needs first. Walk through your facility and inventory everything that needs refrigeration. Then consider your future growth over the next 5-10 years. It's much cheaper to buy a slightly larger unit now than to replace it entirely when you outgrow it.

Small restaurants and funeral homes typically do well with 8×8 to 10×10 foot units. Medium-sized operations like larger restaurants or regional funeral homes often need 10×12 to 12×16 foot spaces. Anything bigger usually calls for custom sizing.

Don't forget about workflow considerations either. You need room for staff to move around safely, especially when carrying heavy items or stretchers. A cramped cooler isn't just inconvenient—it's a safety hazard.

How can I improve energy efficiency in my walk-in cooler?

The fastest way to cut energy costs is surprisingly simple: clean those coils monthly. Dirty condenser and evaporator coils can bump up your energy bill by 20-30%. It's like trying to breathe through a dirty air filter.

Vinyl strip curtains at doorways make a huge difference too. They let people pass through easily while keeping most of the cold air inside. Pair those with LED lighting and motion sensors, and you'll see noticeable savings on your electric bill.

For bigger improvements, consider upgrading to digital thermostats with precise control and smart monitoring systems. These technologies optimize your compressor cycles automatically, so you're not wasting energy maintaining unnecessarily cold temperatures.

The beauty of efficiency improvements is that they pay for themselves over time. A well-maintained, properly equipped walk-in cooler can run for decades while keeping operating costs reasonable.

How long does a walk-in cooler last with proper care?

With good maintenance, you can expect 15-20 years from a quality walk-in cooler. That's a solid return on investment, especially when you consider the daily reliability these units provide.

Scheduled maintenance is your best friend here. Monthly coil cleaning and annual professional inspections catch small problems before they become expensive emergencies. Component replacement when parts show wear—rather than waiting for failure—extends overall system life significantly.

Indoor units generally outlast outdoor installations because they're protected from weather extremes. Heavy-use applications might need more frequent service, but even busy facilities can hit that 20-year mark with consistent care.

When major components start failing after 15+ years, refurbishment often makes more sense than complete replacement. Door upgrades, floor renovation, and refrigeration system modernization can give your cooler a second life at a fraction of replacement cost.

At American Mortuary Coolers, we've seen properly maintained units serve funeral homes faithfully for decades. The key is treating maintenance as an investment in reliability rather than an expense. After all, when you're serving families during difficult times, equipment failure simply isn't an option.

Conclusion

Now that you understand what is a walk-in cooler and how these remarkable systems work, you can see why they're such game-changers for businesses that need reliable cold storage. These aren't just big refrigerators—they're sophisticated temperature control systems that keep your most valuable inventory safe and fresh.

Think about it: whether you're a restaurant owner protecting thousands of dollars in fresh ingredients or a funeral director ensuring dignified care for families, your walk-in cooler becomes the silent guardian that never takes a day off. With their 15-20 year lifespan and rock-solid reliability, these units earn their keep every single day.

At American Mortuary Coolers, we've seen how the right cooling system transforms a funeral home's operations. Based here in Tennessee, we've been delivering custom mortuary coolers across all 48 contiguous states, and we know that choosing the right unit isn't just about size—it's about understanding your specific needs.

The key factors that make or break your walk-in cooler investment include getting the temperature requirements exactly right for your application, selecting a size and configuration that fits your space like a glove, and choosing energy-efficient features that keep your utility bills reasonable. Don't forget about maintenance accessibility—you'll thank yourself later when service time comes around.

Modern walk-in coolers are smarter and more efficient than ever before. With smart controls that practically think for themselves, LED lighting that sips electricity, and insulation that would make an arctic explorer jealous, today's units deliver incredible performance while being kinder to both your wallet and the environment.

The beauty of understanding what is a walk-in cooler lies in recognizing that you're not just buying equipment—you're investing in peace of mind. When that compressor kicks on and those fans start humming, you know your products are protected, your business is secure, and your customers can count on you.

For funeral service providers who need specialized cooling solutions, we're here to help you steer the options and create something that perfectly matches your facility's unique requirements. After all, every funeral home deserves equipment that's as reliable and dignified as the services they provide.

More info about The Complete Guide to Walk-In Cooler Features and Prices