Why Custom Walk-In Coolers Are Essential for Modern Businesses

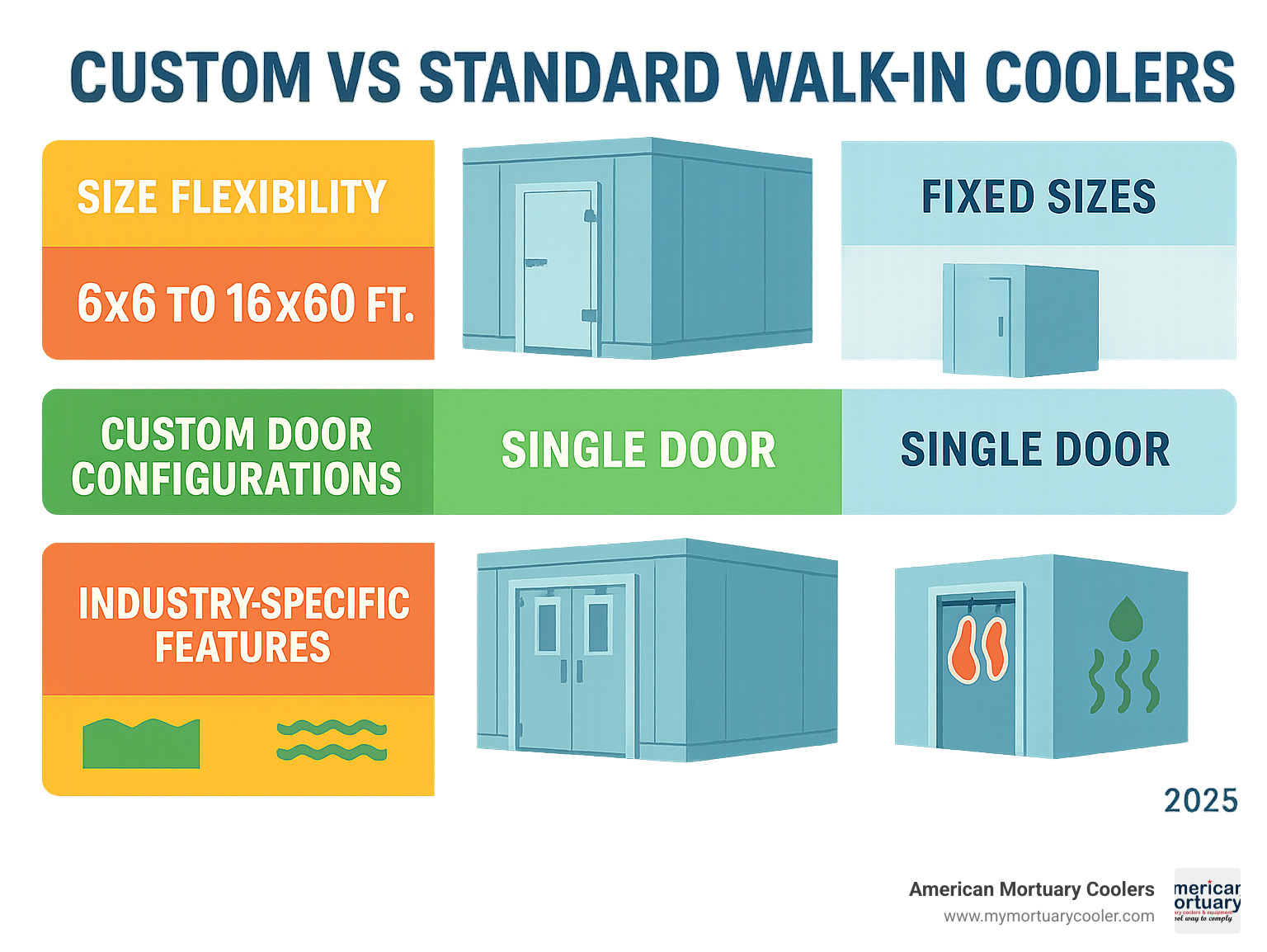

A custom walk-in cooler is a refrigerated storage unit designed to fit your exact space requirements, temperature needs, and operational workflow. Unlike standard models with fixed dimensions, custom units can be built in widths from 6′ to 16′ and lengths up to 60′, with heights reaching 28′ to maximize your available space.

Quick Answer for Custom Walk-In Cooler Buyers:

- What it is: Large refrigerated room you can walk into (33-38°F operating range)

- Custom vs Standard: Built to your exact dimensions vs fixed nominal sizes

- Key benefits: Space optimization, energy efficiency, workflow improvement

- Industries: Restaurants, healthcare, retail, mortuaries, breweries, pharmaceuticals

- Cost factors: Size, insulation thickness, indoor/outdoor placement, accessories

- Timeline: 10-day quick-ship options available for standard configurations

The majority of restaurants and hotels in Canada find walk-in coolers essential for storing the food needed for daily service operations. Custom sizing eliminates the layout inefficiencies that come with trying to fit standard nominal-sized units into unique spaces.

Whether you're a funeral home director needing precise temperature control for mortuary applications, a restaurant owner maximizing kitchen efficiency, or a brewery requiring specialized storage, custom walk-in coolers deliver the exact footprint and features your operation demands.

We're American Mortuary Coolers, a Tennessee-based specialist in custom walk-in cooler solutions for funeral homes and commercial applications. Our expertise helps businesses nationwide find durable, American-made refrigeration systems that fit their exact space constraints and operational requirements.

What Is a Custom Walk-In Cooler and Why It Matters

A custom walk-in cooler is like having clothes custom to fit perfectly versus buying off the rack. While reach-in refrigerators only give you access through front doors, a walk-in cooler lets you step inside to organize and retrieve products. Custom units eliminate the guesswork of standard sizing—that "6x6x8" cooler is actually 5'10½" x 5'10½" x 7'6" when it arrives, but custom builds deliver your exact measurements.

The cold chain—that unbroken temperature-controlled journey from farm to table—depends on reliable refrigeration at every step. Your walk-in cooler becomes the guardian of food safety, product quality, and your business reputation.

Key Benefits of Going Custom

Space optimization transforms how you use every square foot. Custom dimensions maximize both storage capacity and workflow efficiency, especially valuable in expensive urban locations.

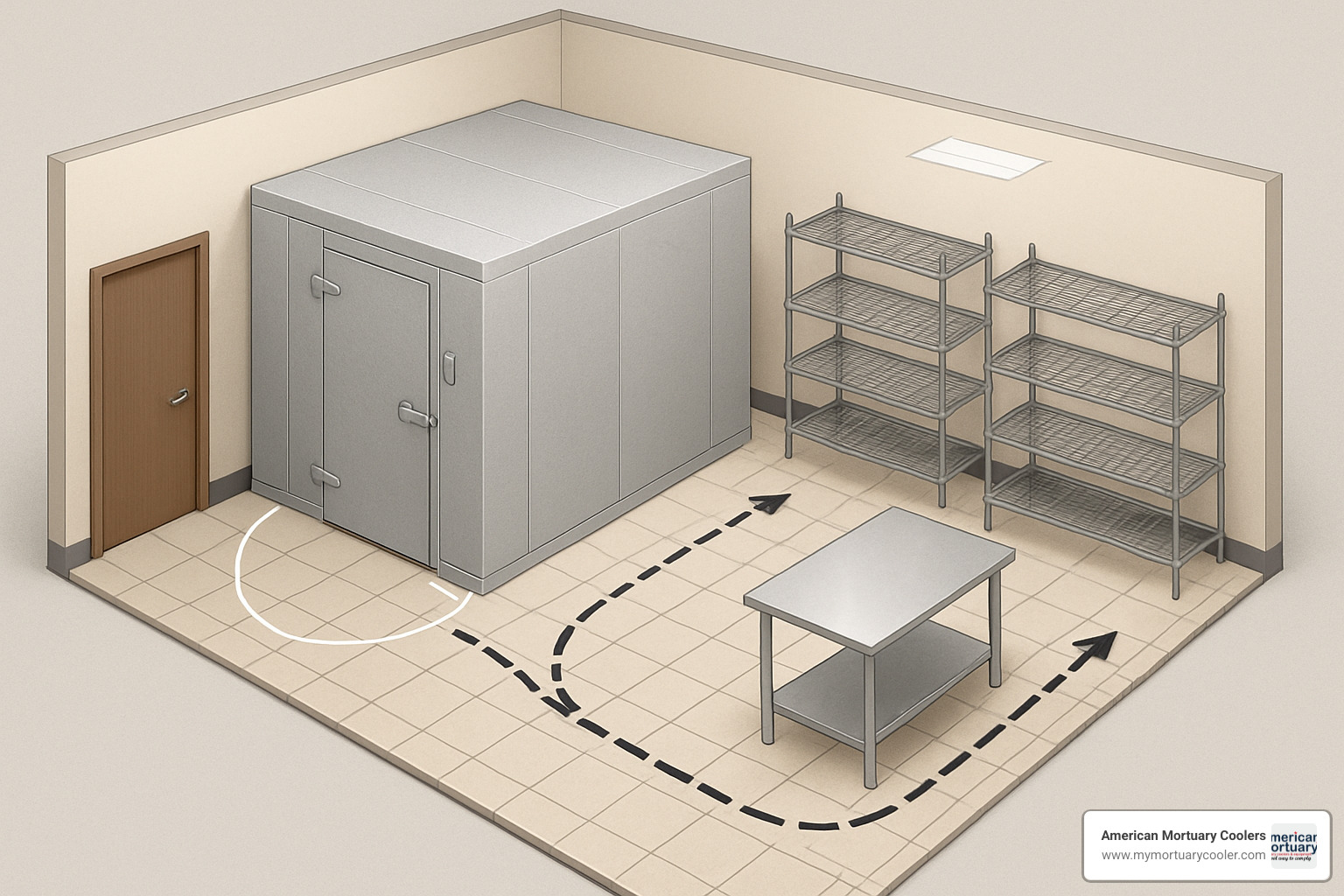

Workflow improvements happen when your cooler works with your team. Custom door placement means shorter trips for staff. Strategic shelving reduces lifting and reaching. Interior layouts designed around your products save minutes on every restocking session.

Energy savings come from proper sizing and advanced insulation. A perfectly fitted unit with high-performance polyurethane foam panels can dramatically reduce monthly utility bills. Seamless construction eliminates thermal bridges that waste energy.

Dual-temperature capabilities maximize versatility by letting a single unit serve both cooling and freezing functions with dial-controlled temperature switching.

More info about cooling solutions

Industries That Rely on Custom Walk-In Coolers

Food service operations represent the backbone of the custom cooler market. Restaurants, cafeterias, and catering companies need cold storage that fits their unique kitchen layouts and volume demands.

Breweries and beverage operations have specialized needs including keg rails, oversized doors for easy loading, and dual-zone temperature control for different products.

Pharmaceutical and healthcare facilities operate under strict regulations demanding precise temperature control and detailed monitoring capabilities with specialized construction materials.

Mortuaries represent one of the most specialized markets. Funeral homes require precise temperature control and configurations that accommodate their unique operational requirements. At American Mortuary Coolers, we've built our expertise around these specialized needs, delivering custom solutions nationwide.

Industrial applications span food processing facilities, distribution centers, and manufacturing operations needing large-scale cold storage integrated into production workflows.

Hunters and game processors choose custom units with specialized meat and game rail systems, configured for easy hanging and processing of large game animals.

Designing Your Custom Walk-In Cooler: From Concept to Footprint

Planning your custom walk-in cooler starts with understanding your space and workflow. The beauty of custom sizing is building up when you can't build out—units can reach up to 28 feet high for maximum vertical storage.

Only about 70% of your cooler's floor space will actually hold products once you add shelving and walking room. So a 10x12 cooler provides about 84 square feet of usable storage space.

Indoor versus outdoor placement significantly impacts your project. Outdoor units need weather protection but install without disrupting operations. Indoor units stay protected but require proper ventilation and complex refrigeration line installation.

Sizing & Location Essentials

Proper site surveys with precise measurements are essential. Door swing clearance needs extra space beyond the 35½" x 78" door dimensions for staff to maneuver carts and products efficiently.

Smart placement near loading areas saves hours of labor weekly. Areas prone to earthquakes or hurricanes need additional structural anchoring and engineering certifications.

| Nominal Size | Actual Dimensions | Custom Alternative |

|---|---|---|

| 6x6x8 | 5'10½" x 5'10½" x 7'6" | 6'0" x 6'0" x 8'0" exact |

| 8x10x8 | 7'10½" x 9'10½" x 7'6" | 8'0" x 10'0" x 8'0" exact |

| 10x12x8 | 9'10½" x 11'10½" x 7'6" | 10'0" x 12'0" x 8'0" exact |

Temperature Strategy & Dual-Purpose Builds

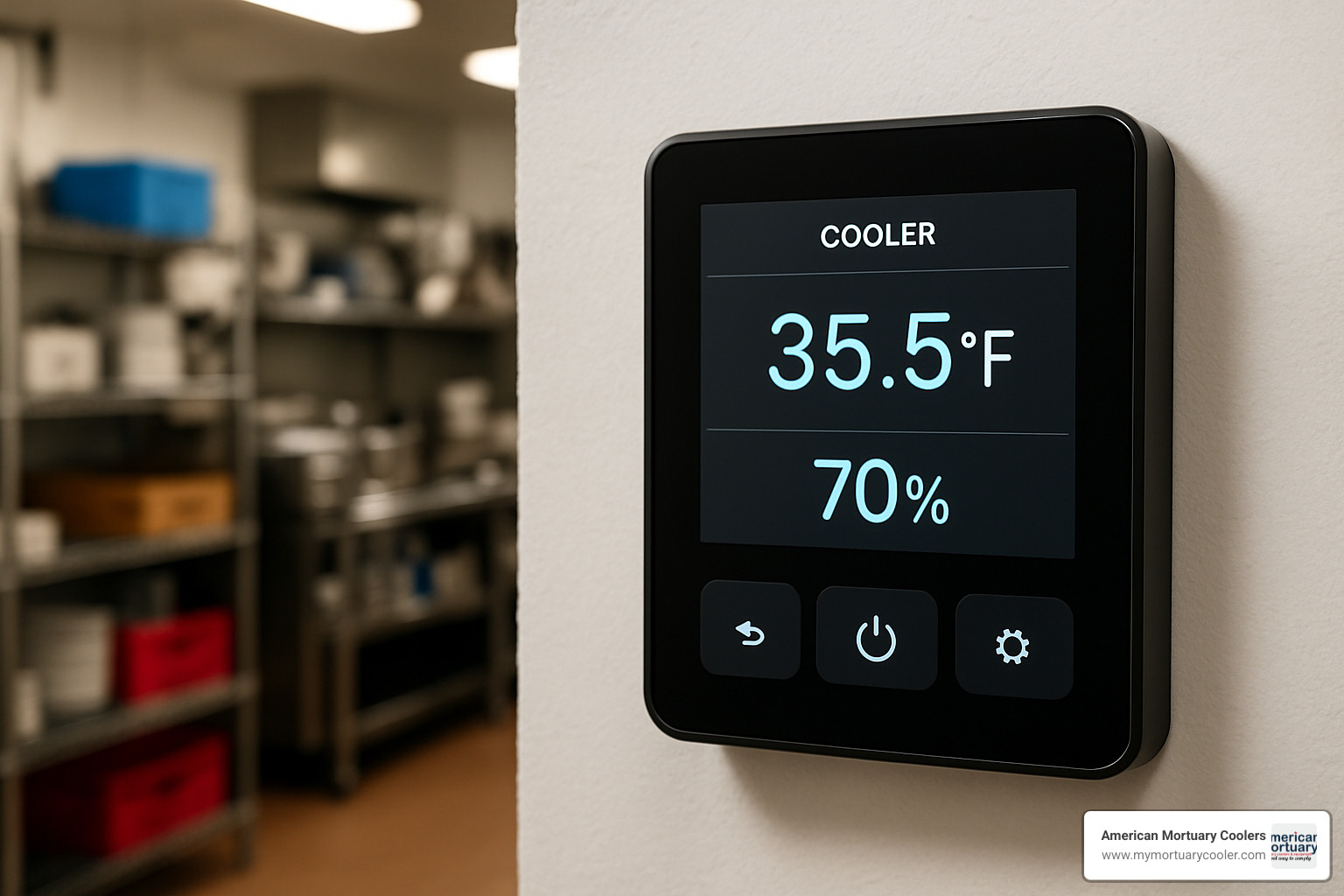

Most custom walk-in coolers run between 33-38°F—cold enough for food safety without freezing products. Dual-temperature systems let one unit switch between cooling and freezing with dial adjustment.

Humidity control maintains exact moisture levels different products need. Your product turnover rate should influence temperature strategy—quick turnover allows slightly warmer temperatures and energy savings.

Panel Construction, Insulation & Energy Codes

Polyurethane foam insulation is the gold standard—CFC-free with continuous thermal barriers eliminating cold spots. Expanded polystyrene (EPS) cores offer budget-friendly options meeting Energy Star requirements.

Cam-lock joints between panels create water-tight, vapor-tight seals while eliminating thermal bridges. All modern coolers must meet EISA compliance standards with minimum R-values and self-closing doors.

Scientific research on insulation efficiency

Customization Options & the Latest Tech

When investing in a custom walk-in cooler, door selection impacts daily operations. Standard hinged doors work for most situations, but sliding doors up to 10' wide by 10' high work perfectly in tight spaces without swing clearance needs.

Glass doors create retail appeal where customers need product visibility. Kick plates with diamond tread surfaces protect doors from cart damage in high-traffic areas.

Finish options now include custom exterior colors matching your facility's branding. LED lighting systems provide better visibility while slashing energy bills with smart automatic adjustment features.

Modern IoT sensors track temperature, humidity, and door openings, sending alerts to your phone before problems become expensive disasters.

Door, Shelving & Finish Upgrades

High-performance doors feature advanced sealing systems and superior insulation maintaining steady temperatures in high-traffic situations. Energy savings often justify upgrade costs.

Specialized meat rails and hanging systems are engineered into the cooler's framework for maximum strength. Custom keg systems for breweries include rolling systems and specialized racking for different keg sizes.

Merchandising glass doors bring retail appeal with integrated LED lighting. Antimicrobial panels provide extra protection through specialized coatings fighting bacterial growth.

Practical additions like ramps and strip curtains improve operations. Ramps make moving carts effortless while strip curtains maintain temperature during frequent door openings.

Smart Controls, Energy Management & Innovations

Variable-speed compressors automatically adjust cooling capacity based on demand, potentially cutting energy costs by 20-30% during slower periods.

Improved Vapor Injection (EVI) technology ensures consistent operation in challenging conditions. Hot-gas defrost systems use refrigerant gas to melt ice more efficiently than electric heating.

Remote monitoring capabilities put complete control in your pocket through smartphone apps. Quick-ship prefab options deliver popular configurations in 10 days for urgent replacements.

Solar-ready units include design features for straightforward renewable energy integration, potentially eliminating energy costs in sunny locations.

More info about cooling features

Budgeting, Ordering & Installation Workflow

Getting your custom walk-in cooler from idea to installation involves key steps affecting timeline and budget. Quote forms should capture every detail affecting pricing—dimensions, insulation, doors, refrigeration, and accessories.

Lead times depend on customization level. Standard configurations ship in 10 days, while highly customized units require 4-6 weeks. Shipping logistics get complex with larger units often needing crane placement for installation.

Permitting requirements vary by jurisdiction for electrical work, refrigerant handling, or structural modifications. Professional installation ensures proper assembly, refrigerant charging, and system commissioning with warranty protection.

Cost Drivers & Warranty Protection

Size is the biggest cost factor—a basic 8x8x8 cooler runs around $24,400, while an 8x20 combination unit reaches $54,343. Insulation thickness costs more upfront but delivers better energy efficiency paying for itself within years.

Indoor versus outdoor placement impacts budget significantly. Outdoor units need additional weatherproofing, typically adding 25% to base cost, but save on site preparation.

Accessories and customization can substantially increase investment. Popular additions include LED lighting, digital monitoring, specialized shelving, and upgraded door hardware.

Standard warranties include 1 year on parts and labor with 5 years on compressor. Premium warranties extend to 25 years on foam structure.

Compliance, Safety & Code Checklist

NSF certification ensures food-contact surfaces meet commercial safety standards. UL listing provides safety certification for electrical components. OSHA compliance covers workplace safety including ventilation and emergency procedures.

Local health department regulations often specify additional requirements for temperature monitoring and maintenance documentation. Vapor barriers prevent moisture infiltration damaging insulation.

Self-closing doors are required by energy standards and health codes. Working with experienced suppliers like American Mortuary Coolers ensures equipment meets all codes and passes inspections.

More info about choosing suppliers

Maximizing Lifespan, Workflow & ROI

Your custom walk-in cooler represents a significant investment that can deliver exceptional returns for decades with proper care and smart design choices.

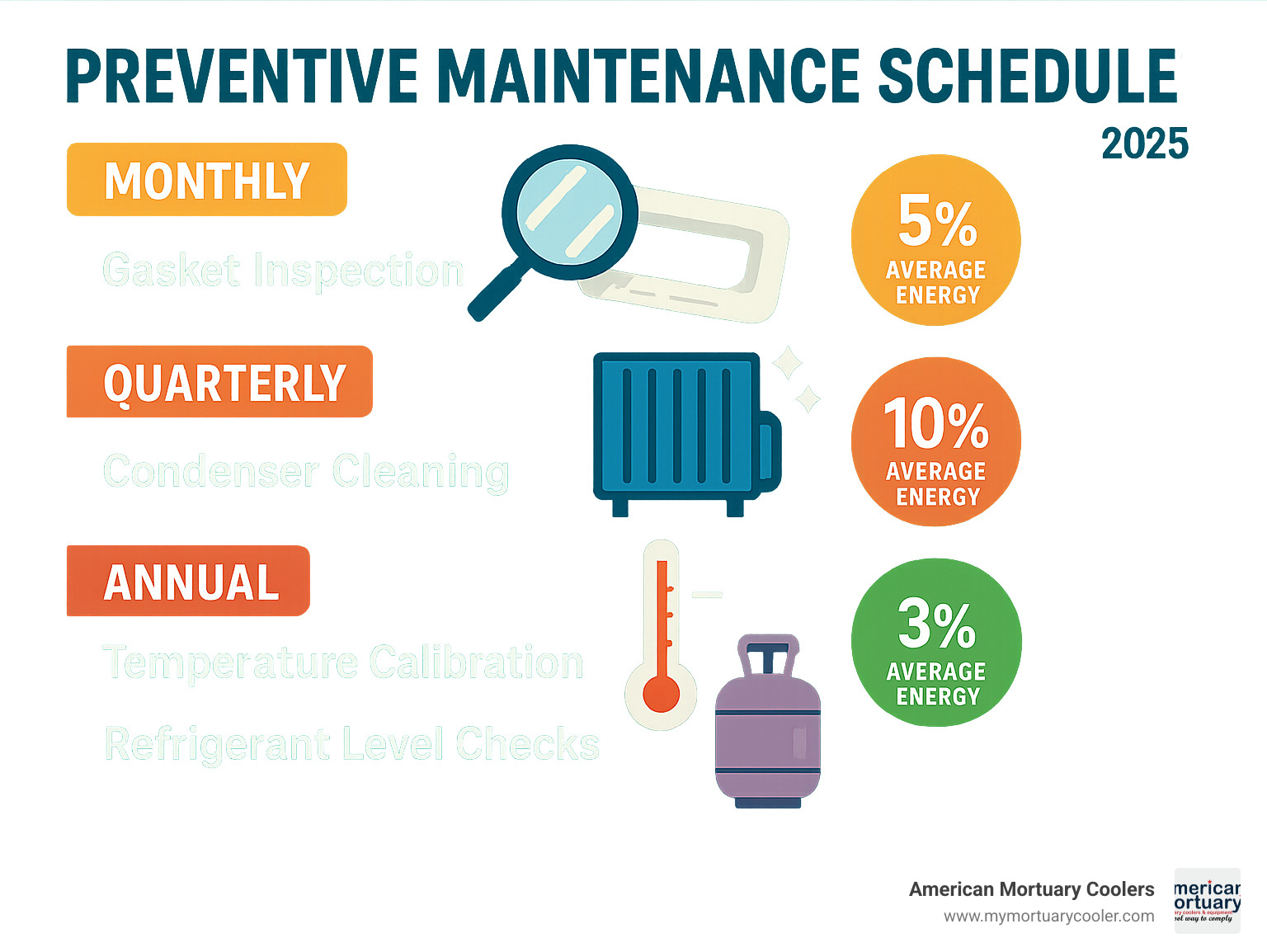

Preventive maintenance prevents most major problems. Monthly routines checking door gaskets, cleaning condenser coils, and verifying temperatures take minutes but save hundreds in energy costs.

Gasket care prevents warm air infiltration and cold air escape. When gaskets get worn, your cooler works harder and energy bills climb. Condenser cleaning becomes critical in dusty environments—clean condensers improve efficiency by 15-20%.

Temperature logs keep you compliant while helping spot performance trends early. Modern digital monitoring makes this effortless with phone alerts if temperatures drift outside safe ranges.

Retrofit opportunities can upgrade older coolers with variable-speed compressors, smart controls, or improved insulation. These improvements typically pay for themselves within 2-3 years through reduced operating costs.

Air curtains reduce cold air loss by up to 80% when doors open frequently. Ergonomic shelving improves worker comfort and operational efficiency while maximizing storage capacity.

Labor savings from thoughtful design compound over time. Features like easy-access doors, efficient layouts, and proper LED lighting reduce staff time retrieving products. In busy restaurants, saving 30 seconds per trip adds up to hours of labor savings weekly.

Return on investment extends beyond energy savings through improved workflow, reduced maintenance costs, and better product preservation. At American Mortuary Coolers, we've seen businesses recoup cooler investment within 3-5 years through these combined benefits.

Frequently Asked Questions about Custom Walk-In Coolers

What's the difference between a walk-in cooler and a walk-in freezer?

The biggest difference comes down to temperature ranges and what they're designed to store. Walk-in coolers keep things nice and cool at 33°F to 38°F - perfect for fresh food, beverages, and products that need refrigeration without freezing. Walk-in freezers, on the other hand, crank things down to 0°F or below for long-term frozen storage.

But it's not just about turning down the thermostat. Freezers need beefier everything - more powerful refrigeration systems with higher horsepower, thicker insulation (usually 4-6 inches instead of the 3-4 inches you'll find in coolers), and specialized components that can handle the extreme temperature differences.

You'll also notice construction differences that matter for daily operations. Freezers come with hot-gas defrost systems to manage ice buildup, more robust door sealing systems, and sometimes even heated door frames to prevent ice formation around the seals. These features add cost but they're essential for reliable freezer operation.

At American Mortuary Coolers, we understand that funeral homes often need precise temperature control for their specific applications. Whether you need cooling or freezing capabilities, we can design a system that meets your exact requirements.

Can one unit be designed to switch between cooling and freezing?

Yes, but it's more complicated than just flipping a switch. Dual-temperature units can switch between cooling and freezing modes, though the approach varies quite a bit between manufacturers.

Some systems use dial controls that let you switch between preset temperature ranges - pretty straightforward for operators. Others require manual adjustment of refrigeration settings, which might need a service technician depending on your comfort level with the equipment.

Here's the catch: standard walk-in coolers can't just be converted to freezer operation without major modifications. You'd need upgraded refrigeration equipment, improved insulation, and specialized components - basically rebuilding the whole system. That's why dual-temperature models are specifically engineered for this flexibility from day one.

The most effective approach we've seen uses separate compartments with independent temperature controls. This lets you run cooling and freezing simultaneously in different zones of the same unit. It costs more upfront than single-purpose units, but the flexibility can be worth it for operations with varying storage needs.

How do I ensure my new cooler meets local building and health codes?

Start early and ask lots of questions - that's our best advice. Contact your local building department and health authorities before you even finalize your cooler specifications. Requirements vary dramatically from one jurisdiction to another, and food service operations typically face the most stringent requirements.

Common requirements you'll likely encounter include minimum insulation R-values, self-closing doors (required by current energy standards), temperature monitoring systems, and specific construction materials. Many jurisdictions also require permits for electrical work, refrigerant installation, and any structural modifications to your building.

The good news is that working with experienced manufacturers and installers makes this process much smoother. Professional installation teams should handle permit applications and coordinate required inspections to ensure your custom walk-in cooler meets all applicable standards.

We've been delivering custom solutions nationwide for years, so we understand the maze of local codes and requirements. Our team works with you to ensure your cooler not only meets your operational needs but also satisfies all the regulatory requirements in your area. It's one less thing you need to worry about during what's already a complex installation process.

Conclusion & Next Steps

Investing in a custom walk-in cooler is one of the smartest decisions you can make for your business. The benefits—perfect space utilization, energy savings, streamlined workflow, and better product protection—add up to real improvements in daily operations and bottom line.

You now have the knowledge to make informed decisions about sizing, placement, temperature control, and customization options. We've covered budgeting, installation workflows, and compliance requirements so you can move forward with confidence.

American Mortuary Coolers, based in Tennessee, has built our reputation on understanding exactly what different industries need from refrigeration systems. Whether you're running a funeral home requiring precise temperature control, managing a busy restaurant kitchen, or operating any business depending on reliable cold storage, we create durable, custom solutions fitting your exact specifications.

We deliver nationwide across the contiguous 48 states, working with you from initial consultation through installation and beyond. Our specialists understand local building codes, energy efficiency requirements, and industry-specific needs.

Don't let inadequate cold storage hold your business back. The difference between struggling with poorly designed coolers and having the right system is dramatic. Your staff will work more efficiently, products will stay fresher longer, and energy bills will be lower.

Ready to see what a properly designed custom walk-in cooler can do for your operation? Reach out to us today for a detailed consultation and quote. We'll discuss your specific needs, explain your options, and show you exactly how a custom solution can transform your cold storage challenges into competitive advantages.