Finding the Right Cold Storage Partner for Your Business

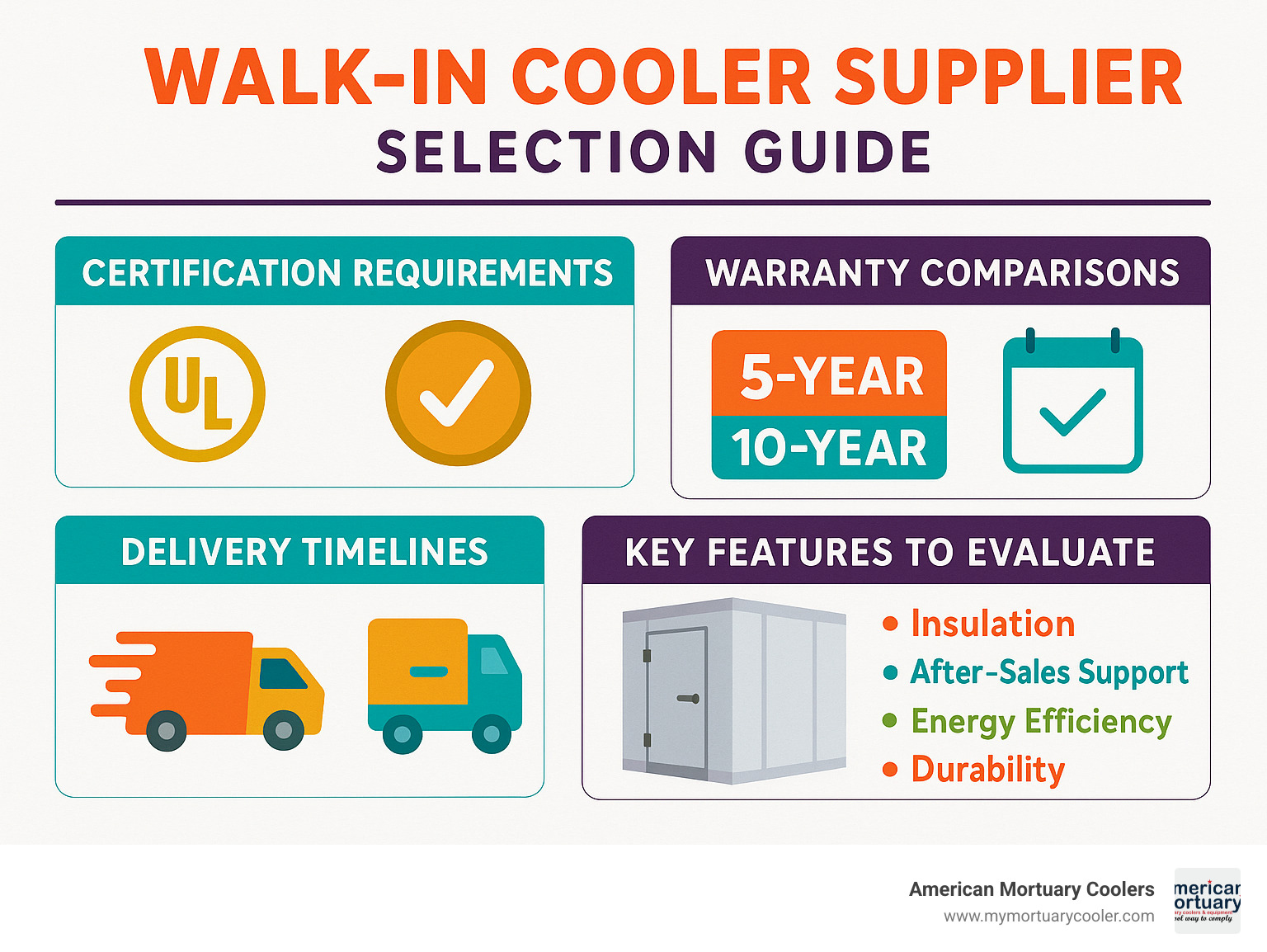

If you're looking for a walk in cooler supplier, here's what you need to know upfront:

- Top Considerations: Quality of insulation (R-value), warranty coverage, delivery timeframe, and after-sales support

- Leading Suppliers: American Walk-In Coolers, U.S. Cooler, Arctic Industries, Mr. Winter, and Barr Refrigeration

- Quick Delivery: Many suppliers offer ready-to-ship units within 14 days

- Standard Warranties: Typically 10-20 years on panels, 1-5 years on refrigeration components

Choosing the right walk in cooler supplier is a critical decision that directly impacts your business operations, energy costs, and long-term satisfaction. Whether you're running a restaurant, grocery store, brewery, floral shop, or mortuary, your refrigeration equipment represents a significant investment that demands careful consideration.

Walk-in coolers are essential refrigerated spaces that preserve perishable items by maintaining consistent temperatures, typically between 35°F and 45°F. Unlike regular refrigerators, these commercial-grade units provide substantial storage capacity and are custom-built to fit your specific space and operational needs.

The challenge many business owners face isn't just finding any supplier, but identifying one that delivers quality, reliability, and support throughout the equipment's lifecycle. With options ranging from quick-ship standard models to fully customized solutions, the selection process can quickly become overwhelming.

"The wrong walk-in cooler can cause major workflow inefficiencies, stress you and your employees out, lead to spoilage and perishable loss, and result in larger expenses down the road." - Mr. Winter Refrigeration

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience providing walk-in cooler solutions for funeral homes, medical facilities, and various commercial applications. Having worked with numerous walk in cooler suppliers across the United States, I understand the critical factors that determine long-term satisfaction with these essential refrigeration systems.

Simple walk in cooler supplier glossary:

Understanding Walk-In Coolers & Who Needs Them

Whether you're just starting your research or ready to contact a walk in cooler supplier, understanding what these systems actually are and who benefits from them is essential. Let's break it down in simple terms.

What Is a Walk-In Cooler?

Think of a walk-in cooler as your regular refrigerator's big, industrial cousin. It's essentially a cold room you can step inside, designed specifically to keep perishable items at the perfect temperature.

Unlike your kitchen fridge, these commercial spaces are built from thick insulated panels that create a sealed environment where you can store large quantities of temperature-sensitive items. The magic happens through a basic refrigeration system with two main components working together: the condenser (usually mounted outside or on the roof) pulls heat from inside the cooler, while the evaporator (inside the unit) distributes the cold air.

Most walk-ins include heavy-duty doors with special gaskets and often strip curtains that help maintain consistent temperatures when people are going in and out. While the shelving is typically purchased separately, it's an essential part of maximizing your storage space and keeping everything organized.

The digital controls have come a long way in recent years, offering precise temperature management and even remote monitoring capabilities – something we at American Mortuary Coolers know is particularly important for sensitive applications.

Industries That Rely on Walk-Ins

You might be surprised at just how many businesses consider walk-in coolers absolutely essential to their daily operations:

Food Service & Restaurants need reliable cold storage to keep ingredients fresh, prepared foods safe, and beverages cold. Without proper refrigeration, restaurants simply couldn't function while meeting health department standards.

Grocery & Convenience Stores use walk-ins both behind the scenes for bulk storage and as customer-facing display areas with glass doors. That wall of cold drinks you grab from at the convenience store? That's likely a walk-in cooler with display doors.

Hotels & Catering Companies rely on spacious walk-ins to manage food for hundreds of guests at once. When you're serving a 300-person wedding, you need serious cold storage capacity!

Breweries & Beverage Producers have specialized cooling needs for ingredients, controlling fermentation temperatures, and storing finished products. Craft beer enthusiasts understand that temperature precision can make or break a great brew.

Floral Shops use specially-designed coolers with higher humidity levels to keep flowers fresh and vibrant. The right walk-in can significantly extend the life of delicate blooms.

Mortuary & Funeral Services require particularly specialized walk-in coolers with precise temperature control and thoughtful design. As a dedicated walk in cooler supplier for the funeral industry, we at American Mortuary Coolers understand the unique needs of funeral homes and medical examiners.

Medical Facilities & Labs depend on pharmaceutical-grade units for storing temperature-sensitive medications, biological samples, and research materials. These applications often require redundant cooling systems and alarm features.

Warehouses & Distributors employ industrial-sized walk-ins as crucial links in the cold supply chain, ensuring products maintain proper temperatures from production to consumer.

Each industry has specific requirements for their walk-in coolers, from temperature ranges and humidity controls to shelving configurations and door types. That's why finding a walk in cooler supplier who understands your particular needs is so important – a one-size-fits-all approach simply doesn't work when it comes to commercial refrigeration.

Types, Sizes & Materials You'll Encounter

When shopping for a walk in cooler supplier, you'll quickly find there's a whole world of options to steer. Think of it like buying a car – you need to understand the basics before making such a significant investment.

Standard vs Custom Walk-Ins

Most suppliers offer two main paths: grab-and-go standard units or tailor-made custom solutions.

Standard or "quick-ship" models are the refrigeration equivalent of ready-to-wear clothing. These units come in popular sizes (usually from 6'x6' to 12'x14') and can arrive at your doorstep within two weeks or less. They're built from modular panels that snap together like high-end building blocks, giving you a functional cooler without the wait.

These ready-made options make perfect sense when time is of the essence. I've worked with restaurant owners who needed refrigeration yesterday after equipment failures, and these quick-ship units were absolute lifesavers. They're also ideal when your space accommodates standard dimensions and your budget has firm boundaries.

On the flip side, custom walk-in coolers offer a "bespoke" approach. We build these units to your exact specifications, considering every inch of your available space. At American Mortuary Coolers, we regularly create custom solutions for funeral homes where standard units simply wouldn't work – whether due to unusual room dimensions, doorway constraints, or specific temperature requirements.

Custom units do require patience – typically 3-6 weeks from order to delivery, depending on complexity. But that wait delivers a perfect fit for your space and needs, which is especially important for specialized applications like mortuary storage, floral displays, or brewery fermentation rooms.

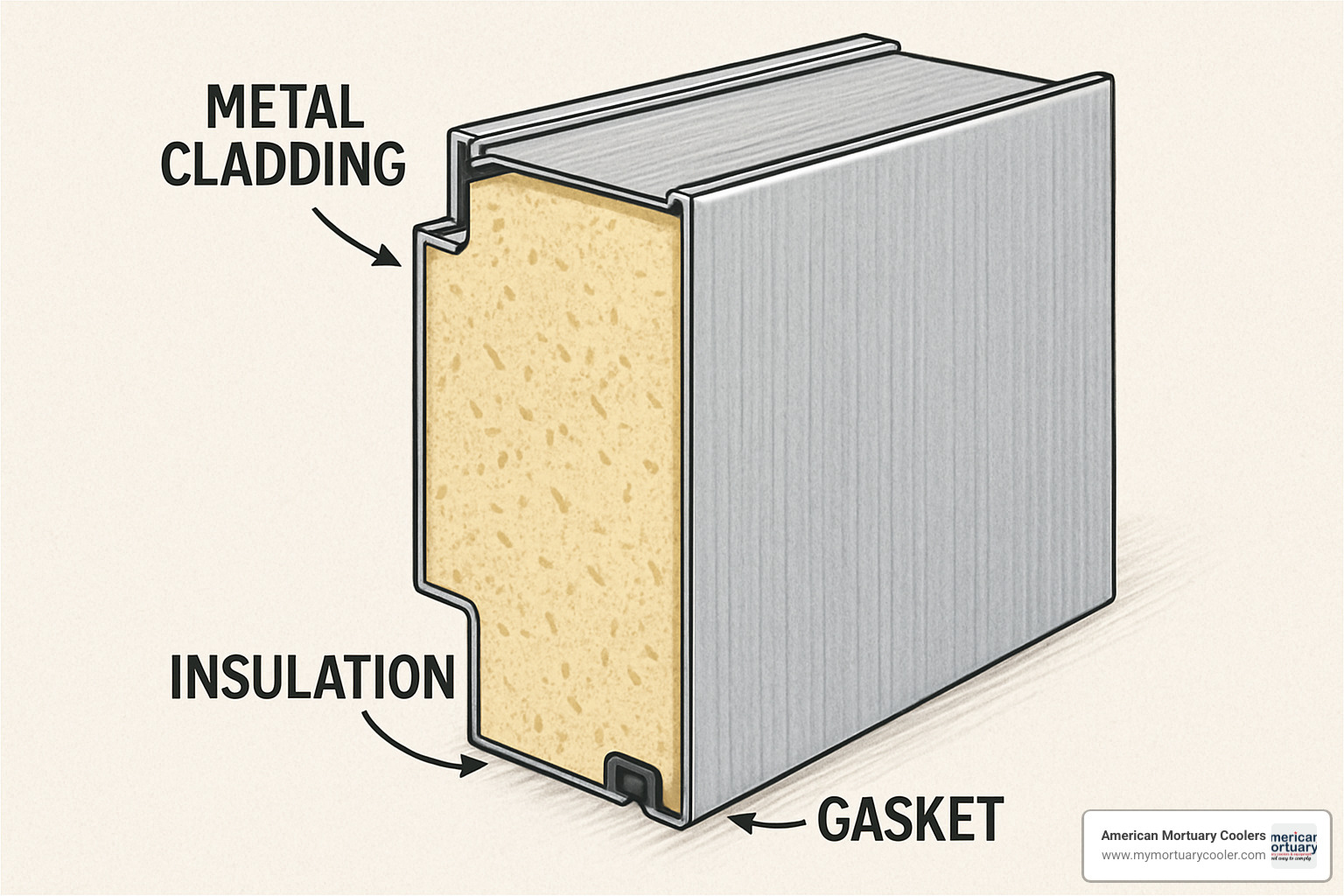

Materials & Insulation Choices

The materials in your walk-in cooler affect everything from energy efficiency to longevity – and ultimately, your bottom line.

For exterior panel materials, galvanized steel remains the most common choice, offering good durability at a reasonable price point. Stainless steel provides a premium, easy-to-clean surface that's worth considering for healthcare settings or food preparation areas. Aluminum shines in outdoor applications where weight and corrosion resistance matter, while fiberglass reinforced plastic (FRP) offers excellent sanitation properties for food processing environments.

When it comes to what's inside those panels – the insulation – you have several options:

Foamed-in-place polyurethane is the gold standard in the industry. This material delivers exceptional R-32 performance (exceeding federal requirements) with excellent structural integrity. When we build mortuary coolers, we rely on this insulation type because it provides consistent temperature control with maximum energy efficiency.

Extruded polystyrene (XPS) works well in high-humidity installations or underground applications thanks to its moisture resistance, though it offers slightly lower R-value per inch than polyurethane.

Expanded polystyrene (EPS) provides a more economical option for non-critical applications, particularly in larger installations where budget considerations are paramount.

Don't forget about flooring! You'll need to decide between insulated floors (essential when installing over unconditioned spaces), floorless units (which can go directly on insulated concrete slabs), or reinforced floors rated to handle heavy equipment like pallet jacks.

Federal regulations set minimum standards – the Energy Independence and Security Act requires at least R-25 for cooler panels and R-32 for freezer panels. Quality suppliers like us at American Mortuary Coolers typically exceed these requirements because we understand that better insulation means lower operating costs over the life of your cooler.

When selecting materials for your walk-in cooler, think about your specific needs – the demands of your business, your local climate conditions, expected traffic patterns, and the balance between upfront investment and long-term energy savings. The right combination of materials will serve your business faithfully for decades to come.

How to Evaluate a Walk in Cooler Supplier

Finding the right walk in cooler supplier is a bit like dating – you want someone reliable, who meets your standards, and will be there for you long after the initial excitement wears off. As we've helped countless funeral homes find their perfect cooling solution, we've learned what truly matters in this relationship.

Certifications Every Walk in Cooler Supplier Must Have

When you're trusting a company with such an important investment, you need to know they meet industry standards. Think of certifications as the "background check" of your supplier relationship.

The NSF Standard #7 is non-negotiable for food-related businesses. This certification ensures your cooler meets proper sanitation requirements – absolutely essential if you're storing food products that will eventually reach consumers.

Any reputable supplier will offer UL Listed components. This means the electrical parts and panels have passed rigorous safety testing by Underwriters Laboratories – giving you peace of mind that your cooler won't become a fire hazard.

Energy compliance isn't just good for the planet – it's good for your wallet too. The federal Energy Independence and Security Act (EISA) requires minimum insulation values of R-29 for coolers and R-32 for freezers. Quality suppliers like us at American Mortuary Coolers exceed these standards, which translates directly to lower energy bills for you.

Depending on your location, you might need regional approvals too. If you're in hurricane territory, look for Miami-Dade County approval or HVHZ certification. Businesses in Los Angeles, New York City, or Oregon face additional regulatory requirements that your supplier should understand.

For specialized applications like mortuary coolers, pharmaceutical storage, or hazardous environments, additional certifications become important. We ensure all our mortuary units comply with state-specific funeral service regulations – something generic suppliers often miss.

How a Walk in Cooler Supplier Ensures Energy Efficiency

Energy efficiency isn't just a buzzword – it's the difference between reasonable monthly bills and eye-watering expenses for the entire life of your cooler.

The magic starts with the panels. High-density foam insulation with superior R-values keeps the cold in and heat out. The best suppliers use cam-lock connections that create tight seals between panels, and incorporate thermal breaks to prevent heat transfer – think of it like a thermos versus a regular cup.

Walk in cooler suppliers who care about your long-term satisfaction will recommend energy-efficient condensing units with ECM (Electronically Commutated Motor) technology. These smart motors adjust their speed based on demand, using up to 70% less energy than traditional motors. Properly sized evaporators maintain optimal humidity while electronic expansion valves provide precise temperature control.

The little things add up too. LED lighting comes standard with quality suppliers (we include it free), and motion sensors ensure lights aren't running when nobody's inside. Simple additions like strip curtains dramatically reduce cold air loss during entry and exit.

Forward-thinking suppliers now offer environmentally friendly refrigerants like R290 (propane), R448A and R449A. These not only comply with EPA regulations but often deliver better performance while reducing your carbon footprint.

The bottom line? Upgrading to a high-efficiency walk-in cooler can slash energy consumption by 20-40% compared to older models. For a business operating 24/7 like a funeral home or restaurant, that's thousands of dollars saved annually.

Comparing Warranties, Service & Financing

The true test of a walk in cooler supplier isn't just getting the unit installed – it's what happens in the years that follow.

A quality warranty package typically includes tiered protection: 10-20 years for panels, 5 years for doors, 5 years for compressors, and 1 year for parts and labor. At American Mortuary Coolers, we stand behind our products with a 20-year panel warranty, 5-year entrance door warranty, and 5-year compressor warranty – reflecting our confidence in building coolers that last.

Service matters tremendously. When your cooler isn't working properly, every minute counts. Look for suppliers offering 24/7 technical support, nationwide service networks, and preventative maintenance programs. Ask tough questions about parts availability – will they have what you need in stock, or will you face weeks of downtime waiting for a specialized component?

The best suppliers understand that cash flow matters to businesses. Many offer flexible purchasing options including 100% financing programs, leasing with purchase options, and even 0% introductory financing. Some progressive companies provide equipment-as-service models with maintenance included – simplifying your budget planning.

Remember to look beyond the sticker price when comparing suppliers. A slightly more expensive unit with better energy efficiency, stronger warranty coverage, and reliable service support often proves far less expensive over its lifetime. After all, in the cooling business, it's the long game that counts.

Ordering, Delivery & Installation Made Simple

Understanding the process from quote to installation helps set realistic expectations and ensures a smooth experience.

Nationwide Logistics & Quick-Ship Timelines

The delivery process varies significantly between suppliers and product types:

Quick-Ship Programs Many suppliers offer expedited options:

- Standard sizes available within 14 days

- Limited customization options

- Pre-assembled refrigeration systems

Custom Order Timelines For custom units, expect:

- 24-hour quote turnaround for most projects

- 1-2 weeks for engineering and drawings

- 3-4 weeks for manufacturing

- 1-2 weeks for shipping (depending on location)

Shipping Considerations Quality suppliers provide:

- Direct shipping to all 50 states

- Crated panels for protection during transit

- Inside delivery options

- Lift-gate service for locations without loading docks

At American Mortuary Coolers, we provide direct delivery across the contiguous 48 states, with specialized handling for our sensitive mortuary applications. Our delivery teams understand the unique needs of funeral homes and medical facilities.

Installation Options Most suppliers offer:

- Turnkey installation services

- Supervised self-installation

- DIY installation with detailed instructions

- Video support and telephone assistance

The modular panel systems used by most manufacturers are designed for relatively straightforward assembly using cam-lock technology, though professional installation is recommended for refrigeration components.

After-Sales Support & Maintenance

The relationship with your supplier continues long after installation:

Technical Support Look for suppliers offering:

- 24/7 emergency technical assistance

- Online troubleshooting resources

- Video tutorials for common maintenance tasks

Parts Availability Quality suppliers maintain:

- Comprehensive parts inventories

- Cross-compatibility with multiple brands

- Quick-ship options for critical components

Preventative Maintenance Many suppliers provide:

- Scheduled maintenance programs

- Performance monitoring services

- Energy efficiency audits

- Refrigerant management compliance

Documentation & Training Expect suppliers to provide:

- Detailed operation manuals

- Staff training resources

- Compliance documentation

- Energy usage guidelines

U.S. Cooler's ReFridge program is an example of a comprehensive replacement parts resource that simplifies maintenance and repairs throughout the life of your walk-in cooler.

Custom Applications & Future-Proofing Your Investment

A quality walk in cooler supplier doesn't just sell you a refrigerated box—they help you plan for both today's needs and tomorrow's growth. This forward-thinking approach is something we've acceptd at American Mortuary Coolers, where we understand that your cold storage needs may evolve over time.

New vs Used Walk-Ins

The "new versus used" debate is one we hear often, and it's worth exploring both paths.

New walk-in coolers come with clear advantages that many businesses find essential. You'll enjoy full warranty protection (typically 10-20 years on panels), the latest energy-saving technology, and the ability to customize every detail to your exact specifications. Perhaps most importantly, new units comply with all current regulations—something particularly critical for industries like funeral services, healthcare, and food service.

On the flip side, used or refurbished walk-ins can make sense in certain situations. Companies like Barr Refrigeration offer quality pre-owned options that cost 30-50% less than new units. These coolers are typically inspected and reconditioned by certified technicians and may include limited warranty coverage.

Used walk-ins might be worth considering if you're facing tight budget constraints, need temporary cold storage, or have standard size requirements for non-critical applications. Just remember to inspect thoroughly before purchasing—check panel condition for damage or moisture, test door operation and gasket integrity, verify the refrigeration system's performance, determine the age of major components, and confirm compliance with current regulations.

In our experience at American Mortuary Coolers, we generally recommend new equipment for funeral service applications. The critical nature of mortuary refrigeration simply demands the reliability and performance that comes with new units. When dignity and respect are paramount, cutting corners rarely makes sense.

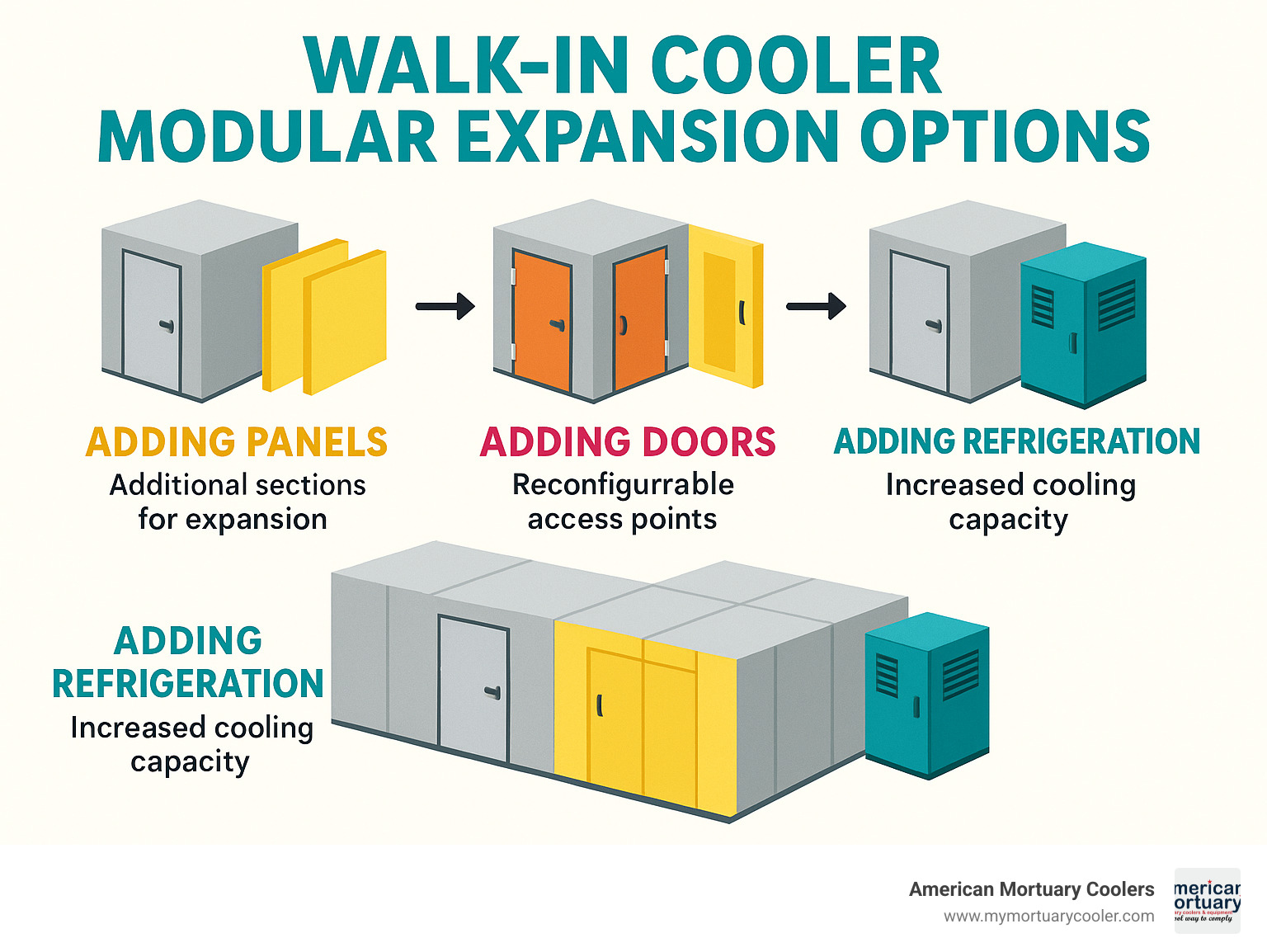

Scaling & Modular Add-Ons

One of the smartest ways to protect your investment is choosing a walk-in cooler with room to grow.

Many quality suppliers (ourselves included) offer expandable, modular designs that adapt as your business evolves. These systems let you add sections to increase capacity, reconfigure door placements to improve workflow, convert from cooler to freezer temperatures as needs change, and even relocate the entire unit if you move facilities. This flexibility can save you thousands compared to replacing a unit that's been outgrown.

Technology upgrades represent another aspect of future-proofing. Forward-thinking suppliers offer systems compatible with remote monitoring integration, energy management controls, IoT-enabled components, and smartphone app control capabilities. These features might seem like luxuries today but could become essential as labor costs rise and remote management becomes standard practice.

Different industries benefit from specialized add-ons worth considering from the start. Retail businesses often add glass display doors for merchandising. Breweries incorporate keg racks and special temperature zones. Medical facilities require pharmaceutical-grade stainless steel shelving. And in our specialty at American Mortuary Coolers, funeral homes often need specialized racking systems designed with dignity and efficiency in mind.

The most progressive walk in cooler suppliers also address environmental considerations. Look for options like solar-ready condensing units, water-reclamation systems for water-cooled units, compatibility with low-GWP refrigerants, and energy monitoring capabilities. These features not only reduce your carbon footprint but often deliver substantial operational savings over time.

At American Mortuary Coolers, we've seen how thoughtful planning at the purchase stage pays dividends for years. By selecting a supplier that offers these expansion and upgrade paths, you protect your initial investment while maintaining flexibility for whatever business changes lie ahead. After all, the only constant in business is change—your refrigeration should be ready for it.

Frequently Asked Questions about Walk-In Cooler Suppliers

How long does it take from quote to cold storage readiness?

One of the most common questions we hear at American Mortuary Coolers is about timing. After all, when you need refrigeration, you often need it quickly!

The timeline really depends on whether you're going with a standard unit or something custom-built for your specific needs:

For quick-ship standard units, you're looking at about 2-3 weeks total from start to finish. This typically breaks down as one day for us to prepare your quote, about two weeks for manufacturing, and another 2-5 days for shipping to your location.

If you need a custom solution (which is often the case for our mortuary clients), the timeline stretches to 4-8 weeks total. We'll spend 1-3 days crafting a detailed quote, 3-6 weeks in manufacturing to get everything just right, 3-10 days for shipping, and then 1-3 days for installation.

Many of our competitors like Mr. Winter offer similar timelines, with delivery in as little as 2 weeks for their standard units. For our specialized mortuary coolers, we take a bit more time in the engineering and manufacturing process—typically adding 2-4 weeks—because we believe getting the details perfect for such a sensitive application is worth the extra care.

What site prep is required before delivery?

Preparing your site properly before your walk-in cooler arrives will save you headaches and ensure a smooth installation. Think of it as setting the stage for success!

First, let's talk about flooring. You'll need either a level concrete pad if you're installing a floorless unit, or a properly insulated subfloor if you're installing over wood. Make sure whatever surface you choose can handle the weight of your fully-loaded cooler—these aren't lightweight appliances!

For electrical preparation, you'll need dedicated circuits specifically for your refrigeration equipment. Most units require 208-230V with either single-phase or three-phase power, depending on the size. Don't forget ground fault protection where local codes require it.

Remember to plan for proper clearance too. Your condensing units need room to breathe—at least 2-3 feet of clearance all around. Check your ceiling height as well; you'll need the height of the cooler plus an additional 12-24 inches for proper air circulation. And don't forget to account for door swing space in your layout planning.

Finally, think about drainage. You'll need a floor drain for condensate, proper slope for water runoff, and potentially a condensate pump if gravity drainage isn't possible.

Don't worry—we provide detailed site preparation guidelines specific to your unit when you place your order. We want your installation to go as smoothly as possible!

Can I finance or lease a custom walk-in cooler?

Absolutely! We understand that a quality walk-in cooler is a significant investment, which is why we and most established walk in cooler suppliers offer several financing options to make it more manageable for your business.

At American Mortuary Coolers, we offer 100% financing packages that allow you to preserve your working capital while still getting the exact cooler solution you need. This is especially helpful for funeral homes that need to allocate resources across many different equipment needs.

Many of our clients prefer leasing options, typically running 36-60 months with purchase options at the end. This approach gives you predictable monthly expenses and can offer tax advantages compared to an outright purchase.

Some newer options in the industry include equipment-as-service plans, which bundle the equipment, maintenance, and even some operational costs into a single monthly payment. This approach is gaining popularity for its simplicity and comprehensive coverage.

Don't forget that walk-in coolers qualify for Small Business Administration equipment loans if you're looking for favorable government-backed financing terms.

What's nice about financing a walk-in cooler is that the operational savings from energy efficiency can often offset a good portion of your monthly payments. Plus, these units maintain good residual value over time, making them a sound business investment rather than just an expense.

When you reach out to us for a quote, just mention that you're interested in financing options, and we'll be happy to walk you through what would work best for your specific situation.

Conclusion

Selecting the right walk in cooler supplier isn't just a purchase decision – it's a long-term partnership that affects your daily operations, energy bills, and bottom line for years to come. At American Mortuary Coolers, we've seen how the right refrigeration equipment can make all the difference, especially in specialized fields like funeral services.

We're proud to call Tennessee home, but our reach extends nationwide with service locations in Atlanta, Chicago, Columbia, Dallas, Los Angeles, New York, Pittsburgh, and comprehensive coverage throughout the Midwest, Northeast, Rocky Mountain, Southeast, Southwest, and Pacific regions. Our specialty? Crafting custom mortuary coolers that address the unique challenges and requirements of the funeral industry.

After years in this business, we've learned that successful walk-in cooler installations always begin with a thoughtful conversation. Understanding your specific needs, mapping out detailed specifications, and establishing a relationship with a supplier who'll stand behind their product through thick and thin – these are the foundations of refrigeration success.

When you're evaluating potential walk in cooler suppliers, keep these essential factors in mind:

Quality of Construction matters tremendously. Look for high R-value insulation, materials that will stand the test of time, and precision manufacturing that eliminates weak points and energy leaks.

Appropriate Sizing is about balance – enough capacity for today's needs while allowing breathing room for tomorrow's growth. A good supplier helps you project future requirements, not just current ones.

Energy Efficiency pays dividends every month on your utility bill. The best suppliers exceed minimum standards, knowing that every dollar saved on energy goes straight to your bottom line.

Support Infrastructure reveals a supplier's true colors. Comprehensive warranties, readily available service technicians, and easy access to replacement parts tell you they're in it for the long haul.

Customization Capabilities matter because your business isn't exactly like anyone else's. Your supplier should listen carefully and tailor solutions to your unique application.

Delivery & Installation experiences can range from nightmare to dream. Clear timelines, professional setup, and proper training make all the difference.

Long-term Partnership value becomes apparent long after the installation. The right supplier becomes a trusted advisor throughout your equipment's lifecycle.

Whether you're launching a new facility or upgrading existing equipment, a walk-in cooler isn't just another purchase – it's an investment in your operational efficiency and product quality that will pay returns for years.

For specialized applications like mortuary refrigeration, the stakes are particularly high. Working with experienced suppliers who truly understand your unique requirements isn't just preferable – it's essential. At American Mortuary Coolers, we take genuine pride in providing durable, custom solutions with direct delivery across the contiguous 48 states.

Ready to take the next step in selecting your walk in cooler supplier? We'd love to have a conversation about your specific needs and industry requirements. There's no obligation, just practical guidance from folks who understand the challenges you face.