Understanding the Precision of Scalpel Blades

Scalpel blades are precision cutting instruments designed for accurate incisions across medical, laboratory, and craft applications. These specialized blades come in various shapes and sizes to meet specific cutting needs.

| Quick Facts About Scalpel Blades |

|---|

| Common Sizes: #10, #11, #15, #22, #60, #70 |

| Materials: Carbon steel (sharper) or stainless steel (rust-resistant) |

| Packaging: Individually wrapped, boxes of 100 |

| Price Range: $65-90 per box of 100 for sterile medical-grade |

| Handle Compatibility: #3, #4, #5, #7 handles (size-dependent) |

Scalpel blades are manufactured to exacting standards, with most conforming to US Federal specification GGN211b and German DIN-13170 quality requirements. The right blade can make all the difference in precision work, whether you're performing a delicate dissection or creating intricate craft details.

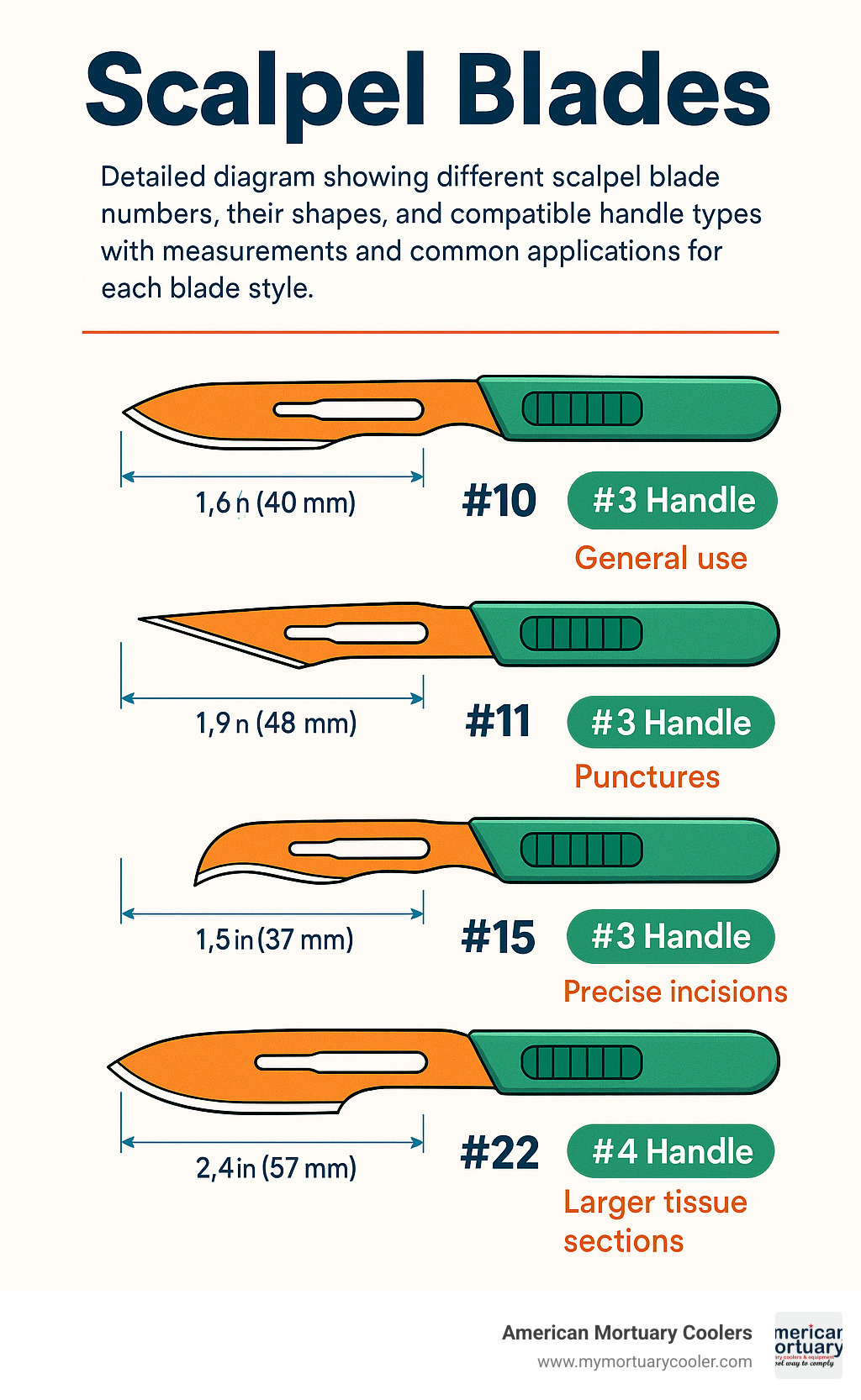

Unlike standard utility knives, scalpel blades feature specialized geometries optimized for specific cutting tasks. The #10 and #15 blades offer versatile cutting edges for general use, while the pointed #11 excels at punctures and the heavy-duty #22 handles larger tissue sections.

Most professional-grade scalpel blades are individually wrapped for sterility and packaged in boxes of 100, with prices ranging from $65.99 to $90.99 depending on the blade type and manufacturer.

I'm Mortuary Cooler, with over a decade of experience selecting and supplying precision instruments including scalpel blades for mortuaries and funeral homes across America. My work ensures professionals have access to the right tools for respectful and efficient post-mortem care.

What Are Scalpel Blades? Fundamentals & Applications

When you hold a scalpel blade in your hand, you're holding a marvel of precision engineering. These ultra-sharp cutting instruments are designed to make clean, controlled cuts with minimal damage to tissues or materials. Unlike your kitchen knife or even a utility blade, scalpel blades are crafted for extraordinary sharpness and specific cutting geometries.

At their core, scalpel blades are removable cutting edges made from high-quality metals that attach to handles (sometimes themselves called "scalpels"). While many folks use these terms interchangeably, it's worth knowing that the blade is just the replaceable cutting part of the complete instrument.

In the medical world, scalpel blades are the trusted companions of surgeons making life-saving incisions. They're equally essential in post-mortem examinations, where detailed dissection requires unfailing precision. Our mortuary professionals know that the difference between a clean, respectful incision and a jagged cut comes down to having the right blade for the job.

Beyond medical settings, these precision tools have found their way into research laboratories, veterinary clinics, and even the hands of artists and crafters. From plant propagation to model building, when precision matters, scalpel blades deliver.

Scalpel Blades in Modern Surgery

In the operating room, not just any cutting tool will do. Surgical scalpel blades are engineered with tissue-friendly edges that minimize trauma. They glide through skin and tissue with minimal drag, creating clean incisions that heal more readily and leave finer scars.

Modern surgical scalpel blades come individually wrapped in sterile packaging – a simple but crucial innovation. This single-use approach ensures every procedure starts with a perfectly sharp, contamination-free blade. No surgeon wants to wonder if their blade might fail midway through an incision or introduce harmful bacteria.

The operating room typically sees blades like the versatile #10 and #15 for general cutting, the precisely pointed #11 for punctures, and the delicate #12 for tight spaces. Each has earned its place in the surgical toolkit through years of reliable performance.

Scalpel Blades for Labs, Crafts & Post-mortem Work

Step outside the operating room, and scalpel blades take on fascinating new roles.

In anatomy labs and pathology departments, the larger #22, #60, and #70 blades become indispensable tools for tissue sectioning. These workhorse blades are built sturdier than their surgical cousins, standing up to the challenges of preserved tissues and repeated use.

In our years at American Mortuary Coolers, we've seen how mortuary professionals select specific blades for different aspects of post-mortem care. The robust #22 blade handles general dissection beautifully, while specialized PM40 blades with their thoughtfully rounded tips are designed specifically for autopsy procedures.

The crafting world has enthusiastically adopted scalpel blades too. Model builders achieve crisp edges on plastic or balsa wood that hobby knives can't match. Leather crafters create precise details, paper artists cut intricate designs, and cosplayers shape EVA foam with surgical precision. Many hobbyists find that a quality scalpel blade makes their projects look professionally finished.

Even gardeners have found that the clean cuts made by scalpel blades create ideal conditions for successful grafting and propagation. Unlike the crushing action of scissors, these blades leave plant tissues intact at the cellular level.

Popular laboratory and craft kits now include assortments of sterile blades (#10, #11, #15, #22) with multiple handles, making professional-grade cutting tools accessible to everyone who values precision.

Scalpel Blade Shapes & Numbers Decoded

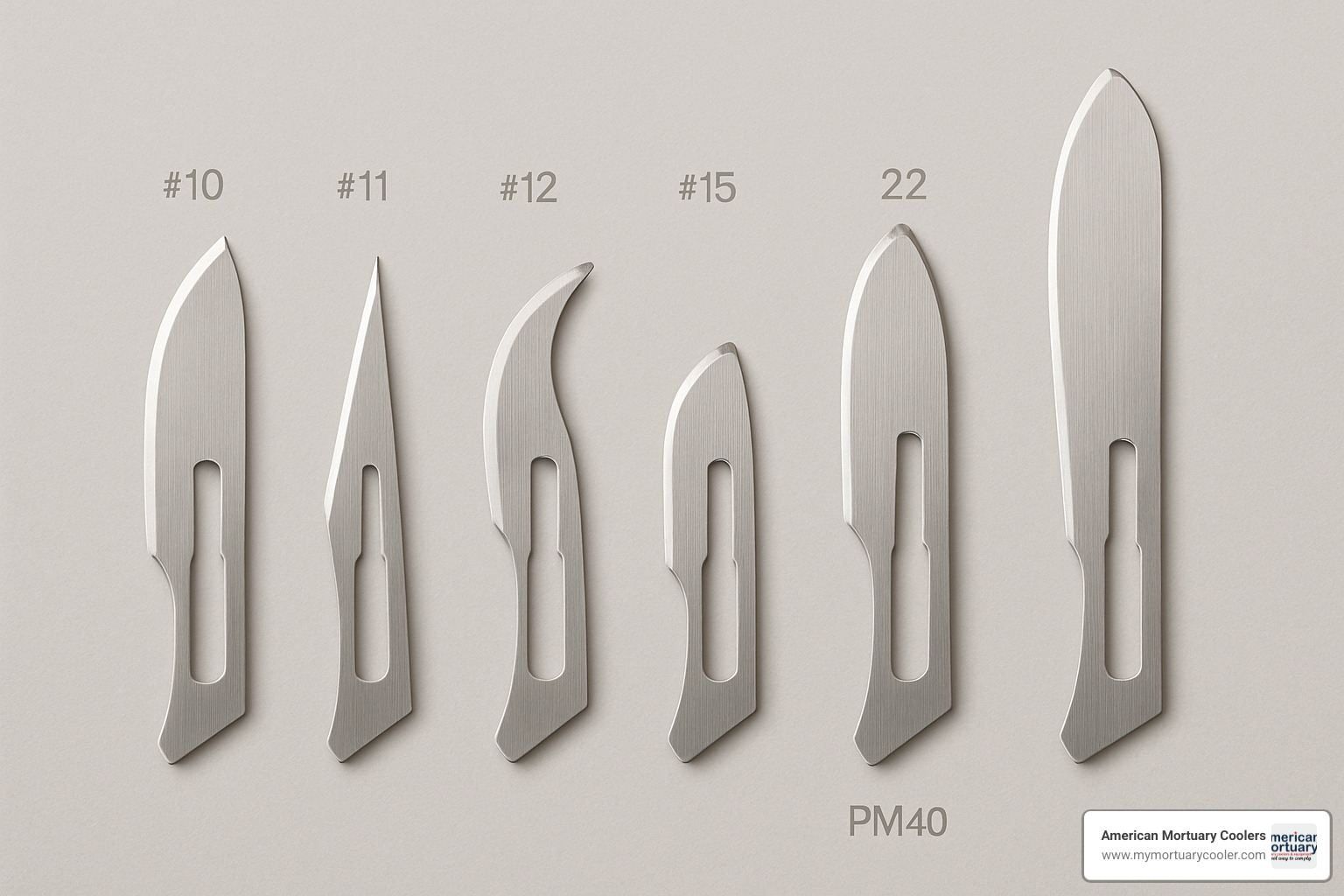

One of the most confusing aspects of scalpel blades for newcomers is the numbering system. Each blade number corresponds to a specific shape optimized for particular cutting tasks. Understanding these differences is crucial for selecting the right blade for your application.

Think of scalpel blades like paintbrushes – artists don't use just one type, and neither should anyone working with precision cutting tools. Let me walk you through the most common blade shapes and why they matter.

#10 vs #15: The Everyday Workhorses

The #10 blade is the Swiss Army knife of the scalpel blade world. With its curved cutting edge and broad belly, it excels at long, sweeping incisions. I've seen mortuary professionals reach for this blade time and again for general preparation work. The curved profile allows your hand to maintain steady pressure throughout the cutting motion – something you'll appreciate during longer procedures.

Its smaller cousin, the #15 blade, shares a similar curved profile but in a more compact package. I like to think of the #15 as the "goldilocks" of scalpel blades – not too large, not too small, just right for most detailed work. When you need to make precise trims or work with delicate tissues, the #15's slightly sharper point and smaller cutting surface give you incredible control without sacrificing versatility.

#11 & #12: Sharp Angles for Precision Punctures

When you need to make a clean, precise puncture before cutting, the #11 blade becomes your best friend. Its distinctive triangular shape with a sharp, pointed tip is unmistakable in any blade collection. This design makes it perfect for stab incisions, creating arthroscopy ports, or even removing sutures with pinpoint accuracy.

The #11's unique geometry also makes it invaluable for craft applications where you need to pierce material before making a clean cut – something our clients who dabble in taxidermy particularly appreciate.

The #12 blade takes precision even further with its small, curved cutting edge and sharp point. When you're working in tight spaces or on tiny structures, the #12's compact profile prevents accidental cuts to surrounding areas. I've watched skilled pathologists use the #12 to perform miracles of dissection in spaces where larger blades simply wouldn't fit.

Heavy-Duty #22–#70 Scalpel Blades for Grossing & Taxidermy

When standard surgical blades just won't cut it (pun intended), it's time to bring out the heavy artillery. The #22 blade features a broader cutting surface that makes short work of larger tissue sectioning. At American Mortuary Coolers, we've found this blade to be particularly popular for post-mortem procedures where efficiency matters.

Moving up in size, the #60 blade stretches to an impressive 60mm long and 0.6mm thick. This curved carbon steel workhorse provides extended reach for deep dissections and holds up admirably against tougher tissues. Its larger cousin, the #70 blade, measures a full 70mm in length and has become the go-to for serious taxidermy work, especially skinning and caping.

These larger scalpel blades pair with heavier #8 handles that provide the leverage needed for substantial cutting tasks. They're built for durability rather than delicacy, though they still maintain impressive precision for their size.

| Blade Type | Length | Thickness | Compatible Handle | Primary Use |

|---|---|---|---|---|

| #10 | 25mm | 0.4mm | #3, #5 | General surgery, long incisions |

| #11 | 22mm | 0.4mm | #3, #5 | Precision punctures, stab incisions |

| #12 | 20mm | 0.4mm | #3, #5 | Confined spaces, delicate work |

| #15 | 24mm | 0.4mm | #3, #5 | General surgery, precise cuts |

| #22 | 35mm | 0.5mm | #4, #6 | Grossing, post-mortem work |

| #60 | 60mm | 0.6mm | #8 | Gross anatomy, deep dissection |

| #70 | 70mm | 0.6mm | #8 | Post-mortem, taxidermy |

I've seen how choosing the right blade shape can make all the difference in achieving clean, professional results. Whether you're performing delicate procedures or handling tougher dissection tasks, understanding these blade profiles ensures you'll always have the right edge for the job.

Materials Matter: Carbon Steel, Stainless & Beyond

The material of your scalpel blades makes a world of difference in how they perform. As someone who's spent years working with mortuary professionals, I've seen how choosing the right blade material can make a procedure go smoothly—or create frustration.

Carbon-Steel Scalpel Blades—Sharper but Short-Lived

If you're looking for that perfect first cut, carbon steel scalpel blades are hard to beat. These blades offer exceptional sharpness that slices through tissue with minimal resistance.

Carbon steel creates an incredibly fine edge at the molecular level, which explains why professionals who need precision often reach for these first. During testing, some manufacturers have found these blades can make ten times as many clean cuts through materials like EVA foam compared to standard hobby blades. This remarkable edge retention makes them perfect for detailed work.

The downside? These blades are temperamental. Leave a carbon steel scalpel blade exposed to air or moisture, and you'll quickly see oxidation forming. Even unused blades in storage gradually deteriorate, giving them a limited shelf life. They're also more brittle than their stainless counterparts, making them prone to chipping if you apply lateral pressure.

As one of our pathologist clients once told me, "I'll only use carbon steel when I need that perfect first cut—but I always keep extras on hand because they don't forgive exposure to fluids."

Stainless-Steel Scalpel Blades—Durable & Rust-Resistant

When working in moist environments—which is common in mortuary settings—stainless steel scalpel blades shine. These workhorses resist corrosion and maintain their integrity much longer than carbon steel versions.

Stainless steel blades offer impressive durability, standing up to more demanding cutting tasks without breaking. They also have a significantly longer shelf life, so you don't need to worry about unused blades deteriorating in storage.

The trade-off comes in edge sharpness. While still very sharp, stainless steel can't quite achieve the razor-fine edge of carbon steel. You'll also find yourself replacing them more frequently during extended cutting sessions as they tend to dull faster with continuous use.

Most of our mortuary professionals prefer stainless steel for daily work. The wet environment of post-mortem care makes corrosion resistance essential, and the added durability means less frequent blade changes during lengthy procedures.

Specialty-Coated & Safety Blades

Modern blade technology has given us exciting innovations beyond basic materials. PTFE-coated scalpel blades feature a non-stick surface that glides through tissues with minimal drag. This coating prevents material from sticking to the blade—particularly helpful when working with fatty tissues—and keeps your cutting line visible by preventing buildup on the blade edge.

For those concerned about metal reactivity or needing extended cutting sessions, ceramic-edge blades offer impressive edge retention and reduced tissue reactivity. They cost more upfront but can deliver value through their extended lifespan.

Safety has become a major focus in blade design, with retractable systems that feature audible clicks when locked into position. These systems allow for single-handed blade removal, eliminating the dangerous direct handling of used blades. Color-coded sliders provide visual confirmation of blade position, while slip-resistant grips reduce the chance of accidents during procedures.

"Retractable safety scalpels reduce sharps injuries while maintaining the precision cutting performance medical professionals demand," notes one manufacturer we work with regularly.

At American Mortuary Coolers, we understand that choosing the right blade material is just as important as selecting the right shape. The best choice depends on your specific application, working environment, and personal preference—something we're always happy to discuss when helping outfit your facility.

More info about mortuary bone saws

Safe Handling, Installation & Disposal

Working with scalpel blades requires careful attention to safety protocols. These ultra-sharp instruments can cause serious injuries if mishandled, making proper techniques for installation, use, and disposal essential.

Installing Scalpel Blades Without Injury

I've seen my fair share of nicked fingers in my years working with mortuary professionals. Trust me when I say that properly mounting a scalpel blade is a skill worth mastering!

Always use tools instead of your fingers when handling these razor-sharp blades. A needle holder, forceps, or dedicated blade installation tool will keep your fingertips intact and infection-free. The technique is straightforward once you know what you're doing: grasp the blade with your tool just above the opening on the non-cutting side, align the groove on the handle with the blade's opening, and slide it into place until you hear that satisfying click.

Visual alignment is key to success. Look for the groove or notch on the scalpel blade and make sure it lines up perfectly with the corresponding ridge on the handle. When properly seated, many blades will reward you with an audible "click" – that's your confirmation that everything is secure.

As one of our surgical suppliers likes to remind us: "Use pliers or a tool when mounting/dismounting blades to avoid injury. The groove on the handle must align perfectly with the opening of the blade for secure attachment." It's simple advice that can save you a trip to the emergency room!

For those using disposable scalpels, those protective caps aren't just packaging – they're safety features designed to keep you cut-free until the moment you need to make that first incision.

Disposing of Used Scalpel Blades Safely

What goes on must come off – but safely! Proper disposal of used scalpel blades isn't just good practice; it's often regulated by institutional policies and governmental requirements.

Never, ever toss loose blades into regular trash. These sharp hazards must go into designated sharps containers that are specifically designed to be puncture-resistant. Modern blade removal systems like the Qlicksmart BladeFlask or Aunex Blade Remover have revolutionized safety by allowing single-handed removal without direct blade contact. These clever containers can hold between 100-200 used blades and feature mechanisms that detach the blade from the handle without requiring your hands to come anywhere near the cutting edge.

In the United States, OSHA has specific mandates for sharps disposal, including scalpel blades. Many facilities also require documentation of blade disposal for regulatory compliance – another detail that's easy to overlook but important to remember.

Here at American Mortuary Coolers, we've long recommended that our mortuary clients maintain dedicated sharps containers specifically for scalpel blades and other cutting instruments used in post-mortem care. This simple practice not only keeps everyone safer but also simplifies compliance with those sometimes-confusing regulatory requirements.

As one safety device manufacturer puts it: "Blade removal systems with single-handed removal and containment reduce sharps injury risk significantly compared to manual removal techniques." That's not just marketing talk – it's a fact that could save you from a nasty injury.

Tool Talk: A Deep Dive into Mortuary Tools

Choosing the Right Scalpel Blade & Handle Combo

Pairing the perfect scalpel blade with the right handle is a bit like finding a dance partner – when the match is right, everything just flows. After years of supplying mortuary professionals, I've seen how the right combination can make all the difference in precision, comfort, and safety.

Matching Scalpel Blades to Handles

Think of scalpel blades and handles as puzzle pieces – they need to fit together perfectly. The good news is there's a standardized system, but you'll still need to know which pieces work together:

For delicate, precise work, reach for Handle #3 or #5. These smaller handles accept blades #10 through #15 and are the workhorses in surgical settings. The difference? Handle #3 is straight as an arrow, while #5 has a slight angle that gives you better visibility when working – a small detail that makes a world of difference during intricate procedures.

When you need more substantial cutting power, Handle #4 or #6 are your go-to options. These heftier handles pair with larger blades (#20 through #25) and provide a more substantial grip. In our mortuary work, we see these used frequently for pathology and post-mortem applications where more robust cutting is needed. Like their smaller cousins, #4 handles are straight while #6 offers that helpful angle.

For specialized post-mortem work, Handle #7 is purpose-built for the job. It's designed specifically to work with PM40 and other autopsy-specific blades. Its solid construction holds up to the demanding conditions of mortuary work – something we at American Mortuary Coolers appreciate when outfitting facilities.

The heavyweight champion is Handle #8, designed exclusively for the largest blades like #60 and #70. These heavy-duty combinations shine in gross anatomy labs and taxidermy settings where substantial cutting power is required.

The ergonomics of your handle matter tremendously, especially during long procedures. Heavier handles provide stability for precise work but can cause fatigue over time. Many professionals I work with prefer handles with textured, anti-slip surfaces – particularly valuable in the often-wet environment of mortuary work. The handle's diameter and balance point also significantly impact comfort during extended use.

Cost & Brand Snapshot

When it comes to scalpel blades, you'll find options ranging from premium surgical-grade to budget-friendly craft varieties.

On the premium end, Swann-Morton blades are often considered the gold standard in medical settings. Their British-made blades deliver exceptional consistency and sharpness. Feather blades from Japan and Aesculap from Germany also command respect (and higher prices) for their precision engineering.

For solid performance at mid-range prices, many laboratories and educational institutions turn to brands like Havel's and Excel. These offer good value while maintaining medical-grade quality standards. Fine Science Tools has carved out a niche specializing in research applications where precision is paramount.

Craft enthusiasts and hobbyists often gravitate toward more budget-friendly options like WORKPRO (popular on Amazon) and the familiar X-Acto brand. These won't break the bank but still deliver respectable performance for non-medical applications.

Price-wise, expect to pay between $65.99 and $90.99 for a box of 100 sterile, individually-wrapped medical-grade blades. Specialty blades for specific applications will typically cost more, while buying in bulk can significantly reduce your per-blade costs. If convenience is your priority, disposable scalpels (pre-mounted blades on handles) offer grab-and-go simplicity at a higher per-unit price.

For those just starting out or needing blades for occasional craft projects, Amazon offers numerous affordable kits. One popular option includes 40 sterile blades in various sizes (#10, #11, #15, #22) with four handles for just $12.99 – perfect for hobbyists but not medical applications.

Shop the Store on Amazon ›WORKPRO blades

At American Mortuary Coolers, we've found that most mortuary professionals prefer investing in quality scalpel blades and handles. When precision and reliability matter – as they certainly do in post-mortem care – saving a few dollars on inferior cutting tools rarely proves worthwhile in the long run.

Frequently Asked Questions about Scalpel Blades

What's the difference between sterile and non-sterile scalpel blades?

When shopping for scalpel blades, you'll quickly notice both sterile and non-sterile options. The difference isn't just in the name—it fundamentally changes what you can safely do with them.

Sterile blades come individually sealed in special packaging that maintains their pristine condition until the moment you open them. Each blade has gone through rigorous sterilization processes validated to eliminate microorganisms. These are the blades you'd want for any surgical procedure or when working with living tissue.

On the flip side, non-sterile blades haven't been through this careful process. They're perfectly suitable for educational settings, post-mortem work (something we're quite familiar with at American Mortuary Coolers), taxidermy projects, or creative crafting. Some facilities purchase non-sterile blades with the intention of sterilizing them in-house before use.

I've noticed many of our mortuary clients choose non-sterile options for cost savings—they typically run 30-50% less expensive than their sterile counterparts. As one supplier bluntly puts it: "Non-sterile scalpel blades are not intended for medical applications or patient use." That's a distinction worth remembering.

Can I reuse a scalpel blade after autoclaving?

This is a question we hear surprisingly often, and I understand the temptation—quality scalpel blades aren't cheap! However, the clear answer from manufacturers is that most blades are designed for single use only, and for good reason.

When you autoclave a blade, several things happen that compromise its performance. The intense heat can subtly alter the metallurgical properties of the steel, making it more brittle. The once-perfect cutting edge becomes microscopically dulled. Even worse, tiny crevices in used blades can harbor biological material that may not be fully removed during cleaning.

Beyond performance issues, there are regulatory concerns too. In medical settings, reusing single-use devices may violate important regulations designed to protect patients. Even the cleaning process itself poses injury risks to staff handling used blades.

I've seen some of our non-medical customers occasionally reuse blades after cleaning, particularly for craft applications. But even there, I always recommend caution—especially when precision cutting is essential to your work.

How do scalpel blades compare to razors or hobby knives?

At first glance, scalpel blades, razor blades, and hobby knives might seem interchangeable—they're all small, sharp cutting tools, right? But the differences become apparent as soon as you start working with them.

Scalpel blades are designed with specific cutting motions in mind. Their varied shapes (remember those #10, #11, #15 configurations we discussed earlier?) each serve particular purposes—from making long, sweeping incisions to precise punctures. They're typically thicker and more durable than standard razor blades, with medical-grade versions undergoing stricter quality control.

Standard razor blades, by contrast, feature straight edges optimized for shaving or scraping motions. They're generally thinner and more flexible, which works well for some applications but makes them less versatile overall.

When compared to hobby knives, the difference in quality becomes even more apparent. One manufacturer's testing found that premium carbon steel scalpel blades could make "ten times as many cuts in EVA foam compared to standard hobby knives" before dulling. While hobby blades might save you money upfront, you'll replace them far more frequently.

As a craft supplier I know likes to say: "The ultra-thin, super-hard carbon steel holds its edge far longer than standard hobby blades." That longevity makes real scalpel blades worth considering even for non-medical precision work.

At American Mortuary Coolers, we've found that investing in the right cutting tools—whether for post-mortem care or craft projects—ultimately saves time, improves results, and can even improve safety. The right blade makes all the difference.

Conclusion

Choosing the right scalpel blade might seem like a small detail, but as we've seen throughout this guide, it can make all the difference in your work—whether you're in a medical setting, laboratory, or crafting at your kitchen table.

These precision cutting tools have evolved far beyond simple sharp edges. They're carefully engineered instruments with specific designs that serve particular purposes. Understanding these nuances helps ensure you get the cleanest cuts and best results possible.

Throughout my years working with mortuary professionals, I've seen how the right blade can transform difficult procedures into smooth, efficient processes. It's similar to having the right key for a lock—when you match the blade to the task, everything just works better.

Remember these key points as you select your scalpel blades:

Match your blade to your specific task. Those numbers (#10, #11, #15, etc.) aren't random—each shape was designed with specific cutting motions in mind. The curved belly of a #10 excels at long incisions, while the pointed tip of an #11 makes precise punctures a breeze.

Think about material properties when making your selection. Carbon steel blades offer that incredible initial sharpness that slices through tissue like butter, but they'll rust quickly. Stainless steel might not start quite as sharp, but it'll resist corrosion and maintain its edge longer in moist environments.

Never compromise on safety. These blades are extraordinarily sharp—that's their job! Proper handling techniques, secure installation, and safe disposal aren't just recommendations—they're essential practices that prevent painful (and potentially dangerous) injuries.

Double-check compatibility before purchasing. Not all blades fit all handles. The frustration of opening a box of blades only to find they don't fit your handles is entirely avoidable with a quick compatibility check.

Balance quality against cost for your specific needs. While premium Swann-Morton or Feather blades might be justified for surgical procedures, more budget-friendly options could serve perfectly well for educational or craft purposes.

Here at American Mortuary Coolers, we understand that quality tools are essential. Just as we design our mortuary refrigeration systems to meet exact specifications, we know that precision instruments like scalpel blades need to be carefully selected for professional post-mortem care.

For those working in mortuary settings, I recommend keeping a variety of scalpel blades on hand. Different procedures call for different cutting profiles—from the initial Y-incision where a #22 might be perfect, to more delicate work where a #15 could provide the precision you need. This approach ensures both efficiency and dignity in post-mortem care.

The right tools make all the difference in our work. Whether you're selecting a mortuary cooler or choosing the perfect scalpel blade, attention to detail matters. After all, it's these seemingly small choices that ultimately define the quality of our work and the respect we show to those in our care.

More info about morgue refrigeration solutions — American Mortuary Coolers