Understanding Lysol Liquid Cleaner Safety Data Sheets: A Critical Resource

If you're searching for information about a lysol liquid cleaner safety data sheet, here's what you need to know:

| Key Information | Details |

|---|---|

| Purpose | Safety Data Sheets (SDS) provide comprehensive information about hazards, handling, storage, and emergency procedures for Lysol liquid cleaners in workplace settings |

| Main Ingredients | Typically contains ethanol (30-60%), quaternary ammonium compounds (1-5%), and may include other ingredients like clorofene (5-10%) |

| Health Hazards | Can cause eye irritation (Category 2A) or skin corrosion (Category 1) depending on formulation |

| First Aid | For eye contact: Rinse with water for 15-20 minutes; For skin: Wash thoroughly with soap and water |

| Where to Find | Available directly from manufacturer websites or by contacting Lysol/Reckitt Benckiser |

A lysol liquid cleaner safety data sheet is a technical document designed for workplace employees and emergency personnel rather than for everyday consumers. Unlike the product label you see at home, these sheets contain detailed information about chemical composition, hazard identification, safe handling procedures, and emergency response protocols.

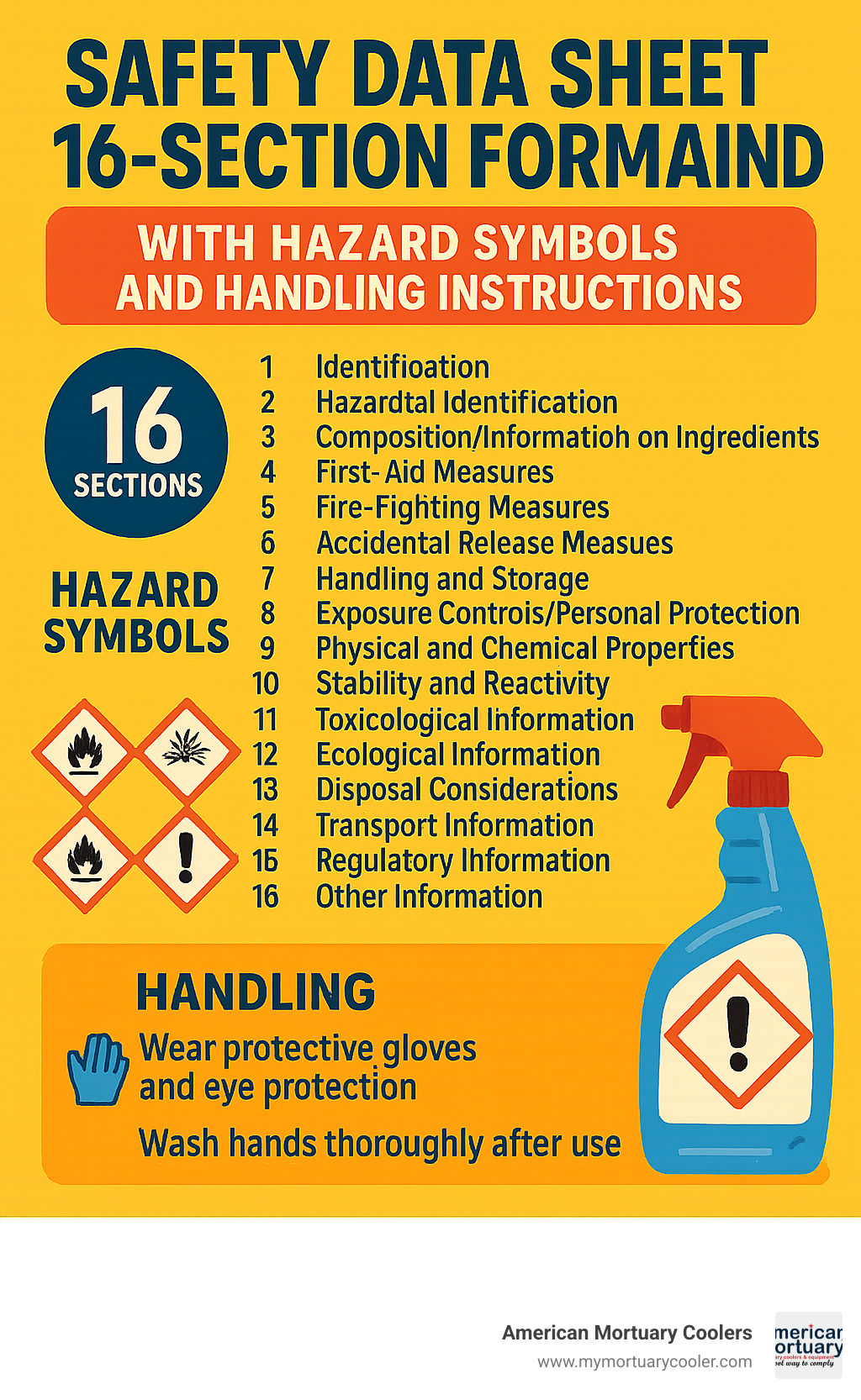

Safety Data Sheets follow a standardized 16-section format required by OSHA's Hazard Communication Standard (29 CFR 1910.1200). They're essential for maintaining workplace safety, ensuring proper chemical handling, and providing critical information during emergencies.

While Lysol products are common household items, their industrial and professional formulations may contain higher concentrations of active ingredients that require special handling. Understanding the SDS helps prevent accidents, ensures compliance with workplace regulations, and guides appropriate emergency response.

I've specialized in facility safety compliance for over 15 years, helping funeral homes and medical facilities properly manage cleaning chemicals including proper interpretation of lysol liquid cleaner safety data sheets for mortuary environments. Having worked with numerous facilities on chemical safety protocols, I understand the critical importance of these documents in maintaining safe operations.

Why Safety Data Sheets Matter for Cleaning Chemicals

Ever wondered why those thick, technical documents come with your cleaning supplies? Safety Data Sheets (SDS) aren't just paperwork—they're your roadmap to using chemicals safely in any workplace setting. For those using Lysol liquid cleaners in professional environments, these documents are absolutely essential.

Think of an SDS as the "behind the scenes" information that consumer labels just don't have room to include. When you're working with lysol liquid cleaner, the safety data sheet provides critical details that could literally save lives.

OSHA takes these documents seriously—and you should too. Under their Hazard Communication Standard (29 CFR 1910.1200), employers must keep SDSs for all hazardous chemicals and make sure employees can access them during their shifts. This isn't just a suggestion; it's federal law designed to protect workers.

In emergency situations, a lysol liquid cleaner safety data sheet becomes even more valuable. Imagine a significant spill in your facility—the SDS tells you exactly how to contain it safely. Or if someone gets the cleaner in their eyes, the SDS provides precise instructions for first aid that could prevent permanent damage.

Here's how an SDS differs from what you see on a regular bottle:

| Consumer Product Label | Safety Data Sheet |

|---|---|

| Basic precautions | Comprehensive hazard information |

| Limited first-aid | Detailed emergency procedures |

| General usage instructions | Technical handling protocols |

| No detailed composition | Full ingredient disclosure with percentages |

| Minimal regulatory information | Complete regulatory compliance data |

| Designed for household use | Designed for workplace and emergency response |

In our years of working with funeral homes across the country, we've seen how proper risk assessment makes all the difference when using cleaning chemicals in sensitive environments like preparation rooms. The detailed information in an SDS helps you evaluate potential risks and implement the right safety measures before problems occur.

Legal Framework & Global Standards

The world of chemical safety documentation isn't simple—it's a carefully constructed system of overlapping regulations. At its core, OSHA's Hazard Communication Standard (HAZCOM) requires manufacturers to assess chemical hazards and share this information through standardized SDSs.

Gone are the days when every country had different formats for safety information. The Globally Harmonized System (GHS) has standardized how SDSs look and what they contain worldwide. This means whether you're in Tennessee or Tokyo, you can understand the hazards of your lysol liquid cleaner safety data sheet because it follows the same 16-section format.

For Lysol products specifically, there's another layer of oversight—EPA registration. Because these cleaners kill germs, they're technically classified as pesticides (surprising, right?). That EPA registration number you might notice (like EPA Reg. No. 777-89 on some Lysol products) confirms the product has been evaluated and approved for its intended use.

Beyond these regulations, Lysol products must also comply with the Toxic Substances Control Act (TSCA) and, in California, may require Proposition 65 warnings if they contain chemicals known to cause cancer or reproductive harm. If you're curious about these California-specific requirements, our comprehensive guide to Prop 65 certification explains everything you need to know.

Consequences of Ignoring SDS Guidance

Skipping over the guidance in a lysol liquid cleaner safety data sheet isn't just cutting corners—it can have serious, sometimes painful consequences.

Chemical burns are a real risk with certain Lysol formulations that contain corrosive ingredients like potassium hydroxide. Without the proper gloves and eye protection specified in the SDS, direct contact could mean a trip to the emergency room and potentially lasting damage.

Respiratory irritation is another concern, especially in smaller spaces like preparation rooms. Many cleaning products contain volatile compounds that can irritate lungs and trigger asthma attacks when used in poorly ventilated areas. The SDS specifically outlines ventilation requirements to keep everyone breathing easily.

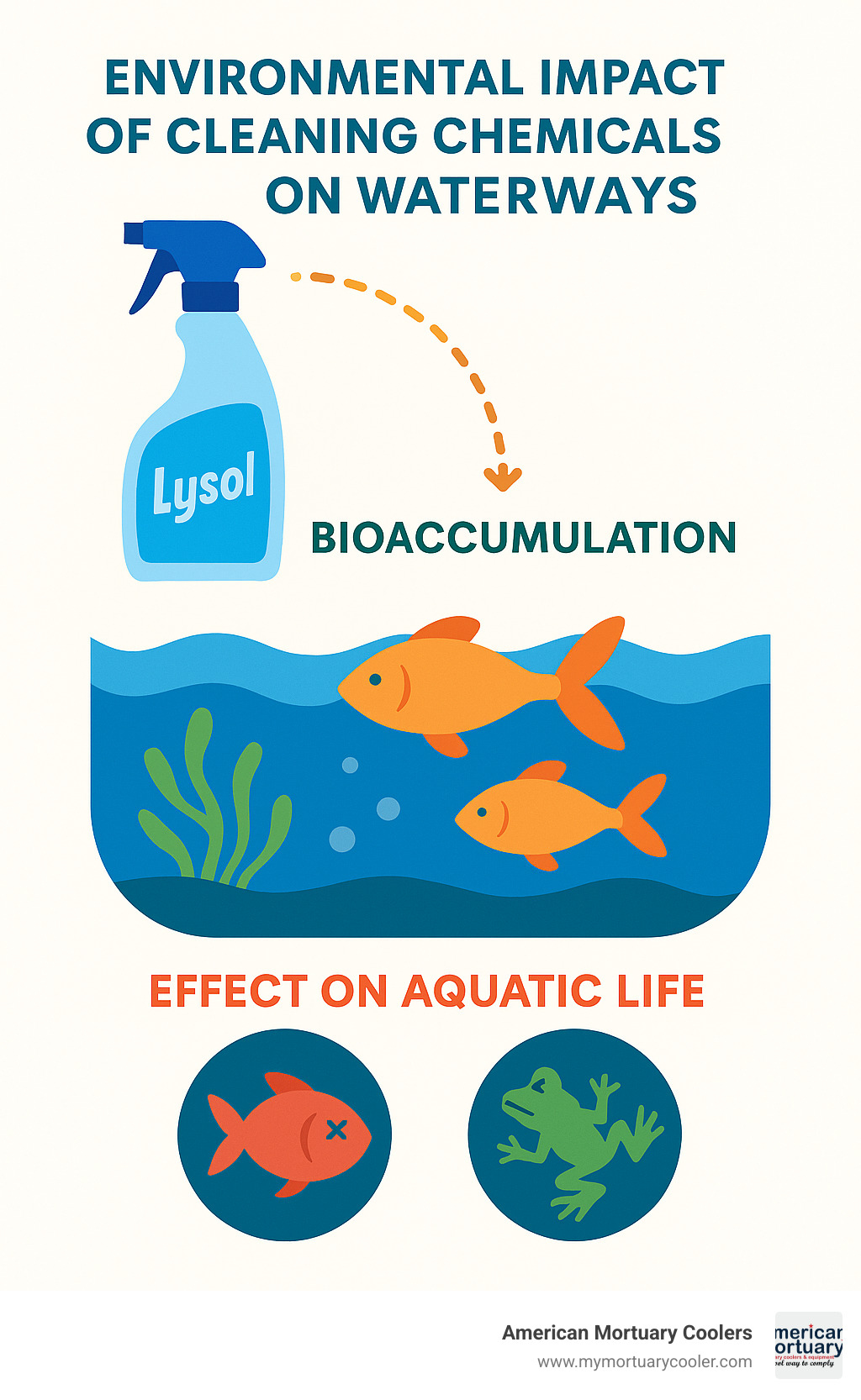

From an environmental perspective, improper disposal can lead to significant fines. Many don't realize that quaternary ammonium compounds in Lysol products are toxic to aquatic life. Pour these down the drain without following proper disposal guidelines, and you could face EPA penalties.

Finally, a chemical incident can cause facility downtime—something no funeral home can afford. A major spill might require evacuation and professional cleanup, disrupting services and potentially damaging your reputation. Following SDS guidance helps prevent these disruptions, ensuring your facility remains operational when families need you most.

At American Mortuary Coolers, we understand the importance of maintaining safe, compliant facilities—it's why we design our cooling systems with safety in mind, complementing your careful chemical management practices.

Decoding the Lysol Liquid Cleaner Safety Data Sheet

Ever stared at a lysol liquid cleaner safety data sheet and felt like you were trying to decode a foreign language? You're not alone! These documents might look intimidating, but they're actually designed to keep you safe. Let's break down this technical document into something we can all understand.

Think of an SDS as the "behind the scenes" look at your cleaning products. While the consumer label gives you the highlights, the SDS pulls back the curtain to reveal everything happening backstage. It starts with the basics – product name, who makes it, what it's used for, and who to call in an emergency.

The hazard identification section is where things get interesting. Here, you'll find either "Danger" or "Warning" as signal words – kind of like nature's way of saying "Heads up!" or "Really, REALLY heads up!" For example, if you see "Danger" on a Lysol Brand Concentrate Disinfectant sheet, that's not just for dramatic effect – it's because those corrosive ingredients mean business!

Those little pictures (pictograms) aren't just decorative – they're universal symbols that cut through language barriers. An exclamation mark means "irritant," a symbol of corrosion means exactly what you'd think, and a flame symbol isn't suggesting a cozy evening by the fireplace – it's warning about flammability.

Transport codes might seem like random numbers and letters (like UN1950 for Lysol Disinfectant Spray), but they're crucial information for shipping companies handling these products. Meanwhile, those NFPA/HMIS ratings are like a cheat sheet for emergency responders – a 0-4 scale that quickly tells them what they're dealing with if there's an incident.

Main Sections of the Lysol Liquid Cleaner Safety Data Sheet

A lysol liquid cleaner safety data sheet follows a standardized 16-section format that's consistent across products and manufacturers. Think of it as chapters in a safety story, each telling you something important:

Sections 1-4 cover the basics: what the product is, its hazards, what's in it, and what to do if something goes wrong. Need to know what to do if someone accidentally splashes Lysol in their eyes? Section 4 has you covered with step-by-step first aid instructions.

Sections 5-7 are all about emergencies and handling: how to fight fires involving the product, what to do if you spill it, and the right way to handle and store it. Did you know some Lysol products have specific temperature requirements for storage? This is where you'd learn that!

Sections 8-11 get into the technical details: exposure controls, physical properties, stability information, and health effects. This is where you'd find why ventilation matters when using certain products, or why mixing Lysol with certain other chemicals is a definite no-no.

The final sections (12-16) cover environmental concerns, disposal instructions, transportation requirements, regulatory information, and other miscellaneous details. These sections might seem less urgent, but they're incredibly important for businesses that need to comply with environmental regulations or transport these products.

Key Ingredients Listed on the Lysol Liquid Cleaner Safety Data Sheet

When you look at a lysol liquid cleaner safety data sheet, you'll notice it doesn't just say "cleaning stuff" – it breaks down exactly what's inside, often with percentages and identification numbers.

Ethanol is a major player in many Lysol formulations, making up 30-60% of some products, especially aerosols. It's great at killing germs but also contributes to flammability (which explains those warning symbols!).

Quaternary ammonium compounds (or "quats" for those in the know) typically appear at 1-5%. These are disinfectant powerhouses but can irritate your skin and eyes, which is why the SDS recommends specific protective gear.

Some concentrated formulations contain clorofene (5-10%) and potassium hydroxide (1-5%). These ingredients mean business when it comes to cleaning, but they're also why the SDS emphasizes safety precautions – potassium hydroxide in particular can cause severe burns if mishandled.

Aerosol products contain propellants like butane and propane in small percentages. They're what helps the product spray out of the can, but they're also highly flammable (hence the storage recommendations to keep away from heat).

For the complete ingredient breakdown of specific Lysol products, you can visit SmartLabel.org Safety Data Sheets where manufacturers provide regularly updated information.

Understanding Hazard & Precautionary Statements

The hazard statements on a lysol liquid cleaner safety data sheet aren't just legal jargon – they're straightforward warnings about what could go wrong. For example, "Flammable aerosol" isn't mincing words about what happens if you leave that can near a heat source.

Some concentrated Lysol formulations carry the warning "Causes severe skin burns and eye damage" – that's not exaggerating for effect, it's letting you know that proper protection isn't optional. Many Lysol cleaners are labeled as Eye Irritant Category 2A, which means they "Cause serious eye irritation" – a good reason to keep those safety goggles handy!

Environmental hazards get equal billing, with statements like "Toxic to aquatic life with long lasting effects" reminding us that proper disposal isn't just about following rules – it's about protecting our waterways.

The precautionary statements act as your safety checklist. Prevention statements tell you what protective gear to wear, response statements explain what to do if something goes wrong (like detailed instructions for rinsing eyes), storage statements provide guidance on keeping products safely (away from sunlight and below 50°C/122°F), and disposal statements ensure you're not causing environmental harm when you're done with the product.

Those little PPE icons might seem simple, but they're powerful visual reminders of what protection you need – gloves, goggles, face shields, or protective clothing – before you start working with the product.

In our work at American Mortuary Coolers, we've seen how critical these safety details are in mortuary and funeral home settings, where disinfection is paramount but must be balanced with staff safety and equipment protection. Understanding your cleaning chemicals isn't just about compliance – it's about creating a safer workplace for everyone.

Safe Handling, Storage, and Spill Response

Working with Lysol liquid cleaners doesn't have to be intimidating, but it does require some common-sense precautions. Think of proper handling as a recipe for safety—get the ingredients right, and everyone stays protected.

Good ventilation tops the list when handling these products. Just like you wouldn't paint in a closed closet, you shouldn't use concentrated Lysol in poorly ventilated spaces. Those fumes need somewhere to go! For products containing alcohol or other flammable ingredients, be mindful of ignition sources. That means no smoking, no candles, and keeping away from hot surfaces that could spark a fire.

Smart storage prevents dangerous situations. One cardinal rule: never store Lysol products near bleach. This isn't just good organization—it's critical safety. Mixing these chemicals accidentally can release chlorine gas that can cause serious respiratory issues. I've seen this happen in funeral homes when cleaning supplies get jumbled together, and it creates a dangerous situation for everyone in the building.

Secondary containment—like placing bottles in plastic bins—is worth the extra effort. It's like having insurance for your chemicals. If a bottle leaks, the spill stays contained instead of spreading across your storage area or mixing with other chemicals.

For facilities using larger quantities, having spill kits ready is non-negotiable. These typically include materials like vermiculite or sand that soak up liquid spills like a sponge. When cleaning up flammable Lysol formulations, reach for non-sparking tools (usually made of brass or plastic) to prevent any chance of ignition.

Cleanup isn't complete until the waste is properly labeled and disposed of according to your local regulations. Different areas have different requirements, so check with your local waste management authority if you're unsure.

For more specialized environments like morgue facilities, additional safety protocols may apply. Our guide on essential safety protocols for morgue freezers provides more detailed information relevant to funeral service professionals.

Personal Protective Equipment (PPE) Essentials

When it comes to handling lysol liquid cleaner safety data sheets, reading about required PPE is one thing—actually wearing it is another. But trust me, your skin and eyes will thank you for the extra few seconds it takes to gear up properly.

Gloves are your first defense against skin irritation and chemical burns. Not just any gloves will do—chemical-resistant gloves made of nitrile, neoprene, or PVC are what you're looking for. The lysol liquid cleaner safety data sheet will tell you exactly which material works best for that specific formulation. Think of them as your hands' best friends when working with these products.

Eye protection isn't optional when working with cleaners that can cause serious eye damage. Chemical splash goggles are better than standard safety glasses because they create a seal around your eyes, preventing those sneaky splashes from coming in from the sides. I've heard too many stories of people who thought "it'll just take a second" before getting a painful reminder about eye safety.

For the stronger stuff, especially concentrated formulations, you might need to step up your protection game:

Face shields work alongside splash goggles (not instead of them) to protect your entire face from corrosive splashes. This is especially important when handling concentrated disinfectants that can cause serious burns.

Chemically resistant aprons keep your clothing and skin protected. Think of it as a raincoat for chemical splashes—much easier to clean an apron than treat a chemical burn!

In emergency situations involving large spills in confined spaces, self-contained breathing apparatus (SCBA) may be necessary. This isn't everyday equipment for most users, but emergency responders should have access to respiratory protection when needed.

For a deeper dive into selecting the right protective gear for different situations, check out our essential guide to choosing personal protective gear.

Storage Do's & Don'ts

Proper storage of Lysol products isn't just about preventing accidents—it's also about maintaining the product's effectiveness. After all, what good is a disinfectant that's lost its potency?

Keep it original. Store products in their original containers with labels intact. Those labels contain important safety information and instructions that generic bottles won't have. Plus, transferring chemicals to unmarked containers is asking for trouble—is that clear liquid water or disinfectant? Nobody should have to guess.

Keep it cool and airy. Store in well-ventilated areas away from direct sunlight and heat sources. This is especially important for aerosol products, which should never be exposed to temperatures above 50 °C (122 °F). Heat can build pressure inside the can, potentially causing it to rupture.

Keep it secure. In facilities with public access, like funeral homes, keeping cleaning chemicals in locked cabinets prevents accidental access by visitors or children. Secondary containment for larger quantities helps contain any leaks before they become major problems.

Keep it separate. Never store Lysol products near chlorine bleach or other incompatible chemicals. This isn't just good organization—it's essential safety. Accidental mixing can create toxic gases that pose serious health risks.

Keep it organized. Rotate your stock so older products get used first. This reduces waste and ensures you're always using product within its effective lifespan. A simple "first in, first out" system works well for most facilities.

Avoid storing products near food, beverages, or animal feed to prevent contamination. And if you're working with flammable formulations, proper storage in approved flammable cabinets may be required by local fire codes, especially for larger quantities.

Spill & Fire-Fighting Procedures

Even with careful handling, accidents can happen. Being prepared makes all the difference between a minor inconvenience and a major emergency.

If you experience a significant spill of Lysol liquid cleaner, first assess whether evacuation is necessary. In confined spaces with limited ventilation, evacuating the immediate area keeps everyone safe from potentially harmful vapors. If the product is flammable, eliminate all ignition sources immediately—no smoking, no electrical equipment, no open flames.

When it comes to fire situations, the lysol liquid cleaner safety data sheet typically recommends specific extinguishing agents. Water fog, CO2, or dry chemical extinguishers are usually appropriate, but always check the specific product's SDS for guidance. For fires involving aerosol products, water spray can help cool containers and prevent them from exploding due to heat exposure.

Fire-fighters responding to significant incidents should wear full protective gear, including self-contained breathing apparatus, to protect against smoke and chemical vapors.

According to EPA testing, many Lysol products effectively kill a range of pathogens, including the virus that causes COVID-19. For the most current information on Lysol's effectiveness against specific pathogens, the EPA's coronavirus resources page provides regularly updated guidance.

After containing a spill, don't just throw the cleanup materials in the regular trash. The collected waste should be disposed of through a licensed waste contractor in accordance with local regulations. Improper disposal not only harms the environment but can also result in significant fines and penalties.

At American Mortuary Coolers, we understand that proper chemical handling is just one aspect of maintaining a safe, efficient facility. Our Tennessee-based team specializes in creating custom cooling solutions that complement your facility's safety protocols while meeting your specific needs.

Health, Environmental, and First-Aid Information

When you're handling cleaning products, understanding their potential health effects and environmental impact is crucial. The lysol liquid cleaner safety data sheet provides comprehensive information about both short-term (acute) and long-term (chronic) health effects that might occur with exposure.

Lysol products typically list acute effects like skin irritation, eye redness, and respiratory discomfort. The SDS also details any potential chronic concerns such as organ damage or carcinogenicity, though these vary by formulation.

You'll often see toxicity measurements expressed as LD50 (lethal dose for 50 % of test animals) and LC50 (lethal concentration for 50 % of test animals). For context, ethanol—a common Lysol ingredient—has an oral LD50 of 7,060 mg/kg in rats. These technical values help safety professionals assess risk levels in workplace settings.

From an environmental perspective, many Lysol formulations contain quaternary ammonium compounds that can harm aquatic life. These "quats" can be toxic to fish at concentrations as low as 0.28 mg/L in a 96-hour exposure period—a stark reminder of why proper disposal is so important.

The SDS also covers biodegradability and environmental persistence, helping facilities make informed decisions about which products to use. This is especially important in specialized settings where cleanliness must be balanced with environmental responsibility.

For more eco-friendly cleaning approaches in specialized environments, our guide on essential tips for maintaining your American Mortuary Cooler offers practical advice that complements SDS information.

First-Aid Measures for Exposure

Knowing how to respond quickly to chemical exposure can prevent serious injury. The lysol liquid cleaner safety data sheet provides clear, step-by-step instructions for various exposure scenarios:

For eye contact, time is critical. Hold the eye open and rinse gently with water for 15-20 minutes. If you wear contacts, remove them after the first 5 minutes of rinsing, then continue. Even if symptoms improve, it's wise to seek medical attention, as some eye damage may not be immediately apparent.

When Lysol contacts your skin, immediately remove any contaminated clothing and wash the affected area thoroughly with water for at least 15 minutes. This extended rinsing time helps ensure all chemical residue is removed. For more concentrated or corrosive formulations like Lysol Brand Concentrate Disinfectant, don't wait—seek medical help right away.

If someone has inhaled too much product vapor, especially in a poorly ventilated area, move them to fresh air immediately. Watch their breathing carefully—if they're struggling, oxygen may help. If breathing stops, start CPR and call emergency services immediately.

For ingestion cases, first rinse the mouth with water if the person is conscious. Contrary to what you might think, don't induce vomiting unless medical professionals specifically direct you to do so—vomiting can sometimes cause additional damage with certain chemicals. Instead, contact poison control or get emergency medical help right away.

Remember to bring the product label or SDS to medical appointments—this information helps healthcare providers deliver the most appropriate treatment.

Recognizing Overexposure Symptoms

Being able to recognize when someone has been overexposed to cleaning chemicals can save precious time in an emergency. Different types of exposure produce distinct symptoms that signal when to seek help.

Eye exposure typically causes immediate discomfort—a burning sensation, redness, excessive tearing, and blurred vision are common. With stronger formulations, you might notice more intense pain, swelling, and potentially lasting damage if not treated promptly.

When Lysol contacts skin for too long or in concentrated form, look for redness and irritation that may progress to pain. More concerning is when skin appears blanched or whitened—this can indicate a chemical burn is developing. Some individuals may develop allergic dermatitis with itching, redness, and a distinctive rash pattern, especially with repeated exposure.

Breathing in too much product often triggers coughing, wheezing, and shortness of breath. Headaches and dizziness frequently follow, particularly in poorly ventilated spaces. If someone shows these symptoms after using Lysol, move them to fresh air immediately and monitor them closely for worsening respiratory distress.

Swallowing any cleaning product is serious. Watch for nausea, vomiting, stomach pain, and diarrhea. Corrosive formulations can burn the mouth, throat, and digestive tract, causing visible tissue damage, drooling, or difficulty swallowing.

If you observe any of these symptoms after Lysol exposure, don't wait to see if they improve on their own. Seek medical attention promptly, and remember to bring the lysol liquid cleaner safety data sheet to help guide treatment decisions.

Environmental Impact & Disposal

The cleaning products we use daily can have surprising impacts downstream. Lysol liquid cleaners, while effective for disinfection, require thoughtful handling to minimize environmental harm.

The quaternary ammonium compounds (quats) in many Lysol products are particularly concerning for aquatic ecosystems. Even small amounts can harm fish, disrupt algae growth, and damage the gills of aquatic organisms. These effects can ripple through the food chain, affecting species that weren't directly exposed.

Ethanol, another common Lysol ingredient, presents different challenges. While it evaporates quickly and doesn't persist in water, its volatility means it can contribute to air quality issues when used in large quantities or industrial settings.

To minimize these impacts, the lysol liquid cleaner safety data sheet provides specific guidance for proper disposal:

First, never pour unused product down drains or flush it down toilets where it can enter waterways untreated. For household-sized containers, triple-rinsing before recycling helps remove residual product that could harm the environment.

Facilities using Lysol products in larger quantities should partner with licensed waste contractors who understand local regulations. These professionals ensure that chemical waste is treated properly before returning to the environment.

Empty containers deserve special attention too—never repurpose them for storing other substances, especially food or beverages. Chemical residues can linger even in seemingly clean containers, posing unexpected risks.

Disposal regulations vary significantly between locations. What's acceptable in Tennessee might be prohibited in California, so always check with your local waste management authority for specific guidelines. Taking these extra steps helps protect our shared water resources for generations to come.

Frequently Asked Questions about the Lysol Liquid Cleaner Safety Data Sheet

What PPE is mandatory when diluting Lysol concentrate?

I've worked with numerous cleaning staff who ask this question regularly, and it's an important one. When you're diluting Lysol concentrate products, you absolutely need to protect yourself properly. At minimum, you should wear chemical-resistant gloves (nitrile works well) and chemical splash goggles - not just regular safety glasses.

For the more aggressive formulations like Lysol Brand Concentrate Disinfectant, you'll want to step up your protection. The lysol liquid cleaner safety data sheet specifically recommends adding a face shield and chemical-resistant apron to your setup. Think of it this way - these concentrates can cause serious burns, so treating them with respect is essential.

In our work with funeral homes, we've found that creating a dedicated dilution station works wonders. This should be a specific area with good ventilation, all the necessary PPE within arm's reach, and an emergency eyewash station nearby. This simple setup dramatically reduces the risk of accidents and exposure.

How do I dispose of empty Lysol containers safely?

This is something many facilities struggle with, but proper disposal isn't complicated once you know the steps. To safely dispose of your empty Lysol containers:

First, make absolutely sure the container is completely empty - every last drop. Then give it a thorough triple-rinse with water to remove any residual product that could harm the environment or waste handlers. Always replace the cap before disposal - this prevents any remaining residue from leaking during handling.

Look for recycling symbols on the container and follow your local recycling guidelines if possible. Many Lysol containers are recyclable, but policies vary by location. If recycling isn't an option in your area, dispose according to your local waste management regulations.

One important safety note: never puncture or incinerate aerosol containers, even when they seem empty! They often contain residual propellant that can cause dangerous explosions. I've seen this happen, and it's not something you want to experience firsthand.

For larger facilities like funeral homes that go through significant quantities of cleaning products, I recommend consulting with a waste management professional. They can help develop a comprehensive disposal program that keeps you compliant with regulations while protecting the environment.

Can Lysol liquid cleaner corrode stainless steel surfaces?

This is a question I hear frequently from mortuary professionals concerned about their expensive equipment. The short answer is: it depends on the specific Lysol formulation and how you're using it.

Some concentrated Lysol formulations contain potassium hydroxide or other corrosive ingredients that could potentially damage stainless steel if left in contact for too long. The lysol liquid cleaner safety data sheet provides specific information about corrosivity for each formulation.

Based on technical manuals for stainless steel equipment used in mortuary settings, I recommend these practical steps:

Always dilute concentrated formulations exactly according to the manufacturer's instructions - no guesswork. Limit contact time to just what's needed for proper disinfection (typically 3-10 minutes, check the label). After that, rinse thoroughly with clean water and dry the surface completely to prevent water spots and potential long-term corrosion.

For specialized equipment like mortuary coolers, autopsy tables, and other funeral home equipment, always check the manufacturer's cleaning recommendations first. We've seen cases where using the wrong cleaner voided equipment warranties, which is an expensive mistake you definitely want to avoid.

At American Mortuary Coolers, we provide specific cleaning guidelines with all our equipment to ensure you're using compatible products that won't damage your investment while still maintaining proper disinfection standards.

Conclusion

When it comes to workplace safety, understanding a lysol liquid cleaner safety data sheet isn't just a regulatory box to check—it's a vital practice that protects everyone in your facility. This is especially true in sensitive environments like funeral homes and medical facilities where cleanliness is paramount but must be balanced with safety.

Throughout my years working with funeral directors and mortuary staff, I've seen how following SDS guidance makes all the difference between a safe operation and a potential disaster. The most successful facilities I've worked with share some common approaches to chemical safety.

They always ensure staff members thoroughly read and understand the SDS before handling any chemical products. They're meticulous about providing and requiring appropriate personal protective equipment—those gloves and goggles aren't just suggestions! They store their chemicals properly, keeping incompatible materials separated and away from heat sources. Perhaps most importantly, every staff member knows exactly what to do if something goes wrong—whether it's a spill on the floor or splashback in someone's eyes.

Regular training sessions keep safety protocols fresh in everyone's mind, and proper disposal practices protect both staff and the wider community. These aren't complex practices, but they require consistent attention and commitment.

Here at American Mortuary Coolers, we understand that maintaining pristine equipment is essential in your line of work. As a Tennessee-based manufacturer crafting custom morgue refrigeration systems, we're committed to supporting your safety as well as your refrigeration needs. The mortuary equipment we build is designed for thorough cleaning, but always in accordance with proper chemical safety protocols.

We encourage all our clients to develop a comprehensive chemical safety program that includes regular training sessions. When staff understand not just what to do but why it matters, safety becomes part of your facility's culture rather than just another regulation to follow.

The care you take with chemical safety reflects the same professionalism and attention to detail that defines your service to families during their most difficult moments. By prioritizing these practices, you create a workplace that protects your team while they perform their essential work.

For more information about our custom mortuary coolers and refrigeration solutions designed with your safety needs in mind, please visit More info about our morgue coolers.