The Ultimate Guide to Diamond Plate Sheets for Your Project

Diamond plate sheets are metal sheets with a raised diamond pattern that provides slip resistance and durability for a variety of applications. If you're looking for quick answers about diamond plate options, here's what you need to know:

| Feature | Details |

|---|---|

| Common Materials | Aluminum (3003-H22, 6061-T6), Steel, Stainless Steel |

| Popular Thicknesses | 0.025" to 0.5" (most common: 0.063"/1/16") |

| Standard Sizes | 1'×1' to 5'×12' (most common: 4'×8') |

| Weight Comparison | Aluminum is 66% lighter than steel of same thickness |

| Key Benefits | Slip resistance, durability, corrosion resistance, aesthetic appeal |

| Common Applications | Flooring, wall protection, vehicle surfaces, toolboxes, mortuary coolers |

Whether you're outfitting a funeral home, upgrading a mortuary cooler, or simply need durable, slip-resistant surfaces, diamond plate sheets offer the perfect combination of functionality and industrial style. These versatile metal sheets feature a distinctive raised pattern that not only improves traction but also adds a professional, finished look to any installation.

The distinctive raised diamond pattern wasn't just designed for looks—it originated in the 1960s specifically to provide traction on slippery surfaces. Today, this practical feature continues to prevent slips and falls while also offering impressive durability and corrosion resistance depending on the material you select.

What makes diamond plate sheets special is their dual-purpose nature: they simultaneously improve safety through improved grip while providing a distinctive industrial aesthetic that many professionals prefer over plain metal surfaces.

I'm Mortuary Cooler, a national supplier of mortuary coolers with extensive experience incorporating diamond plate sheets into our high-quality, American-made units. My team has helped countless funeral directors select the right diamond plate options for durability, safety, and professional appearance.

Dimond Plate Sheets Explained: Key Features & Patterns

Ever wondered what gives dimond plate sheets their distinctive look and feel? These remarkable metal sheets (also known as diamond plate, tread plate, or checker plate) feature a raised pattern that's not just for show – those textured lugs work hard to keep you safe by providing reliable traction on what would otherwise be a slippery surface.

There's a key difference between genuine and imitation products worth knowing. True dimond plate sheets are forged, not stamped, giving them a solid backside. As industry experts often say, "Real diamond plate is forged and solid on the backside; fake is stamped and hollow behind the diamonds." This distinction matters because genuine diamond plate delivers significantly better durability and strength when put to the test.

Born in the 1960s as "tread plate," these specialized sheets were specifically engineered to prevent slips on wet or icy surfaces. The raised pattern creates natural friction that keeps feet firmly planted – a crucial safety feature in demanding industrial environments where accidents simply can't happen.

Beyond their practical benefits, dimond plate sheets bring a distinctive industrial aesthetic that's become increasingly popular beyond factory floors. The brilliant shine of polished aluminum diamond plate adds visual character while serving a vital purpose, making it a favorite choice for both commercial applications and decorative projects.

Why Choose Dimond Plate Sheets for Traction & Style

Dimond plate sheets stand out from other flooring and surface options for several compelling reasons. First and foremost is their exceptional durability. At American Mortuary Coolers, we've seen how diamond plate flooring in our mortuary units withstands years of heavy carts and equipment traffic without significant wear.

The superior corrosion resistance is another major advantage, especially in aluminum and stainless steel varieties. Aluminum naturally develops a protective oxide layer that shields against rust and corrosion, making it perfect for environments exposed to moisture or chemicals – a critical consideration in mortuary settings.

Weight matters in many applications, which is why the lightweight alternative of aluminum diamond plate (approximately 66% lighter than steel of the same thickness) makes installation easier and reduces structural load requirements on your building.

The aesthetic appeal shouldn't be overlooked either. That distinctive diamond pattern adds visual interest and a professional, industrial look that many of our clients prefer over plain surfaces. In mortuary coolers specifically, this appearance conveys a sense of quality and durability that families and funeral directors appreciate.

For those concerned about environmental impact, aluminum diamond plate offers impressive sustainability credentials. It's 100% recyclable and requires only 5% of the energy to recycle compared to producing new aluminum – an environmentally responsible choice for the modern business.

Industry testing confirms that "the raised diamond pattern increases slip resistance by up to 30% compared to flat aluminum sheet," highlighting the practical safety benefits that make this material so valuable in high-risk environments.

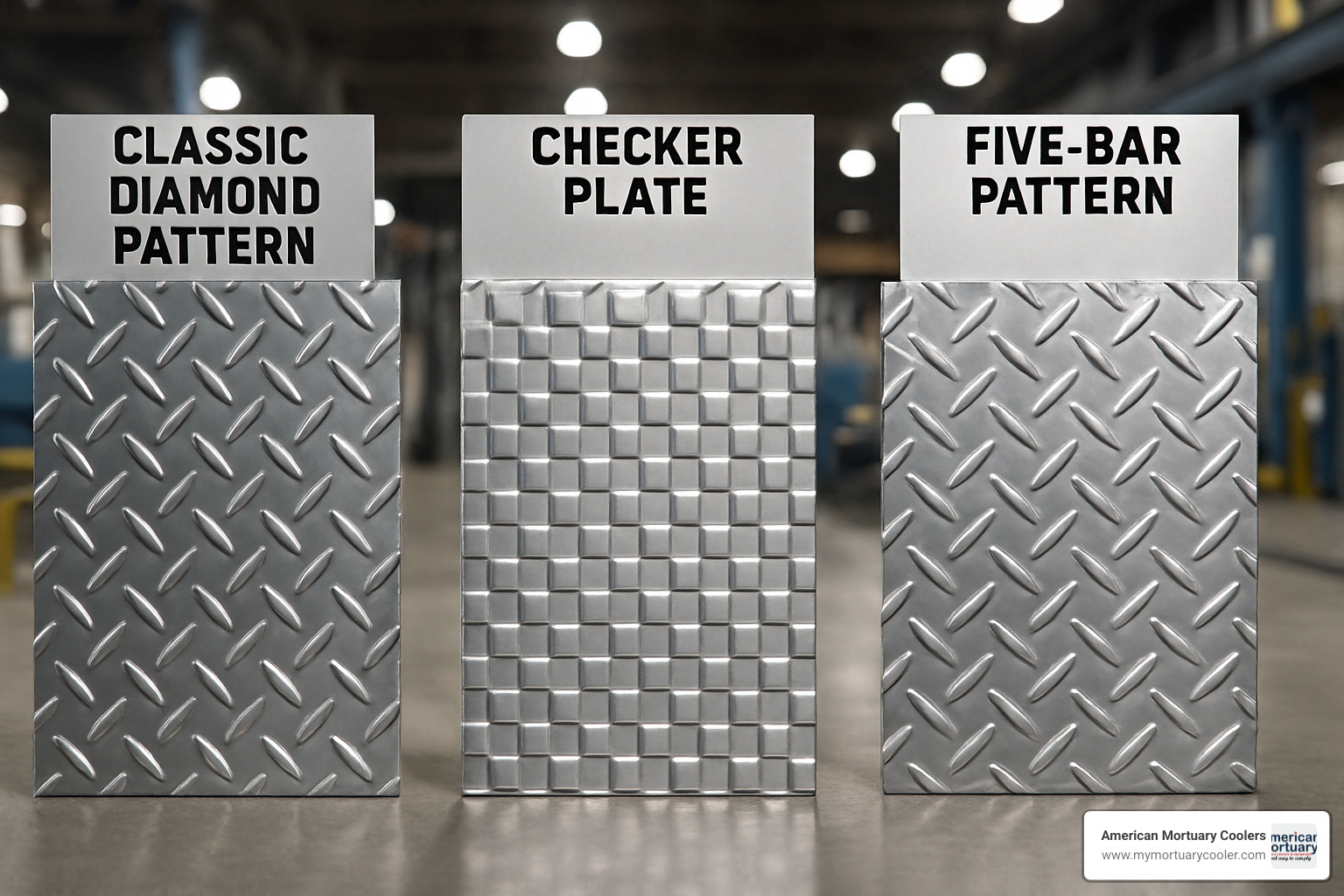

Common Patterns & Textures

While most people recognize the classic diamond pattern, dimond plate sheets actually come in several distinctive variations to suit different needs:

The traditional diamond pattern remains most popular for good reason – those raised diamond-shaped lugs arranged in a consistent grid provide excellent traction in all directions. It's the pattern we typically recommend for mortuary cooler flooring due to its proven performance and timeless appearance.

Some projects benefit from checker plate with its square pattern rather than diamond shapes. This variation is sometimes preferred for specific aesthetic requirements or when matching existing installations.

For applications where traffic typically moves in consistent directions, the five-bar pattern with its five raised bars or ridges offers directional traction that can be strategically oriented to match typical foot traffic patterns.

The three-bar pattern provides a more subtle texture while still maintaining essential slip resistance. With just three ridges in its repeating pattern, it offers a good middle ground between safety and visual subtlety.

For environments where hiding scratches and wear is a priority, the stucco embossed pattern features a random, textured surface resembling stucco. This variation provides omnidirectional traction while more effectively concealing the inevitable marks that come with heavy use.

At American Mortuary Coolers, we can accommodate any of these pattern preferences based on your specific needs, though most of our clients find the classic diamond pattern offers the ideal balance of performance, durability and professional appearance for mortuary environments.

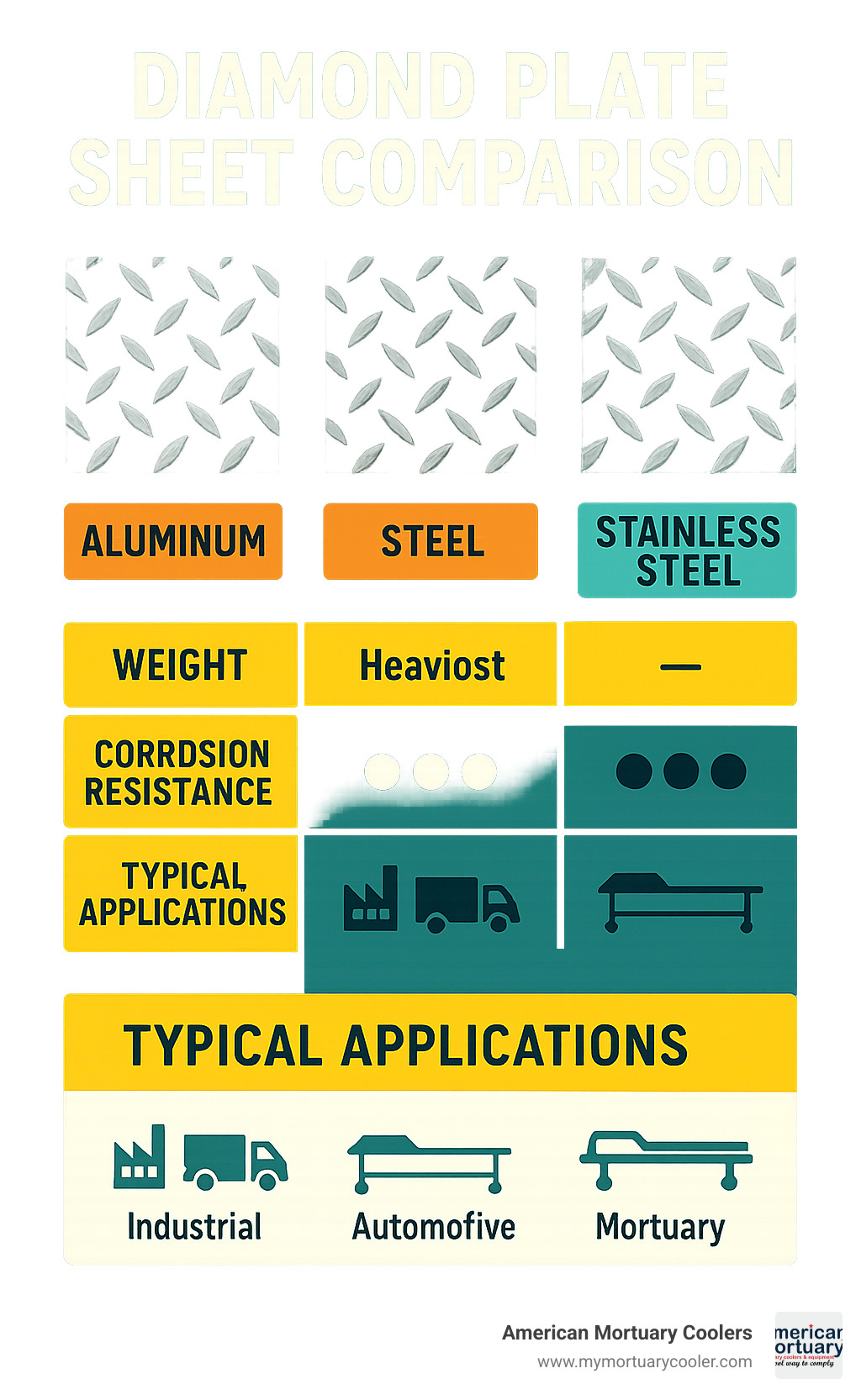

Material Showdown: Aluminum, Steel & Stainless

Choosing the right material for your dimond plate sheets is a bit like picking the perfect tool for a job – each option brings something special to the table. Let's break down these choices in a way that makes sense for your project.

Aluminum Diamond Plate

When it comes to aluminum, you've got two main players in the diamond plate world: 3003-H22 and 6061-T6 alloys.

Aluminum diamond plate gives you a fantastic combination of benefits. It's remarkably lightweight – about 66% lighter than steel, which means easier handling and installation. Your back will thank you! It naturally fights corrosion without needing special treatments, and it'll never rust, even in humid environments.

One thing I love about aluminum is its bright, eye-catching finish that adds a touch of industrial chic to any space. And when the product eventually reaches the end of its life? It's 100% recyclable, making it an environmentally friendly choice.

Of course, aluminum isn't without its drawbacks. It's not as strong as steel and can be more prone to dents and scratches. You'll also typically pay a bit more upfront compared to steel options.

As one of our suppliers puts it, "Aluminum diamond plate 3003-H22 alloy shines in decorative applications because of its beautiful polish and flexibility," while "6061-T6 offers up to twice the strength, making it the go-to choice when durability matters most."

Steel Diamond Plate

When maximum strength is non-negotiable, steel diamond plate steps into the spotlight.

Steel diamond plate is the workhorse of the bunch. It stands up to heavy loads, impacts, and abrasion like a champion. If you're outfitting an area that will see serious weight or traffic, steel deserves your consideration. It's also generally the most budget-friendly option upfront and welds beautifully for custom fabrication.

The tradeoffs? Steel is substantially heavier – about three times the weight of aluminum – which can make installation more challenging and may require additional structural support. It's also vulnerable to rust and corrosion unless properly treated, so you'll need to factor in the cost and maintenance of protective coatings for most applications.

Stainless Steel Diamond Plate

Think of stainless steel diamond plate as the premium option that blends the best of both worlds.

Stainless steel gives you exceptional corrosion resistance even in harsh environments like coastal areas or spaces with frequent cleaning using chemicals. Its chromium content (typically around 18% in Type 304 stainless) forms a protective layer that actually self-heals minor scratches through oxidation – pretty impressive technology from Mother Nature!

For applications where cleanliness is critical, like food service areas or medical facilities, stainless steel diamond plate is often the clear winner. It's NSF compliant for food-safe environments and maintains its appearance beautifully over time without special treatments.

The main consideration with stainless is cost – it represents the highest investment among these three options. Like carbon steel, it's also on the heavier side and requires specialized techniques for fabrication and welding.

For a deeper dive into stainless options, check out The Ultimate Guide to Stainless Diamond Plate on our site.

Aluminum Grades 3003-H22 vs 6061-T6

Let's take a closer look at the two aluminum alloys you'll most commonly encounter when shopping for dimond plate sheets.

3003-H22 aluminum is often called "Tread Bright" because of its eye-catching, mirror-like finish that many customers love for visible applications. It's the more formable option, making it ideal when you need to bend or shape the material. This alloy bends more easily without cracking, welds nicely, and still offers good corrosion resistance for most environments.

The trade-off is that 3003-H22 is softer, which means it's more susceptible to scratches and dents over time. This makes it better suited for decorative applications or areas with light to moderate use.

6061-T6 aluminum is the stronger, tougher cousin. With up to twice the strength of 3003-H22, it stands up remarkably well to heavy use and resists deformation under load. It typically comes in a mill finish that's less shiny but more practical for working environments.

Because of its hardness, 6061-T6 is less formable – it resists bending and requires more force to shape. However, this same quality makes it excellent for structural and industrial applications where durability matters more than formability.

At American Mortuary Coolers, we generally prefer 6061-T6 for our cooler floors. The added strength is essential for supporting heavy loads and withstanding frequent cleaning without wearing down.

Steel & Stainless Strength and Corrosion Resistance

When your project demands exceptional strength or needs to stand up to challenging environments, steel and stainless steel options really shine.

Steel diamond plate is the undisputed champion of strength. You'll find it in demanding applications like heavy-duty flooring, truck beds, and loading ramps where maximum load capacity is essential. It's the material of choice for fire trucks, emergency vehicles, and industrial settings where durability against impacts is critical.

The main consideration with steel is its vulnerability to rust. In most environments, you'll need to apply and maintain proper coatings or paint to keep rust at bay, which adds to the lifetime maintenance requirements.

Stainless steel diamond plate offers remarkable corrosion resistance thanks to its special composition. Type 304 stainless – the most common grade for diamond plate – contains approximately 18% chromium and 8% nickel. The chromium creates a passive oxide layer that acts like a shield against corrosion.

One of the most fascinating aspects of stainless steel is its self-healing properties. Minor scratches can actually "repair" themselves as the exposed metal forms a new oxide layer. This makes stainless ideal for environments with strict sanitation requirements like food processing facilities, marine applications, and yes – mortuary coolers.

"Stainless steel floor plate is the go-to choice in corrosive or marine environments," as one of our industry partners puts it. The exceptional performance in challenging conditions makes it worth the higher initial investment for many facilities.

For our mortuary coolers that need to maintain impeccable cleanliness while supporting heavy loads, stainless steel diamond plate flooring provides the perfect balance of durability and sanitization. That's why we often recommend it for medical examiners' facilities and high-volume funeral homes where performance can't be compromised.

Sizing, Thickness & Measurement Guide

Getting the right size and thickness for your dimond plate sheets is like choosing the right shoes – it needs to fit your project perfectly! Let's break down what you need to know about measurements so you can make the best choice for your needs.

Understanding Gauge & Thickness Specs

When you're looking at dimond plate sheets, thickness measurements only refer to the base metal itself – not including those raised diamond patterns on top. This distinction matters a lot when you're calculating how much weight your installation can handle.

Aluminum diamond plate comes in a range of thicknesses from whisper-thin 0.025 inches all the way up to hefty 0.5 inches. Most folks find that 0.063 inches (1/16 inch) hits the sweet spot between durability and weight for general applications.

Steel and stainless steel thickness is often described using gauge numbers, which can be a bit confusing at first. Just remember: the lower the gauge number, the thicker the material. Here's what that means in real terms:

| Thickness (inches) | Weight (lbs/sq ft) |

|---|---|

| 0.063 | 1.20 |

| 0.100 | 1.60 |

| 0.125 | 2.00 |

| 0.188 | 2.82 |

| 0.250 | 3.80 |

| 0.375 | 5.50 |

| 0.500 | 7.30 |

For lighter applications like decorative wall coverings, thinner sheets (0.045" or 0.063") will serve you well and keep weight down. But if you're creating flooring that needs to support heavy equipment – like in our mortuary coolers – you'll want to step up to thicker options like 0.125" or 0.250" to prevent bending under load.

As one of our suppliers puts it, "For veneer applications use 0.045" or 0.063"; for structural use, 0.125" or 0.250". Deflection depends on span and load." That's solid advice we've found to be true in our years of building durable mortuary equipment.

Standard Sheet Sizes & Custom Cuts

When it comes to size options, dimond plate sheets are like pizza – they come in standard sizes, but you can also get them cut exactly how you want them!

The most common size you'll find is the trusty 4' × 8' sheet, which offers the best value for most projects. But you can also find sheets ranging from small 1' × 1' squares all the way up to massive 5' × 12' sheets. Larger sheets mean fewer seams in your finished project, but they can be a bear to transport and handle without proper equipment.

Need a custom size? No problem! Most suppliers offer two main cutting options:

Shear cutting gives you clean, straight cuts with a tolerance of about ±0.062" at a lower cost, but it's limited to straight lines. If you need something fancier, laser cutting offers precision up to ±0.015" and can create complex shapes, though it typically includes a setup fee (around $65).

When ordering custom cuts, keep in mind that standard tolerances are ±1/16" unless you specifically ask for tighter measurements. And here's a money-saving tip: many suppliers offer quantity discounts – typically 10% off for 11-50 pieces and 20% off for 51+ pieces.

At American Mortuary Coolers, we're sticklers for precision. We source exactly-cut diamond plate for our mortuary units with carefully finished edges to prevent any sharp points that could cause injury or damage equipment. After all, when you're building equipment that needs to last for years in demanding environments, those details matter!

Looking for a quick way to save on your next project? Many suppliers offer promotions like Get $5 off when you sign up for emails with savings and tips.GO – a small savings that can add up when you're ordering multiple sheets.

From Factory to Floor: Manufacturing, Cutting & Installation

The journey of dimond plate sheets from raw material to finished installation is fascinating, involving several specialized processes that ensure you get a product that's not just beautiful, but built to last.

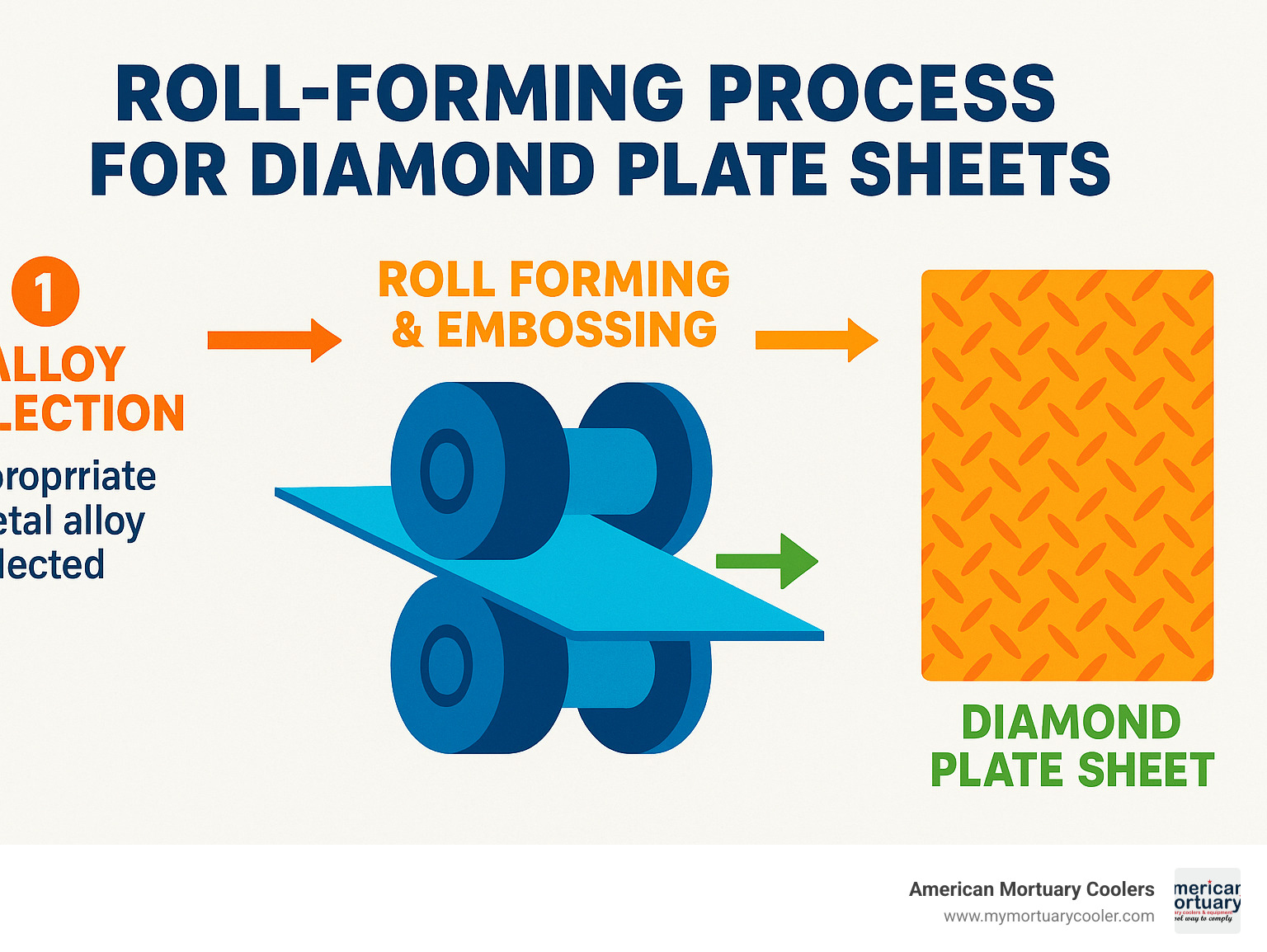

Roll Forming & Embossing Process

Creating dimond plate sheets isn't as simple as stamping a pattern onto metal. It's a carefully choreographed dance of heat, pressure, and precision.

The journey begins with selecting the right metal alloy for your needs. These raw materials are melted down and cast into large slabs or ingots that don't look anything like the finished product you'll eventually see.

Next comes the change process. Those thick ingots are heated and passed through massive rollers in what's called hot rolling – think of it as a giant metal pasta maker, stretching and thinning the metal. After that initial shaping, cold rolling further refines the thickness at room temperature, giving the metal its precise dimensions and improving its overall properties.

The magic happens during pattern embossing, where those distinctive diamond shapes are born. For aluminum, this can happen at room temperature, but steel needs to be heated to its recrystallization point before those high-pressure embossing rollers can work their magic.

"Roll-forming creates an upraised lug pattern that improves skid resistance, cleanability, impact resistance, support strength, and corrosion resistance," as one industry expert puts it. It's not just about looks – every aspect of that pattern serves a purpose.

After embossing, the sheets are cut to standard sizes, and depending on your needs, might receive additional treatments like anodizing, painting, or polishing. The quality you'll receive depends greatly on how well temperature, pressure, and rolling speed were controlled during manufacturing.

Fabrication Tips: Cutting, Drilling, Welding

Working with dimond plate sheets isn't quite the same as working with wood or other materials. With the right approach, though, you can achieve professional results even if you're a DIYer.

When cutting diamond plate, your best friends are circular saws, jigsaws, or bandsaws equipped with fine-tooth blades designed specifically for sheet metal. For thinner aluminum sheets (under 0.063"), you might even get away with using tin snips or hobby shears. Always support the sheet fully to prevent warping, and use cutting oil to reduce friction and heat. A pro tip: cut from the smooth back side when possible to keep that beautiful pattern intact.

Drilling requires sharp, high-quality bits designed for metal. Start with a center punch to give your drill bit a place to grip, and use cutting oil for larger holes. Apply steady, moderate pressure – let the tool do the work. Don't forget to deburr those holes afterward to remove any sharp edges that could cause injuries later.

If you're welding dimond plate sheets, your approach will depend on the material. For aluminum, TIG welding typically provides the cleanest results, while steel can be effectively joined with either MIG or TIG welding. Always clean the surface thoroughly before welding, and be aware that welding will affect any protective coating. Take time to carefully grind and finish your welds for a professional appearance.

Safety isn't optional when fabricating diamond plate. Always wear appropriate gloves, eye protection, and respiratory protection when necessary. Your fingers and lungs will thank you!

Installing Dimond Plate Sheets Safely

Whether you're adding dimond plate sheets to walls, floors, or stairs, proper installation ensures both safety and longevity.

For wall panels, start with a clean, dry, and structurally sound surface. A good construction adhesive or epoxy will create a strong bond, but consider adding mechanical fasteners like screws or rivets for extra security, especially in high-traffic areas. Remember to allow for expansion and contraction, particularly in outdoor applications where temperature fluctuations are common. Adding edge trim or J-molding gives a finished look while protecting potentially sharp edges.

Flooring installations require special attention to the subfloor – it must be level and clean for proper adhesion. Apply adhesive evenly and respect the manufacturer's curing times (rushing this step often leads to problems down the road). In high-traffic areas, supplementary mechanical fastening provides added security. Don't forget those transition strips where diamond plate meets other flooring materials for a seamless, trip-free surface.

Stairs and ramps deserve extra care since they present higher safety risks. Ensure proper support underneath, use fasteners rated for the expected load, and consider additional non-slip treatments for wet environments. If you're building public access features, follow ADA guidelines for ramp slopes and stair dimensions. Installing nosing on stair edges adds both safety and a professional finished look.

At American Mortuary Coolers, we've seen how properly installed diamond plate flooring dramatically improves both safety and durability in our mortuary units. As we detail in our article on American Mortuary Coolers Improve Safety and Durability with Diamond Plate Flooring, taking time with installation makes all the difference in long-term performance.

One installation guide we follow advises, "Ensure cam-lock spacing does not exceed 48 inches on center for structural strength and seal integrity." These small details make a big difference in the final result.

Real-World Applications & Cost Factors

Dimond plate sheets aren't just functional—they've become iconic in industries ranging from automotive to architecture. Their distinctive diamond pattern has transcended pure utility to become a symbol of rugged durability and industrial chic.

Industries & Use Cases

Walk through any industrial area, and you'll likely spot dimond plate sheets in numerous applications. Their versatility makes them a favorite across multiple sectors.

In the transportation world, these sheets have become almost standard equipment. You've probably seen them as truck bed liners, providing both protection and traction for cargo. They're equally at home in toolboxes (like the one pictured above), trailer floors, and as protective running boards that take daily abuse without complaint.

The industrial sector accepts dimond plate sheets for their practical benefits. Factory floors benefit from their slip resistance, while stair treads and catwalks become significantly safer when covered with this textured material. I've visited warehouses where loading dock ramps faced constant abuse from heavy equipment—the diamond plate surfaces showed barely a scratch after years of service.

For food service and medical applications, the easy-cleaning nature of these sheets makes them ideal. At American Mortuary Coolers, we've incorporated diamond plate flooring in countless units because they stand up to rigorous cleaning protocols while maintaining their non-slip properties. Walk-in coolers, freezers, and food processing facilities similarly benefit from this combination of durability and cleanability.

The marine environment presents unique challenges that dimond plate sheets handle beautifully. Boat decks and docks need surfaces that remain slip-resistant even when wet—something the raised diamond pattern excels at. The corrosion resistance of aluminum and stainless steel variants makes them particularly well-suited for these applications.

Perhaps most surprisingly, dimond plate sheets have found their way into decorative applications. What started as purely functional has become stylish. I've seen stunning accent walls in restaurants, bar fronts that catch the light beautifully, and even custom furniture that turns industrial materials into conversation pieces.

Budgeting: Material, Finish & Thickness Impact

When planning your project, understanding cost factors helps you make informed decisions that balance budget with performance needs.

Material choice significantly impacts your bottom line. Steel diamond plate typically offers the most economical entry point, making it perfect for indoor applications where corrosion isn't a major concern. Aluminum sits in the middle price range, offering a compelling balance of weight, corrosion resistance, and cost. Stainless steel, while commanding a premium price, often proves its worth in harsh environments through reduced maintenance and extended lifespan.

Thickness considerations aren't just about strength—they directly affect your wallet too. As one of our suppliers often reminds us, "Every doubling of thickness roughly doubles the price." For non-structural applications like wall protection, thinner gauges (0.063" or less) may be perfectly adequate. High-traffic flooring, however, benefits from thicker material (0.125" or greater) that resists deformation under load.

Finish options add another dimension to budgeting. Mill finish aluminum provides industrial functionality at the lowest price point, while polished finishes add visual appeal at a modest cost increase. Specialized coatings for improved slip resistance or colored finishes can add 15-30% to base material costs but may be worth it for specific applications.

Don't overlook fabrication costs in your budgeting. While standard 4'×8' sheets offer the best value, custom cutting (around $35 per cut) and bending services (approximately $75 per bend) quickly add up. As one fabricator told me with a wink, "We're not cutting corners, we're just taking a break to sharpen our skills"—a humorous reminder that quality fabrication is worth the investment.

Volume discounts can substantially reduce costs for larger projects. Most suppliers offer tiered pricing, with discounts of 10-20% for bulk orders. If your project requires multiple sheets, consolidating your purchase can lead to significant savings.

At American Mortuary Coolers, we've found that investing in quality materials up front often results in lower lifetime costs. A mortuary cooler floor made from premium dimond plate sheets might cost more initially, but when it's still performing flawlessly after a decade of daily use, that investment proves its worth many times over.

Care, Maintenance & Safety Compliance

Let's face it – you've invested in dimond plate sheets for their durability and good looks, so naturally you want to keep them in top condition for years to come. With just a little routine care, your diamond plate surfaces will continue to shine and perform beautifully while meeting essential safety standards.

Cleaning & Oxidation Prevention

Keeping your dimond plate sheets clean isn't just about appearance – it's also essential for maintaining that all-important slip resistance that makes diamond plate so valuable in the first place.

For everyday cleaning, simplicity is your friend. A mixture of mild soap and water is typically all you need to keep your diamond plate looking great. Grab a soft cloth or brush (nothing abrasive that might scratch the surface), and give it a gentle scrub. After cleaning, always rinse thoroughly – soap residue can be surprisingly slippery, which defeats the whole purpose of your textured surface!

What you don't want to use is equally important. Harsh chemicals can damage protective finishes and actually shorten the life of your diamond plate. For aluminum surfaces in particular, avoid strongly alkaline cleaners with a pH above 10, as these can etch the surface and dull that beautiful finish.

Over time, aluminum dimond plate sheets naturally develop a protective oxide layer – it's part of what makes aluminum so resistant to corrosion. However, this can sometimes appear as a white, chalky residue. Don't worry! This isn't damage; it's just nature doing its thing. If appearance matters, a specialized aluminum polish can restore the shine.

For steel diamond plate, rust prevention is the name of the game, especially in humid environments. As one of our suppliers likes to say, "An ounce of prevention is worth a pound of rust removal." A protective coating of rust-inhibiting paint can save you countless hours of maintenance down the road.

At American Mortuary Coolers, we've found that our stainless steel diamond plate surfaces stand up beautifully to the disinfectants commonly used in mortuary environments. For these surfaces, regular cleaning is usually all that's needed to maintain both appearance and function.

"Apply paint or a clear coat finish for long-term outdoor durability," recommends one of our trusted suppliers. This extra step can make a world of difference for outdoor applications where elements constantly challenge your metal surfaces.

Safety & Regulatory Notes

When it comes to dimond plate sheets in commercial settings, safety isn't just a good idea – it's often the law. Understanding the regulatory landscape helps ensure your installation remains compliant while protecting users.

While diamond plate provides better traction than smooth metal, it's important to understand its limitations. As one candid supplier puts it, "Diamond plate is not a true grip surface and becomes very slick when wet or snow-covered." This honest assessment reminds us that in areas frequently exposed to water, ice, or oils, additional safety measures may be necessary.

The Americans with Disabilities Act (ADA) provides specific guidelines for slip resistance on accessible routes. If your diamond plate installation is part of a public access area, you'll need to ensure it meets these standards. Similarly, OSHA has workplace safety requirements regarding floor surfaces that may apply to your industrial applications.

For food service environments, material selection becomes even more critical. Dimond plate sheets used around food preparation must meet NSF certification requirements. This is why stainless steel diamond plate is typically the go-to choice for these applications – its non-porous surface can be thoroughly sanitized without harboring bacteria.

California's Proposition 65 is another consideration for some metal products, particularly those containing lead or other regulated substances. Be sure to check if your specific diamond plate material requires these warnings, especially if you're selling products incorporating diamond plate to California residents.

Fire safety ratings may also come into play for certain applications. While metal diamond plate is generally non-combustible (good news!), it can transfer heat effectively (potentially bad news in a fire scenario). Understanding these properties helps you make informed decisions about where and how to use diamond plate in your facility.

At American Mortuary Coolers, we've made it our business to ensure all materials in our products comply with relevant industry standards. When we incorporate dimond plate sheets into our mortuary coolers, we're not just thinking about durability and appearance – we're considering the full spectrum of safety considerations that provide our clients with both protection and peace of mind.

For those particularly challenging environments where standard diamond plate might not provide sufficient traction, don't worry – solutions exist. Anti-slip coatings and applied grip tapes can supplement the natural texture of diamond plate in areas like ramps, stairs, or zones frequently exposed to moisture.

Frequently Asked Questions about Diamond Plate

What thickness of diamond plate should I use for flooring?

Choosing the right thickness for dimond plate sheets in flooring applications doesn't have to be complicated, though it does depend on how you'll be using the space.

For most homeowners installing diamond plate over a well-supported subfloor, a 0.063" (1/16") aluminum sheet works beautifully. It's lightweight enough to handle easily but still provides that distinctive industrial look and feel.

If you're outfitting a commercial space with regular foot traffic, I'd recommend stepping up to 0.125" (1/8") thickness. This sweet spot balances cost with durability for most business applications.

For industrial environments where you'll have heavy equipment rolling around, don't skimp – go with 0.188" (3/16") or 0.250" (1/4") thickness. Your future self will thank you for the investment when that flooring still looks great years later!

The support structure underneath matters too. The closer together your floor joists or supports are placed, the thinner your diamond plate can be. Conversely, wider spans between supports call for thicker material to prevent that unsettling bounce when people walk across.

Here at American Mortuary Coolers, we've found that 0.125" or 0.188" diamond plate hits the perfect balance for our mortuary cooler floors. This thickness stands up admirably to the weight of bodies and transport equipment without showing wear.

How do I cut aluminum diamond plate without warping it?

Cutting aluminum dimond plate sheets without ending up with a warped mess is absolutely doable with a little preparation and the right approach.

Support is everything. Before making any cuts, ensure your sheet is completely supported on both sides of your cutting line. This prevents the dreaded flex that leads to warping. I like to use a sturdy workbench with scrap wood underneath to provide even support.

Tool selection makes a difference. For thinner sheets (under 0.063"), a good pair of tin snips can work wonders. For thicker material, reach for a circular saw with a fine-tooth blade specifically designed for aluminum. Making curves? A jigsaw with a metal-cutting blade is your friend.

Slow and steady wins the race. Maintain a consistent, moderate cutting speed – rushing through the cut generates heat, and heat leads to warping. Think of it as a marathon, not a sprint.

A little lubricant goes a long way too. I keep WD-40 or dedicated cutting lubricant handy to reduce friction and heat buildup during cutting. Just a light spray along your cutting line makes a noticeable difference.

Whenever possible, cut from the back (flat) side rather than trying to cut through the raised diamond pattern. The saw blade will thank you, and you'll get a cleaner cut.

For truly precision cuts or complex shapes, don't hesitate to call in the professionals. Water jet or laser cutting services minimize heat and pressure on the material, giving you perfect results without the headache.

Is diamond plate really non-slip when wet or icy?

Let's be honest about dimond plate sheets and slip resistance – they're better than flat metal, but they're not magic.

The raised diamond pattern definitely improves traction compared to smooth metal surfaces – about 30% better in dry conditions. You can feel the difference underfoot immediately. However, when water, oil, or ice enters the picture, even diamond plate can become treacherously slippery.

As one of our suppliers bluntly puts it: "Diamond plate is not a true grip surface and becomes very slick if wet or snow-covered." This is crucial to understand if you're planning an outdoor installation or in areas that might get wet.

If you're dealing with potentially wet conditions, consider these practical solutions:

Anti-slip coatings or adhesive grip tape designed specifically for metal surfaces can dramatically improve safety. These products are relatively inexpensive insurance against slips and falls.

Material choice matters too. Aluminum tends to become more slippery when wet compared to steel, which might influence your selection for outdoor steps or ramps.

Regular cleaning is non-negotiable. Even the best diamond plate becomes hazardous when contaminated with oil, grease, or other slippery substances.

In our mortuary coolers, where bodily fluids are an unfortunate reality, we often recommend additional non-slip treatments or patterns specifically designed to channel liquids away from walking surfaces. Safety comes first, especially in environments where workers are often carrying heavy, precious cargo.

Conclusion & Next Steps

After exploring dimond plate sheets together, it's clear why these versatile metal surfaces have become such popular options across countless industries. From providing safe, durable flooring in mortuary coolers to adding that perfect industrial touch to a custom garage, diamond plate combines practical benefits with distinctive character that's hard to match.

Throughout this guide, we've covered the essentials you need to make informed decisions about your next diamond plate project. Let's take a moment to reflect on what we've learned.

When selecting your dimond plate sheets, your material choice fundamentally shapes performance. Aluminum offers lightweight corrosion resistance, steel provides economical strength, and stainless delivers the ultimate in durability and sanitation. I've seen clients light up when they find the perfect match for their specific needs—whether that's a mortician who needs easy-to-clean surfaces or a boat owner looking for lightweight traction.

Thickness isn't just a specification—it's the difference between a surface that performs beautifully for years and one that disappoints quickly. For decorative applications like wall panels, thinner gauges (0.025"-0.063") often suffice, while structural uses like flooring typically demand thicker options (0.125"-0.250"). At American Mortuary Coolers, we've learned through years of experience which thicknesses stand up to the daily challenges of mortuary environments.

The pattern you choose affects both function and aesthetics. While the classic diamond pattern remains most popular for good reason, don't overlook alternatives like checker plate or five-bar patterns if they better suit your specific needs. Each pattern creates a slightly different underfoot feel and visual impact.

When it comes to working with dimond plate sheets, proper fabrication techniques make all the difference. I've seen beautiful installations ruined by improper cutting or drilling, and masterful projects liftd by careful attention to detail. Take your time, use the right tools, and don't hesitate to seek professional fabrication for complex requirements.

Maintenance isn't complicated, but it is essential. Regular cleaning with appropriate products will preserve both function and appearance, while protective treatments can significantly extend service life in challenging environments. A little care goes a long way with diamond plate surfaces.

At American Mortuary Coolers, we've incorporated diamond plate into our products for decades because it simply works. Our mortuary coolers face demanding conditions—frequent cleaning, heavy loads, and the need for absolute sanitation—and quality diamond plate surfaces continue to prove their worth year after year.

If you're planning your own diamond plate project, I'd encourage you to:

Take time to thoroughly assess your specific needs, considering environmental conditions, load requirements, and aesthetic goals before making decisions.

Request material samples whenever possible. There's simply no substitute for holding actual pieces in your hands to compare finish quality, pattern depth, and gauge options.

Look beyond initial price to consider total lifetime cost, including installation, maintenance, and expected service life. The least expensive option upfront often costs more in the long run.

Tap into expert knowledge, especially for specialized applications. Whether it's our team at American Mortuary Coolers or specialists in your particular industry, experienced advice can save you from costly mistakes.

Whether you're outfitting a professional facility or enhancing your personal space, the right diamond plate solution provides years of reliable service while adding that distinctive industrial character that's both functional and visually striking.

For more information on our mortuary coolers featuring premium diamond plate surfaces, visit your-one-stop-shop-for-mortuary-coolers-mymortuarycooler-com. American Mortuary Coolers delivers custom, durable solutions nationwide from our facilities across the country, including Johnson City TN, Atlanta GA, Chicago IL, and other major metropolitan areas.