Why Pet Cremation Equipment Represents Today's Hottest Mortuary Investment

Pet cremation equipment for sale is experiencing unprecedented demand as the companion animal aftercare market explodes nationwide. With over 90 million dogs and 94 million cats in American homes, the pet cremation industry has become a $2 billion market that's growing 15% annually.

Top Pet Cremation Equipment Categories Available Today:

- Single-Chamber Units: $21,700-$75,000 | 75-200 lbs capacity | 1-7 pets/day

- Multi-Chamber Systems: $85,000-$180,000 | 4-9 chambers | 30-60 pets/day

- Large Animal/Equine: $120,000-$250,000 | 1,200-2,000 lbs capacity | Livestock & horses

- Processing Equipment: $3,500-$35,000 | Remains processors, lifts, cooling racks

The numbers tell the story. A small Firelake A-model cremator costs $21,700 and generates $47,520 annually with just one cremation per day at $180 each. That's a $20,332 net profit yearly after operating costs - meaning full payback in under five years with 10+ years of profitable operation ahead.

Modern pet cremation equipment offers weight-based automation, secondary afterburners for odor control, and multi-chamber designs that preserve individual remains integrity. Leading manufacturers like Addfield, Matthews, Keller, and B&L provide UL-listed systems with remote diagnostics and comprehensive service support.

I'm Mortuary Cooler, a national-level mortuary equipment supplier with extensive experience helping facilities select the right pet cremation equipment for sale based on capacity needs and budget constraints. My background in mortuary cooling systems gives me unique insight into the complete workflow from storage through final processing.

Simple pet cremation equipment for sale word guide:

Quick-Glance Comparison of Pet Cremation Equipment for Sale

Shopping for pet cremation equipment for sale starts with one crucial decision: single-chamber versus multi-chamber systems. Single-chamber units handle one cremation at a time, making them ideal for small veterinary clinics. Multi-chamber systems process multiple pets simultaneously while keeping remains completely separate.

| Feature | Single-Chamber | Multi-Chamber |

|---|---|---|

| Capacity | 100-2,000 lbs | 200-1,000 lbs per chamber |

| Throughput | 1-15 pets/day | 30-60+ pets/day |

| Privacy | One at a time | Up to 9 simultaneous |

| Price Range | $21,700-$120,000 | $85,000-$250,000 |

| Best For | Small clinics, rural areas | High-volume facilities |

Keller's subcompact units process 75 lbs per hour, while their large systems handle 400 lbs hourly. Addfield's PET-200 manages up to 7 pets daily, but their A50-IC(4) processes 60 pets per day through its four-chamber design.

Single-Chamber Units: Entry-Level Choices

The Firelake A-model at $21,700 delivers complete cremation capability with excellent ROI. With one cremation daily at $180, you're looking at $20,332 annual net profit after operating costs - a 5-year payback with over 10 years of profitable operation ahead.

Keller's KMA-1200-75 features robust construction with 75 lbs/hr burn rates and 300-lb capacity. The hot-hearth design and cast refractory lining provide superior heat retention, reducing fuel costs. Touch-screen controls eliminate operator training complexity.

Addfield's PET-200 brings British engineering precision to small operations, processing up to 7 pets daily with DEFRA approval and EU compliance - crucial for international markets.

Multi-Chamber Units: High-Volume Solutions

Addfield's A50-IC(4) leads with four independent chambers processing 60+ pets daily. Each chamber operates with individual controls, ensuring complete privacy while maximizing throughput. The British build quality supports decades of operation.

B&L's BLP-500 M3 offers three-chamber functionality with their pioneering multi-door design and Hot Hearth System for improved efficiency.

Matthews' IEB-32-5S features sealed-chamber technology preventing cross-contamination and Tek Marshal remote diagnostics reducing service calls.

Large-Animal & Equine Systems

B&L's BLP-2000 handles 2,000-lb maximum loads with reinforced construction for horses and cattle. Keller's Batch 1200 processes 1,200-lb loads with 400 lbs/hr burn rates and large door openings for easy loading.

Addfield's TB-AB equine cremators target the horse industry with chambers optimized for equine proportions and hot-hearth design ensuring complete bone combustion.

Key Buying Considerations & Must-Have Features

Shopping for pet cremation equipment for sale requires understanding essential features that make operations efficient and compliant. Modern systems offer weight-based automation that automatically adjusts burn cycles based on actual case weight - no more guessing cycle times.

Secondary afterburners operating at 1,600-1,800°F eliminate odors and smoke completely while meeting EPA regulations. UL and CSA listings provide safety validation, while DEFRA approval keeps international options open.

Remote diagnostics like Addfield's Tek Marshal system allow technicians to monitor equipment and diagnose issues remotely, often fixing problems without site visits.

More info about choosing features

Capacity & Throughput Planning

Seasonal variations catch many operators off guard - veterinary clinics often see 40% higher volumes during winter months. Multi-chamber systems excel here, allowing you to run fewer chambers during slow periods while having full capacity ready for busy seasons.

Chamber size versus load volume requires balance. A 500-pound chamber processing a 50-pound pet wastes energy, but cramming a 400-pound animal doesn't allow proper air circulation.

Hot-hearth systems typically finish 20-30% faster than cold-hearth alternatives through retained heat between cremations. Weight-based automation optimizes times further by eliminating fixed timer settings.

Emissions, Safety & Regulatory Compliance

Secondary afterburners now represent minimum requirements in most areas, maintaining 1,600°F minimum temperatures with proper retention time to destroy volatile compounds completely.

Opacity limits typically restrict visible emissions to 10% or less using EPA Method 9 protocols. CANA membership and CPCO certification provide industry-recognized training covering combustion theory and safe operating practices.

Safety features include flame safeguards, high-temperature cutoffs, and emergency shutdown systems as standard equipment.

Automation, Monitoring & Remote Support

Touch-screen PLC controls replace confusing mechanical timers while automatically logging performance data for regulatory compliance. Automated loading systems eliminate manual lifting hazards in high-volume operations.

Data logging capabilities track cycle times, temperatures, fuel consumption, and maintenance intervals, supporting regulatory reporting while identifying optimization opportunities.

Remote support capabilities enable manufacturers to diagnose problems and adjust parameters without site visits - especially valuable for rural installations.

Spotlight on Leading Manufacturers & Hot Models

When shopping for pet cremation equipment for sale, knowing manufacturers helps you pick equipment that fits your operation perfectly.

Addfield Environmental Systems brings over 40 years of British engineering excellence with equipment operating in 150+ countries. Their craft-built quality features time-served craftsmen and premium refractory materials throughout.

Matthews Environmental Solutions focuses on automation and efficiency with weight-based operation systems and remote diagnostics. ISO certification and global service networks provide worldwide support.

Firelake Manufacturing offers the industry's lowest entry costs while delivering 15-year operational life. Straightforward designs keep maintenance simple - perfect for rural areas.

Keller Manufacturing builds tank-like equipment handling continuous operation. UL-listed components and comprehensive automation appeal to municipal and commercial operators.

B&L Cremation Systems pioneered multi-chamber technology and Hot Hearth systems. As the largest family-owned independent manufacturer, they offer extensive customization with direct factory support.

Budget-Friendly Pet Cremation Equipment for Sale

Firelake's A-series remains the gold standard for budget-conscious buyers at $21,700. Financial analysis shows 5-year payback periods with over 10 years of profitable operation ahead.

Addfield's PET-200 brings premium British engineering without premium pricing, processing up to 7 pets daily with build quality justifying extended operational life.

Keller's KMA subcompact series features hot-hearth design and cast refractory lining providing superior heat retention and lower fuel costs compared to alternatives.

Fetching Deals on Pet Crematories You Can Own

Premium Pet Cremation Equipment for Sale

Addfield's A50-IC(4) represents multi-chamber technology pinnacle with four independent chambers processing 60+ pets daily. British build quality and global service support installations worldwide.

Matthews' IEB-32-5S incorporates sealed-chamber technology and weight-based automation eliminating operator guesswork. Remote diagnostics reduce service calls significantly.

B&L's BLP-1000 M8 offers eight-chamber capability with Hot Hearth System and separate remains removal technology streamlining operations while maintaining complete privacy.

Game-Changing Accessories & Upgrades

Matthews' ACP-200 Animal Cremains Processor completes processing in 30 seconds with quiet, dust-proof operation. Hydraulic lift systems eliminate manual lifting hazards while ensuring consistent procedures.

Automated urn loaders complete workflows by transferring processed remains directly into containers. Cooling racks and receiving stations organize workflow and improve efficiency during peak periods.

Costs, Financing & ROI Math

Understanding the complete financial picture helps you make smart decisions about pet cremation equipment for sale. Equipment prices start at $21,700 for basic units and climb to $250,000+ for multi-chamber systems. Installation typically adds 25-50% to equipment costs.

Entry-level units ($21,700-$45,000) offer single-chamber operation with basic automation. Mid-range systems ($45,000-$120,000) provide bigger capacity with improved features. Premium equipment starts at $120,000 for multi-chamber systems.

Operating expenses include fuel ($24-$50 per cremation), electricity, maintenance, and labor. Profit margins typically hit 30-50% after all costs, with premium services reaching 60%+.

The Real Price of Pet Incinerators: What You Need to Know

Typical Price Brackets & What Drives Them

Chamber count makes the biggest pricing impact. Multi-chamber systems cost 2-3 times more than comparable single-chamber units due to complex controls and multiple burners.

Refractory quality varies dramatically. Premium systems use high-alumina refractories handling thermal cycling better than basic fire brick, costing more upfront but saving through longer life.

PLC sophistication ranges from simple timers to advanced weight-based automation with remote diagnostics, adding $10,000-$25,000 but often paying for themselves through efficiency.

Emission control systems represent increasingly important costs. Basic secondary burners add $15,000-$25,000, while sophisticated scrubbers can exceed $50,000.

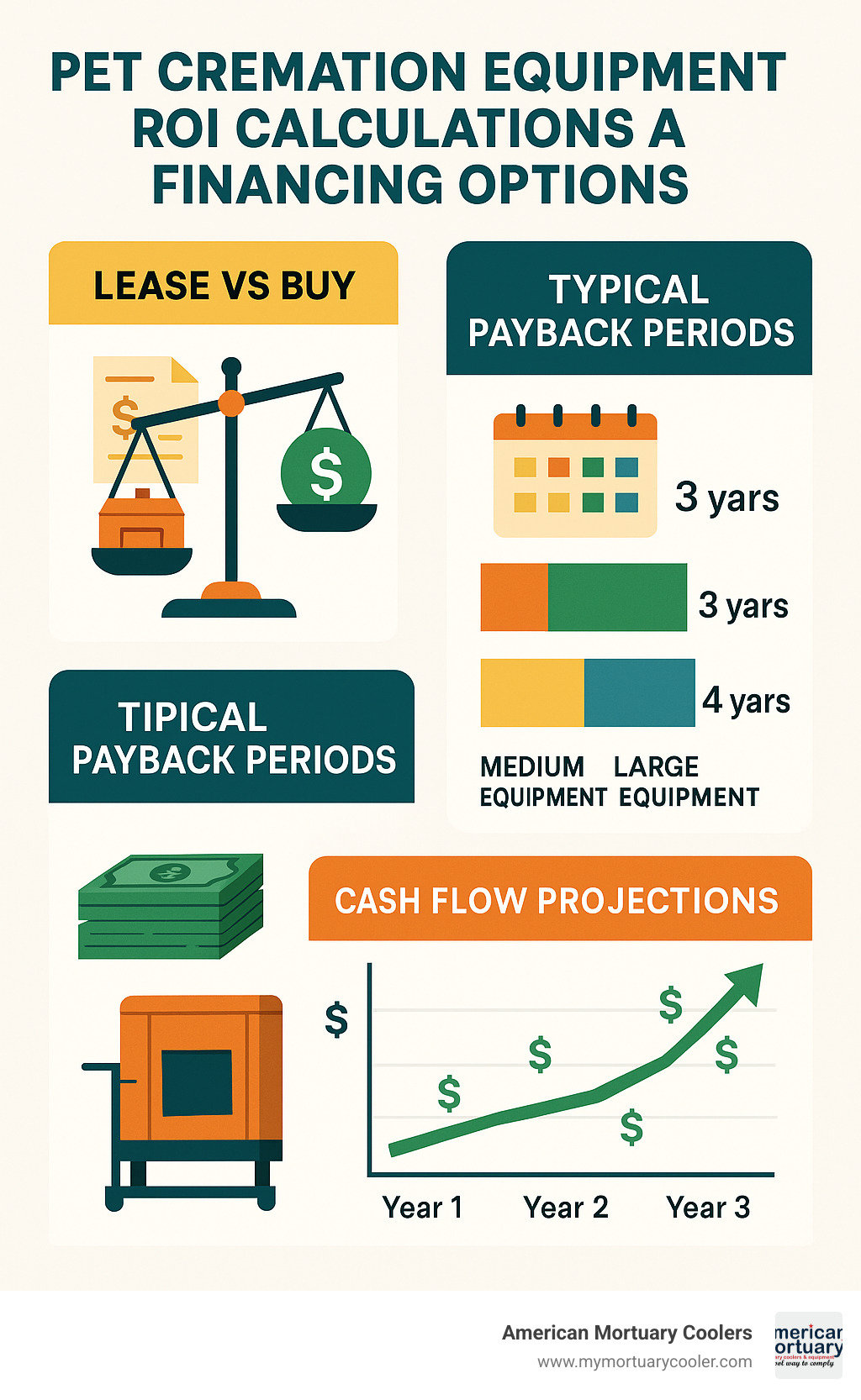

Financing Options & Leasing Paths

Traditional bank loans offer lowest interest rates with strong credit. SBA loans provide longer terms and lower down payments for qualifying small businesses.

Equipment leasing preserves capital with potential tax advantages. Many manufacturers offer financing programs with competitive terms and simplified approval processes.

Lease-to-own programs enable immediate operations while building equity toward ownership - particularly helpful for new businesses without established credit histories.

Return on Investment Examples

One Cremation Daily with Firelake A-series costs $29,700 total investment. Daily cremations at $180 generate $47,520 annual revenue with $20,332 net profit - 4.2-year payback.

Seven Daily Cremations with Addfield PET-200 requires $80,000 investment. Seven daily cremations generate $332,640 revenue with $107,640 net profit - 2.2-year payback.

Sixty Daily Cremations with premium multi-chamber equipment costs $225,000 investment. Processing 60 cremations daily generates $2,851,200 revenue with $1,426,200 net profit - 1.9-year payback.

Payback periods consistently fall within 2-5 years across all categories when properly sized. With 15-year equipment life, you get 10+ years of profitable operation after payback.

Installation, Maintenance & Ongoing Support

Getting pet cremation equipment for sale operational successfully requires proper installation, ongoing maintenance, and support systems. Most cremators need concrete pads rated for their weight with 3-4 feet clearance on all sides for service access.

Zoning compliance often requires conditional use permits for crematory operations. Sort this out before ordering equipment to avoid delays and expensive design changes.

Utility requirements include 200+ amp electrical service, properly sized gas lines, and adequate water pressure. Professional installation maintains warranty coverage - most manufacturers require factory-authorized installation.

From Paws to Peace: A Guide to Pet Cremation Equipment

Site Prep & Utilities Checklist

Foundation requirements start with reinforced concrete pads at least 6 inches thick, extending 12 inches beyond equipment on all sides. Pads must be level within 1/4 inch.

Gas service requires natural gas at 1/2 PSI minimum or adequate propane capacity. Emergency shutoff valves within 25 feet and pressure testing before startup are mandatory.

Electrical service typically needs 200-400 amps with dedicated circuits and emergency disconnect switches visible from equipment locations.

Stack height follows manufacturer specifications and local codes with proper clearances. Water and drainage include adequate pressure for cleaning and floor drains for wash-down procedures.

Training, Warranty & Service Plans

CPCO certification covers combustion theory, safety procedures, and regulatory compliance. Many jurisdictions require this training for permits and insurance.

Warranty coverage typically includes one year parts and labor, but requires authorized installation and proper training. Extended warranties are available for critical components.

Service plans range from basic annual maintenance to comprehensive 24/7 support. Remote diagnostics provide automatic alerts and predictive maintenance scheduling.

Ancillary Gear & Workflow Optimization

Remains processors like Matthews ACP-200 complete processing in 30 seconds. Hydraulic lift tables eliminate manual lifting while ensuring consistent procedures.

Mobile receiving stations organize intake processing, while storage refrigeration handles temporary holding during backlogs. Urn loading systems provide professional presentation justifying premium pricing.

Workflow optimization often provides greater impact than equipment upgrades alone. Well-designed facilities with appropriate supporting systems process more volume with fewer operators while maintaining higher service quality.

Frequently Asked Questions about Buying Pet Cremation Equipment

How do single-chamber and multi-chamber cremators differ?

Single-chamber cremators handle one companion at a time, perfect for small veterinary clinics or funeral homes starting pet services. Costs range $21,700-$120,000, processing 1-15 pets daily.

Multi-chamber systems handle multiple pets simultaneously while keeping remains completely separate. These feature 3-9 independent chambers with individual controls, costing $85,000-$250,000 but processing 30-60+ pets daily.

The decision comes down to volume needs. Under 10 pets daily, single-chamber units serve beautifully. Higher volumes requiring individual cremation integrity need multi-chamber systems.

Multi-chamber systems provide incredible flexibility - run fewer chambers during slow periods, fire up all chambers when demand spikes during winter months.

What permits and environmental tests are required?

Most locations require conditional use permits for crematory operations - call local authorities before shopping for equipment. Environmental requirements have become standardized with secondary afterburners for odor control now mandatory in most places.

Opacity limits typically restrict visible emissions to 10% or less with periodic stack testing using EPA protocols required. Operator certification through CPCO programs often proves mandatory for permit approval.

Zoning varies significantly - some areas restrict crematory operations entirely while others require special setbacks. A few jurisdictions require public hearings before approving permits.

Engage environmental consultants familiar with local regulations early in planning. They'll guide equipment selection, handle permits, and ensure long-term compliance.

Can I start small and expand capacity later?

Absolutely - it's one of the smartest approaches. Many manufacturers design systems with expansion in mind, offering clear upgrade paths and modular designs letting you add chambers to existing installations.

Some manufacturers offer trade-in programs when you outgrow initial equipment. Plan for expansion from day one - oversized utilities, extra space, and proper foundations prevent costly modifications later.

Size initial equipment for realistic 3-5 year volume projections rather than current needs. Conservative sizing often proves more profitable than aggressive expansion creating expensive excess capacity.

Conclusion

The pet cremation equipment for sale market offers tremendous opportunities for smart operators. With pet families spending over $2 billion annually on aftercare services and 15% annual growth, there's never been a better time to enter this compassionate industry.

Success lies in scaling smart rather than going big immediately. That Firelake A-model at $21,700 pays for itself in under five years with just one cremation daily, while operators jumping to $250,000 multi-chamber systems often struggle until volumes catch up.

Choosing the right features makes the difference between profitable operations and expensive headaches. Weight-based automation saves fuel costs, secondary afterburners satisfy regulators, and remote diagnostics prevent service emergencies.

ROI math works beautifully when matching equipment to realistic demand. Rural clinics generate $20,000+ annual profits with entry-level units, while high-volume facilities clear over $1 million yearly with premium systems.

This industry combines meaningful service with solid business fundamentals - helping families through difficult moments while building profitable enterprises operating successfully for decades.

At American Mortuary Coolers, we've helped hundreds of facilities plan pet cremation operations from our Tennessee headquarters. Our mortuary cooling systems experience provides unique workflow insight from temporary storage through final processing.

Whether you're a funeral director adding pet services, veterinarian seeking in-house solutions, or entrepreneur launching a dedicated crematory, we deliver custom solutions with direct shipping across the contiguous 48 states.

Success comes down to quality equipment matching your needs, proper installation and training, and ongoing support when needed. Get these right, and you'll build a business serving your community while generating strong returns for years to come.