The Complete Guide to Comparing Embalming Stations

Why Modern Embalming Stations Transform Prep Room Efficiency

Embalming stations- are specialized stainless steel workstations that serve as the central hub for fluid management, body preparation, and chemical processing in funeral home prep rooms. These essential units combine sinks, aspirators, mixing faucets, and safety equipment into one integrated system.

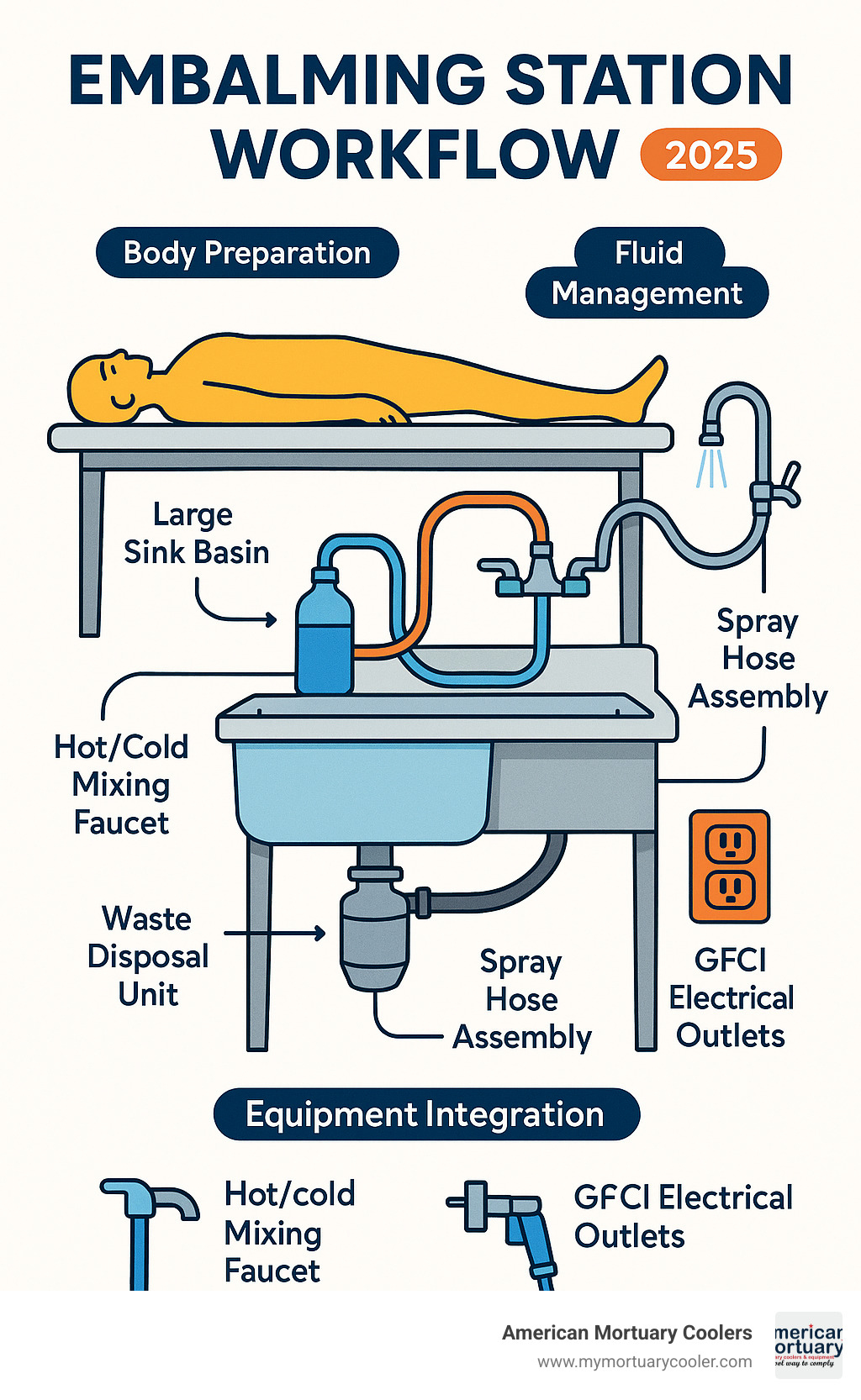

Key Components of Embalming Stations:

- Large sink basin - for washing and fluid collection

- Hydro aspirator - removes bodily fluids during preparation

- Hot/cold mixing faucet - feeds embalming machines with proper temperature control

- GFCI electrical outlets - power embalming equipment safely in wet environments

- Spray hose assembly - rinses surfaces and equipment

- Waste disposal unit - grinds solid waste for proper drainage

Today's prep rooms require medical-grade environments with hard, nonabsorbent surfaces like tile, stainless steel, and concrete - similar to hospital surgical suites.

Most embalming stations are constructed from 304-grade stainless steel for maximum durability and corrosion resistance. Prices typically range from $5,795 to $21,995 depending on features like eyewash attachments, flushing systems, and customization options.

Whether you're upgrading an existing prep room or designing a new facility, choosing the right embalming station impacts workflow efficiency, safety compliance, and long-term operational costs.

I'm Mortuary Cooler, a national-level mortuary equipment supplier specializing in embalming stations- and related prep room solutions. With years of experience helping funeral homes optimize their facilities, I've seen how the right station selection can streamline operations and improve service quality.

Know your embalming stations- terms:

Understanding Embalming Stations: Definition, Purpose & Core Workflow

Embalming stations- serve as the command center of any prep room - they're where science meets compassion in the funeral industry. At its heart, embalming is "the disinfecting, preserving and restoration of the dead human body to a natural form and color." These specialized workstations make this delicate process possible by combining multiple functions into one integrated system.

Embalming stations- create a sterile, controlled environment where funeral professionals can preserve remains with dignity while safely managing hazardous chemicals. Modern stations have revolutionized the industry by integrating functions that once required separate pieces of equipment scattered around the prep room.

Key Functions of embalming stations-

Arterial injection stands as the most critical function of any embalming station. The high-spout mixing faucet supplies water at the exact temperature needed for embalming machines to create proper chemical dilutions. Most quality stations accommodate popular machines like the Duotronic and Porti-Boy models.

Drainage systems handle the complex mix of waste streams that embalming generates. The oversized sink basin captures everything from rinse water to displaced bodily fluids and chemical runoff. Advanced stations include perimeter rinse assemblies that ensure every surface gets thoroughly cleaned after each procedure.

Cavity aspiration removes fluids from internal organs and body cavities using the station's hydro aspirator. This system uses water pressure to create powerful suction, drawing materials through specialized tubing. Modern units feature reverse-flow capabilities that instantly clear clogs by reversing water pressure.

Chemical mixing happens through integrated water control systems that blend hot and cold water to achieve optimal temperatures for different embalming solutions. Getting the temperature right is crucial because it directly affects how chemicals react and distribute throughout the body.

Anatomy of a Modern Station

The high-spout faucet serves as the heart of the entire fluid management system. These are built with extended reach and precise flow control, specifically designed to accommodate the height requirements of embalming machines while providing easy access for manual tasks.

Hydro aspirators include anti-clogging heads and reverse-flow mechanisms that prevent the frustrating blockages that used to interrupt procedures. The aspirator connects to both water supply and drainage systems, using water pressure differentials to create the suction power needed for thorough fluid removal.

Disposal units typically feature robust 0.75 horsepower motors designed to grind organic waste materials efficiently. These units connect directly to your facility's drainage system and help prevent blockages.

GFCI electrical receptacles with waterproof covers are now standard equipment on quality stations. These safety devices protect operators from electrical hazards in the inherently wet environment of prep rooms.

Spray hose assemblies provide the targeted cleaning power that makes thorough sanitation possible. These retractable units let embalmers rinse specific areas without flooding the entire workspace.

Types, Features & Materials of embalming stations-

Choosing the right embalming stations- becomes easier once you understand what works best for your facility.

Wall-mounted stations are the space-saving champions of the prep room world. If you're working with limited floor space, these units mount directly to your wall and deliver full functionality without eating up precious square footage. Installation typically takes just 5-6 weeks from order to delivery.

Floor-mounted stations give you extra storage and larger work areas. These freestanding units often include additional shelving, bigger sink basins, and more room for instruments. They're ideal for busy facilities where multiple embalmers need to work efficiently.

Flushing systems bring automation to your cleaning routine. These premium stations include built-in rinse cycles that automatically clean surfaces and drainage components between procedures. While they cost more upfront, they save significant labor time and ensure consistent sanitation.

Collection systems focus on fluid management and waste handling. These specialized units either integrate with your existing embalming tables or work as standalone workstations.

When it comes to construction materials, 304 stainless steel dominates the market for good reasons. This grade offers the perfect combination of durability, corrosion resistance, and hygienic properties that prep rooms demand.

From Wall-Mounted to Flushing: Classifying embalming stations-

Space-saving wall-mounted units can reduce your floor space requirements by up to 40% compared to traditional models. This efficiency doesn't mean sacrificing functionality - these units pack all essential features into their compact design.

Portable carts offer ultimate flexibility for funeral homes with multiple prep rooms or varying caseloads. You can wheel these units wherever they're needed most.

Low-boy units emphasize efficiency through smart, consolidated design. These stations pack all essential functions into a single streamlined unit that requires only one connection point for both water and power.

Why Stainless Steel Rules the Prep Room

Durability is where stainless steel truly shines. Quality embalming stations- face daily battles with harsh chemicals, high temperatures, and constant use. The 304-grade stainless steel used in most stations provides decades of reliable service with minimal maintenance requirements.

Corrosion resistance becomes absolutely critical when dealing with the acidic and alkaline chemicals common in embalming work. Lesser materials quickly deteriorate under these harsh conditions, leading to costly replacements and potential safety hazards.

Hygiene considerations drive material selection in modern prep rooms, and stainless steel delivers exactly what you need. Its non-porous surface prevents bacterial growth and allows for thorough sterilization between procedures.

Adjustable-Height & Custom Builds

Electric lifts represent the premium option for ergonomic flexibility in modern embalming stations-. These systems allow embalmers to adjust working height at the touch of a button, significantly reducing physical strain during lengthy procedures.

Foot-pedal control systems provide hands-free operation of key functions like water flow, aspiration, and height adjustment. This feature proves particularly valuable during procedures when maintaining sterile technique is critical.

Modular add-ons allow facilities to customize their stations over time as needs evolve and budgets allow. Common additions include instrument racks, chemical storage systems, and specialized drainage components.

Safety, Compliance & Installation Essentials

When it comes to embalming stations-, safety isn't just a nice-to-have feature - it's absolutely essential. These workstations handle hazardous chemicals and bodily fluids daily, so every safety feature serves a vital purpose in protecting both operators and the facility.

Eyewash attachments might seem like overkill until you need them. While not always required by local building codes, these emergency fixtures can be real lifesavers when chemical splashes occur. They provide instant decontamination capability right where accidents are most likely to happen.

Splash guards work as your first line of defense against chemical and fluid splatter. These removable barriers keep hazardous materials from contaminating surrounding surfaces while still allowing easy cleaning access.

Every electrical component on modern embalming stations- includes GFCI protection as standard equipment. These devices monitor electrical current constantly and shut off power immediately when they detect problems.

OSHA compliance shapes virtually every design decision in today's embalming stations. Modern stations accommodate all required safety equipment without making your workflow more complicated.

Plumbing & Electrical Requirements

Installing modern embalming stations- requires careful attention to both plumbing and electrical specifications. Getting these fundamentals right from the start prevents headaches and expensive modifications later.

Single water feed systems have become the standard approach. While stations need both hot and cold water connections, the single connection point simplifies installation and reduces potential leak sources.

Drainage systems need more capacity than you might expect. The 1.5-inch minimum drain lines handle the combination of fluids, chemicals, and ground waste materials that embalming generates. Proper slope and venting are absolutely critical.

Electrical requirements vary depending on your station's configuration. Most components run on standard 110V circuits, but waste disposal units typically require 220V service. Every circuit in wet prep room locations must include GFCI protection.

Regulations Impacting embalming stations-

OSHA 1910 standards establish the baseline safety requirements that every commercial funeral operation must meet. These regulations address electrical safety, chemical exposure limits, and personal protective equipment.

State codes create the most variation in requirements across different locations. Some states require specific equipment features or installation procedures that exceed federal minimums. Before selecting your station, check with local authorities about any special requirements in your area.

ADA clearances affect both station selection and prep room layout decisions. The Americans with Disabilities Act requires accessible routes and adequate clear floor space around equipment.

Maintenance & Cleaning Protocols

Proper maintenance keeps your embalming stations- running smoothly and extends their service life significantly. Quality stainless steel construction makes maintenance straightforward when you follow the right procedures.

Daily rinse procedures form the foundation of effective station care. Thorough rinsing after each use prevents chemical buildup that can cause corrosion and equipment problems.

Enzymatic cleaners tackle the organic residues that accumulate during embalming procedures. Regular detergents just can't break down protein deposits and other biological materials effectively.

Quarterly inspections should cover all mechanical components, electrical connections, and safety systems. Professional service technicians can identify wear patterns and potential failures that aren't obvious to regular users.

For facilities with multiple pieces of complex equipment, more info about Anatomic Pathology Equipment provides additional guidance on maintaining sophisticated mortuary systems effectively.

Integration, Workflow Efficiency & Optional Accessories

Think of your prep room as a carefully choreographed dance. Every piece of equipment needs to work together smoothly, and embalming stations- serve as the conductor of this orchestra.

The magic happens when your preparation tables sit right next to your embalming station. The station's upper deck becomes home to your embalming machine, whether it's a trusted Duotronic or reliable Porti-Boy model. These machines plug directly into your table's arterial and drainage systems.

Mortuary coolers complete the workflow triangle in most prep rooms. Bodies travel from refrigerated storage to your preparation area, where the embalming stations- handle all the chemical processing. At American Mortuary Coolers, we've designed thousands of refrigeration systems that work hand-in-hand with existing prep room layouts across Tennessee, Georgia, Illinois, South Carolina, Texas, California, New York, and Pennsylvania.

Modern aspirators have come a long way from the old days of separate vacuum pumps and complicated setups. Today's hydro aspirators use simple water pressure to create powerful suction for fluid removal. The real game-changer is the reverse-flow feature on premium units - when you hit a blockage, just flip a switch and the system clears itself instantly.

Streamlining Prep Rooms with Connected Equipment

Integrated table systems represent the next evolution in prep room design. These units combine your embalming station with the preparation surface itself, creating one unified workstation. You'll save significant floor space while actually improving how efficiently you work.

The workflow in busy facilities typically follows a predictable pattern: refrigeration to prep tables to embalming stations and back to cold storage. When this flow works smoothly, you can handle multiple cases without chaos or confusion.

More info about Embalming Equipment Options provides comprehensive guidance on selecting compatible equipment for integrated prep room systems.

Optional Add-Ons That Boost Performance

Perimeter rinse systems might sound fancy, but they're really just smart automation. These systems spray around your entire sink basin automatically, ensuring thorough cleaning between procedures.

Reverse-flow aspirators solve one of the most frustrating problems in prep room work. Traditional systems require you to stop everything and manually clear blockages. Reverse-flow units eliminate this headache by instantly clearing clogs with reversed water pressure.

Digital scales built into your station design bring precision to chemical mixing. Instead of guessing, you get exact measurements every time. Some units even log your data automatically, which helps with quality assurance and regulatory compliance.

Foot valve controls free up your hands for more important tasks. You can control water flow, aspiration, and other functions without breaking your sterile technique or interrupting your workflow.

4 Tips to Perform Embalming Successfully offers practical guidance on maximizing the efficiency of station accessories and add-on features.

Essential Workflow Components of embalming stations-

Machine docking shelves provide a secure home for your embalming equipment while keeping everything within easy reach. These platforms adjust to accommodate different machine models and can be positioned to match your preferred working height.

Instrument racks might seem like a simple addition, but good organization makes a huge difference in efficiency. Quality stainless steel racks keep your tools organized and accessible while making cleaning and sterilization straightforward.

Waste disposal grinders handle the solid materials that can't go through standard drainage. The 0.75 horsepower units found in quality embalming stations- can process most materials you'll encounter during routine procedures.

Comparing Leading Manufacturers & Innovations

When you're shopping for embalming stations-, you'll quickly find that not all manufacturers approach design and functionality the same way. Each company has carved out its own niche, focusing on different aspects that matter most to funeral professionals.

Mobimedical has built its reputation around flexibility. Their modular approach means you can start with a basic station and add components as your needs grow. Their wall-mounted and floor-standing options come with extensive safety systems that meet demanding requirements.

Mopec takes a different approach, putting workflow efficiency front and center. Their automated cleaning systems and integrated instrument storage focus on facilities that want streamlined operations. They've also earned high marks for customer service.

For high-volume facilities, Mortech builds stations engineered to handle intensive daily use while maintaining precision in fluid management. Their customization options are extensive, perfect for unique requirements that standard units can't address.

Kelco understands that not every funeral home has an unlimited budget. They focus on delivering reliable performance with straightforward designs. It's the practical choice for smaller facilities that need dependable equipment without premium price tags.

At the premium end, Vischer incorporates advanced technology with digital controls, automated systems, and sophisticated monitoring capabilities. You'll pay more, but you're getting cutting-edge functionality that can streamline complex operations.

Price ranges typically span from $5,795 to $21,995, with most facilities finding their sweet spot in the $8,000-$15,000 range. Lead times vary considerably - standard configurations might arrive in 5-6 weeks, while heavily customized systems can take 12-16 weeks or more.

Feature & Price Snapshot

| Feature | Mobimedical | Mopec | Mortech | Kelco | Vischer |

|---|---|---|---|---|---|

| Sink Dimensions | 24"x18"x12" | 26"x20"x14" | 28"x22"x16" | 22"x16"x10" | 30"x24"x18" |

| Aspirator Type | Hydro | Hydro+ | Heavy-Duty | Standard | Digital |

| Safety Features | Eyewash, GFCI | Full Package | OSHA+ | Basic | Advanced |

| Starting Price | $8,995 | $12,500 | $15,800 | $5,995 | $18,900 |

| Lead Time | 8 weeks | 10 weeks | 12 weeks | 6 weeks | 14 weeks |

| Customization | High | Medium | Very High | Limited | Extensive |

Emerging Trends: Ventilated Sinks & Smart Sensors

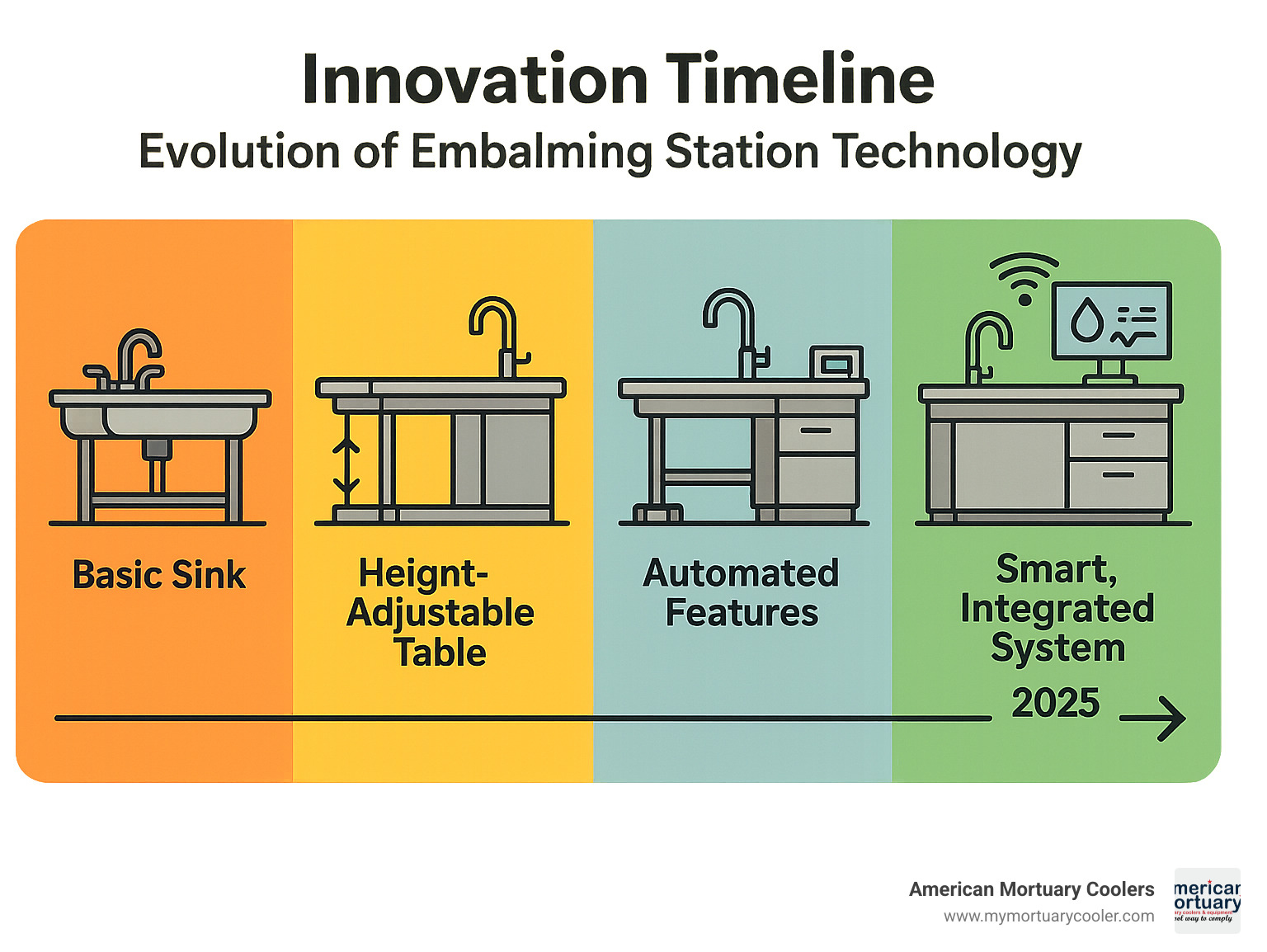

The funeral industry might not be the first place you'd expect to find cutting-edge technology, but embalming stations- are becoming surprisingly sophisticated. IoT flow meters now monitor everything in real-time - fluid usage, chemical consumption, and system performance. This data helps facilities optimize operations while maintaining detailed records.

HEPA exhaust systems represent a significant leap beyond traditional ventilation. These advanced filtration systems capture microscopic particles and chemical vapors that standard exhaust fans simply can't handle.

Environmental consciousness is driving the development of greener chemistry options in embalming fluids. These more environmentally friendly formulations often require different mixing ratios and handling procedures, which means station manufacturers are adapting their designs accordingly.

Space efficiency continues to drive innovation in compact combination units. These clever designs integrate embalming stations, preparation tables, and storage systems into unified workstations. Some facilities report reducing their floor space requirements by up to 50% while actually improving functionality.

The technology integration we're seeing today would have seemed like science fiction just a decade ago. Smart sensors can now predict maintenance needs before problems occur, automated systems reduce manual labor, and digital monitoring ensures consistent quality across all procedures.

Frequently Asked Questions about embalming stations-

How much space do embalming stations- require?

The space requirements for embalming stations- depend largely on whether you choose a wall-mounted or floor-standing model. Wall-mounted units are the space-saving champions, typically needing just 6 feet by 4 feet of floor area. Floor-standing models require more room - about 8 feet by 5 feet - but they offer additional storage and workspace.

Here's where it gets a bit more complex: you can't just measure the station itself. ADA compliance requires clear floor space of at least 30 inches by 48 inches directly in front of the station. This ensures wheelchair accessibility where required by local codes.

Don't forget about operator movement and equipment access. Your embalmers need room to work comfortably, and you'll occasionally need to service the equipment. A cramped prep room leads to inefficient workflows and potential safety issues.

Wall-mounted stations really shine in smaller facilities. They can reduce your floor space requirements by up to 40% compared to floor-standing models. If you're working with limited square footage, this difference can be the deciding factor in your station selection.

What ongoing maintenance keeps embalming stations- in top shape?

Think of embalming station maintenance like caring for a high-performance car - regular attention prevents expensive problems down the road. The good news is that stainless steel construction makes most maintenance tasks straightforward.

Daily care starts with thorough rinsing after each use. Those perimeter rinse systems available on many modern stations make this almost automatic, but you should still do a visual check to ensure complete cleaning. Chemical residues left on surfaces can cause staining and corrosion over time.

Weekly deep cleaning involves enzymatic cleaners that break down protein deposits and organic materials that regular detergents can't handle. These specialized products are worth the investment - they prevent buildup that could affect your station's performance.

Monthly stainless steel polishing keeps your station looking professional while maintaining its protective properties. This step also helps you spot potential issues like scratches or wear patterns before they become serious problems.

Quarterly professional inspections are your insurance policy against unexpected breakdowns. A qualified technician can check all mechanical components, electrical connections, and safety systems. This preventive approach saves money and ensures you stay compliant with safety regulations.

Can I retrofit an older prep room with a modern embalming station?

The short answer is usually yes, but older prep rooms often need some updates to handle modern embalming stations- properly. It's like putting a new engine in a classic car - possible, but you might need to upgrade other systems too.

Plumbing modifications are the most common requirement. Older facilities often have smaller drain lines that can't handle the waste flows from modern stations. You'll typically need to upgrade to 1.5-inch minimum drain lines and ensure adequate hot and cold water supply pressure.

Some older buildings may need pressure boosting systems to meet the water pressure requirements of modern hydro aspirators and mixing systems. Without adequate pressure, your station won't perform at its full potential.

Electrical upgrades frequently include adding GFCI-protected circuits and ensuring sufficient capacity for waste disposal units. Modern stations have more electrical components than older models, and safety standards have evolved significantly over the years.

The best approach is getting a professional assessment before making your purchase decision. Qualified plumbing and electrical contractors can identify exactly what modifications you'll need and provide accurate cost estimates. This upfront investment in professional evaluation prevents costly surprises during installation.

Conclusion

Choosing the right embalming stations- can transform how your funeral home operates. After decades of helping facilities upgrade their prep rooms, I've seen how the right equipment investment pays off through smoother workflows, better safety compliance, and fewer headaches down the road.

The key is looking beyond just the price tag. Yes, quality stations cost more upfront - typically between $5,795 and $21,995 - but they'll serve your facility reliably for decades. A well-chosen station handles thousands of cases over its lifetime, making the per-case cost surprisingly affordable.

At American Mortuary Coolers, we've learned that embalming stations- work best as part of complete prep room systems. Our custom mortuary coolers pair perfectly with quality embalming stations, maintaining optimal temperatures while your team focuses on preparation work. We deliver directly across all 48 contiguous states from our Tennessee facility.

Your Embalming Station Buyer Checklist:

- Measure your space carefully and check clearance requirements

- Have a qualified contractor assess your plumbing and electrical capacity

- Review local codes to identify required safety features

- Consider how new equipment will work with your existing setup

- Research manufacturer support and service in your area

- Think about future needs - will you expand or change operations?

Your next step is reaching out to reputable suppliers for detailed proposals. Quality manufacturers will visit your facility, assess your specific needs, and recommend solutions that fit both your workflow and budget.

You're not just buying a sink with some fancy attachments. You're investing in equipment that will handle your most important work for years to come. Take time to evaluate your options thoroughly, ask plenty of questions, and choose equipment that will grow with your business.

The funeral industry continues evolving, with new technologies like IoT monitoring and improved ventilation systems becoming more common. Selecting equipment from established manufacturers ensures you'll have access to upgrades and support as these innovations become standard.

More info about our custom mortuary coolers and how they integrate seamlessly with quality embalming stations to create prep rooms that work as hard as you do.