Walk In Cooler Service 101: Find Reliable Repair Providers

Understanding Walk-In Cooler Service: The Basics You Need to Know

If you're searching for walk in cooler service information, here's what you need to know:

| Walk-In Cooler Service Essentials | What to Know |

|---|---|

| Regular Maintenance Frequency | At least twice yearly (more in dusty environments) |

| Common Issues Requiring Service | Door seal damage, refrigerant leaks, ice buildup, temperature fluctuations |

| DIY vs Professional | Clean coils & inspect gaskets yourself; leave refrigerant handling to certified technicians |

| Service Call Duration | Typically 2-5 hours depending on the issue |

| When to Call Immediately | Strange noises, temperature above 40°F, frost in unusual places |

A walk in cooler service appointment is essential for maintaining the efficiency and longevity of your refrigeration system. These critical storage units represent a significant investment for any business that relies on temperature-controlled storage, and neglecting maintenance can lead to costly emergency repairs, inventory loss, and potential health code violations.

Whether your walk-in cooler suddenly stops cooling efficiently or you're establishing a preventative maintenance schedule, understanding the basics of refrigeration service can save you thousands of dollars and countless headaches. A well-maintained walk-in cooler can last between 10 to 15 years, with some units functioning properly for over 30 years when serviced regularly.

Shutting down a walk-in cooler due to malfunction can feel like a nightmare for any business. The FDA requires that food be stored below 40°F (4°C) to ensure safety, making reliable operation non-negotiable. Regular maintenance, such as cleaning condenser and evaporator coils at least twice yearly, is the key to avoiding disruptions and extending equipment life.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience providing walk in cooler service for specialized refrigeration needs across various industries. My work with both US Cooler systems and custom installations has given me unique insight into maintaining optimal performance in critical temperature-controlled environments.

Walk in cooler service basics:

How a Walk-In Cooler Works & Why Maintenance Is Non-Negotiable

Ever wondered what's happening behind those insulated panels while you're grabbing ingredients from your walk-in cooler? Let me walk you through it in simple terms. Understanding your cooler's operation isn't just interesting—it's essential for keeping it running smoothly.

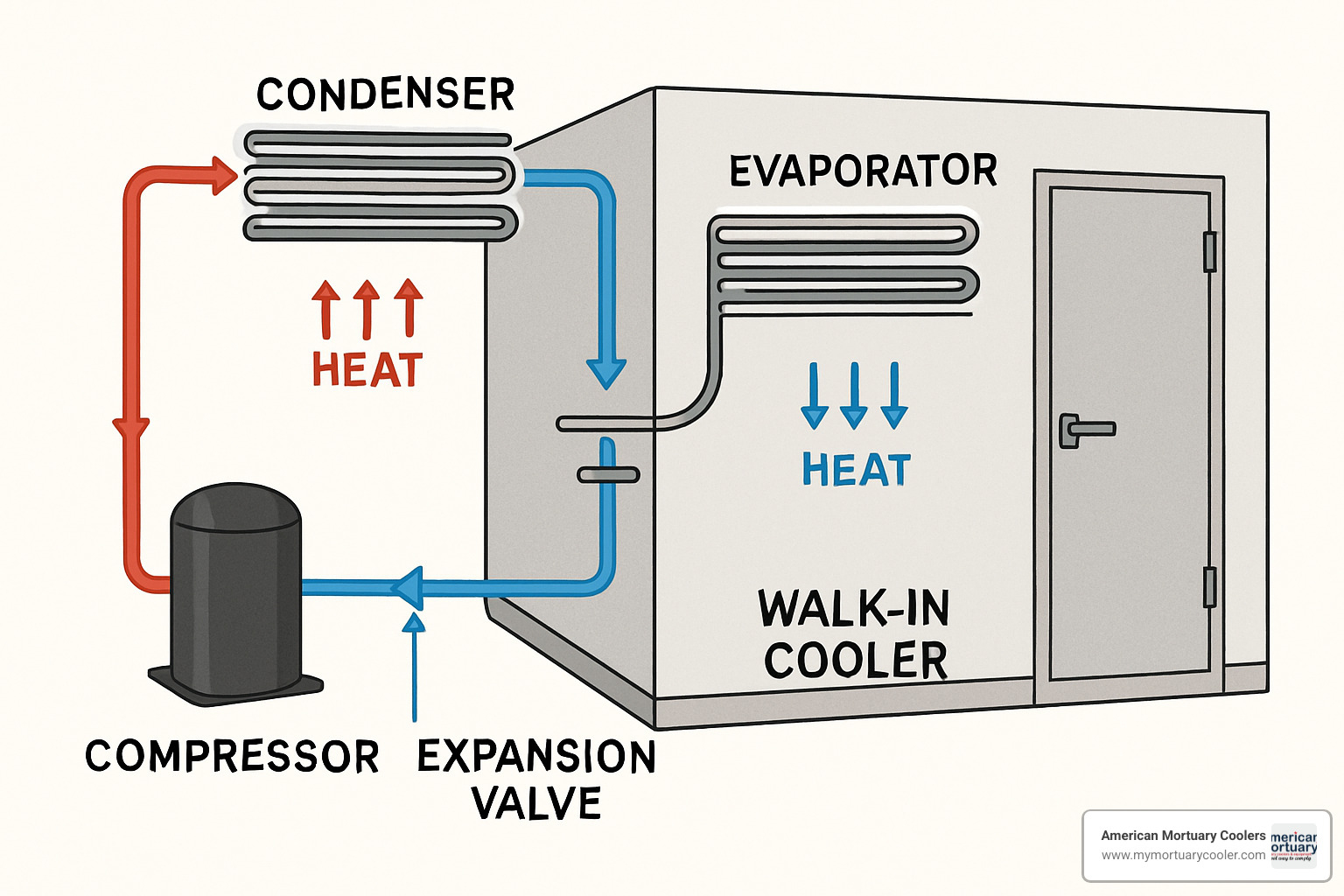

Your walk-in cooler operates like a continuous heat removal system, with four key components working together in perfect harmony:

- Compressor: Think of this as the heart of your system. It pumps refrigerant gas, compressing it to increase temperature and pressure.

- Condenser: This component releases heat from the refrigerant to the outside world, changing hot gas into liquid.

- Expansion Valve: Here, pressure drops dramatically, allowing the refrigerant to expand and cool rapidly.

- Evaporator: Inside your cooler, this component absorbs heat as the refrigerant evaporates back to gas form.

This neat cycle repeats continuously, whisking heat away from your products. Modern systems increasingly use environmentally friendlier refrigerants like R454B, which have significantly lower global warming potential than older options.

The entire system is wrapped in heavily insulated panels—the unsung heroes that keep outside heat from sneaking in. These panels, along with properly sealed doors, create the thermal barrier that maintains your cooler's efficiency.

When it comes to temperature-controlled storage, the FDA isn't joking around. Their food storage safety guidelines mandate strict temperature control, making reliable operation not just good business sense, but a regulatory requirement.

Key Benefits of Regular Service

Let's talk about why regular walk in cooler service makes dollars and sense:

Your energy bills will thank you. Clean coils and properly functioning components can slash energy consumption by up to 25%. Would you believe that simply adding air curtains can reduce compressor runtime by up to 27%? That's not just our claim—it's backed by studies presented to the Department of Energy.

Your equipment will live longer. With proper care, your walk-in cooler can easily reach its expected 15-year lifespan, and many well-maintained units keep humming along for 30+ years. That's like getting two coolers for the price of one!

You'll avoid those dreaded midnight emergency calls. There's nothing worse than finding your cooler has failed over a weekend. Regular maintenance catches small issues before they become temperature emergencies.

Your warranty stays intact. Many manufacturers require proof of regular maintenance to honor their warranties. Skip the service, and you might be voiding your protection plan without even knowing it.

Temperature stability becomes a non-issue. This is particularly crucial for specialized applications like mortuary coolers, where consistent cooling is absolutely non-negotiable.

Risks of Neglecting Maintenance

Now for the flip side—what happens when you skip your walk in cooler service?

Inventory loss can be devastating. Imagine coming in Monday morning to thousands of dollars of spoiled product. It happens more often than you'd think.

Compressor burnout is the repair that makes owners wince. As the most expensive component, replacing a failed compressor often costs several thousand dollars—money that could have been saved with regular maintenance.

Health code violations don't just bring fines; they can temporarily shut down your business. Temperature fluctuations quickly lead to regulatory non-compliance.

Mold and bacteria love neglected coolers. Poor drainage combined with inconsistent temperatures creates the perfect breeding ground for harmful microorganisms—definitely not something you want near your products.

Energy costs skyrocket when systems run inefficiently. Dirty coils, leaking seals, and struggling components can double your energy consumption without you even realizing it.

Equipment lifespan shrinks dramatically. A neglected walk-in might fail after just 5-7 years instead of the 15+ years you should expect.

As one of our service technicians likes to say, "Skipping maintenance is like skipping oil changes in your car—you might save money today, but you'll pay dearly tomorrow." Most professionals in our industry agree: regular maintenance isn't an expense—it's the most cost-effective approach to walk-in cooler ownership.

Comprehensive Walk In Cooler Service Guide

Taking care of your walk-in cooler doesn't have to be complicated, but it does need to be consistent. At American Mortuary Coolers, we've seen how a little regular attention can prevent major headaches down the road. Let me walk you through what a thorough walk in cooler service program should include.

Maintenance Checklist

Think of your walk-in cooler like your car – it needs regular check-ups to run smoothly. The most important maintenance tasks include cleaning those condenser and evaporator coils (they're like the lungs of your system), checking door gaskets for tears, and making sure drain lines aren't clogged.

I can't tell you how many service calls I've been on where a simple clogged drain line caused water to back up and create a mini ice rink inside the cooler! Door hardware needs adjustment periodically too – doors that don't close properly are literally letting your cold air (and money) escape.

Don't forget about checking refrigerant levels, inspecting electrical connections, verifying your defrost system is working properly, and lubricating those fan motors. Your temperature controls need calibration occasionally too – I've seen coolers running several degrees off without owners realizing it. And if you have strip curtains or air curtains, make sure they're not torn or misaligned.

Speaking of coil cleaning – it's arguably the most important maintenance task you can perform. When condenser coils get caked with dust and debris, your compressor works overtime, your energy bills skyrocket, and your equipment ages faster than it should. Proper cleaning involves carefully removing buildup without damaging those delicate fins – something worth learning to do correctly.

Walk In Cooler Service Schedule: Daily, Monthly, Annual

The key to effective maintenance is consistency. Here's how to break it down:

Daily Tasks: Start by recording temperatures morning and evening – this simple habit can alert you to problems before they become disasters. Listen for unusual noises (compressors shouldn't sound like they're running a marathon), make sure doors close properly, and check that lights turn off when the door closes.

Weekly Tasks: Give those door sweeps and gaskets a good wipe-down – it's amazing what can build up in just a week. Look for unusual frost patterns (they're trying to tell you something!), clear debris from around your condensing unit, and make sure your drain pan isn't holding water.

Monthly Tasks: This is when you should really inspect those door gaskets for damage, check hinges and closers, verify all fans are spinning happily, and look over strip curtains for tears.

Quarterly Tasks: Now we're getting serious – clean those condenser coils, check the refrigerant sight glass if you have one, inspect the evaporator for ice buildup, and test your defrost cycle.

Bi-Annual Professional Service: Twice a year, it's worth having a pro evaluate system performance, clean those evaporator coils, check refrigerant charge, and inspect all electrical connections.

Annual Professional Service: Once yearly, have a technician tighten all electrical connections, test safety controls, check compressor oil levels, evaluate overall efficiency, and calibrate all thermostats and sensors.

As one of our refrigeration experts likes to say, "Watch your coil cleanliness monthly for a year, and you'll learn exactly how often your specific environment demands cleaning." Dustier environments might need monthly cleaning, while cleaner spaces might go longer between services.

Essential Components Requiring Walk In Cooler Service

Understanding what makes your cooler tick helps you take better care of it. Let's break down the key components:

Condenser Coils are the workhorses that release heat from the refrigerant to the outside world. Whether they're perched on top, mounted on the side, or located remotely, they're dust magnets. Plan to clean them every 60-90 days, adjusting based on your environment.

Evaporator Coils do the opposite job inside your cooler, absorbing heat from the interior. These need professional cleaning annually to remove buildup that can choke your cooling capacity.

Fans & Motors keep air moving across both sets of coils. Listen for unusual noises or vibrations – they're crying for help! Some motors need lubrication while others are sealed units.

Thermostats & Sensors are the brains of the operation. Double-check their readings with a separate thermometer regularly, and don't hesitate to recalibrate when needed.

Defrost Heaters prevent ice buildup on evaporator coils, especially important for freezers. Make sure their timing and function get verified during professional service.

Insulation Panels are your thermal barrier. Inspect them for damage or moisture, paying special attention to seams and any places where pipes or wires penetrate the walls.

Door Hardware – hinges, closers, and latches – ensure proper sealing. Give them a little love with annual lubrication (unless they're self-lubricating) and adjustment as needed.

For those of you who enjoy rolling up your sleeves, check out our detailed guide on how to do walk-in cooler repair. Just remember, while some maintenance is DIY-friendly, refrigerant handling should always be left to certified professionals.

Regular walk in cooler service isn't just about preventing problems – it's about extending the life of your investment, saving energy, and ensuring everything inside stays at the perfect temperature. Your cooler works hard for you 24/7; giving it some regular attention is the least we can do in return!

Troubleshooting: From Ice Buildup to Temperature Fluctuations

Let's face it – even with the best maintenance routine, walk-in coolers sometimes develop issues that leave you scratching your head. The good news? Most problems give you early warning signs before they turn into full-blown emergencies. Recognizing these signals can save you thousands in emergency repairs and protect your valuable inventory.

Common Problems and Their Causes

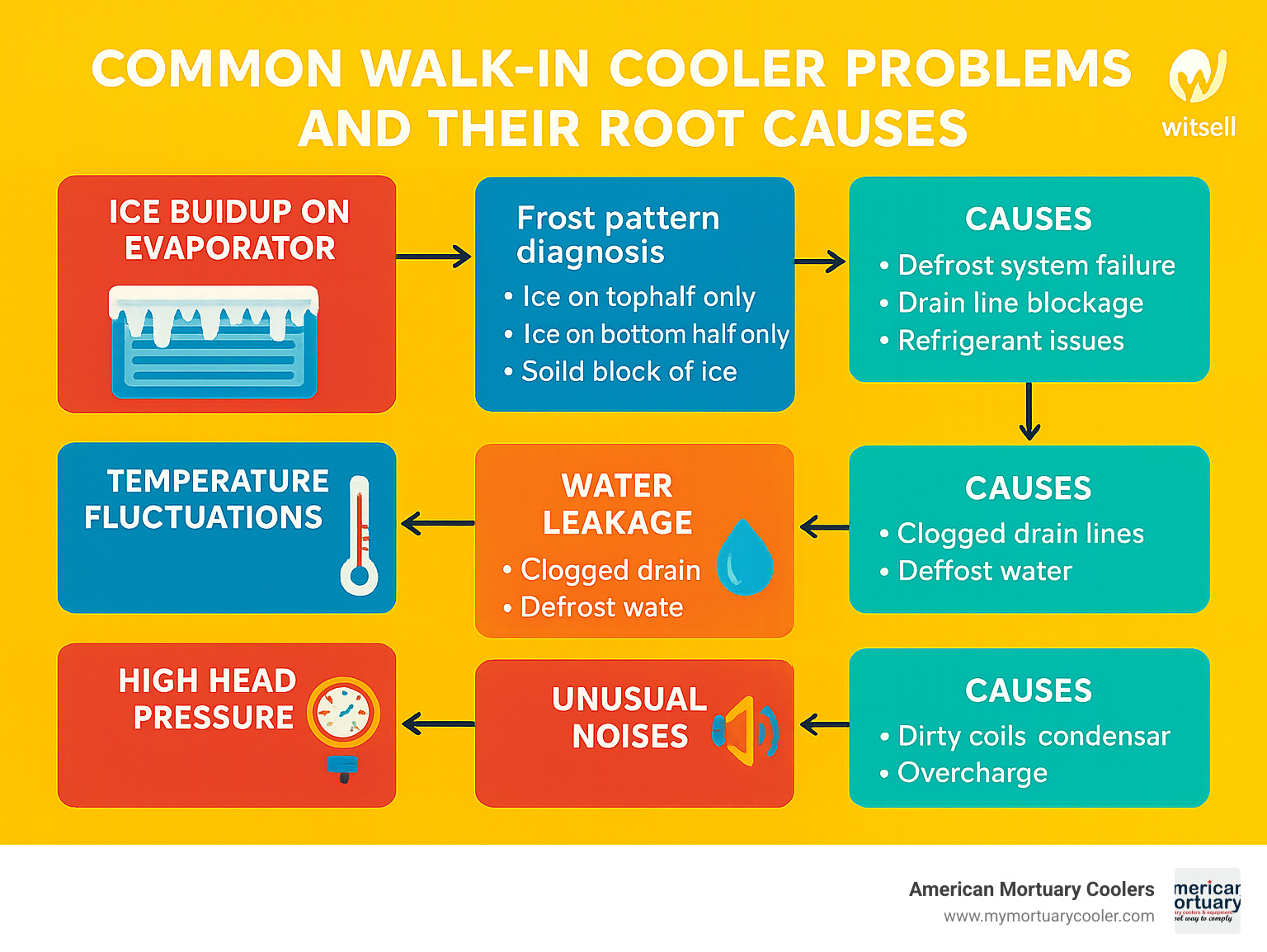

When it comes to ice buildup on your evaporator, the frost pattern actually tells an interesting story. Ice forming only on the top half often points to a stuck expansion valve, while ice on just the bottom half typically suggests your system is low on refrigerant. Finding your evaporator encased in a solid block of ice? That's usually your defrost system waving a white flag. The culprits behind these icy conditions range from defrost timer malfunctions to heater failures, blocked drain lines, or refrigerant issues.

Temperature fluctuations can be equally frustrating. Your walk-in might be struggling with thermostat calibration problems, refrigerant charge issues, or those pesky dirty coils we talked about earlier. Sometimes it's as simple as door seals that aren't sealing or a compressor that's cycling incorrectly. To diagnose the issue, grab a separate thermometer and compare its reading with what your system displays, then monitor how often your unit cycles on and off.

Water leakage is another common headache. You might be dealing with clogged drain lines, a drain pan that's not positioned correctly, excessive defrost water, or condensation forming because of poor sealing. The best approach? Follow the water trail back to its source and check those drain lines for blockages.

When your cooler starts making strange noises, it's definitely trying to tell you something. Listen carefully during different parts of the cooling cycle to pinpoint whether it's loose fan blades, worn bearings, refrigerant flow issues, or compressor problems causing the racket.

High head pressure requires professional attention, but knowing the likely causes helps you communicate better with your service provider. Dirty condenser coils, a failed condenser fan, refrigerant overcharge, or non-condensable gases in the system are typical suspects.

Quick Fixes Before Calling Walk In Cooler Service

Before you reach for the phone to schedule walk in cooler service, try these simple troubleshooting steps that might just solve your problem:

First, check those door seals. Try the paper test – close a piece of paper in the door and try to pull it out. If it slides out easily, your gaskets aren't making proper contact. Next, take a moment to clear any airflow obstructions. Remove boxes or containers blocking evaporator fans inside the cooler and sweep away leaves or debris around the outdoor condensing unit.

Double-check your thermostat settings. Coolers typically run best between 35°F-38°F, while freezers should be set around -10°F. If you have a unit with manual defrost timers, try resetting the cycle – sometimes that's all it takes to kick the system back into proper operation.

Keeping a temperature log can be incredibly helpful. If you document fluctuations over a 24-hour period, you'll give your service technician valuable information for diagnosing the problem. And don't forget to check for ice buildup on those evaporator coils – excessive frost often signals defrost issues that need attention.

Want more guidance on selecting the right system for your specific needs? Our guide on selecting the best walk-in cooler system offers valuable insights.

When to Repair vs Replace Major Components

Making the "repair or replace" decision can feel overwhelming, but a few practical guidelines can help. If your walk-in has been faithfully serving you for over 15 years, replacement often makes more financial sense than pouring money into major repairs. Similarly, if you're calling for service repeatedly to address the same issue, there's likely a deeper problem that band-aid fixes won't solve.

Consider the repair cost ratio – one of my favorite rules of thumb comes from a seasoned refrigeration expert who told me, "A repair cost plus parts generally should not exceed two-thirds of full system replacement cost." This practical advice has saved many of our customers from throwing good money after bad.

Pay attention to your insulation panels, too. After about a decade, they start losing effectiveness, and unlike mechanical components, they can't be repaired – only replaced. Refrigerant considerations also factor into this decision. Systems using phased-out refrigerants may require expensive retrofits that make replacement the smarter option.

Don't overlook the energy efficiency angle. Newer systems often deliver substantial energy savings that can offset replacement costs faster than you might expect. At American Mortuary Coolers, we've seen customers recoup a significant portion of their investment through reduced utility bills within just a few years.

Selecting & Working With a Reliable Service Provider

Finding someone you can truly trust for your walk in cooler service needs isn't just a good idea—it's essential for your peace of mind and your business's bottom line. Here at American Mortuary Coolers, we've worked with service providers across the country, from Johnson City, TN to Atlanta, GA, and we've learned what separates the reliable professionals from the rest.

Key Qualities to Look For

When you're evaluating potential service partners, think about more than just price. The cheapest quote might end up costing you more in the long run! Look for technicians who are EPA certified and have specific training for your equipment. This isn't just about qualifications on paper—it's about having someone who truly understands the unique needs of your cooling system.

Refrigeration emergencies don't politely wait for business hours, so 24/7 emergency availability is non-negotiable. The best technicians arrive with well-stocked service vehicles, carrying common parts that might save you from waiting days for a simple fix.

We've found that providers who offer preventive maintenance plans (not just emergency service) tend to take a more holistic approach to your equipment's health. They should also handle refrigerants properly and stay current with environmental regulations—both for the planet's sake and to keep you compliant.

Clear response time commitments, specific industry experience with your application (whether restaurant, mortuary, or other), and strong customer reviews round out what makes a service provider worth your trust.

| Service Aspect | DIY Approach | Professional Service |

|---|---|---|

| Coil Cleaning | Possible with care and proper tools | More thorough, less risk of damage |

| Door Seal Inspection | Easy to perform | Same effectiveness |

| Refrigerant Handling | Not legal without certification | Properly certified and equipped |

| Electrical Troubleshooting | Basic checks only | Comprehensive diagnosis |

| Cost | Lower immediate cost | Higher upfront cost, potential long-term savings |

| System Optimization | Limited capability | Can fine-tune for maximum efficiency |

| Emergency Response | Limited options | 24/7 availability |

Questions to Ask Before Signing a Walk In Cooler Service Contract

Before you sign on the dotted line, have a heart-to-heart conversation with your potential service provider. Ask them about their guaranteed emergency response time—you'll want someone who can be there within 2-4 hours when critical failures happen.

Get specific details about what their service agreement covers and excludes. Are parts included? How about labor? How often will they visit for maintenance? Understanding these details upfront prevents surprises later.

Responsible refrigerant management is crucial, so confirm they follow EPA guidelines. Ask about their documentation practices too—detailed service reports aren't just paperwork, they're essential for warranty purposes and tracking your system's performance over time.

Make sure their technicians have experience with your specific equipment brands and models. And don't forget to ask about contingency plans—the best providers can offer temporary cooling solutions like refrigerated trailers during extended repairs.

Finally, be clear on payment terms and repair warranties. A quality provider stands behind their work and makes the financial aspects transparent from the start.

Boosting Efficiency With Accessories

Sometimes, the little things make a big difference in your cooling system's performance. Strip curtains create a simple but effective barrier that allows people to pass through while keeping cold air where it belongs. They're especially helpful in busy environments where doors open frequently.

Air curtains create an invisible shield of air when doors open, and they're surprisingly effective—studies presented to the Department of Energy found they can reduce compressor runtime by up to 27%. That's not just energy savings; it's extended equipment life and fewer service calls.

Those moments when someone leaves the cooler door wide open? Door-open alarms can put an end to that, alerting staff when doors stay open too long. Meanwhile, data loggers quietly monitor and record temperatures around the clock, giving you documentation for compliance and early warning of potential issues.

Even lighting makes a difference—LED lighting produces significantly less heat than traditional options, reducing the cooling load and cutting energy costs.

For more scientific research on how air curtains can improve efficiency, check out Berner's research on walk-in cooler efficiency.

Emergency Response, Costs & Lifecycle Planning

Let's face it – when your walk-in cooler breaks down, it feels like an emergency. And it often is! As someone who's been in the trenches with countless business owners during these stressful moments, I want to share some practical insights about what to expect financially and how to plan for the inevitable.

A typical walk in cooler service call isn't a quick fix – most service visits take between 2-5 hours from start to finish. Of course, this varies based on what's actually wrong. A simple diagnostic visit might wrap up in 1-2 hours, while a thorough coil cleaning usually takes 2-3 hours. If you're dealing with a refrigerant leak, expect 4+ hours (especially if it's playing hide-and-seek with the technician). And replacing a compressor? That's usually a full day's work, ranging from 4-8 hours depending on your system's complexity.

When it comes to costs, several factors come into play:

- Labor rates vary significantly by region (what you'd pay in Johnson City, TN is quite different from Atlanta, GA)

- Parts pricing depends on availability and your specific model

- Refrigerant type matters – some of the newer, environmentally-friendly options cost more

- After-hours or weekend emergency calls typically come with a premium (sometimes 1.5-2x standard rates)

- How far the technician needs to travel to reach you

Here's a lifesaver tip: in truly dire situations, many service providers can arrange a temporary refrigerated trailer (typically 5'x10') to protect your inventory during extended repairs. It's worth asking about this option when choosing your service provider. And remember, a typical walk-in will maintain temperature for about 12 hours during a power outage if you keep those doors closed!

Lifecycle Planning

I always tell my customers that planning for replacement should start long before your unit gives up the ghost. Around the 7-10 year mark, it's smart to begin setting aside funds for eventual replacement. This gives you the freedom to make a calculated decision rather than a panicked one when the time comes.

When you do replace your unit, consider it an opportunity for upgrades – newer models often offer significant energy efficiency improvements that can offset costs over time. Sometimes you don't need to replace everything at once. Many businesses opt for replacing just the refrigeration system while keeping the insulated box intact if it's still in good condition.

Don't want to pay for everything upfront? Many providers (including us at American Mortuary Coolers) offer financing options for major replacements, which can make the transition more manageable.

Want to extend your current system's lifespan? Here's what works:

- Stick religiously to your maintenance schedule

- Don't procrastinate on small issues – they become big ones

- Consider upgrading just the refrigeration components if the structure is sound

- Train your team on proper usage (minimizing door openings, proper product loading)

Handling Walk In Cooler Service Emergencies

When disaster strikes and your walk-in cooler fails, quick action can save thousands in inventory. Here's your emergency game plan:

First, isolate your inventory by moving critical items to functioning units if possible. Keep those doors closed as much as humanly possible – every opening releases precious cold air.

Immediately call for emergency service using your provider's 24/7 line (you do have one, right?). While waiting, document temperatures hourly – this documentation is invaluable for insurance claims and regulatory compliance.

If repairs will take extended time, request a refrigerated trailer to maintain your inventory. For food service operations, proactively communicate with health inspectors if temperatures exceed safe levels – they'll appreciate the transparency.

After the crisis passes, take time to review what happened and implement preventive measures. Often, emergencies reveal weaknesses in your maintenance program or operational procedures.

At American Mortuary Coolers, we understand that in specialized applications like mortuary coolers, emergency response isn't just about convenience – it's absolutely essential. That's why our service network across the Southeast, Southwest, and Midwest is designed for rapid response when you need it most.

The best emergency plan is the one you never have to use – which is why regular walk in cooler service remains your best insurance policy against unexpected downtime.

Frequently Asked Questions about Walk-In Cooler Service

What is the best temperature setting for my walk-in?

One of the most common questions we get at American Mortuary Coolers involves temperature settings. The truth is, there's no one-size-fits-all answer – it really depends on what you're storing.

For standard walk in cooler service applications, you'll want to maintain temperatures between 35°F and 38°F (1.7°C to 3.3°C). This sweet spot prevents freezing while keeping everything safely below the FDA's critical 40°F (4°C) threshold for food safety.

If you're operating a freezer, aim for -10°F to 0°F (-23°C to -18°C), with most commercial operations running around -10°F for standard frozen goods.

For specialty applications, you'll need to adjust accordingly. Ice cream requires colder temperatures (around -18°F to -10°F), while floral storage works best between 34°F and 38°F. In our specialty – mortuary coolers – we typically recommend maintaining 35°F to 37°F for optimal preservation.

One tip I always share with our customers: don't trust the unit's display blindly. Invest in a good quality, calibrated thermometer and verify your actual temperatures regularly. It's a simple step that can prevent major headaches down the road.

How can I prevent ice buildup in the drain line?

That frustrating ice buildup in drain lines is something we see all too often during walk in cooler service calls. Not only is it annoying, but it can lead to water backup and potential damage to your cooler and inventory.

The good news? There are several effective prevention methods. First, check if your drain line heater (often called heat tape) is working properly. This small element prevents freezing in the line and is a common culprit when ice starts forming.

Proper pitch matters too – your drain lines should have enough slope to allow complete drainage. Water that sits in level sections of pipe is just asking to freeze.

I recommend cleaning drain lines quarterly using compressed air or a drain snake. It's amazing what can build up in there over time! While you're at it, verify your defrost settings are appropriate – they need to be frequent enough and long enough to fully clear any ice accumulation.

For coolers in colder environments, don't forget to insulate any external portions of the drain line. I once visited a customer in Minnesota who couldn't figure out why their drain kept freezing – turns out the line was exposed to -20°F temperatures as soon as it exited the building!

If you're still having issues despite trying these fixes, it might be time to call in the professionals. Sometimes there are system-specific issues that require a trained eye to diagnose.

How long does a typical walk-in cooler service call take?

"How long will this take?" is probably the second question we hear after "How much will this cost?" when scheduling walk in cooler service. The honest answer is: it depends on what we're fixing.

For routine maintenance visits, we typically block off 2-3 hours to properly clean and inspect everything. This gives us enough time to be thorough without rushing.

Leak detection and repair is trickier – usually 4-5 hours, but I've seen complicated cases take much longer. Finding a tiny refrigerant leak can sometimes feel like looking for a needle in a haystack! That's why many of our technicians will book a full day when leak detection is involved.

Component replacements vary widely: a door gasket might take just 1-2 hours, while a full compressor replacement could require 4-8 hours depending on your system's complexity. Control boards typically take 2-3 hours, and evaporator fan motors about the same.

As one of our veteran technicians likes to say, "Don't trade speed for quality; a thorough repair the first time avoids callbacks." We've found this approach saves everyone time and frustration in the long run.

Several factors can extend service time, including difficult access to components (especially in tight utility spaces), parts availability, and system complexity. That's why we prioritize having well-stocked service vehicles and properly trained technicians who know how to efficiently diagnose and address issues.

At American Mortuary Coolers, we understand that downtime costs you money and potentially compromises your inventory. While we won't rush a job and risk quality, we do respect your time and work efficiently to get your system back up and running properly.

Conclusion

There's a reason why walk in cooler service isn't just a good idea—it's essential for your business. Think of maintenance as an investment that pays dividends through efficiency, longevity, and peace of mind. When your walk-in runs smoothly, you're protecting both your equipment and the valuable inventory inside.

Here at American Mortuary Coolers, we've built our reputation on being more than just equipment suppliers. We're your partners in maintaining optimal performance for all your temperature-controlled storage needs. Whether you're running a mortuary cooler in Johnson City, managing a restaurant refrigeration system in Atlanta, or operating a medical storage facility in Chicago, our expertise extends across the entire continental United States.

The journey of walk-in cooler ownership doesn't end with installation—it's just beginning. Those who achieve decades of reliable service from their units aren't lucky; they're disciplined about maintenance. They understand that clean coils and intact door seals are the foundation of efficiency. They recognize small issues before they snowball into system failures. They partner with certified professionals for specialized tasks like refrigerant handling. And importantly, they keep detailed service records that protect warranties and track performance over time.

I've seen how a well-maintained walk-in can outlast its expected lifespan by years, even decades. On the flip side, I've witnessed the frustration when businesses try to save a few dollars by skipping maintenance, only to face emergency repairs that cost ten times more—not counting the lost inventory and business disruption.

Your walk-in cooler is more than equipment—it's a critical business asset that deserves proper care. By following the guidance we've shared throughout this guide, you'll be well-positioned to maximize your investment, avoid costly surprises, and maintain the consistent temperatures your operation depends on.

We're just a call away when you need support. From custom manufacturing to ongoing service, American Mortuary Coolers is your one-stop resource for all things related to temperature-controlled storage. For more details about our comprehensive solutions, check out our guide on American Mortuary Coolers: Your One-Stop Shop.