Lift Like a Pro with These Hydraulic Pump Essentials

Why Choosing the Right Hydraulic Pump for Lift Applications Matters

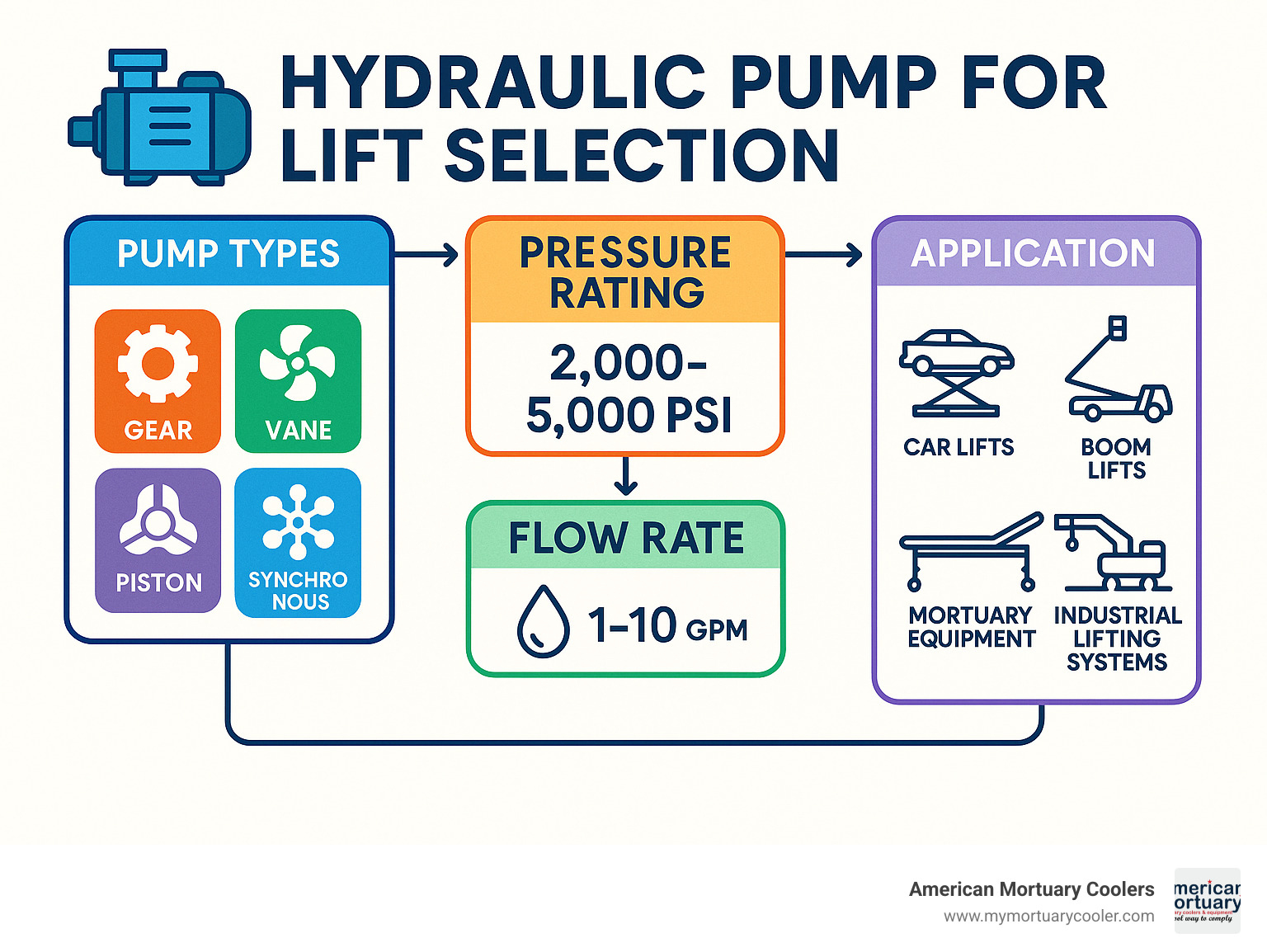

Hydraulic pump for lift systems are the heart of any reliable lifting operation, converting mechanical energy into pressurized fluid flow to power everything from car lifts to mortuary equipment. Whether you need 2,000-5,000 psi for heavy-duty applications or quieter operation for indoor use, selecting the right pump type determines your lift's performance, reliability, and maintenance costs.

Quick Reference - Hydraulic Pump Types for Lifts:

- Gear Pumps: Budget-friendly, 1,500-3,000 psi, ideal for car lifts

- Vane Pumps: Quiet operation, up to 200 bar (2,900 psi), perfect for boom lifts

- Piston Pumps: High-pressure powerhouse, 350+ bar (5,000+ psi), demanding applications

- Synchronous Pumps: Multi-point precision lifting with servo control

- Gas Power Packs: Portable field units, 5 GPM at 2,900 psi

The stakes are high when choosing lift equipment. Temperature tolerance ranges from -13°F to 175°F for quality units, while UL Recognition ensures safety compliance. Flow rates typically span 1-10 GPM depending on lift speed requirements.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with experience in hydraulic pump for lift systems across funeral home applications. My background includes sourcing and installing reliable lifting equipment that meets the demanding durability standards mortuary professionals require.

This guide breaks down the top pump categories, compares specs side-by-side, and helps you avoid the costliest selection mistakes.

Hydraulic pump for lift terms to remember:

Meet the Hydraulic Pump for Lift – How It Works, Components & Specs

Think of a hydraulic pump for lift as the beating heart of your lifting system. Just like your heart pumps blood through your body, these pumps move hydraulic fluid through your lift to create the power you need.

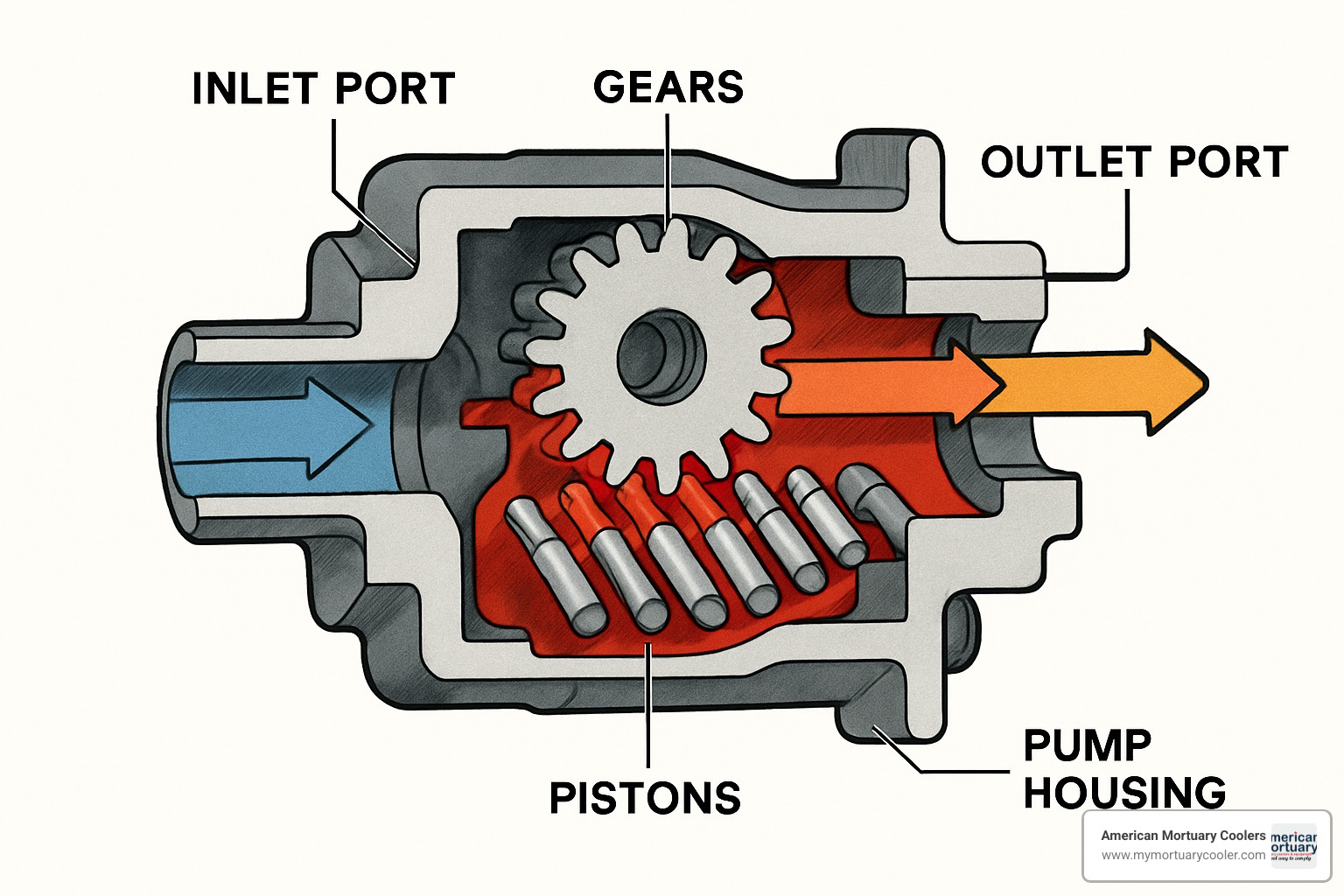

The magic happens through positive displacement. Picture a pump creating a vacuum at its inlet to pull fluid in, then using mechanical action to squeeze that fluid and push it out under pressure to your hydraulic cylinders. It's that simple conversion from mechanical energy to hydraulic energy that gives you reliable lifting power.

Most hydraulic pump for lift systems work within a pressure range of 2,000 to 5,000 psi. Flow rates typically run between 1 to 10 GPM depending on how fast you need your lift to move. Want a quick lift? You'll need higher flow rates. Need precision control? Lower flow rates give you that smooth, controlled movement.

Inside every pump, you'll find the same basic components: a sturdy pump housing, the displacement mechanism (whether that's gears, vanes, or pistons), inlet and outlet ports, a drive coupling, and a built-in pressure relief valve. That relief valve is your safety hero—it's usually preset to 2,500 to 2,900 PSI to prevent dangerous pressure buildup.

Motor options are flexible too. You can go with 12V DC for portable units or 230V AC for heavy-duty shop installations. Tank sizes range from compact 1.5-gallon units for smaller lifts up to 15+ quart reservoirs for high-cycle operations.

Hydraulic Pump for Lift: Working Principle

Gear pumps are the workhorses. Picture two gears meshing together like clockwork. As they turn, they create little pockets between the gear teeth and the housing. These pockets trap fluid and carry it from the inlet to the outlet, making them cost-effective and easy to maintain.

Vane pumps are the smooth operators. They use a rotor with sliding vanes inside an off-center chamber. As the rotor spins, the vanes slide in and out, creating chambers that change size. This gives you incredibly smooth, pulse-free flow with very little noise.

Piston pumps are the powerhouses. They use pistons moving back and forth in cylinders to create displacement. The axial piston design arranges pistons parallel to the drive shaft, with a swashplate controlling how far each piston moves. This setup gives you variable displacement and the highest pressure capabilities.

Hydraulic Pump for Lift: Key Specs to Compare

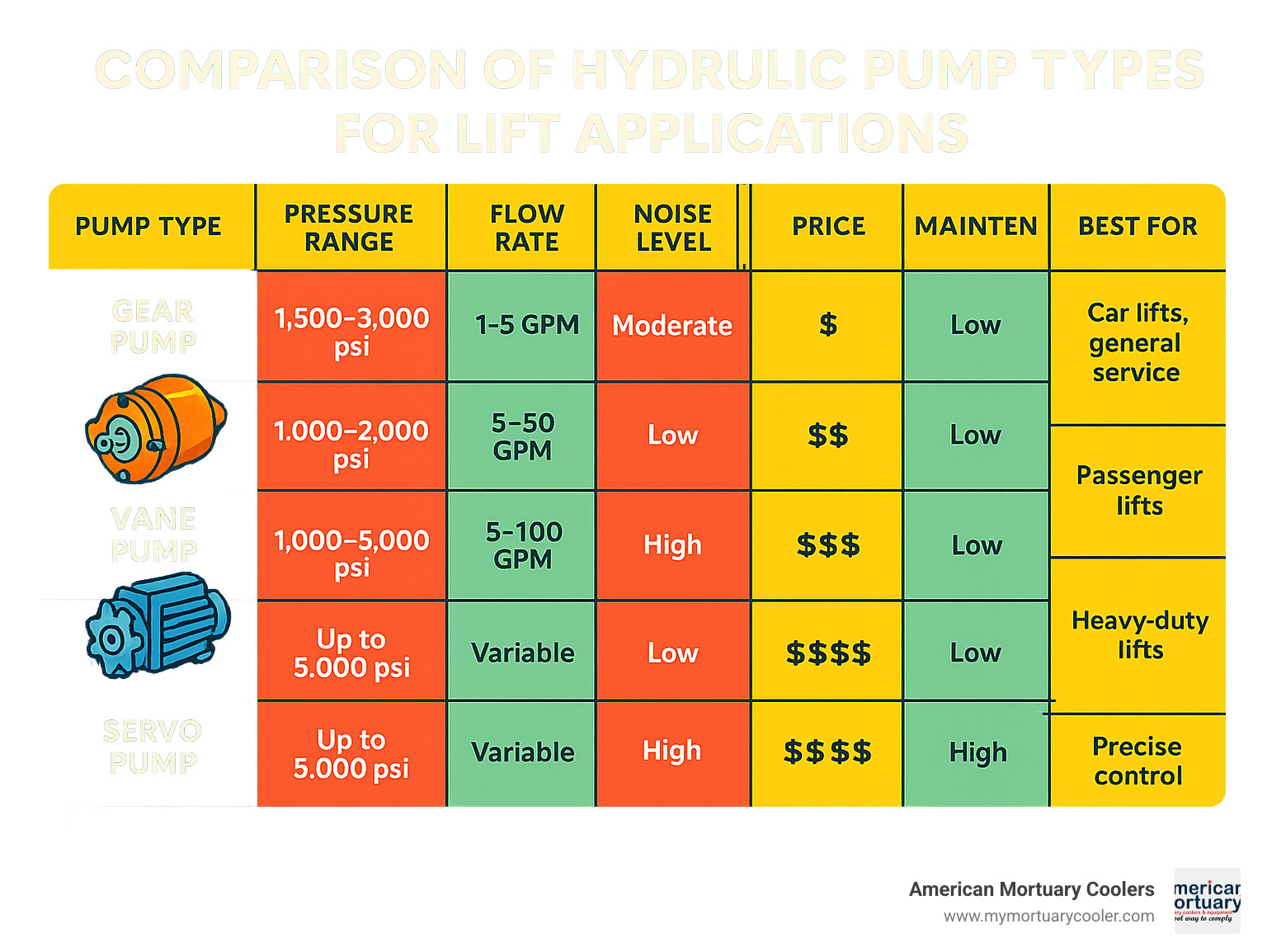

Pressure rating tells you how much force your pump can deliver. Gear pumps typically handle 1,500 to 3,000 psi, vane pumps can reach up to 200 bar (2,900 psi), while piston pumps exceed 350 bar (5,000+ psi).

Flow rate is measured in GPM (gallons per minute) and determines how fast your lift moves. A single-acting unit might deliver 1.3 GPM at 2,500 psi for steady lifting, while larger units provide 3 to 5 GPM when you need speed.

Tank size affects how well your system handles heat and how long it can run between cycles. An 8-quart capacity works well for moderate use, but continuous operation requires larger tanks.

Look for safety certifications like UL Recognition, CSA approval, or CE marking. Finally, check the temperature range. Quality units operate reliably from -13°F to 175°F.

Top 5 Pump Categories & Star Products for Every Lift Application

After years of working with funeral homes across the country—from our Tennessee base to installations in Chicago, Los Angeles, and New York—I've learned that choosing the right hydraulic pump for lift comes down to understanding what each pump type does best.

The market offers five main pump categories, each with its own strengths. Some prioritize budget-friendly reliability, while others focus on whisper-quiet operation or maximum power. Whether you're operating single-acting units that rely on gravity for return or double-acting systems that provide powered movement in both directions, understanding these categories will save you headaches and money.

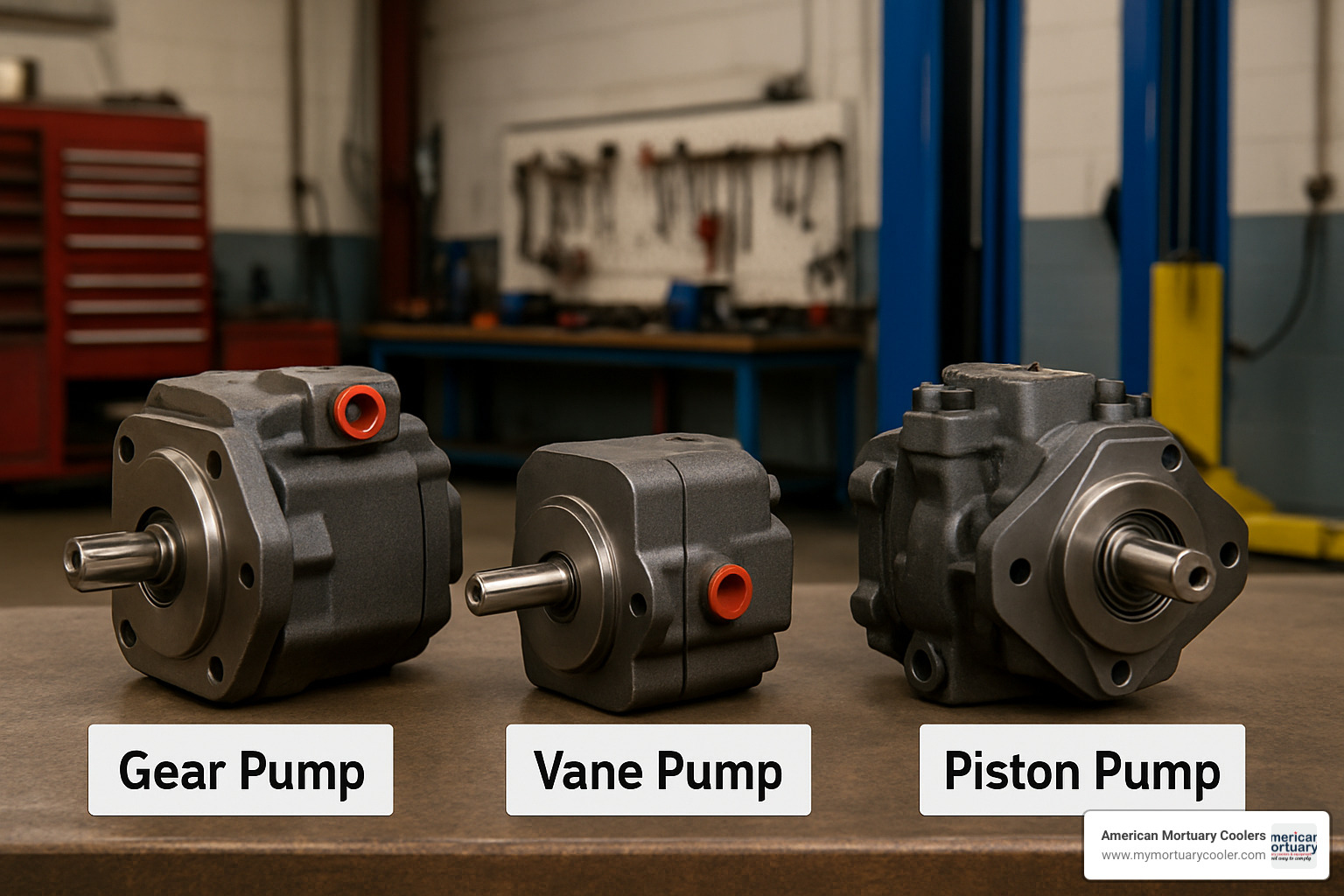

Best Gear Pump Pick – Budget & Reliable

The Twin Hydraulics Honor pump represents everything good about external gear pumps. These units are the Honda Civics of the hydraulic world—not flashy, but they'll run for years without drama. The Honor series uses two intermeshing gears to create consistent flow, delivering up to 3,000 psi in a single-stage design.

What makes gear pumps special is their simplicity. With fewer moving parts than other designs, there's less that can go wrong. The Twin Hydraulics model features pressure-loaded aluminum construction that boosts efficiency while keeping weight reasonable.

The 1-stage design means straightforward maintenance and repair. For car lifts and general automotive service, these pumps hit the sweet spot between performance and cost.

Best Vane Pump Pick – Quiet Boom Lift Performer

When noise matters, TVH TotalSource vane pumps shine. These units handle pressures up to 200 bar (about 2,900 psi) while running so quietly you might forget they're there. For funeral homes where respectful quiet is essential, or any indoor application where noise disrupts operations, vane pumps are worth their weight in gold.

The magic happens inside the pump, where sliding vanes in an eccentric chamber create smooth, pulseless flow. Unlike gear pumps that can have a slight rhythmic pulse, vane pumps deliver steady hydraulic power that translates to smoother lift operation.

TVH stocks quality brands like TotalSource, Danfoss, Casappa, and Bosch. The low noise operation makes them perfect for boom lifts operating in noise-sensitive environments.

Best Piston Pump Pick – High-Pressure Pro

The HYDAC axial piston pump is the powerhouse of the bunch. When you need more than 350 bar (over 5,000 psi), piston pumps step up to the plate. These units use a swashplate design that allows variable displacement—meaning you can adjust flow without changing pump speed for maximum efficiency.

Latest research on piston efficiency shows these pumps achieve the highest power-to-weight ratios in the industry. The axial design arranges pistons parallel to the drive shaft, with the swashplate controlling how much fluid each piston moves per revolution.

For heavy industrial lifts or high-pressure systems, piston pumps justify their higher cost through superior performance and efficiency.

Best Synchronous Pump – Precision Multipoint Lifts

The Riverlake HSE series takes hydraulic pumps into the digital age. These servo drive units can control up to 24-point lifting operations with precision that would be impossible manually.

Controlled lifting pumps overview explains how these systems eliminate manual intervention while preserving structural integrity. The HSE80120-4-3 model delivers 18 L/min at 36kW for 12-point operations, while the HSE90200-8 provides 21.6 L/min at 44kW for 8-point control.

For large structural lifting, building jacking, or precision assembly work, synchronous pumps prevent the dangerous situation where one lift point gets ahead of others.

Best Gas Power Pack – Field & Trailer Duty

When you need to work away from electrical power, the Twin Hydraulics gas-powered unit delivers freedom. Built around a robust 13 HP Honda engine, this portable powerhouse pumps 5 GPM at 2,900 psi from its 4.25-gallon hydraulic reservoir.

The Honda engine option gives you the reliability that brand is known for, while the self-contained design means you're not hunting for electrical outlets. For outdoor work and mobile applications, these gas-engine packs offer independence that electric HPUs simply can't match.

Side-by-Side Selection Guide

Let's be honest—choosing a hydraulic pump for lift systems can feel overwhelming with all the technical specs and marketing claims. After years of helping funeral homes and service shops across Tennessee and beyond, I've learned that the best decisions come from understanding how each pump type performs in real-world conditions.

Gear pumps are your reliable workhorses, handling 1,500-3,000 psi with moderate noise levels and rock-bottom maintenance needs. They're perfect for car lifts and general service work where budget matters more than whisper-quiet operation. Think of them as the dependable pickup truck of hydraulic pumps—not fancy, but they get the job done day after day.

Vane pumps step up the game with low noise operation up to 2,900 psi and smooth 2-8 GPM flow rates. Yes, they cost more upfront and need moderate maintenance, but when you're running boom lifts indoors or in noise-sensitive areas, that quiet operation pays for itself in customer satisfaction. One funeral director told me, "The difference is night and day—our families barely notice when we're moving equipment now."

Piston pumps are the heavy hitters, delivering 5,000+ psi with impressive flow rates up to 15 GPM. They're expensive and require skilled maintenance, but for demanding industrial applications, nothing else comes close to their power and efficiency. These are the units that earn their keep in high-pressure, high-cycle operations.

Synchronous pumps occupy their own specialty niche with 6-22 L/min flow rates and precise multi-point control. The price tag reflects their sophisticated servo drive systems, but when you need perfect coordination across multiple lift points, they're worth every penny. Building jacking and precision assembly work simply can't be done safely any other way.

Gas power packs sacrifice quiet operation for ultimate portability, delivering 5 GPM at 2,900 psi wherever you need it. They're louder than a morning rooster but invaluable for field service and mobile operations. When the power's out or you're miles from the nearest outlet, these self-contained units keep working.

More info about choosing a hydraulic lift pump covers additional selection factors specific to different industries and applications.

Quick Selector Flowchart

The fastest way to narrow your choices? Start with your primary application and work backwards. Car and vehicle lifting calls for gear pumps when budget's tight or vane pumps when noise matters. Boom and aerial work almost always benefits from vane pumps' quiet operation—your neighbors will thank you.

Heavy industrial applications demand piston pumps' maximum pressure capabilities, while multi-point lifting requires synchronous pumps' coordination features. Field and mobile work naturally points toward gas power packs for their independence from electrical power.

Your environment shapes the decision too. Indoor or noise-sensitive locations favor vane or synchronous pumps, while outdoor or rugged conditions suit gear pumps or gas power packs better. All quality units handle -13°F to 175°F temperature ranges, so extreme weather shouldn't eliminate any category.

Budget considerations often make the final call. Gear pumps deliver the best value for straightforward applications, piston pumps justify their higher cost through superior efficiency in demanding work, and synchronous pumps make sense only when their unique capabilities are truly needed. Sometimes the most expensive option costs less in the long run—but sometimes simple really is better.

Maintenance, Troubleshooting & Safety Must-Dos

With hydraulic pump for lift systems, a little attention goes a long way. After working with funeral homes from Tennessee to California, I've seen too many expensive failures that could've been prevented with simple care.

Most pump problems announce themselves before they become disasters. That grinding noise, the slower lift speed, or the puddle of fluid under your equipment—these are your pump's way of asking for help.

Daily checks take just two minutes. Look at your fluid level and color through the sight gauge. Clean fluid should be clear or amber, not black or milky. Weekly inspections mean listening for unusual noises and checking for leaks around fittings and seals.

Monthly pressure relief valve testing prevents dangerous over-pressure situations. These components typically open at 2,500-2,900 psi. Gradually increase load until the valve releases—if it doesn't open at the correct pressure, replacement is critical for safety.

Quarterly fluid changes with proper filtration prevent 80% of pump failures. Contaminated fluid destroys pumps faster than anything else. The "hopping technique"—quarter-turning the hydraulic valve—helps clear debris and reseat pumps when trash gets in the system.

Temperature matters more than most people realize. Quality units handle -13°F to 175°F, but extreme heat accelerates wear dramatically. Safety certifications like UL, CSA, and CE markings ensure your equipment meets electrical and pressure vessel standards. Always follow lock-out-tag-out procedures before any maintenance work. Scissor lift safety checklist covers additional protocols specific to lift applications.

Preventing the 5 Most Common Pump Failures

Contamination causes nearly half of all pump failures. Dirt, metal particles, and water destroy internal components. Large suction-tube filters and proper air-filter caps on your reservoir make a huge difference.

Cavitation happens when pumps can't get enough fluid. You'll hear that distinctive grinding, rattling noise. Check fluid levels first, then inspect suction lines for restrictions or leaks.

Overheating kills pumps that run beyond their duty cycle. Most car lift pumps need cool-down periods between operations. Continuous operation without breaks causes oil breakdown and seal failure.

Seal failure is inevitable with time and pressure cycles. Replace seals at manufacturer intervals, not after they start leaking. Prevention costs less than emergency repairs.

Wrong fluid type causes more problems than you'd expect. Always match manufacturer specifications for viscosity and additive packages.

DIY Fix or Call the Pro?

Some repairs make sense to tackle yourself, others don't. Fluid and filter changes are straightforward with basic tools. Seal kit installation is doable if you have the right pullers and drivers.

Pressure relief valve adjustment requires a gauge and patience, but saves service calls. Electrical connection tightening prevents mysterious failures from vibration-loosened wires.

Motor rebuilds need professional attention. Pump internal repairs fall into the same category—false economy often turns minor issues into major expenses.

The replacement versus rebuild decision usually comes down to economics. If repair costs exceed 60% of replacement cost, or your unit is over 10 years old, replacement typically offers better long-term value.

Frequently Asked Questions About Hydraulic Lift Pumps

After helping countless funeral homes and service shops across the country choose the right hydraulic pump for lift systems, I've noticed the same questions come up again and again. Let me share the answers that have helped our customers make confident decisions.

How do I size a pump for my car lift?

Getting the sizing right feels overwhelming at first, but it's actually straightforward once you know what to look for. Think of it like buying shoes—you need the right fit for comfort and performance.

Start with pressure requirements. Most car lifts need 2,500-3,000 psi to operate safely. Your lift's nameplate or manual will tell you the exact number. Never go below this rating—it's like trying to inflate a tire with a bicycle pump.

Calculate your flow rate next. This determines how fast your lift moves. If you want your lift to reach full height in 30 seconds and you're working with 4-inch cylinders, you'll need approximately 2-3 GPM flow rate. Faster isn't always better—too much flow can make precise positioning difficult.

Don't forget cylinder volume. Add up the total fluid volume needed by multiplying cylinder area by stroke length for all cylinders. Your tank should hold 3-4 times this volume to prevent overheating and ensure smooth operation. I've seen too many pumps fail early because someone skimped on tank size.

What's the difference between single-acting and double-acting units?

This question usually comes up when customers see different price points and wonder what they're paying for. The difference is simpler than most people think.

Single-acting systems provide power in just one direction—typically lifting up. Gravity or springs handle the return trip down. The HPU-LG-24VDC we often recommend works exactly this way with "power-up, gravity-down" functionality. These systems cost less, have fewer parts to break, and work perfectly for most car lifts and scissor lifts.

Double-acting systems power movement both ways, giving you controlled lifting and lowering. You get better precision, but you'll pay more for the complex valve arrangements and additional components.

Here's my rule of thumb: single-acting works great for car lifts, basic scissor lifts, and any application where gravity return makes sense. Choose double-acting when you need to hold loads at specific heights or when controlled lowering matters for safety.

How much should I budget for a replacement pump?

Nobody likes budget surprises, especially when equipment fails unexpectedly. Based on our experience installing systems from Tennessee to California, here's what you should realistically expect to spend.

Basic gear pump units that handle most car lift applications run $400-800 for 2-3 GPM capacity. These workhorses get the job done without breaking the bank. Quality vane pump systems for quieter operation cost $800-1,500—worth it if noise matters in your shop.

High-pressure piston units for demanding applications jump to $1,500-3,000, while specialized synchronous multi-point systems start around $5,000. Gas power packs for field work typically run $2,500-2,700.

Don't forget the extras that add up quickly. Installation labor runs $200-500 depending on complexity. You'll need $50-150 for fresh hydraulic fluid, possibly $100-300 for new hoses and fittings, and another $100-200 for electrical connections.

Here's the thing about value—higher-priced units often include comprehensive warranties covering parts, labor, and shipping. When you're comparing options, factor in the peace of mind that comes with solid warranty coverage. A pump failure during your busiest season costs more than just the repair bill.

Conclusion

Choosing the right hydraulic pump for lift system isn't just about getting your equipment up and running—it's about ensuring years of reliable service, safe operation, and smart financial investment. After walking through everything from basic gear pumps to sophisticated synchronous systems, the path forward becomes clearer.

The beauty of hydraulic lifting lies in matching the right tool to your specific job. Gear pumps remain the workhorses for everyday automotive lifting, delivering dependable performance without breaking the budget. When noise matters—think indoor boom lifts or customer-facing areas—vane pumps provide that smooth, quiet operation your ears will thank you for.

For those heavy-duty applications where nothing else will do, piston pumps step up with the muscle to handle extreme pressures. Meanwhile, synchronous pumps bring precision to complex multi-point lifting that would be impossible to coordinate manually. And when you need to get the job done where there's no power outlet in sight, gas power packs deliver that independence.

At American Mortuary Coolers, we've seen how the right lifting equipment transforms operations. From our Tennessee headquarters, we've delivered custom solutions from the Pacific Northwest to the Florida Keys, and one thing remains constant: quality matters. Whether it's a funeral home in Chicago needing reliable body lift systems or a facility in Dallas requiring specialized mortuary equipment, the principles stay the same.

Temperature extremes from -13°F to 175°F don't faze quality units, and proper certifications like UL, CSA, and CE aren't just letters on a nameplate—they're your assurance that safety engineering went into every component.

Your hydraulic pump for lift system is only as good as how well you maintain it. Those simple daily checks, regular fluid changes, and professional inspections aren't just suggestions—they're insurance policies against costly breakdowns and safety incidents.

Safety never takes a back seat. Follow those maintenance schedules religiously, stick with manufacturer-specified fluids, and never bypass safety systems. When something doesn't feel right, trust your instincts and call in the professionals.

More info about mortuary lifts

Ready to take the next step? Our team understands that every application has its unique challenges. We deliver custom solutions across all 48 contiguous states, backed by the technical support that makes installations successful from day one. Because when it comes to lifting equipment, you deserve solutions that work as hard as you do.