The Power Behind Modern Lifting Systems

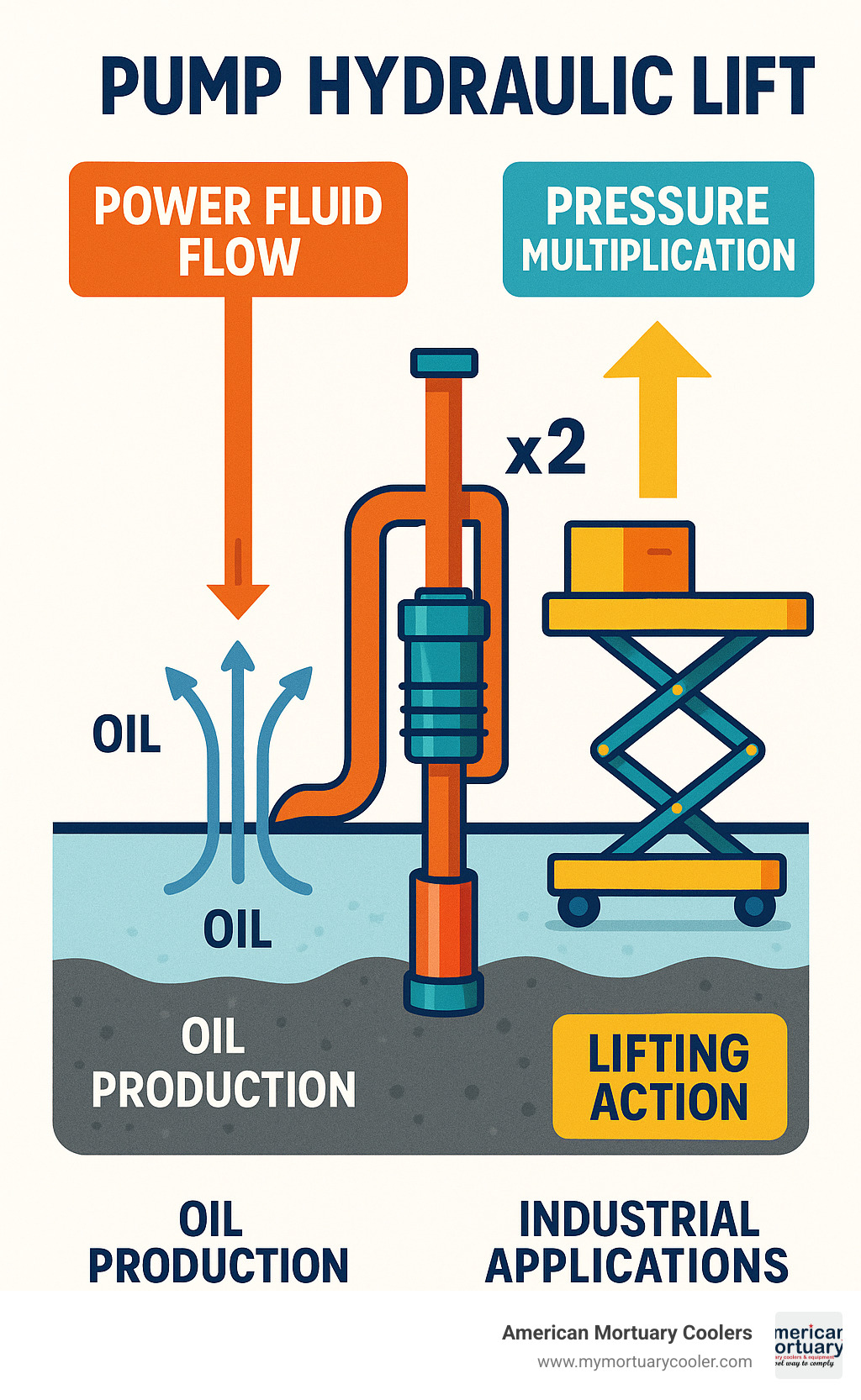

A pump hydraulic lift is a versatile artificial lift system that uses pressurized fluid to move liquids from one level to another. Whether you're in oil production, industrial applications, or specialized settings like mortuaries, understanding these systems is crucial for operational efficiency.

Quick Answer: What is a pump hydraulic lift?

| Aspect | Details |

|---|---|

| Definition | A system that uses pressurized hydraulic fluid to create lifting force |

| Operating Pressure | Typically 2,000-5,000 psi |

| Production Ratio | 3 barrels power fluid in → 5 barrels total out (2 barrels new production) |

| Key Advantage | Works on both upstroke and downstroke for continuous production |

| Best Applications | Oil wells, industrial equipment, specialized lifts (mortuary, automotive) |

| Types | Jet pumps, piston pumps, free parallel, fixed insert |

Hydraulic lift pumps convert mechanical energy into fluid power, creating impressive lifting capabilities without electricity in some designs. The beauty of these systems lies in their simplicity and effectiveness - they harness Pascal's Law to multiply force through fluid pressure.

In oil and gas production, these systems can handle everything from low to high volumes, making them incredibly versatile across different well conditions. The ability to adjust power fluid volumes on the fly with a simple valve makes optimization quick and straightforward.

For specialized applications like mortuary operations, hydraulic scissor lifts provide reliable, precise movement with capacities exceeding 1,000 pounds - essential for the safe handling of caskets and body trays.

I'm Mortuary Cooler, and I've spent years helping funeral directors select appropriate hydraulic lift pump systems for their mortuary operations, ensuring smooth and dignified handling capabilities through properly engineered pump hydraulic lift solutions. My experience has shown that the right hydraulic system not only improves operational efficiency but also improves staff safety.

Why This Guide Matters

Selecting the right pump hydraulic lift system isn't just about getting the job done—it's about maximizing efficiency, extending equipment life, and controlling costs. In oil and gas operations, an optimized hydraulic lift can mean the difference between a profitable well and one that drains resources. For mortuary operations, it ensures dignified and safe handling while protecting your staff from injury.

At American Mortuary Coolers, we've seen how the right hydraulic system can transform operations. One funeral home director in Tennessee told us, "The Battery Scissor Lift meets my needs perfectly and I am quite satisfied with its operation and overall quality. I like how the Roller Brake system works." This kind of satisfaction comes from understanding the technology and making informed choices.

Who Should Read

This guide is designed for:

- Oil and gas well operators looking to optimize production

- Maintenance teams responsible for hydraulic system upkeep

- Engineers designing new lift installations

- Funeral directors selecting equipment for mortuary operations

- Facility managers overseeing industrial lift systems

Whether you're in Johnson City, TN, or Los Angeles, CA, the principles of hydraulic lift systems remain the same. Our experience serving clients across all regions of the United States has shown us that knowledge is the foundation of successful hydraulic lift implementation.

Pump Hydraulic Lift 101: How It Works & Key Components

At its core, a pump hydraulic lift operates on Pascal's Law, which states that pressure applied to a confined fluid is transmitted equally in all directions. This simple but powerful principle allows hydraulic systems to multiply force dramatically - it's like having a mechanical superpower!

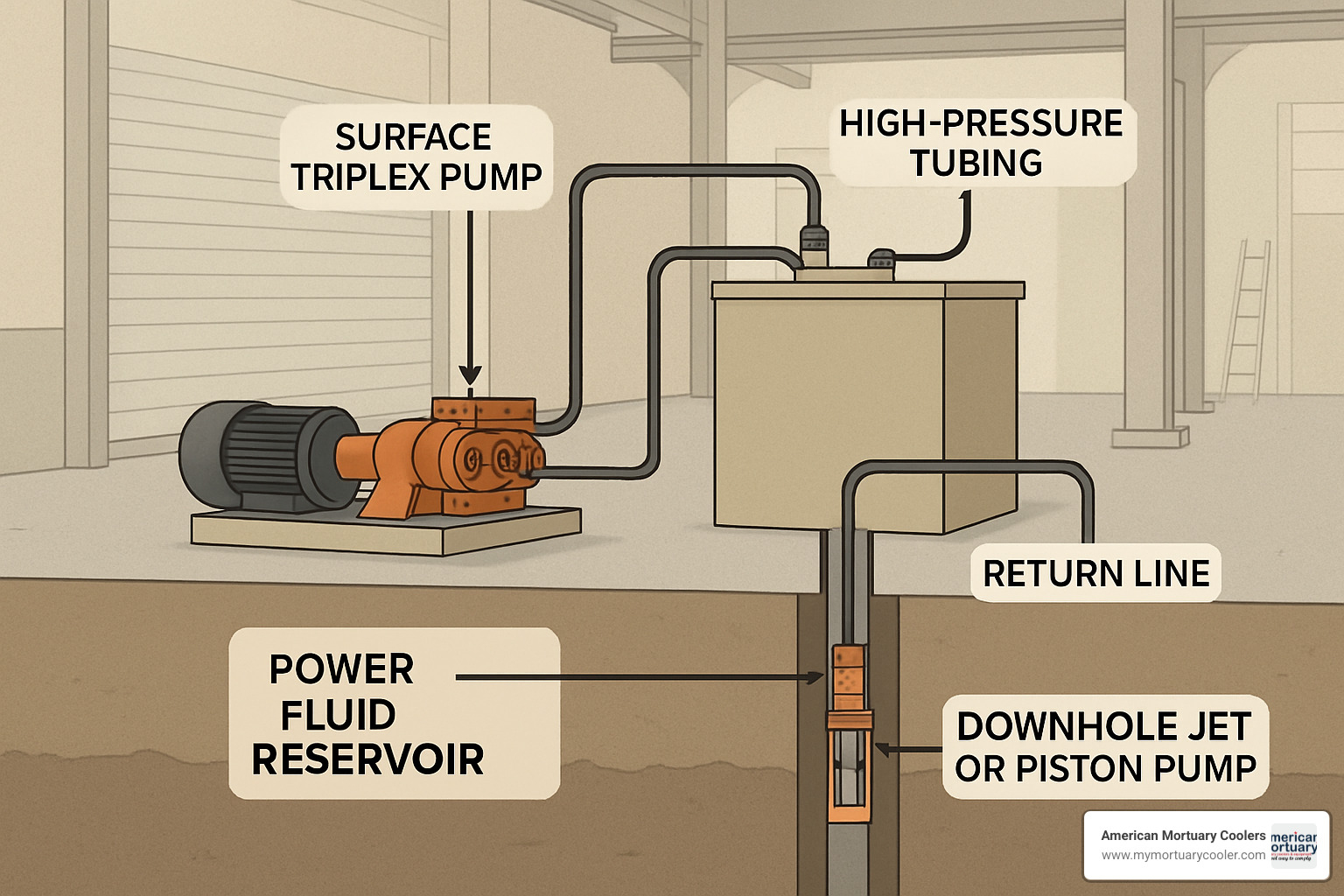

In an oil well application, everything starts with a high-pressure triplex surface pump that pressurizes a power fluid (usually oil or water). This pressurized fluid travels down the well through tubing to the downhole pump. Depending on the type of hydraulic lift, the downhole component might be a jet pump with a nozzle and throat, or a piston pump with standing and traveling valves.

I remember talking with an operator from our Dallas region who explained it perfectly: "Think of it like a water hose with your thumb partially covering the end. The same amount of water has to get through a smaller opening, creating higher pressure and velocity. That's essentially what happens in the jet throat of a hydraulic pump."

Inside a Pump Hydraulic Lift System

The anatomy of a pump hydraulic lift system is like a well-choreographed dance of components working together. At the surface, you'll find a powerful triplex or quadruplex positive displacement pump generating the high pressure needed (2,000-5,000 psi). This pressurizes the power fluid - the hydraulic medium that transmits pressure throughout the system.

The inlet and outlet valves control the flow direction, ensuring everything moves exactly where it should. Downhole, either a jet pump or piston/plunger design does the heavy lifting. Once the work is done, the return line brings both produced fluid and power fluid back to the surface, where a separator divides the production fluid from the power fluid for recirculation.

In a jet pump system, the pressure ratio between the power fluid and production fluid creates a pressure differential that draws well fluids into the pump. As explained in Hydraulic Pumps – How They Work, "A pump does not generate pressure but produces flow; system pressure arises from flow resistance." Understanding this principle is the key to maximizing your hydraulic lift efficiency.

Pressure, Flow & the Production Ratio

The real magic of pump hydraulic lift systems is in their production ratio. Picture this: for every three barrels of power fluid pumped downhole, you get five barrels returned to the surface—meaning two barrels are brand new production. This 3:5 ratio (or 60% efficiency) is what we use as a benchmark when evaluating how well your system is performing.

Most systems operate at pressures between 2,000 and 5,000 psi, with modern surface pumps achieving energy efficiencies greater than 90%. As Wanner Hydra-Cell reports, their "Pro surface power fluid pumps operate at greater than 90% energy efficiency," converting almost all input power into useful hydraulic energy.

A maintenance engineer I worked with in Chicago shared some wisdom: "We monitor the pressure-to-flow relationship daily. Any unexpected changes can signal problems like sand buildup, valve issues, or power fluid contamination. Catching these early saves thousands in repair costs." That's advice worth its weight in gold!

Essential Surface Equipment

The surface equipment in a pump hydraulic lift system deserves just as much attention as what's happening downhole. Your triplex or quadruplex pumps create the high pressure needed to drive the system, typically featuring multiple pistons to maintain consistent pressure. Paired with these, accumulators act like shock absorbers, dampening pressure fluctuations and protecting your system from harmful spikes.

Filters are absolutely critical - they keep your power fluid clean and prevent debris from damaging those expensive downhole components. As one experienced operator told me, "Those tiny abrasion particles 'surf your oil' and go everywhere if you don't filter properly."

Heat exchangers play the important role of temperature control, preventing overheating that can degrade seals and reduce fluid viscosity. And powering it all are your motor drives - whether electric, diesel, or gas-powered, depending on your site conditions and operational requirements.

I always tell our clients across the Southeast, "Your hydraulic lift is only as good as your surface equipment. Invest wisely here, and you'll see the returns downhole." It's like taking care of the heart to ensure the whole body functions well.

Types, Pros & Best Applications of Hydraulic Lift Pumps

The world of pump hydraulic lift technology is surprisingly diverse, with specialized designs to meet almost any lifting challenge you might face. I've seen how choosing the right system can make or break an operation.

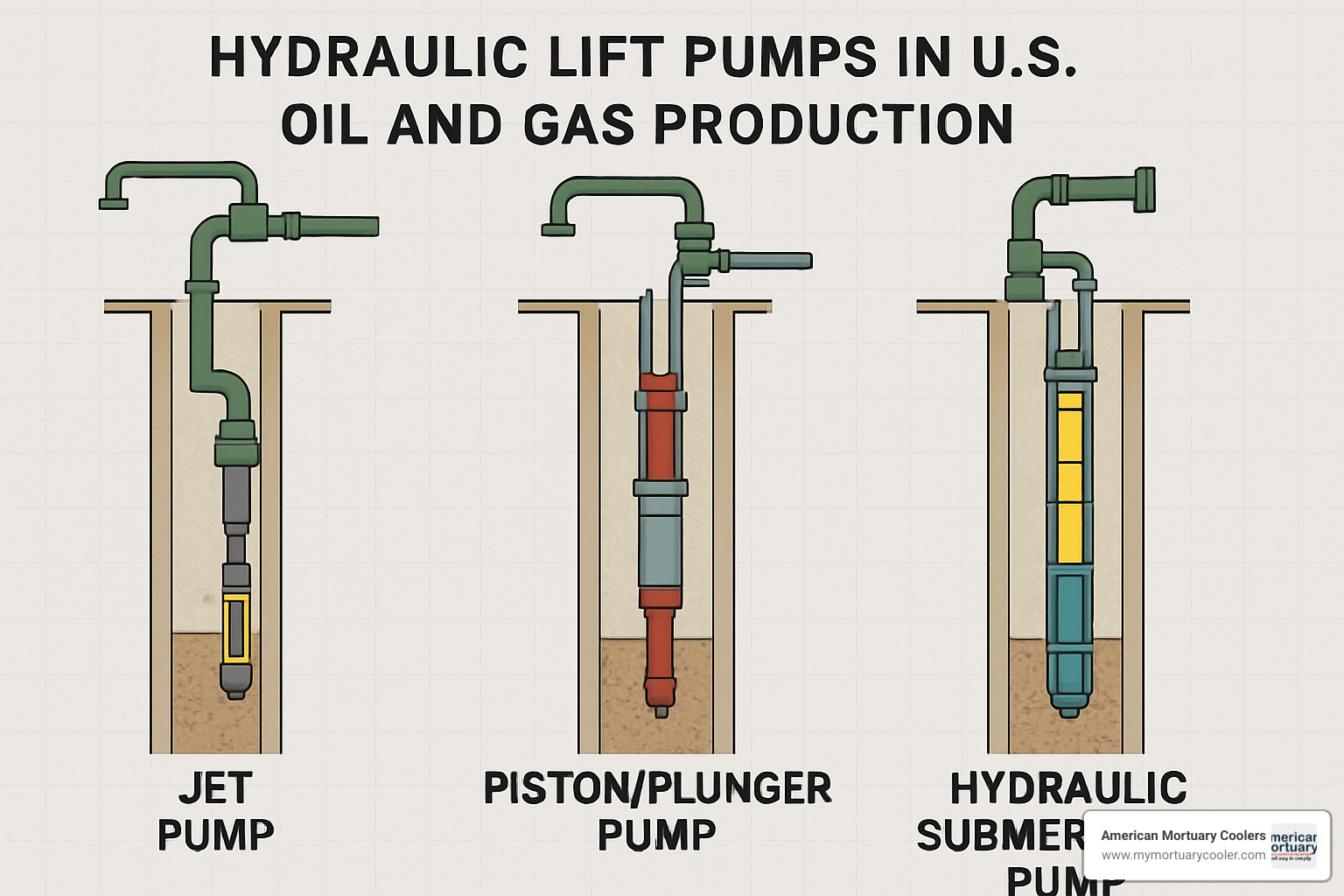

Jet Pump Hydraulic Lift Systems

If you're looking for simplicity and reliability, jet pump systems might be your answer. These clever pump hydraulic lift systems use the Venturi effect—essentially creating a pressure differential that sucks well fluids into the production stream.

What makes jet pumps special is their lack of moving parts downhole. This means far fewer headaches for maintenance teams and fewer things that can break when you least expect it. They're champions at handling sand too—I've seen jet pumps keep chugging along in conditions that would destroy other lift systems in days.

"We switched several challenging horizontal wells to jet pumps after fighting rod wear issues for years," a production engineer from Texas told me recently. "The difference was immediate—production stabilized, and our maintenance calls dropped by 70%."

Jet pumps particularly shine in wells with high gas production and in tricky configurations like slim-hole and deviated wells where traditional rod pumps struggle. Most designs can be installed without expensive workover rigs, using just well pressure to get the job done.

For smaller applications, products like the VEVOR Air Hydraulic Pump bring similar technology to workshops and specialty applications, showing how versatile these systems can be.

Piston & Plunger Hydraulic Lift Pumps

When efficiency is your top priority, piston and plunger pump hydraulic lift systems deserve your attention. Unlike their jet pump cousins, these systems do have moving parts downhole, but they offer excellent volumetric efficiency—often exceeding 90% when properly maintained.

The beauty of piston systems is their double-acting design, producing fluid on both the upstroke and downstroke. This maximizes production without wasting a single stroke. Many operators I've worked with appreciate the "hop-to-clear debris" technique—a simple quarter-turn on the wellhead valve can reseat insert pumps after clearing debris, saving countless hours of downtime.

These systems really shine in wells with stable production characteristics and moderate depths. I've installed dozens across the Midwest where conditions are just right for this technology.

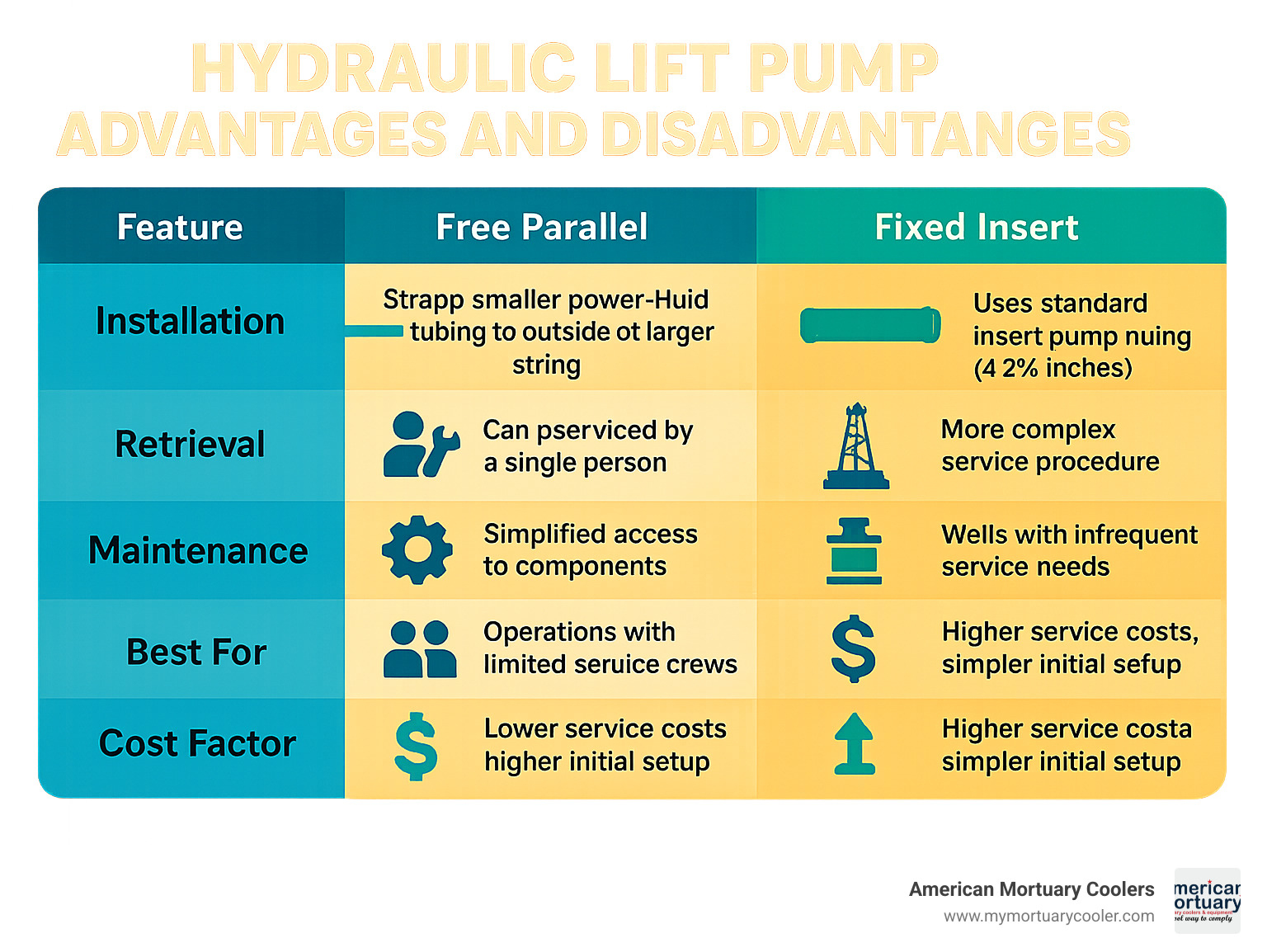

Free Parallel vs Fixed Insert

The debate between free parallel and fixed insert pump hydraulic lift designs continues at every industry gathering I attend. Each has clear advantages depending on your situation.

Free parallel systems strap smaller power-fluid tubing to the outside of a larger string, allowing for simplified access to components. They can often be serviced by a single person without specialized equipment. "Free parallel pumps are my go-to when I know we'll need frequent adjustments," a maintenance supervisor from Atlanta told me. "The ability to service them without calling in a crew pays for itself within the first year."

Fixed insert systems, by contrast, use standard insert pump tubing (typically around 2⅜ inches) and generally require a workover rig for retrieval. While this means higher service costs, they often show better long-term reliability in stable production environments. This makes them popular in regions where labor costs are higher or where service intervals can be longer.

Niche Applications Beyond Oil & Gas

The clever engineering behind pump hydraulic lift systems extends far beyond oil fields. Some of my favorite applications show just how versatile this technology can be.

Water high-lifter pumps are ingenious devices that use falling water's energy to pump some of that water to higher elevations—without external power. They're like nature's hydraulic levers, perfect for remote locations without electricity.

At American Mortuary Coolers, we've integrated hydraulic scissor lifts into our mortuary solutions. These specialized lifts use industrial-strength hydraulic pump cylinders capable of handling over 1,000 pounds, making them perfect for safely moving caskets, body trays, and cremation boxes. As one Tennessee funeral director told us, "I can access all three storage rack levels without issue or strain."

Even hovercraft designers have acceptd hydraulic technology, using it to power lift fans in single-engine craft. The system converts mechanical rotation from the main engine into high-pressure fluid flow that drives the lift fan—a perfect example of hydraulic power's adaptability.

These diverse applications show that the principles behind hydraulic lifting can solve unique challenges across virtually any industry—from the oil field to the funeral home and beyond.

Advantages, Disadvantages & Cost Factors

Let's face it – every lifting technology has its sweet spots and its challenges. When it comes to pump hydraulic lift systems, knowing these ins and outs helps you make choices that won't come back to haunt your budget or operations later.

Key Advantages of Pump Hydraulic Lift

One thing I love about pump hydraulic lift systems is their incredible adaptability. Whether your well is a modest producer or a gusher, these systems can handle it all. This flexibility is worth its weight in gold when production characteristics change over time.

Unlike their rod pump cousins that only produce on the upstroke, hydraulic pumps work both ways – upstroke and downstroke – essentially doubling their efficiency. It's like getting two pumps for the price of one!

"I can literally dial in the perfect production rate while standing at the wellhead," shared an operator from Columbia, SC who I worked with last year. This on-the-fly adjustability means you're not stuck with whatever rate you initially set – just turn a valve and you've optimized your production without calling in a service crew.

For larger operations, the ability to run multiple wells from a single surface power unit is a game-changer. This centralized approach not only simplifies maintenance but substantially reduces your per-well investment. And if you opt for jet pumps, you'll eliminate downhole moving parts entirely – as Wanner puts it, their "rig-free jet pump design eliminates the need for down-hole moving parts and workover rigs, reducing maintenance and downtime."

Common Drawbacks & How to Mitigate

No system is perfect, and pump hydraulic lift technology comes with its own challenges. The good news? Most have practical solutions.

Sand erosion can be a real headache, especially with jet pumps where high-velocity fluid flow acts like liquid sandpaper on your equipment. I've seen operators in the Rockies extend component life dramatically by installing ceramic nozzle inserts – they're harder than the sand particles and resist wear far better than standard materials.

The mixing of power fluid and production often creates stubborn emulsions that refuse to separate. One clever operator I know solved this by adding demulsifier at the wellhead and installing a vertical separator with extended residence time. "Problem solved," he told me with a grin.

Power-fluid contamination happens gradually as production impurities work their way into your system. A maintenance engineer from Pittsburgh shared his simple but effective approach: "We check filter cartridges weekly and change them before pressure rise becomes an issue." This proactive maintenance prevents small problems from becoming expensive ones.

The surface equipment does require space and attention, which can be a consideration for smaller operations. However, by centralizing power fluid systems to serve multiple wells, you can significantly reduce both the physical and maintenance footprint per well.

Budgeting & Lifecycle Costs

When talking dollars and cents with pump hydraulic lift systems, looking beyond the sticker price reveals the true value proposition.

Your initial capital expenditure (CAPEX) will include the surface pump and power system ($50,000-$150,000 depending on capacity), downhole equipment ($15,000-$50,000), and installation costs ($10,000-$30,000, though significantly less for rig-less systems). These numbers might make your accountant nervous at first glance.

But here's where the story gets interesting. Modern systems with greater than 90% efficient pumps keep energy costs surprisingly low. Maintenance typically runs 5-10% of initial CAPEX annually, while fluid treatment and filtration costs vary with your specific production profile.

The real financial magic happens with workover savings. A client operating in the Pacific Region called me last year with exciting news: "We cut our workover frequency by 60% after switching to hydraulic jet pumps. At $50,000 per workover, that's serious money saved." That kind of reduction goes straight to the bottom line.

When we help clients evaluate these systems at American Mortuary Coolers, we encourage thinking about the total 5-10 year ownership horizon. The initial investment in quality equipment almost always pays for itself through reduced operational headaches, fewer emergency service calls, and improved production efficiency. It's the difference between buying cheap and buying smart – and in this business, smart wins every time.

How to Select, Install & Maintain a Pump Hydraulic Lift

Choosing the right pump hydraulic lift system is a bit like finding the perfect pair of shoes – it needs to fit your specific needs, be comfortable to work with, and last through many miles of operation. Let me walk you through the practical side of selection, installation, and maintenance that will keep your system running smoothly for years to come.

Selection Checklist for Pump Hydraulic Lift Systems

When I sit down with clients to help them choose the right pump hydraulic lift, I always start by understanding their well's personality. Every well is unique, just like every funeral home has its own specific needs.

The depth of your well matters tremendously – deeper wells demand higher surface pressure, which affects your entire system design. I had a client in Wyoming who overlooked this factor and ended up with insufficient lift capacity. "I wish someone had just asked me how deep my well was before I bought all this equipment," he told me later.

Your production target is equally important. There's no point installing a Ferrari engine when you only need to drive to the grocery store! Match your pump capacity to what you actually need to produce. The fluid properties also play a crucial role – viscous, waxy crude requires different handling than light oil, just as different mortuary operations have unique requirements.

If you're dealing with high gas-liquid ratios, jet pump designs often work best. I remember a client in Oklahoma who switched to a jet pump and saw his production stabilize almost overnight after struggling with gas locking in his previous system.

Heavy sand production? Lean toward jet pumps with no moving parts. "Those sand particles are like tiny sandblasters," as one of our Texas clients colorfully put it. "They'll eat through moving parts faster than you can replace them."

Don't forget to consider your available power source, space constraints, and local environmental regulations. In colder regions like Minnesota, you'll need to account for potential freezing issues that our Tennessee clients rarely worry about.

One of the best pieces of advice I can offer is to use simulation tools like the Wanner Pump Analyser™ software to model your well's behavior before committing. This upfront homework can save you thousands in the long run.

Installation Essentials & Best Practices

Installing a pump hydraulic lift system reminds me of preparing a mortuary facility – cleanliness is absolutely paramount. Every component should be thoroughly cleaned before assembly. I've seen contamination from the installation process cause more problems than almost anything else.

Start by pressure testing all your surface equipment. One client in Louisiana skipped this step and had a catastrophic leak on day one – an expensive lesson that could have been avoided with a simple test.

When setting up your surface equipment, keep those high-pressure lines as straight as possible. Think of them like arteries – kinks and bends create resistance and heat. Position your hydraulic reservoir above the pump to ensure proper gravity feed, something I learned the hard way early in my career.

Always install pressure relief valves. They're like the safety valves in a mortuary cooler system – you hope you never need them, but you'll be mighty glad they're there if pressure spikes unexpectedly.

"The filter is your system's kidneys," as I often tell clients. Place it on the low-pressure side near the pump to catch those abrasive particles before they can do any damage. Make sure it's in a location where maintenance staff can easily access it – you don't want to need acrobatic skills just to change a filter cartridge.

For downhole configuration, proper seating is critical. A partially seated pump is like a door left ajar – it's going to cause problems sooner rather than later.

Preventive Maintenance & Troubleshooting

Maintaining your pump hydraulic lift is where the rubber meets the road. I always tell my clients that regular maintenance isn't an expense – it's an investment that pays dividends through extended equipment life and reduced downtime.

Start with daily monitoring. Record those operating pressures and compare them to your baseline – unexpected changes are often the first warning sign of developing issues. It's like taking your temperature when you feel a bit off – a simple check that can catch problems early.

Listen to your equipment. Unusual noises rarely improve on their own. One maintenance manager in Florida told me, "My ears catch problems before my gauges do." He wasn't wrong – the human ear is remarkably good at detecting changes in sound that might indicate pump cavitation or bearing wear.

Scheduled maintenance should become as routine as changing the oil in your car. Replace filter cartridges before pressure differentials become excessive. Don't wait until they're completely clogged – that's like waiting until your car runs out of gas to fill up.

When troubleshooting, start with the simplest explanation. When production stalls, try the 'hop' technique first – a quarter-turn on the wellhead valve can often clear debris without requiring a full workover. I've seen this simple trick save operators thousands in unnecessary service calls.

Modern systems can now integrate with software solutions like Greasebook's Pumper Engagement System™, which provides alerts and tracks maintenance needs. One of our clients in Virginia reduced their emergency repairs by 70% after implementing a digital maintenance tracking system.

As we say in both the funeral industry and oil production: preventive care always costs less than emergency intervention. A well-maintained pump hydraulic lift system is like a reliable mortuary cooler – it quietly does its job day after day, only drawing attention when something goes wrong. With proper selection, installation, and maintenance, your system can provide years of trouble-free service.

Innovations, Software Integration & FAQs

The world of pump hydraulic lift technology continues to evolve, with new innovations improving efficiency, reliability, and environmental performance.

How IoT & Software Boost Pump Performance

Remember when we had to physically check every pump gauge daily? Those days are rapidly disappearing. Today's pump hydraulic lift systems have gotten remarkably smarter thanks to Internet of Things (IoT) technology and specialized software.

Take digital twins, for instance. These virtual models of physical pumps let operators play "what if" without touching the actual equipment. A client of ours in Los Angeles recently told me, "Our digital twin model helped us optimize power fluid rates across 12 wells, increasing overall production by 15% without any hardware changes." That's like getting a free production boost just by being smarter about how you use what you already have.

SCADA systems have transformed from simple monitoring tools to intelligent control centers. Modern systems don't just show you what's happening—they automatically adjust operating parameters based on changing well conditions. It's like having your most experienced operator watching your pumps 24/7.

The predictive maintenance revolution has been particularly game-changing. Software like Wanner Pump Analyser™ combines historical data with real-time monitoring to spot potential failures before they happen. As one Tennessee client put it, "We went from reactive to predictive maintenance and cut our unplanned downtime by 80%." That's the difference between constantly fighting fires and preventing them in the first place.

Even the humble field report has evolved. Applications like Greasebook now let field personnel record and track data from their phones, improving accuracy and enabling faster responses. For companies managing wells across wide areas, these tools allow experts in one location to support operations anywhere. At American Mortuary Coolers, we've seen how this same principle applies to monitoring our cooling systems across multiple locations.

Frequently Asked Questions about Pump Hydraulic Lift

What makes a pump hydraulic lift better than ESP or rod lift?

This is probably the most common question I hear when discussing lift options. A pump hydraulic lift shines in several scenarios where ESPs and rod lifts struggle.

Flexibility is a major advantage—hydraulic systems handle production swings that would burn out an ESP or overload a rod pump. They don't need electricity downhole, eliminating a failure point that plagues ESPs in harsh environments.

For those challenging deviated and horizontal wellbores, hydraulic systems (especially jet pumps) significantly outperform rod pumps. One production engineer I work with in Georgia commented, "After fighting rod wear issues in our deviated wells for years, switching to hydraulic jet pumps cut our workover frequency by 70% and stabilized production."

The workover savings alone can justify the switch. When a jet pump needs service, you can often retrieve it without a workover rig—a potential savings of $50,000 or more per intervention.

That said, hydraulic systems aren't always the best choice. ESPs excel in very high-volume, deep wells, while rod pumps remain cost-effective for conventional vertical wells with moderate production rates. Every lifting method has its sweet spot.

When should I choose a jet pump over a piston system?

Think of jet pumps as the "no moving parts" option—perfect when sand would chew up anything that moves downhole. They're also the go-to for wells with high gas content, where gas lock would stop a piston pump.

Jet pumps make particular sense in deviated or horizontal wells, and when you want to avoid workover rig costs for retrieval. They're remarkably adaptable to variable production rates—a real advantage in wells with changing conditions.

Piston systems, on the other hand, deliver maximum efficiency when conditions are stable. One operator from our Chicago area explained it perfectly: "We use jet pumps in our challenging wells with sand issues and high gas content. For our stable, clean producers, we stick with piston systems for their efficiency advantage."

The piston system's ability to "hop" (a quick operation that can clear debris) is another advantage in certain situations. If power fluid consumption is a major concern, the higher efficiency of piston systems often makes them the better choice.

How do I calculate the power-fluid ratio for my well?

This is where the rubber meets the road for pump hydraulic lift efficiency. The calculation isn't complicated, but it's absolutely critical to get right.

Start by measuring the total fluid returned to surface—that's your power fluid plus production—in barrels per day. Then measure how much power fluid you're injecting daily. The difference between these numbers is your net production.

For example, if you're injecting 300 barrels of power fluid daily and getting 500 barrels total return, your net production is 200 barrels per day. Your power fluid ratio is 300:500 or 3:5—which happens to be a common benchmark in the industry.

Finding the ideal ratio for your specific well conditions often requires some experimentation. As one consultant I work with noted, "The ideal ratio varies by well. Using simulation software like Wanner Pump Analyser™ can help you find the sweet spot between power fluid consumption and production optimization."

At American Mortuary Coolers, we apply similar efficiency calculations to our cooling systems. While we're not pumping oil, the principle of optimizing input resources to maximize output performance remains the same. It's all about finding that efficiency sweet spot, whether you're cooling a mortuary or lifting oil from thousands of feet below ground.

Conclusion

Choosing the right pump hydraulic lift system isn't just a technical decision—it's an investment in your operation's future success. Whether you're pulling oil from deep beneath the earth or gently raising a casket in a funeral home, the fundamental principles of hydraulic lifting remain remarkably consistent across industries.

Here at American Mortuary Coolers, we've witnessed how the right hydraulic system transforms operations for our clients. From the rolling hills of Tennessee to the busy coastal cities of California, we've helped funeral directors across America find reliable solutions that meet their unique needs.

What have we learned from serving clients in every corner of the country? That success with hydraulic lift technology boils down to a few essential elements:

Match your system to your specific needs. A hydraulic lift that works perfectly for a high-volume oil well might be completely wrong for a small-town funeral home. Take the time to assess your actual requirements—not just what a salesperson suggests.

Quality components matter more than initial price. One funeral director in Chicago told us, "I saved $2,000 upfront by choosing a cheaper lift, then spent $5,000 in repairs over the next year." The math doesn't lie—investing in quality pays off.

Preventive maintenance prevents painful problems. The most successful operators we work with follow strict maintenance schedules rather than waiting for something to break. This approach minimizes disruptions and extends equipment life significantly.

Accept new technology when it makes sense. Modern monitoring systems can alert you to potential issues before they cause downtime. As one tech-savvy funeral director put it, "The notification system has saved us from at least three potential failures during services."

For funeral professionals looking for dependable hydraulic solutions, American Mortuary Coolers offers durable, custom-designed systems built specifically for mortuary applications. We understand that handling the deceased requires both mechanical reliability and a gentle touch—our systems deliver both.

Our direct delivery service spans the entire contiguous 48 states, ensuring that quality equipment reaches funeral homes from Maine to California without unnecessary delays or middlemen. We're proud to be the partner of choice for funeral professionals who value quality, reliability, and personalized service.

The pump hydraulic lift industry continues to evolve, with exciting innovations improving efficiency, reliability, and environmental performance. By staying informed about these advances and applying sound selection principles, you'll ensure your hydraulic system delivers optimal performance for years to come.

To explore our complete range of cooling systems and hydraulic lift solutions designed specifically for the funeral industry, visit More info about complete cooling systems.

At the end of the day, the best hydraulic lift system is the one that quietly does its job so well that you hardly notice it's there. That's the kind of dependable performance we strive to deliver with every system we create.