Why Choosing the Right Walk In Cooler Contractor Makes All the Difference

Finding a reliable walk in cooler contractor can mean the difference between a smooth installation and costly delays that disrupt your operations. The right contractor brings specialized expertise, proper certifications, and proven experience to ensure your cold storage solution meets your exact needs.

Key qualities of a professional walk in cooler contractor:

- Licensed and insured with EPA 608 certification for refrigerant handling

- Industry experience of 15+ years with verified project references

- Code compliance expertise for local permits and health regulations

- Installation warranty covering panels (up to 20 years) and labor (12-18 months)

- 24/7 emergency support for repairs and maintenance

- Energy-efficient solutions using high-density foam panels and smart controls

The stakes are particularly high for specialized facilities like funeral homes, where temperature control directly impacts service quality and regulatory compliance. According to industry data, contractors like Norlake boast a 98% on-time installation rate, while companies with over 50 years of experience have installed more than 40,000 walk-in units successfully.

"One of the Best Refrigeration Repair Companies I have ever worked with" - this testimonial from Bo Bryan reflects the kind of long-term partnership you should expect from a quality contractor.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience working alongside walk in cooler contractors across the country. My background in the mortuary equipment industry has shown me how the right walk in cooler contractor can deliver reliable, custom solutions that meet the unique demands of funeral home operations.

Terms related to walk in cooler contractor:

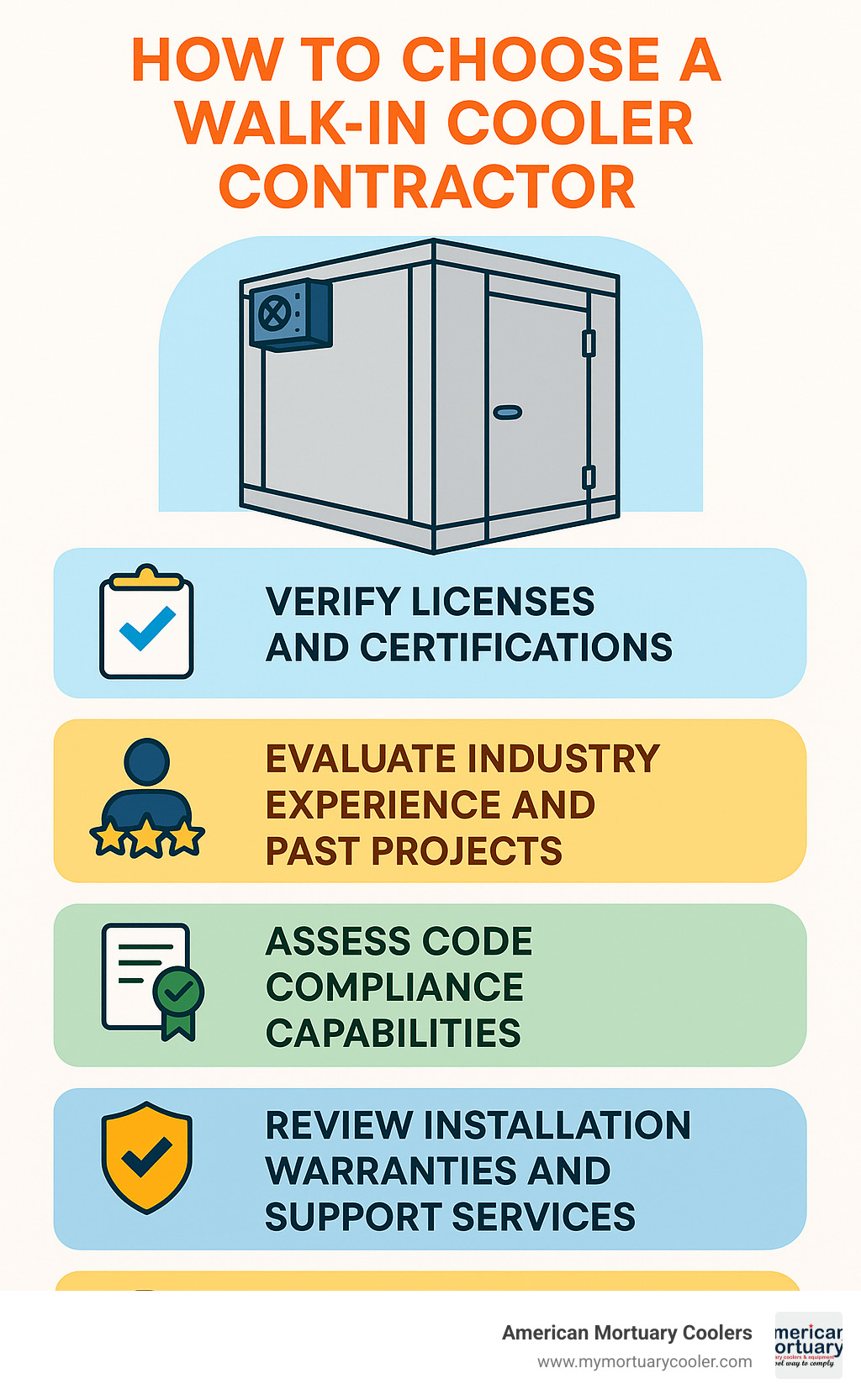

7 Essential Tips When Hiring a Walk In Cooler Contractor

Choosing the right walk in cooler contractor isn't just about finding someone who can install equipment - it's about finding a partner who understands your unique needs and delivers lasting value. These seven essential tips will help you identify contractors who can transform your cold storage vision into reality.

Tip 1 – Verify Licenses, Certifications & Insurance

Before discussing project details, start with the basics. A legitimate walk in cooler contractor should proudly display their credentials and provide documentation without hesitation.

Essential certifications include EPA 608 certification for refrigerant handling - this isn't optional, it's federal law. You'll also want to see their state contractor license for mechanical or refrigeration work, along with UL certification for electrical safety compliance.

For food service applications, NSF Standard #7 certification ensures your contractor understands sanitation requirements. Liability insurance covering both property damage and worker injuries gives you peace of mind if something goes wrong.

We've seen projects turn into nightmares when contractors cut corners on licensing. One funeral home hired an unlicensed contractor who damaged their existing HVAC system during installation. The resulting repairs and delays cost thousands more than hiring a properly licensed professional would have.

Professional contractors with 320 years of combined refrigeration experience understand that credentials aren't just paperwork - they're proof of competency and commitment to doing things right.

Tip 2 – How an Experienced Walk In Cooler Contractor Adds Value

Experience isn't just about years in business - it's about proven results. Norlake's network maintains a 98% on-time installation rate because experienced contractors know how to anticipate and solve problems before they derail your project.

Companies with serious experience bring impressive credentials. Take manufacturers like American Walk-In Coolers, who've installed over 40,000 walk-in units since 1967. This kind of volume means they've encountered every possible challenge and developed solutions that work.

Experienced contractors also bring valuable relationships - direct connections with manufacturers, nationwide installer networks, and factory technical support. When you need parts or service, these relationships can mean the difference between a quick fix and extended downtime.

Seasoned professionals understand how to balance upfront costs with long-term operating expenses, helping you avoid expensive mistakes that less experienced installers often make. More info about walk-in cooler installation cost can help you understand the full financial picture.

Companies like Five Star Mechanical demonstrate this experience advantage with over 20 years of commercial refrigeration expertise. Their fully stocked service vehicles and 24-hour emergency response capability come from understanding what customers need before problems arise.

Tip 3 – Check Industry Fit & Past Projects

Not every walk in cooler contractor understands your industry's unique challenges. A contractor who specializes in restaurant installations might not grasp the precision required for mortuary applications, where temperature control directly impacts service quality and regulatory compliance.

Different industries have different needs. Restaurants need quick installation to minimize revenue loss. Mortuaries require seamless, rounded-corner interiors that prevent moisture intrusion and bacterial growth. Breweries need rapid cooling capabilities. Medical facilities need backup systems and continuous monitoring.

Ask potential contractors for references from facilities similar to yours. A contractor who's successfully installed walk-in coolers for other funeral homes will understand your specific requirements without lengthy explanations. They'll know about the importance of easy-to-clean surfaces, proper drainage, and discrete appearance that respects the dignity of your services.

The best contractors don't just install equipment - they solve problems. We've heard testimonials like "One of the Best Refrigeration Repair Companies I have ever worked with" from clients who found contractors that truly understood their needs. These partnerships often last for decades because the contractor becomes a trusted advisor, not just a service provider.

Tip 4 – Ensure Code, Health & Safety Compliance

Code compliance separates professional contractors from amateurs. The right walk in cooler contractor steers complex regulations seamlessly, ensuring your installation meets all requirements from day one.

Local building permits are just the starting point. Professional contractors understand that states like California, Florida, Oregon, and Washington require specific engineering documentation for seismic, wind, hurricane, or snow-load conditions. They factor these requirements into project timelines and costs upfront.

Food safety regulations add another layer of complexity, especially for funeral homes that may need to meet health department standards. NSF Standard #7 compliance ensures your installation meets sanitation requirements that protect both your operations and your reputation.

The compliance process flows from permit application through final inspection. Experienced contractors schedule inspections at the right times, coordinate with local officials, and ensure all documentation is complete. They understand that shortcuts in compliance can shut down your entire project.

We've seen installations stopped by inspectors because contractors didn't understand local requirements. One funeral home faced a three-week delay when their contractor failed to obtain proper permits, forcing them to rent temporary cooling equipment while waiting for compliance approval.

Tip 5 – Questions to Ask Your Walk In Cooler Contractor About Installation

The right questions reveal whether a contractor truly understands your project. Professional walk in cooler contractors should answer these inquiries confidently and thoroughly.

Start with logistics questions about job-site preparation, delivery coordination, and installation timeline. A contractor who's done this before will know exactly what site conditions they need and how to work around your operational requirements.

Ask about their startup procedures - how do they verify temperatures, test all systems, and ensure everything works correctly before they leave? Professional contractors include comprehensive startup and training in their scope, not as expensive add-ons.

Discuss the punch-list process for final completion. Quality contractors systematically address every detail, from door adjustments to final cleanup, ensuring your installation is truly complete.

Companies in Norlake's network exemplify this thoroughness with comprehensive job-site preparation visits, coordinated delivery schedules, and complete startup procedures. They provide clear answers about what's included and what's excluded from their scope.

Red flags include vague answers about timeline or scope, unwillingness to visit your site before installation, and unclear responsibility for permits or inspections. These warning signs often indicate contractors who underbid projects and try to make up costs through change orders.

Tip 6 – Demand Energy-Efficiency & Smart Technology

Energy efficiency isn't just environmentally responsible - it directly impacts your operating costs for decades. Modern walk in cooler contractors should offer cutting-edge solutions that minimize energy consumption while maximizing performance.

High-density foam panels with R-29 cooler and R-32 freezer ratings provide superior insulation compared to older technologies. Combined with ECM (electronically commutated motor) fans for variable speed control, these systems adapt to actual cooling needs rather than running at full capacity constantly.

LED lighting systems with motion sensors and timers reduce energy consumption while providing better visibility. Smart monitoring controls with remote access capabilities let you track performance and identify issues before they become expensive problems.

Polar King's fiberglass construction demonstrates how material selection affects performance, with 0.04 BTU thermal conductivity compared to aluminum and steel panels. Scientific research on thermal conductivity shows how these differences translate to significant energy savings over the unit's lifetime.

Technology integration options include remote temperature monitoring with alerts, automated defrost cycles based on actual conditions, and energy usage tracking. These features help you optimize performance while reducing operating costs.

The best contractors understand that energy-efficient design pays for itself through reduced utility bills and extended equipment life. They'll help you evaluate options based on your specific usage patterns and local utility rates.

Tip 7 – Assess Warranty, Maintenance & 24/7 Support

Your relationship with a walk in cooler contractor extends far beyond installation day. The best contractors provide comprehensive support that protects your investment for years to come.

Quality warranties demonstrate confidence in workmanship. Look for contractors offering 20-year panel warranties (industry standard for quality manufacturers), 5-year door and compressor warranties, and 18-month parts and labor warranty like Norlake's industry-leading coverage.

Preventive maintenance programs are equally important. Carolina Cooler & Equipment emphasizes that thermal assessments and routine maintenance prevent energy waste, food spoilage, and compliance issues. These programs typically include scheduled inspections, cleaning and calibration of controls, and replacement of worn components.

24-hour emergency service can save your operations when equipment fails. Companies like Five Star Mechanical provide emergency response with fully stocked trucks, ensuring repairs can be completed in one visit. This level of support is invaluable when equipment failure threatens your operations.

The best contractors also provide thermal assessments to identify efficiency issues before they become expensive problems. They understand that proper maintenance extends equipment life and reduces total cost of ownership.

More info about cooler units provides additional insights into maintenance requirements and best practices for maximizing your investment.

Design & Technology: Custom vs. Pre-Fabricated Walk-Ins

When working with a walk in cooler contractor, one of the first decisions you'll face is choosing between custom-built and pre-fabricated options. Both approaches have their place, and the right choice depends on your specific needs, timeline, and budget.

Custom walk-ins shine when you're dealing with unusual spaces or specialized requirements. For funeral homes, this often means industry-specific features like mortuary-grade sanitary surfaces and seamless, rounded corners that prevent bacterial growth. Custom units offer unlimited sizing options to fit any space configuration, whether you're retrofitting a century-old funeral home or building a new facility with unique architectural constraints.

The beauty of custom design lies in its flexibility. Your walk in cooler contractor can incorporate specialized materials like fiberglass for outdoor applications or create unique door configurations that match your workflow. Custom units also integrate seamlessly with existing building systems, making them ideal for complex installations.

Pre-fabricated walk-ins, on the other hand, offer compelling advantages for straightforward applications. The biggest benefit is speed - many manufacturers offer quick-ship options within 30 days, compared to 8-12 weeks for custom units. This faster timeline can be crucial when you need to get operations running quickly.

Cost is another major factor. Lower costs come from standardized manufacturing processes, and you're getting proven designs that have been extensively field-tested. Companies like Polar King and U.S. Cooler have refined their pre-fab designs through thousands of installations, eliminating common problems before they reach your facility.

Material selection makes a significant difference in performance and longevity. Fiberglass panels from manufacturers like Polar King offer superior performance compared to traditional metal panels. With heat resistance tested above 175°F and excellent corrosion resistance, fiberglass handles challenging environments that would damage metal systems. The thermal conductivity of just 0.04 BTU means better energy efficiency and lower operating costs.

Metal panels remain popular for indoor applications where cost is the primary concern. However, they require protective coatings to prevent corrosion and typically need steel framing for snow load capacity that fiberglass panels handle naturally.

| Feature | Fiberglass (Polar King) | Metal Panels (Standard) |

|---|---|---|

| Heat Resistance | Tested above 175°F | Limited heat tolerance |

| Corrosion Resistance | Excellent | Requires protective coatings |

| Snow Load Capacity | Up to 100 lbs/sq ft | Requires steel framing |

| Thermal Conductivity | 0.04 BTU | Higher heat transfer |

| Maintenance | Low | Moderate to high |

Cam-lock panel systems represent the evolution of modular construction. These innovative systems use high-density foam rails that allow custom sizing while maintaining superior insulation properties. The panels snap together with precision-engineered cam locks, creating tight seals without the complexity of traditional welded construction.

What sets quality manufacturers apart is their attention to detail during production. U.S. Cooler's practice of test-assembling all walk-ins in their plant before shipment ensures problem-free on-site installation. This approach catches potential issues in a controlled environment rather than finding them during installation at your facility.

The modular kit approach offers flexibility that bridges custom and pre-fab options. Your walk in cooler contractor can mix and match standard components to create semi-custom solutions that meet specific requirements without the full cost and timeline of completely custom construction.

For funeral homes specifically, the choice often comes down to space constraints and sanitary requirements. Pre-fab units work well for new construction with standard dimensions, while custom units excel in retrofit situations or when you need specialized features for mortuary applications.

From Quote to Grand Opening: Timeline, Cost, Financing & Compliance

Planning your walk-in cooler project from start to finish requires understanding every step of the process. A professional walk in cooler contractor will walk you through realistic timelines and help you prepare for each phase.

The journey typically begins with an initial consultation where your contractor visits your facility to assess the space and understand your specific needs. This site survey usually takes one to two weeks to schedule and complete.

Once the site assessment is complete, the design and engineering phase kicks into gear. For standard pre-fabricated units, this might only take a week, but custom installations designed for specialized facilities like funeral homes often require two to three weeks. This extra time ensures every detail meets your exact specifications and industry requirements.

Permit applications can be the wild card in your timeline. Some jurisdictions approve permits within two weeks, while others might take up to six weeks or longer. Experienced contractors know which local authorities move quickly and which ones require extra patience.

Manufacturing and delivery timelines vary dramatically based on what you're ordering. Quick-ship options from companies like American Walk-In Coolers can get standard units to your door within 30 days. However, fully custom installations with specialized features might require six to eight weeks of manufacturing time.

The actual installation and startup process is usually the fastest part of the entire project. Most standard walk-in coolers can be installed and operational within one to three days. Your contractor will coordinate the installation timing to minimize disruption to your operations.

Final inspections and approvals typically take one to two weeks, depending on inspector availability and whether any minor adjustments are needed. Professional contractors schedule these inspections proactively to avoid delays.

Managing project costs becomes much easier when you understand all the components involved. Equipment costs include your panels, doors, and refrigeration systems, but don't forget about installation labor and any specialized equipment rental your contractor might need. Site preparation costs can vary widely depending on whether you need concrete work, electrical upgrades, or other infrastructure improvements.

Permit and inspection fees vary by location, and financing costs should be factored in if you're not paying cash upfront. Many contractors work with financing partners to help spread these costs over manageable monthly payments.

Financing solutions have become increasingly flexible for equipment purchases. Financing options include traditional equipment loans, leasing programs, and even 100% financing for qualified buyers. Companies like All Pro Coolers partner with multiple lenders including Navitas Credit Corp, CIT Small Business Solutions, and Ascentium Capital to provide payment options that fit different budget situations.

The key to a successful project is choosing a walk in cooler contractor who communicates clearly about timelines and costs upfront. They should provide detailed project schedules that account for potential delays and help you plan accordingly.

Warranty, Preventive Maintenance & Emergency Service

Long-term success with your walk-in cooler depends heavily on ongoing maintenance and support. The best walk in cooler contractors provide comprehensive service programs that extend equipment life and prevent costly failures.

Preventive Maintenance Programs:

- Quarterly inspections of refrigeration systems and controls

- Annual thermal assessments to identify efficiency issues

- Cleaning and calibration of sensors and monitoring equipment

- Gasket and hardware replacement before failures occur

- Documentation and reporting for warranty and regulatory compliance

Emergency Service Capabilities: Professional contractors maintain 24-hour emergency response capabilities. Five Star Mechanical's approach of keeping fully stocked service vehicles ensures most repairs can be completed immediately, minimizing downtime.

Common maintenance issues contractors address:

- Evaporator fan motor failures

- Clogged defrost drain pans

- Thermostat malfunctions

- Ice maker problems

- Door seal degradation

Service Contract Benefits:

- Priority scheduling for emergency calls

- Discounted parts and labor rates

- Preventive maintenance to avoid major failures

- Performance monitoring and efficiency optimization

- Regulatory compliance documentation

Carolina Cooler & Equipment's emphasis on thermal assessments and routine maintenance demonstrates the proactive approach that prevents small issues from becoming major problems.

Frequently Asked Questions about Walk In Cooler Contractors

When you're searching for the right walk in cooler contractor, certain questions come up again and again. Here are the answers that matter most to business owners.

What industries most often need a walk-in?

Restaurants and foodservice operations make up the biggest chunk of our industry - they need rock-solid temperature control to keep food safe and pass health inspections.

Grocery stores and convenience stores have their own unique challenges. They need systems that can handle constant door openings and integrate seamlessly with their display cases.

Medical and pharmaceutical facilities can't mess around - they need backup systems, precise monitoring, and extensive documentation. Breweries are equally demanding because temperature swings can ruin entire batches.

Mortuaries like the ones we serve at American Mortuary Coolers have perhaps the most demanding requirements. We need sanitary surfaces that are easy to clean, reliable temperature control that never fails, and construction that maintains dignity in sensitive situations.

Don't forget about floral shops, ice cream distributors, and cold storage warehouses. Each has specific needs that experienced contractors learn to handle. The best walk in cooler contractors understand these industry differences and adapt their approach accordingly.

How long does installation usually take?

Standard pre-fabricated walk-in coolers typically go in within 1-3 days if everything goes smoothly. Custom installations might need 3-7 days depending on complexity.

Several factors can speed things up or slow them down. Site preparation is huge - if your contractor needs to pour concrete or run new electrical lines, that adds time. Access limitations can be a real headache when crews can't get equipment through narrow doorways or around tight corners.

Custom features like specialized doors or monitoring systems naturally take longer to install and test. Permit and inspection schedules vary wildly depending on location - some jurisdictions move fast, others don't.

Even weather conditions matter for outdoor installations. Nobody wants to install insulation panels in a thunderstorm.

The good news? Companies like Norlake maintain a 98% on-time installation rate because they plan for these variables upfront. That's what separates experienced contractors from the rest.

Can I retrofit my existing space instead of building new?

Absolutely, and it often makes perfect financial sense. Smart walk in cooler contractors love retrofit projects because they can save you serious money while giving you exactly what you need.

The key is having your contractor evaluate your existing structure properly. They need to check structural capacity to make sure your building can handle the additional weight of insulation and refrigeration equipment. Insulation requirements are critical too - older buildings might need extra work to meet current efficiency standards.

Electrical and refrigeration infrastructure often needs upgrading in retrofit situations. Your contractor should map out what's already there and what needs to be added or replaced. Access requirements matter just as much - your service technicians need to reach equipment for maintenance and repairs.

Code compliance can get tricky with retrofits since current building standards might be stricter than when your building was constructed. Experienced contractors know how to work within these constraints while still meeting all requirements.

Many contractors actually specialize in retrofit work because it requires creative problem-solving and deep experience. They've learned how to adapt installations to unique site conditions while maintaining performance standards.

Conclusion

Finding the right walk in cooler contractor doesn't have to feel overwhelming when you know what to look for. The seven tips we've shared give you a solid roadmap for making this important decision with confidence.

Think of it this way: your walk-in cooler will likely serve your facility for 20+ years. That's two decades of daily operation, so choosing a contractor who gets it right the first time makes all the difference. Whether you're dealing with licensing verification, energy efficiency requirements, or long-term maintenance support, the right contractor handles these challenges smoothly.

At American Mortuary Coolers, we've seen how the funeral industry has unique needs that generic contractors simply don't understand. That's why we work exclusively with qualified contractors who meet our high standards and truly understand mortuary applications. Based in Tennessee with nationwide delivery capabilities, we've built our reputation on providing durable, custom mortuary coolers designed specifically for funeral homes.

What sets us apart is our commitment to cost transparency. No surprise fees, no hidden costs - just honest pricing for quality materials and reliable service. When you're planning a significant investment like a walk-in cooler, you deserve to know exactly what you're paying for and why.

The best walk in cooler contractor becomes your long-term partner, not just someone who shows up for installation day. They're there when you need emergency repairs at 2 AM, when you want to upgrade your monitoring system, or when you're planning facility expansions years down the road.

For funeral homes specifically, the stakes are even higher. Temperature control isn't just about equipment performance - it's about maintaining dignity and providing families with the respectful service they deserve. That's why specialized guidance like The Ultimate Guide to Walk-In Refrigerator Installation for Mortuaries can be invaluable when selecting contractors who understand these unique requirements.

Your facility deserves contractors who bring both technical expertise and genuine understanding of your industry's needs. Take the time to evaluate credentials, check references, and ask the tough questions. The right contractor will welcome your thorough approach because they know their work speaks for itself.