Understanding the 1036-10 Wall Mount Autopsy Station

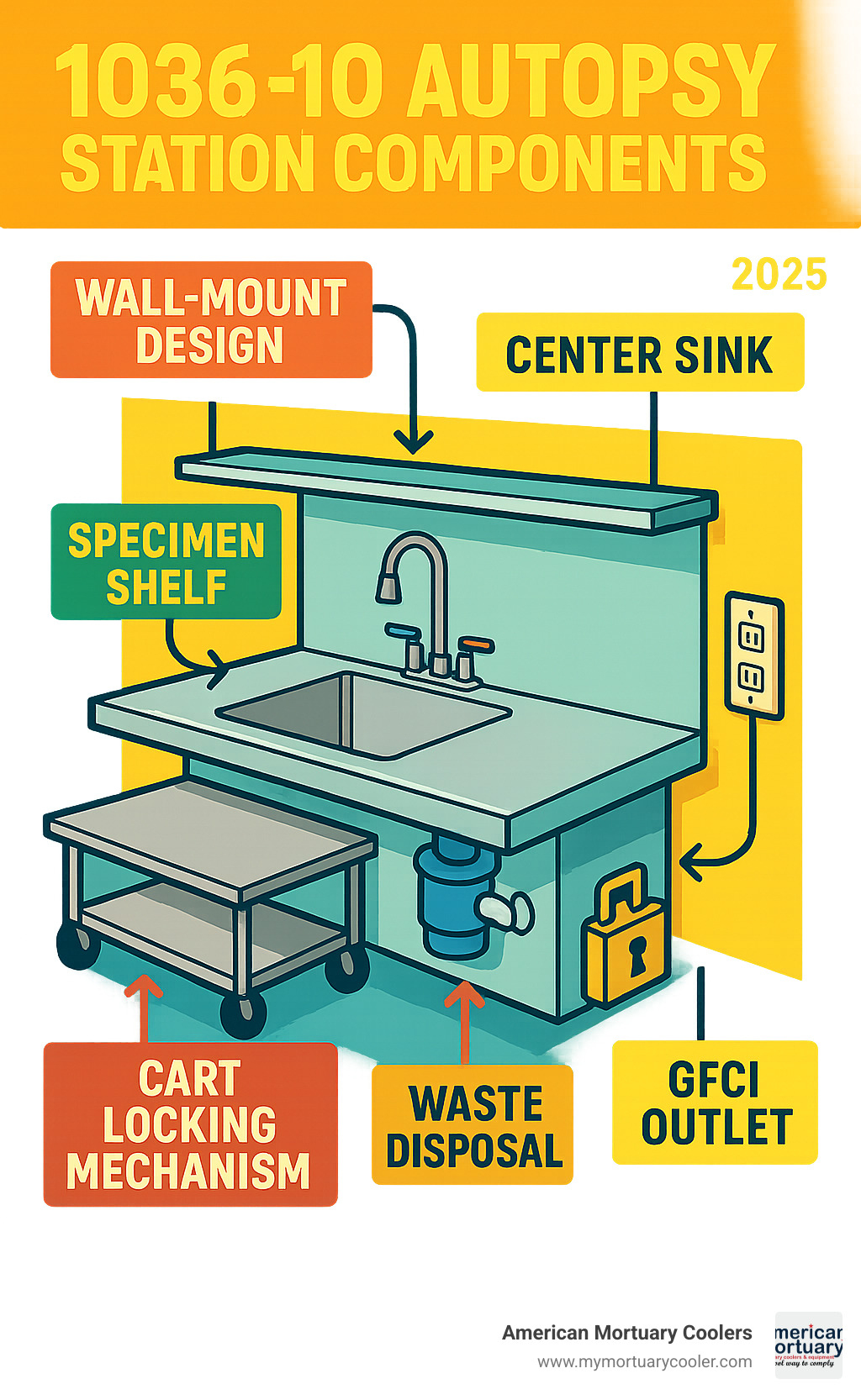

The 1036-10 is a wall-mounted autopsy station with a center sink design that maximizes floor space in mortuary facilities. This professional-grade unit measures 114" L x 29" D x 61" H and features all-stainless steel construction with heliarc-welded seams.

Key 1036-10 Specifications:

- Dimensions: 114" Length x 29" Depth x 61" Height

- Construction: All stainless steel with ground and polished finish

- Sink: Large single-compartment with rapid drainage

- Waste Disposal: Heavy-duty 1/2 HP commercial disposer

- Storage: Full-length specimen shelf (12" wide) and large instrument drawers

- Safety: GFCI duplex receptacles with waterproof covers

- Plumbing: 10-foot spray hose, hot/cold gooseneck faucet, reverse-flow aspirator

- Mounting: Wall-mount design saves valuable floor space

The 1036-10 includes a cart-to-sink locking mechanism accessible from either side, factory-installed plumbing and electrical lines, and large radii on all interior corners for easy cleaning and sanitation compliance.

Target Applications:

- Hospital morgues and pathology labs

- Medical examiner facilities

- Forensic laboratories

- Funeral home preparation rooms

As Mortuary Cooler with years of experience supplying mortuary equipment nationwide, I've helped countless funeral directors select and install 1036-10 units that meet their specific space and workflow requirements.

Relevant articles related to 1036-10:

What Is the 1036-10 Wall Mount Autopsy Station?

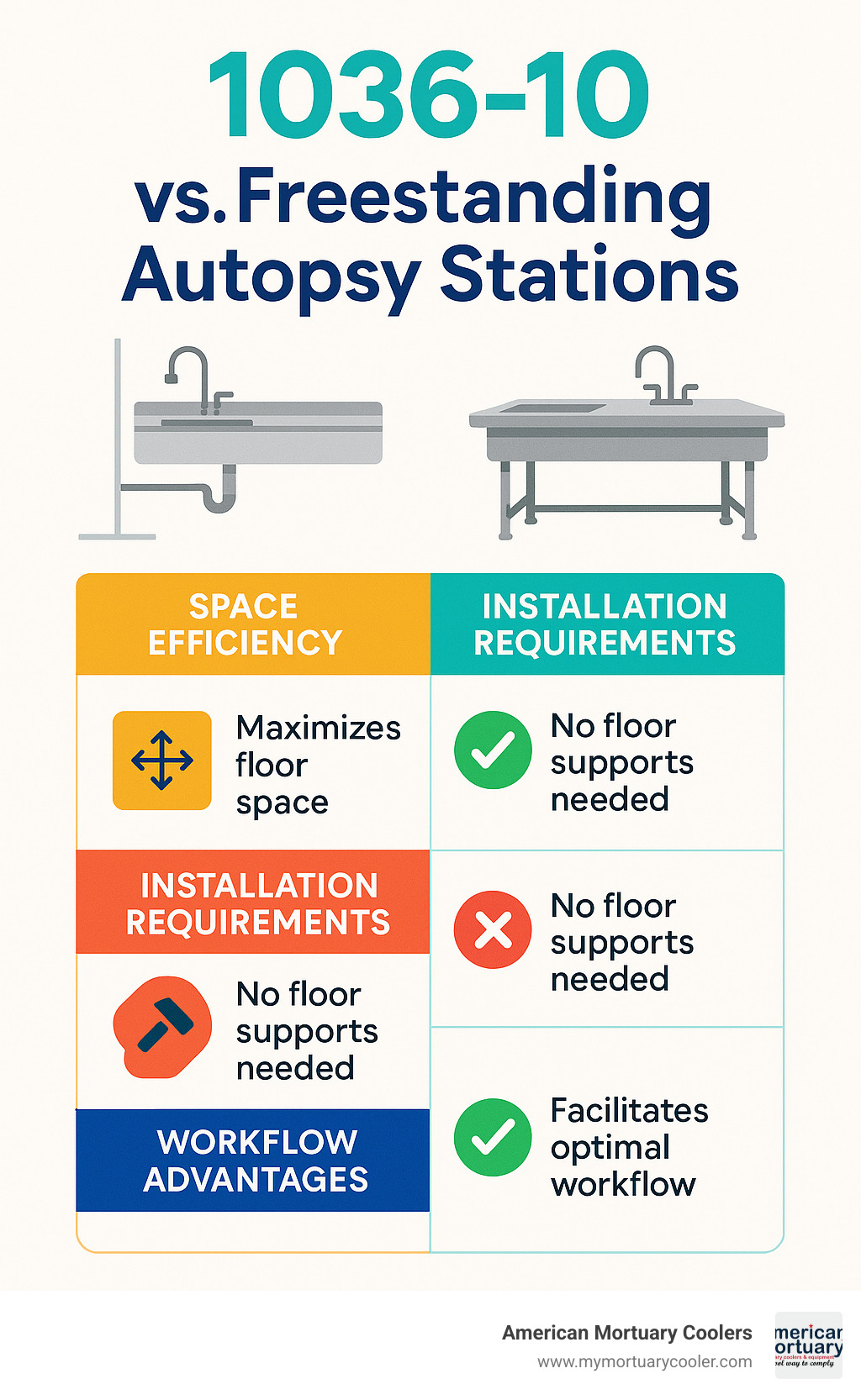

The 1036-10 represents a smart solution for facilities where floor space comes at a premium. This wall-mounted autopsy station brings together everything you need for professional autopsy work while freeing up valuable room for other equipment and workflow.

Think of it as the Swiss Army knife of autopsy stations. The center-sink design puts the large single-compartment sink right where it makes the most sense - in the middle of the 114-inch unit. This means you can work comfortably from either side without constantly moving around the equipment.

The space-saving wall-mount design eliminates those bulky floor supports that always seem to be in the way when you're trying to clean or move other equipment. Instead, everything mounts securely to the wall, giving you a clean, open workspace underneath.

What really makes this unit practical is the thoughtful storage. The full-length specimen shelf runs a generous 12 inches wide along the entire length of the station. That's plenty of room for instruments, specimens, and whatever else you need within arm's reach. The large instrument drawers keep your frequently used tools organized and easily accessible.

The heliarc-welded stainless steel construction isn't just about looking professional - though it certainly does that. It's about creating a surface that's easy to sanitize and built to handle daily use for years to come.

1036-10 Purpose & Typical Environments

We've had the pleasure of installing 1036-10 units in all kinds of facilities over the years, and each one has its own story.

Hospital morgues often surprise us with their space challenges. You'd think hospitals would have plenty of room, but morgue space is usually at a premium. The 1036-10 has been a game-changer for these facilities. By mounting to the wall, it opens up floor space for additional equipment or simply makes the room feel less cramped.

Medical examiner labs have different priorities. They need everything to work flawlessly because their findings might end up in court. The precision and reliability of the 1036-10 fits perfectly with their exacting standards. These facilities particularly appreciate the professional appearance and consistent performance.

Forensic facilities often operate under intense scrutiny, so every piece of equipment needs to meet the highest standards. The 1036-10 delivers that level of quality while providing the functionality forensic pathologists depend on for their detailed work.

1036-10 Cart-to-Sink Locking Mechanism

Here's where the 1036-10 really shows its thoughtful engineering. The slide latch system might seem like a small detail, but it makes a huge difference in daily operations.

The locking mechanism works with standard autopsy carts, securing them directly to the sink unit during procedures. No more worried glances to make sure the cart hasn't shifted. No more having someone hold equipment steady while you work.

What we love about this system is the two-sided access. Whether you're approaching from the left or right side of the unit, you can easily engage or release the lock. It's one of those features that seems obvious once you use it, but you don't realize how much you need it until it's there.

The safety benefit goes beyond just convenience. When equipment stays where you put it, you can focus entirely on the procedure at hand. That peace of mind is invaluable, especially during complex or time-sensitive work.

Core Specifications & Dimensions

The 1036-10 measures exactly 114" L x 29" D x 61" H, making it suitable for most standard mortuary spaces while providing maximum functionality within its footprint. The full-length specimen shelf spans the entire 114-inch length at 12 inches wide, offering 9.5 square feet of specimen staging area.

The single-compartment sink dominates the center of the unit, designed with rapid and positive drainage to handle the demands of autopsy procedures. Large radii on all inside corners facilitate thorough cleaning and meet sanitation requirements essential for mortuary environments.

The heavy-duty 1/2 HP commercial waste disposal comes standard, though facilities with higher volume requirements can upgrade to 3/4 HP, 1 HP, or 2 HP units. The heliarc-welded construction creates seamless joints that prevent bacterial growth and ensure long-term durability.

Key Dimensional Details:

- Overall length: 114 inches (9.5 feet)

- Depth: 29 inches

- Height: 61 inches

- Specimen shelf: 12 inches wide x 114 inches long

- Exhaust duct grill: 8" x 10"

- Clearance requirements: 2 inches from building walls

Materials & Construction Details

The 1036-10 uses 304 stainless steel throughout its construction, providing excellent corrosion resistance and easy maintenance. All seams and joints are heliarc-welded, then ground and polished to a smooth finish that prevents bacterial accumulation and simplifies cleaning protocols.

The stainless steel construction meets NSF/ANSI Standard #7 requirements for commercial food service equipment, ensuring it exceeds the sanitation standards required for mortuary use. The ground and polished finish not only looks professional but also eliminates microscopic surface irregularities where contaminants could hide.

Factory-sealed joints eliminate potential leak points, while the precision manufacturing ensures consistent quality across all units. We've found that the 304 stainless steel grade provides the optimal balance of durability, corrosion resistance, and cost-effectiveness for mortuary applications.

For facilities requiring improved chemical resistance, upgrades to 316 stainless steel are available. This higher grade offers superior resistance to chlorides and other aggressive cleaning agents commonly used in mortuary environments.

Integrated Lighting & Ergonomics

The 1036-10 includes overhead LED light fixtures positioned to provide optimal illumination over the work area. These vapor-proof fixtures with shatterproof globes ensure safe operation in the humid environment typical of autopsy procedures.

Hot and cold gooseneck faucets feature wrist blade handles, allowing for hands-free operation when gloves are contaminated. This ergonomic design reduces cross-contamination risks and improves workflow efficiency during procedures.

The dissecting area rinse assembly provides targeted cleaning capability, while the raised dissecting platform (available as an option) improves ergonomics for extended procedures. The thoughtful placement of controls and fixtures minimizes operator fatigue and supports proper body mechanics during work.

Plumbing, Electrical & Safety Systems

When you invest in a 1036-10, you're getting a complete system that's ready to work right out of the box. The factory-installed plumbing and electrical lines mean less hassle during installation and better integration of all the components that make this unit so reliable.

The 10-foot spray hose assembly gives you incredible flexibility during procedures. That flexible hose with its cold water valve and nozzle reaches every corner of your work area, making thorough cleaning much easier than with fixed spray systems.

Here's where the 1036-10 really shines - the reverse-flow aspirator. After installing dozens of these units across Tennessee, Georgia, and beyond, I can tell you this feature is a game-changer. Traditional aspirators get clogged with tissue and debris, bringing your work to a frustrating halt. The deluxe aspirator on the 1036-10 instantly relieves these clogs by reversing water pressure through the system. No more downtime, no more manual cleaning of blocked lines.

The backsiphon protection comes through a reduced pressure principle assembly - a fancy name for something that does a very important job. It prevents contamination from flowing back into your water supply system, which is absolutely critical when you're working with biological materials. This isn't just good practice; it's required by most local plumbing codes.

For electrical safety, the 1036-10 includes two GFCI duplex receptacles with waterproof covers. These meet NEC wet location standards and protect against electrical shock in the naturally wet environment of autopsy work. The waterproof covers keep moisture out while still giving you convenient power access for equipment.

Latest research on defrost-control energy savings shows how proper system controls can significantly reduce energy consumption in mortuary facilities.

Waste Disposal & Aspirator Function

The standard ½ HP commercial waste disposal handles everything you throw at it during autopsy procedures. This isn't some lightweight residential unit - it's built for the heavy-duty grinding of biological specimens and organic matter that's part of daily operations in mortuary facilities.

You control the disposal with a dedicated switch, and the unit is engineered for continuous use in demanding environments. We've seen these disposals run for years without issues when properly maintained.

But let's talk more about that reverse-flow aspirator system because it really deserves the spotlight. Traditional aspirators are notorious for getting blocked with tissue, hair, and other materials. When that happens, you're stuck manually cleaning lines or waiting for maintenance - neither option keeps your workflow moving smoothly.

The 1036-10's reverse-flow feature changes everything. Hit the reverse function, and water pressure instantly clears the blockage. It's like having a built-in maintenance technician that never takes a day off.

The rapid and positive drainage system ensures your large sink empties quickly between procedures. This isn't just convenient - it's essential for maintaining the efficient workflow that busy facilities depend on. The drainage handles high-volume water usage without backing up or creating delays.

Compliance & Safety Features

Safety isn't negotiable in mortuary work, and the 1036-10 takes this seriously with multiple built-in protection systems. The reduced pressure principle assembly provides complete backsiphon protection, preventing any chance of contamination flowing back into potable water supplies. When you're handling biological materials, this protection is absolutely critical for public health.

The GFCI duplex receptacles with waterproof covers go beyond basic electrical safety requirements. These outlets automatically shut off power if they detect even tiny amounts of electrical leakage, protecting operators from shock hazards in the wet environment that's unavoidable during autopsy procedures.

NSF certification means the unit meets commercial sanitation standards, while UL listing confirms electrical safety compliance. These aren't just nice-to-have certifications - local health departments and insurance providers often require them. Having these certifications built into the 1036-10 saves you the headache of trying to meet compliance requirements after installation.

We've worked with facilities across multiple states, and these safety features consistently meet or exceed local requirements, giving you confidence that your investment will pass inspections and keep your staff protected.

Options, Accessories & Customization

The 1036-10 isn't a one-size-fits-all solution—it's designed to adapt to your facility's unique needs. Whether you're running a small funeral home or a busy medical examiner's office, the right combination of options and accessories can make all the difference in your daily operations.

Waste disposal upgrades are among the most popular customizations we recommend. While the standard ½ HP unit handles most facilities well, you might need the extra power of ¾ HP, 1 HP, or 2 HP disposers if you're processing high volumes or dealing with particularly challenging materials. We've found that facilities performing more than 10 procedures weekly often benefit from these upgrades.

The three-sided rinse assembly transforms how thoroughly you can clean the sink area. Instead of relying on the standard spray hose alone, this system provides targeted water flow around the entire perimeter. It's particularly valuable for facilities with strict sanitation protocols or those handling forensic cases where thorough cleaning is critical.

Magnetic instrument holders might seem like a small detail, but they're incredibly practical. These holders keep your tools organized and within easy reach during procedures, eliminating the frustration of searching for instruments when you need them most. The organ rinse basket serves a similar purpose for specimen cleaning, providing a dedicated space for thorough washing.

For facilities requiring precise measurements, the scale pole and mounting bracket integrate weighing capabilities directly into your workspace. This eliminates the need for separate weighing stations and keeps your workflow streamlined.

Stainless steel leg assemblies provide additional support for installations where extra stability is needed. While the wall-mount design is inherently stable, some facilities prefer the added security, especially in high-traffic areas.

The 8" × 10" exhaust duct option integrates seamlessly with your facility's ventilation system. Proper ventilation is crucial for maintaining air quality and meeting health department requirements.

For facilities dealing with aggressive cleaning chemicals or corrosive environments, the 316 stainless steel upgrade offers superior chemical resistance compared to the standard 304 grade. This upgrade particularly makes sense for facilities using chlorine-based disinfectants regularly.

CO₂, vacuum, and air valves support specialized procedures that require these utilities. These medical-grade connections integrate cleanly into the unit's design while providing reliable access to essential services.

More info about mortuary cooler options can help you plan your complete facility setup.

Selecting the Right Add-Ons for Your Facility

Choosing the right accessories starts with understanding your workflow patterns. We always recommend observing your current procedures for a few weeks before finalizing your 1036-10 configuration. Notice where staff members struggle with the existing setup—those pain points often point toward the most valuable upgrades.

Case volume heavily influences which options provide the best return on investment. A facility processing 2-3 cases monthly has very different needs than one handling 20+ cases weekly. Higher-volume facilities almost always benefit from waste disposal upgrades and improved rinse systems.

Budget planning requires balancing immediate costs against long-term benefits. While premium options like 316 stainless steel cost more upfront, they often save money over the unit's 15-20 year lifespan through reduced maintenance and replacement costs. We've seen facilities save thousands by investing in the right configuration initially rather than upgrading piecemeal later.

Future scalability is something many facilities overlook during initial planning. Installing rough-in work for potential equipment additions costs a fraction during initial installation compared to retrofitting later. Even if you don't need CO₂ or vacuum connections now, having the infrastructure in place provides flexibility as your services expand.

Consider your staff preferences too. Features like magnetic instrument holders and three-sided rinse systems often seem minor until you experience how much they improve daily operations. We've had funeral directors tell us these "small" upgrades made the biggest difference in their satisfaction with the unit.

Ordering & Lead-Time Considerations

The 1036-10 ordering process is straightforward, but planning ahead prevents delays. Standard configurations typically ship within 5-7 days of order confirmation, while custom options may extend lead times depending on complexity.

Requesting a quote early in your planning process gives you accurate pricing and delivery timelines. We've found that facilities often underestimate the time needed for permits, site preparation, and utility coordination. Starting the equipment ordering process early keeps your project on schedule.

Factory consultation is available and highly recommended, especially for facilities with unique requirements or space constraints. Our engineering team can review your facility plans and recommend configurations that optimize both functionality and cost-effectiveness.

Shipping logistics require careful coordination for the 1036-10's size and weight. The unit arrives as a complete assembly, so ensure your facility has adequate access for delivery and positioning. We coordinate with installation teams nationwide to ensure smooth delivery and setup, but advance planning prevents surprises on delivery day.

Installation, Maintenance & Best Practices

Proper installation ensures decades of reliable service from the 1036-10. The wall-bracket system must anchor to framing capable of supporting the unit plus water, instruments and specimens. Verify wall strength (or have a structural engineer sign off) before hanging the station.

Plumbing is straightforward: connect hot and cold supply lines, tie the sink and disposer into the drain, and add the reverse-flow aspirator line. Local code-approved shut-off valves simplify future service.

Electrical hookup only needs a GFCI-protected circuit sized for the disposer horsepower you choose. A licensed electrician familiar with wet-location requirements can complete this in under an hour.

Cleaning & Sanitation Routine for 1036-10

- Rinse all surfaces after each use, giving extra attention to the specimen shelf and sink corners.

- Apply your facility-approved disinfectant, then scrub with brushes or swabs to reach every radius.

- Flush the disposer with water for 30 seconds to prevent odor and buildup.

- Activate the reverse-flow aspirator briefly to ensure it stays clear.

Long-Term Reliability Tips

- Inspect gaskets quarterly for wear or leaks.

- Make sure the cart-to-sink latch slides freely; lubricate if necessary.

- Test the aspirator’s reverse function and the GFCI outlets monthly using their built-in buttons.

These quick checks keep your 1036-10 operating safely and efficiently year after year while meeting the strict sanitation standards your facility demands.

Frequently Asked Questions about the 1036-10

We get a lot of questions about the 1036-10 from funeral directors and facility managers across the country. Here are the three most common ones that come up during our consultations.

What utilities are required to install the 1036-10?

Installing the 1036-10 is pretty straightforward, but you'll need a few key utilities in place. The unit requires hot and cold water supply lines with adequate pressure for the spray hose and gooseneck faucets. You'll also need electrical service - either 115V or 230V depending on which waste disposal option you choose.

Don't forget about drainage connections for the large sink and waste disposal system. The reverse-flow aspirator needs its own connection too. Most importantly, your wall structure needs to be solid enough to support the unit's weight plus everything you'll be using during procedures.

I always recommend having our technical team review your facility's utilities early in the planning process. We've seen too many projects hit delays because someone assumed their electrical panel could handle the load, or finded their water pressure wasn't quite right for optimal operation.

How does the reverse-flow aspirator prevent clogs?

This is honestly one of my favorite features of the 1036-10 because it solves such a common headache. Traditional aspirators get clogged with tissue or debris, and you're stuck stopping everything to manually clear the blockage.

The reverse-flow system works by instantly reversing water pressure through the suction line when you activate it. Instead of trying to pull the blockage through, it pushes water back the other way, clearing out whatever got stuck. It's like having a built-in plumber's snake that works with the flip of a switch.

We've had customers tell us this feature alone has saved them hours of downtime and frustration. When you're in the middle of an important procedure, the last thing you want is equipment problems bringing everything to a halt.

Can the 1036-10 be paired with existing body carts?

The good news is that the 1036-10's slide latch system works with most standard mortuary carts. The mechanism is designed to accommodate the common cart designs used across the industry, so there's a good chance your existing equipment will work just fine.

That said, I always recommend verifying compatibility before you place your order. Cart manufacturers sometimes use slightly different dimensions or locking points, and we want to make sure everything lines up perfectly. The two-sided access makes it easier to work with different cart styles, but proper fit is still important for safety.

If you're not sure about your current carts, just send us the make and model information. We can usually tell you right away whether they'll work with the locking mechanism, or if you might need to consider any modifications.

Conclusion & Next Steps

The 1036-10 wall-mounted autopsy station brings together everything you need for professional autopsy work while saving precious floor space. Its smart design, rock-solid construction, and thoughtful features make it a perfect fit for hospitals, medical examiner offices, and forensic facilities of all sizes.

Here at American Mortuary Coolers, we've been helping facilities across Tennessee, Georgia, and the entire Southeast region for years. We know what works in real-world settings, and we're passionate about creating durable, customized solutions that fit your exact needs—not just what's sitting on a shelf somewhere.

Our durability promise isn't just marketing talk. We back every 1036-10 with comprehensive warranty coverage and the kind of ongoing support that keeps your facility running smoothly. When you need parts, service, or just have questions, we're here to help.

What makes us different? We actually listen to what you need. Every 1036-10 we deliver is configured specifically for your workflow, your space, and your budget. No cookie-cutter solutions, no "close enough" compromises.

Ready to see how the 1036-10 can transform your facility's capabilities? Give us a call for a detailed consultation and quote. We'll walk through your space, understand your procedures, and help you specify the perfect configuration. Then we'll handle everything from manufacturing to delivery across all 48 contiguous states.

More info about mortuary coolers and requirements can help you plan your complete facility setup.

Whether you're modernizing an existing morgue or designing a brand-new facility, the 1036-10 delivers the reliability, functionality, and space efficiency that today's mortuary operations demand. Let's work together to create a solution that serves your community with dignity and professionalism for years to come.