Why Finding the Right Scissor Lift for Sale Matters More Than Ever

When searching for a scissor lift for sale, you need to know the key factors that separate a smart purchase from a costly mistake. Here's what every buyer should consider:

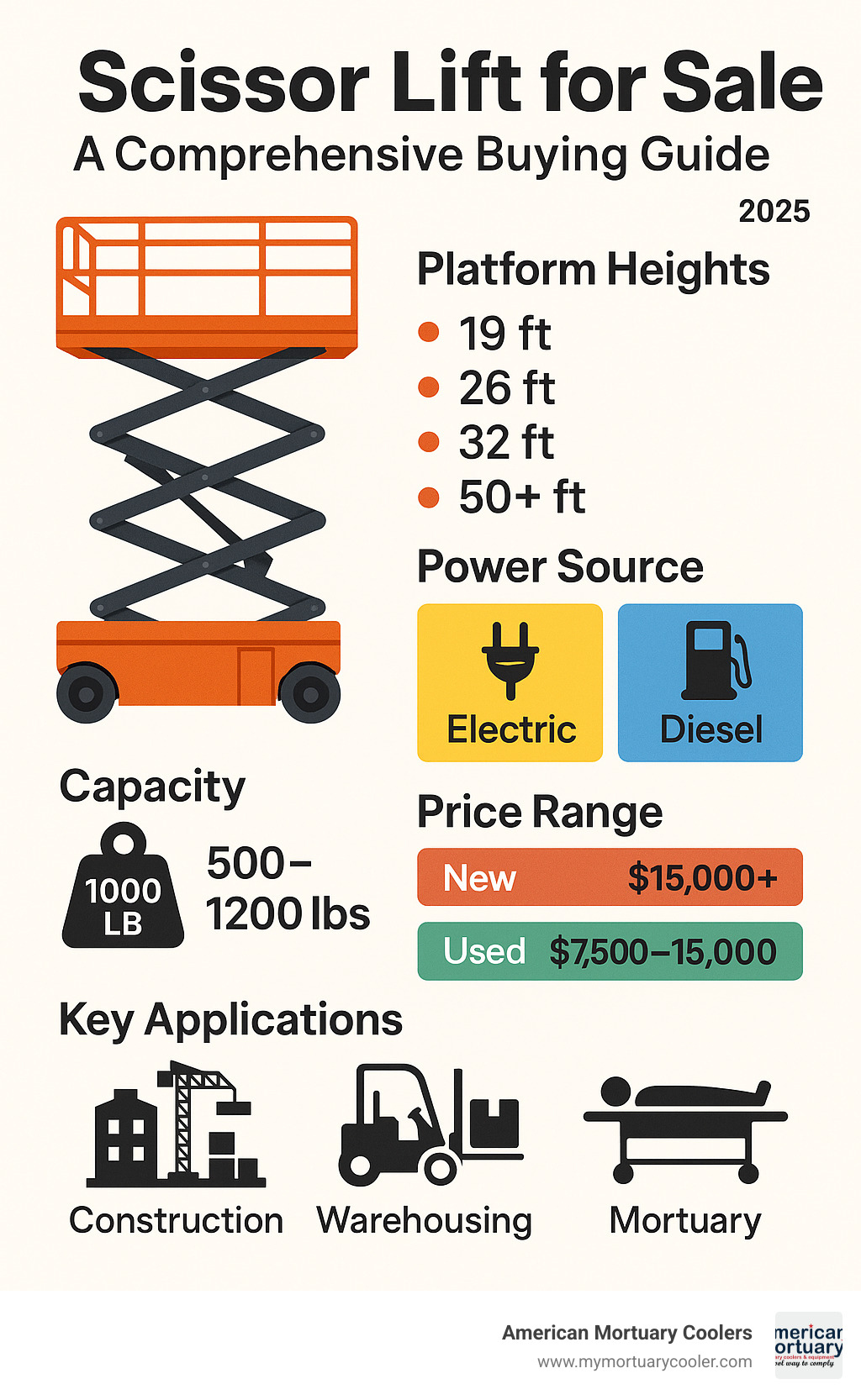

Quick Buyer's Guide:

- Platform Heights: 19ft, 26ft, and 32ft are most popular

- Price Range: Used lifts $7,500-$15,000, new lifts $15,000-$75,000+

- Top Brands: JLG, Genie, Skyjack, Haulotte, Snorkel

- Power Options: Electric (indoor), diesel/dual fuel (outdoor rough terrain)

- Capacity: Most models handle 500-1,200 lbs

- Where to Buy: Authorized dealers, auctions (IronPlanet), online marketplaces (eBay)

Scissor lifts are aerial work platforms that extend vertically using crossed hydraulic cylinders - like a giant pair of scissors. Unlike boom lifts that can reach around obstacles, scissor lifts only move straight up and down. But that simplicity makes them incredibly stable and perfect for tasks requiring a large, steady work platform.

The numbers tell the story: With over 400,000 JLG scissor lifts sold worldwide and 4,052+ units currently available across major marketplaces, the market is robust. Whether you need a compact 19-footer for indoor maintenance or a heavy-duty 50-foot rough terrain model, there's likely a scissor lift that fits your specific needs and budget.

From construction sites to funeral homes, these versatile machines boost productivity while keeping workers safe at height. The key is knowing which type, size, and power source matches your applications - and where to find the best deals.

I'm Mortuary Cooler from American Mortuary Coolers, and as a national-level mortuary equipment supplier, I've helped countless funeral homes find the right scissor lift for sale to meet their specific operational needs.

Key scissor lift for sale vocabulary:

Understanding Scissor Lifts: How They Work & Where They Shine

Picture a giant pair of scissors underneath a sturdy work platform - that's essentially what you're getting with a scissor lift for sale. The engineering is beautifully simple: hydraulic cylinders power those familiar crossed scissor arms in a pantograph design, creating smooth vertical movement that's both reliable and incredibly stable.

What makes scissor lifts special is their focus on doing one thing exceptionally well. While boom lifts can swing around obstacles and reach tricky angles, scissor lifts go straight up and straight down. This vertical-only movement might seem limiting, but it's actually their superpower - you get a rock-solid platform that won't sway or bounce when you're working at height.

The hydraulic system does all the heavy lifting, extending and retracting those scissor arms with precision. Most modern units feature a zero-turn radius, meaning they can spin in place without moving forward or backward. When you're maneuvering in tight warehouse aisles or cramped funeral home prep areas, that ability to pivot on a dime becomes invaluable.

You'll find two main power options when shopping for a scissor lift for sale: electric models perfect for indoor work with zero emissions, and diesel or dual-fuel units built for outdoor rough terrain. Platform heights typically range from compact 19-footers up to massive 50+ foot giants, with most falling in that sweet spot of 26 to 32 feet.

What Is a Scissor Lift?

Think of a scissor lift as your mobile high-rise office. The pantograph design - those crossed metal arms that fold and unfold like an accordion - creates a stable foundation for the work platform above. Every unit comes equipped with guardrails around the platform perimeter, and most models deploy stabilizers automatically when you raise the lift.

The platform itself is where scissor lifts really shine compared to other aerial equipment. Instead of a small bucket that fits one or two people, you get a spacious deck that can accommodate multiple workers, tools, and materials.

What you won't get is horizontal reach. Scissor lifts are purely vertical machines - they go up, they come down, and that's it. But this limitation is also their strength, providing best stability for tasks where you need to work directly overhead.

Typical Applications Across Industries

The versatility of scissor lifts never ceases to amaze me. In construction and facility maintenance, electric models dominate indoor projects like ceiling repairs, lighting upgrades, and HVAC installations. The large platform means technicians can bring everything they need up with them instead of constantly climbing down for tools.

Warehouses have acceptd scissor lifts for inventory management and high-bay maintenance. That zero-turn radius becomes crucial when navigating narrow aisles between towering shelves. Workers can access high storage areas safely while maintaining productivity.

Here at American Mortuary Coolers, we see funeral homes using specialized scissor lifts daily. These aren't your typical construction models - mortuary scissor lifts feature lower profiles for easier casket loading and specialized platforms designed for the unique needs of funeral service. The smooth, quiet operation is particularly important in these sensitive environments.

Automotive shops love portable mid-rise scissor lifts for quick undercarriage access. Unlike permanent in-ground lifts, these units can be moved around the shop as needed. Tree care professionals also rely on scissor lifts, especially in urban settings where traditional bucket trucks can't squeeze into tight spaces between buildings.

The common thread across all these applications? The need for a stable, spacious work platform that goes straight up. When that's what your job requires, no other piece of equipment comes close to what a quality scissor lift for sale can deliver.

Types, Brands & Popular Models of Scissor Lifts for Sale

Shopping for a scissor lift for sale can feel overwhelming with so many options available. The good news? Most buyers find what they need among a handful of proven categories and trusted brands.

The current market is busy with activity - over 425 listings on eBay alone, with the sweet spot being 19ft, 26ft, and 32ft platform heights. These sizes handle about 80% of typical jobs, from routine maintenance to construction work.

Five major brands dominate the scissor lift for sale market: JLG, Genie, Skyjack, Haulotte, and Snorkel. You'll see these names everywhere because they've earned their reputation through decades of reliable performance. Most models in this range offer 500-1,200 pound capacities, though specialized applications can handle much more.

| Category | New Price Range | Used Price Range | Best For |

|---|---|---|---|

| Electric Slab | $15,000-$35,000 | $7,500-$18,000 | Indoor maintenance, warehouses |

| Rough Terrain | $45,000-$75,000+ | $25,000-$40,000 | Construction, outdoor work |

| Specialty/Mortuary | $20,000-$50,000 | $12,000-$28,000 | Funeral homes, auto shops |

Electric & Slab Scissor Lifts

Electric scissor lifts are the quiet heroes of indoor work. They run on battery power, produce zero emissions, and feature non-marking tires that won't leave scuffs on your floors. Perfect for warehouses, retail spaces, and anywhere you need to keep things clean and quiet.

The Genie GS-1930 leads the pack in the popular 19-foot category. With its 500-pound capacity and compact footprint, it handles routine maintenance tasks beautifully. The Skyjack SJIII-3219 offers similar specs but with slightly different controls - some operators prefer one over the other, so it's worth testing both if possible.

JLG's 1932R rounds out the trio of top 19-footers. JLG built their reputation on reliability, and this model continues that tradition. All three typically offer 6-8 hours of runtime per charge and can steer through standard doorways.

For higher reach, the Skyjack SJ4626 stretches to about 32 feet with a 454 kg safe working load. It includes smart safety features like pothole protection and tilt cut-out systems - technology that prevents accidents before they happen.

Rough-Terrain & All-Terrain Scissor Lifts

When your job site has dirt, gravel, or uneven ground, electric slab lifts won't cut it. That's where rough-terrain models shine with their 4WD capability, larger pneumatic tires, and diesel or dual-fuel engines.

These outdoor champions typically reach 40-50+ feet and pack serious power for extended runtime. The pothole protection feature deserves special mention - sensors actually prevent the machine from driving into holes or off edges when lifted.

Construction crews love these models because they combine serious lifting height with the mobility to handle job site conditions. The dual-fuel option is particularly smart - run on propane for cleaner operation or gasoline for maximum power and runtime.

Specialty & Mortuary Scissor Lifts

Here's where my experience at American Mortuary Coolers really comes into play. Mortuary scissor lifts serve very specific needs that general-purpose lifts simply can't handle.

Low-profile crematory lifts can collapse to just 12.5 inches high - crucial for fitting under crematory equipment. Battery-powered body lifts operate quietly in respectful environments while handling 1,000+ pounds to accommodate heavy caskets and multiple operators.

The platforms themselves are specially designed for casket handling and body transfer, with features you won't find on construction lifts. More info about mortuary lifts explains the specific benefits funeral directors should consider.

Portable mid-rise auto lifts represent another growing specialty category. These units offer 48-70 inch lift heights - perfect for brake and tire work without the expense and permanence of installed car lifts. Auto shops love them because they can move the lift to different bays as needed.

Key Buying Considerations for Your Next Scissor Lift for Sale

Finding the perfect scissor lift for sale doesn't have to feel overwhelming. After helping hundreds of customers make this decision, I've learned that success comes down to matching the right machine to your specific needs.

Platform height is your starting point. Your actual working height is about 6 feet higher than the platform height. So that popular 19-foot platform gives you roughly 25 feet of reach - perfect for most ceiling work and routine maintenance tasks.

Lift capacity matters more than you might think. While 500-800 pounds handles most jobs, don't forget to count everything: workers, tools, materials, and that extra equipment you'll inevitably need. I've seen too many buyers regret choosing the smaller capacity when they could have spent just a bit more for peace of mind.

The power source decision is pretty straightforward. Electric models work beautifully indoors with their quiet operation and zero emissions, typically running 6-8 hours per charge. Diesel or dual-fuel engines are your go-to for outdoor work where you need extended runtime and don't have charging stations nearby.

Here's something many buyers overlook: deck extensions. These roll-out platforms can add 2-4 feet of workspace, essentially giving you a much larger work area when you need it. It's like getting a bigger lift without the bigger price tag.

When shopping for used equipment, machine hours tell you more than the year of manufacture. A well-maintained 2018 model with 2,000 hours often outperforms a neglected 2020 model with just 500 hours. The maintenance history matters more than the odometer.

For deeper technical insights, check out this scientific research on lift accessories to understand what upgrades might benefit your specific applications.

New vs Used: Pros, Cons & Price Ranges

The new versus used decision really comes down to your budget and risk tolerance. Let me break down what we're seeing in today's market.

New scissor lifts typically run $15,000 to $75,000 depending on size and features. Yes, that's a significant investment, but you get a full manufacturer warranty, the latest safety technology, and financing options that can make the monthly payments manageable.

Used equipment opens up much more affordable options, with quality lifts available from $7,500 to $40,000. I've seen excellent 2016 Genie GS-1930 models selling for around $11,900, while a comparable new unit might cost $25,000 or more. That's real money saved.

The sweet spot many of our customers find is certified refurbished equipment. These machines undergo thorough inspection and testing, often come with 90-day warranties, and sell at significant discounts to new prices.

Market data from eBay shows over 425 scissor lift listings, with many quality options in that $10,000-$12,000 range. The key is knowing what to look for and having realistic expectations about cosmetic condition versus functional performance.

Choosing the Right Dealer or Marketplace

Where you buy your scissor lift for sale affects everything from price to long-term support. Each option has its place, and the right choice depends on your priorities.

Authorized dealers cost more upfront, but they provide professional reconditioning, financing options, and warranty support that can save you money long-term. They're especially valuable if you're new to scissor lifts and want guidance on the right model for your needs.

Auction sites like IronPlanet currently show over 1,800 scissor lifts with both auction and "Buy Now" formats. Auctions can deliver fantastic deals, but you need to inspect carefully and make quick decisions.

Online marketplaces give you the widest selection. eBay's 425+ current listings include everything from compact indoor models to massive rough-terrain units. Just remember - you're typically buying "as-is" with limited recourse if problems arise.

For serious buyers, used scissor lifts for sale through specialized equipment sites often provide better inspection information and more detailed specifications than general marketplaces.

Your inspection checklist should cover: battery condition and charging systems, hydraulic fluid levels and any leaks, tire condition and remaining tread, platform and guardrail integrity, control responsiveness, safety system functionality, available maintenance records, and current inspection certificates.

Financing, Warranty & After-Sale Support

The financial side of your scissor lift purchase involves more than just the sticker price. Smart buyers think about the total cost of ownership, including financing, warranty coverage, and ongoing support.

Financing options vary dramatically by equipment condition and your credit profile. New equipment typically qualifies for traditional equipment loans with 3-7 year terms and competitive rates. Used equipment financing often requires higher down payments and shorter terms, but it's still usually available.

Warranty coverage ranges from absolutely nothing on private sales to comprehensive manufacturer warranties on new equipment. Those 90-day warranties on certified refurbished equipment typically cover functionality but not cosmetic issues.

After-sale support becomes crucial when you need parts, service, or technical help. Major brands like JLG, Genie, and Skyjack maintain extensive dealer networks across the country. Lesser-known brands might offer great value upfront but leave you scrambling for parts when something breaks.

Safety, Maintenance & Accessories

When you're investing in a scissor lift for sale, safety isn't just a nice-to-have feature - it's absolutely critical. I've seen too many accidents that could have been prevented with proper training and maintenance. Following OSHA and ANSI A92.20 standards isn't complicated, and it protects both your workers and your business.

Every scissor lift operator needs proper certification. This isn't optional paperwork - it's essential training that covers equipment operation, hazard recognition, and emergency procedures. Many companies require annual recertification to keep skills sharp and stay current with safety updates.

Most scissor lift accidents happen because someone skipped the daily inspection or ignored basic safety protocols. A few minutes of checking your equipment before each use can prevent serious injuries and costly downtime.

Essential Safety Checks Before Each Use

Your daily safety routine should become second nature. Start by inspecting the guardrails for any damage, loose bolts, or problems with the latching mechanisms. These rails are your primary fall protection, so they need to be perfect every time.

Next, test the emergency stop button. It should immediately halt all lift functions when pressed. If there's any delay or the lift doesn't stop completely, don't use the equipment until it's repaired.

Check the load charts posted on your lift. Your total weight - workers plus tools plus materials - must stay within the rated capacity. It's tempting to push these limits, but capacity ratings include safety margins that shouldn't be ignored.

Ground conditions matter more than most people realize. Look for holes, steep slopes, and unstable surfaces before positioning your lift. Most scissor lifts can't safely operate on slopes exceeding 25% grade, and even smaller slopes can cause stability problems.

Don't forget your personal protective equipment. Hard hats, safety glasses, and fall protection harnesses are standard requirements. Some work environments need additional PPE like high-visibility vests or respiratory protection.

Modern scissor lifts include tilt alarms that prevent operation on unsafe angles. Test these systems before starting work - they're your electronic safety net when working on uneven ground.

Preventive Maintenance Schedule

Regular maintenance isn't just about preventing breakdowns - it's about keeping your investment working efficiently for years to come. Daily maintenance should include a visual inspection, checking fluid levels, verifying battery charge, and testing safety systems.

Weekly tasks involve more detailed cleaning, lubricating grease points, and checking tire pressure. This is also a good time to look for any developing problems before they become expensive repairs.

Monthly maintenance gets more technical. For electric lifts, check battery water levels if you have flooded batteries. Inspect the hydraulic system for leaks or unusual wear patterns. Look at high-wear components like cables, chains, and pivot points.

Annual inspections require certified technicians who can perform comprehensive system checks, update software, and replace major components as needed. This isn't a DIY job - professional inspection protects your warranty and ensures compliance with safety standards.

Battery care deserves special attention because battery replacement can cost thousands of dollars. Electric scissor lifts use deep-cycle batteries that need proper charging cycles and regular maintenance. More info about battery systems explains how to maximize battery life and avoid premature replacement costs.

Must-Have Accessories to Boost Productivity

The right accessories can transform your scissor lift from basic transportation into a highly efficient work platform. Deck extensions are probably the most popular upgrade because they can add 2-4 feet of platform length without requiring a larger, more expensive lift.

Pipe racks solve a common problem for contractors who work with long materials. Instead of trying to balance conduit, lumber, or piping on the platform, these specialized racks keep everything organized and easily accessible.

Telematics systems might seem like overkill, but they're incredibly valuable for fleet management. These systems track usage patterns, maintenance schedules, and equipment location. You'll know exactly when each lift needs service and can optimize your fleet utilization.

LED lighting kits extend your productive working hours. Whether you're working early mornings, late evenings, or in dimly lit buildings, proper lighting improves both productivity and safety.

Tool trays and organizers keep frequently used tools within arm's reach. This might seem minor, but eliminating trips up and down the lift saves significant time over a full workday.

Non-slip platform treatments provide extra traction in wet or oily conditions. These aftermarket surfaces can prevent slips and falls when working in challenging environments.

Frequently Asked Questions About Buying a Scissor Lift for Sale

When I talk with customers about finding the right scissor lift for sale, the same three questions come up almost every time. Let me share the answers that help folks make confident buying decisions.

How much does a typical 19-ft electric scissor lift cost?

Here's the honest truth about pricing: used 19-foot electric scissor lifts typically run between $7,500 and $15,000, depending on their condition and maintenance history. The sweet spot for popular models like the Genie GS-1930 or Skyjack SJIII-3219 sits around $10,000 to $12,000 for units with reasonable hours and good care.

New 19-foot electric scissor lifts will set you back $20,000 to $30,000 or more, depending on the features you choose. That's a significant jump, but it comes with full warranties and financing options that many businesses find worthwhile.

The price difference often makes used equipment the smart choice for occasional use. But if you're planning heavy daily operation, that new equipment warranty and support might save you money in the long run.

Do I need certification or training to operate a scissor lift?

Absolutely yes - and this isn't just bureaucratic red tape. OSHA requires scissor lift operators to receive proper training and certification, and there's a good reason for this rule. Most scissor lift accidents happen because someone didn't know what they were doing.

The training covers everything you need to know: pre-operation inspections, safe operating procedures, load calculations, spotting hazards, and what to do when things go wrong. Many dealers and training companies offer IPAF (International Powered Access Federation) certification programs that meet all OSHA requirements.

You'll need both classroom instruction and hands-on evaluation to get certified. Most programs also require annual recertification to keep your skills sharp and learn about new safety updates. It's a small investment that could literally save your life.

What is the average lifespan of scissor lift batteries?

Electric scissor lift batteries typically last 3 to 5 years with proper care, though I've seen well-maintained batteries go longer and neglected ones fail much sooner. The deep-cycle batteries used in these lifts can handle 1,000 to 2,000 charge cycles under normal conditions.

Several factors affect how long your batteries will last. Proper charging habits make the biggest difference - overcharging or letting batteries discharge completely will shorten their life significantly. Temperature extremes also take a toll, whether it's blazing summer heat or freezing winter cold.

Usage patterns matter too. Heavy daily use wears batteries faster than occasional light work. Regular maintenance like checking water levels and cleaning terminals can add months or even years to battery life.

When replacement time comes, expect to spend $1,500 to $3,000 depending on your lift size and battery type. Planning ahead for this expense helps avoid unexpected downtime when your batteries finally give up.

Conclusion

Your search for the perfect scissor lift for sale doesn't have to be overwhelming. The key is matching your specific needs with the right equipment - whether that's a nimble 19-foot electric model for warehouse maintenance or a robust rough-terrain lift for outdoor construction projects.

At American Mortuary Coolers, we've built our reputation on understanding specialized equipment needs. From our Tennessee headquarters, we deliver custom solutions nationwide across all 48 contiguous states. While our expertise shines brightest in mortuary applications, our experience spans the full spectrum of lifting equipment across diverse industries.

The path to a smart scissor lift purchase follows a clear roadmap. Start by defining your requirements - platform height, weight capacity, and power source form the foundation of your decision. Next, weigh new versus used options based on your budget and how often you'll use the equipment. Choose your purchasing source carefully - whether that's an authorized dealer, auction site, or private seller, each option carries different benefits and risks.

Don't skip the inspection phase, especially for used equipment. Check everything from battery condition to safety systems before committing your money. Buying the lift is just the beginning - plan for operator training, regular maintenance, and productivity-boosting accessories that'll make your investment pay off.

The current market offers incredible opportunities. With thousands of units available and major manufacturers maintaining strong support networks, you're shopping in a buyer-friendly environment. The challenge isn't finding options - it's knowing which option fits your needs best.

For funeral homes and crematories seeking specialized lifting solutions, our deep industry knowledge becomes invaluable. Maximize Safety with American Mortuary's Durable Crematory and Mortuary Lift Solutions explores how the right equipment transforms daily operations while keeping staff safe.

A scissor lift for sale represents more than just another piece of equipment - it's an investment in your team's safety and productivity. Take the time to choose wisely, maintain properly, and train thoroughly. Your workers will thank you, your projects will run smoother, and your bottom line will reflect the smart decision you made.

Whether you're lifting caskets in a funeral home or installing lights in a warehouse, the right scissor lift makes all the difference. We're here to help you find that perfect match.