The Ultimate Stainless Steel Storage Solution

A stainless steel rolling cabinet is a mobile storage unit constructed from corrosion-resistant stainless steel with wheels for easy movement. These cabinets combine durability with mobility for various workspace applications.

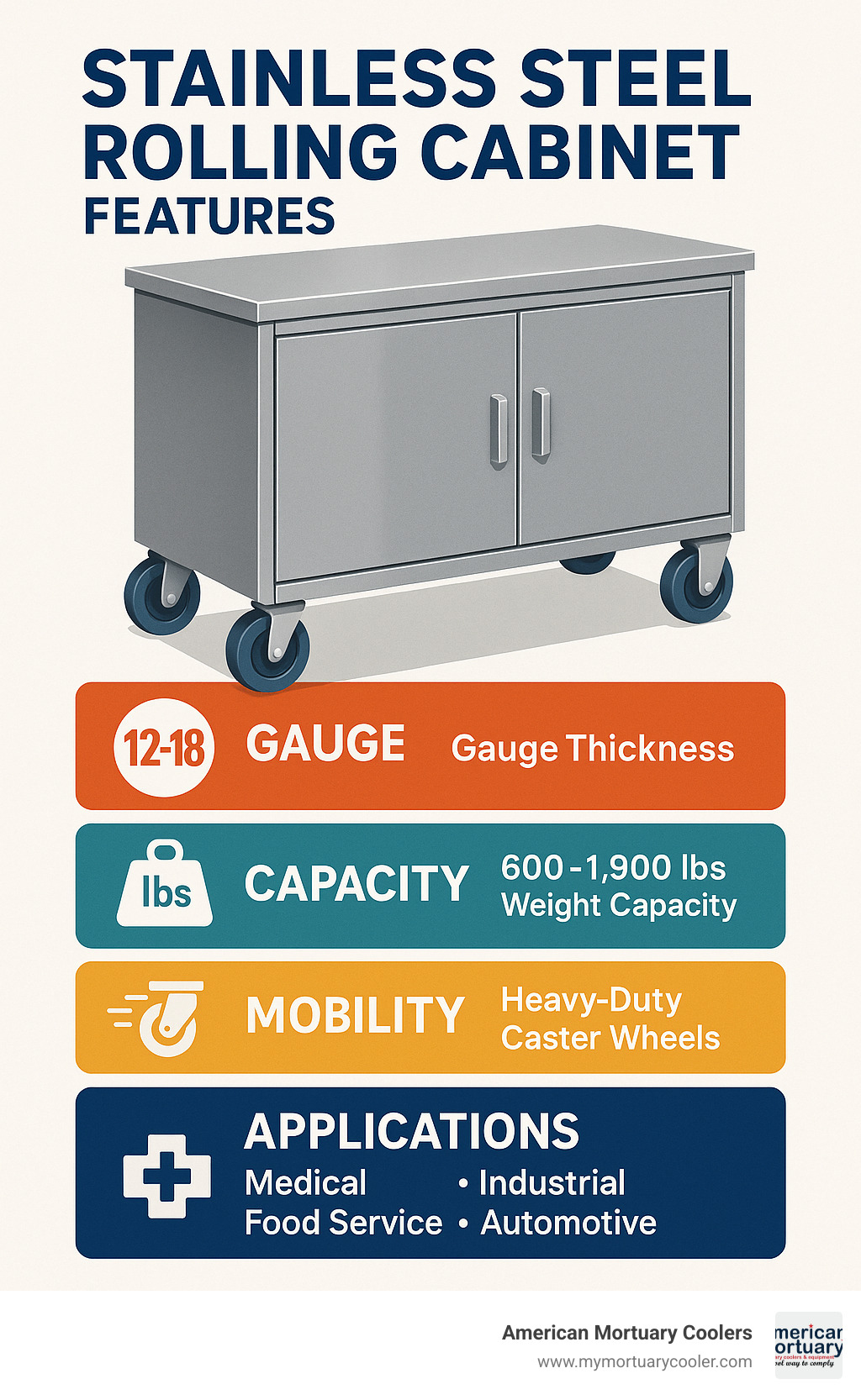

| Key Features of Stainless Steel Rolling Cabinets |

|---|

| Material: 12-18 gauge stainless steel construction |

| Capacity: Shelf weight limits from 600-1,900 lbs |

| Mobility: 5-6" heavy-duty caster wheels |

| Security: 3-point locking systems available |

| Dimensions: Width ranges from 31-84 inches |

| Applications: Medical, industrial, food service, automotive |

Stainless steel rolling cabinets offer a perfect balance of strength and versatility. These workhorses serve multiple functions across industries - from storing sensitive medical supplies in hospitals to organizing heavy tools in automotive shops. The combination of durable stainless steel construction and mobility makes them ideal for environments where both cleanliness and flexibility matter.

What sets these cabinets apart is their resistance to corrosion, moisture, and chemicals. Unlike wooden or standard metal cabinets, stainless steel models can withstand harsh cleaning agents, high humidity, and frequent sanitization - crucial requirements in medical facilities, laboratories, and food preparation areas.

The mobility factor cannot be overstated. With heavy-duty caster wheels (typically 5-6 inches) capable of supporting up to 660 lbs each, these cabinets allow you to bring tools and supplies exactly where you need them, then secure them when not in use.

I'm Mortuary Cooler, a national-level supplier of mortuary equipment including stainless steel rolling cabinets designed specifically for funeral homes and medical facilities. My experience providing durable, customizable stainless steel rolling cabinets has taught me that the right storage solution can dramatically improve workflow efficiency and maintain proper sanitation standards.

Simple stainless steel rolling cabinet glossary:

Stainless Steel Rolling Cabinet 101: Definition, Uses & Industry Demand

When I think about what makes a workspace truly functional, a stainless steel rolling cabinet almost always comes to mind. These workhorses combine mobility with durability – imagine a robust storage solution that goes exactly where you need it, when you need it.

These cabinets serve as mobile workstations, tool organizers, and secure storage units all in one package. With sturdy wheels and durable construction, they bring versatility to any workspace. Whether you're storing medical supplies in a hospital, organizing tools in an automotive garage, or keeping laboratory equipment secure, these cabinets deliver.

What makes them special? It's the perfect marriage of mobility and stainless steel construction. The non-porous, corrosion-resistant surface means they stand up to harsh environments while maintaining hygiene standards that other materials simply can't match.

One of our mortuary clients recently told me, "Having these cabinets has completely changed how we work. We can roll our instruments right where we need them, then thoroughly sanitize everything afterward. It's a game-changer for maintaining our standards."

If you're curious about more specialized applications, you might want to check out our detailed guide on stainless steel medical cabinets for a deeper dive into healthcare applications.

Primary Uses Across Industries

The versatility of stainless steel rolling cabinets makes them invaluable across numerous settings. In tool-heavy environments, they keep everything organized and within reach. Labs use them for sample preparation and instrument transport. Manufacturing facilities rely on them for parts staging, while many businesses appreciate the shift-work security they provide.

Unlike fixed storage, these cabinets adapt to your needs. A funeral director in Memphis shared with me how their stainless steel rolling cabinet serves multiple purposes throughout the day – from holding instruments during preparations to securely storing sensitive items when family members visit.

The beauty of these cabinets lies in their adaptability. The same model that works perfectly in a brewery might serve equally well in a marine environment, thanks to the inherent corrosion resistance of quality stainless steel.

Environments That Benefit Most

Not all workspaces are created equal, and some environments particularly shine when equipped with stainless steel rolling cabinets. Industrial plants with harsh conditions, hospitals with strict hygiene protocols, morgues requiring both cleanliness and durability – these are where stainless truly excels.

Research laboratories benefit from cabinets that resist chemical damage while maintaining clean conditions. Breweries appreciate storage that stands up to constant moisture and cleaning agents. Car workshops need the durability to handle heavy tools and frequent repositioning.

At American Mortuary Coolers, we've seen how crucial these cabinets are in morgue settings. When you're handling sensitive work that demands both mobility and impeccable cleanliness, nothing compares to the reliability of a well-built stainless steel rolling cabinet.

I remember visiting a small-town funeral home that had been using the same cabinets for over a decade. Despite daily use in challenging conditions, they looked remarkably well-preserved – a testament to the longevity that comes with quality stainless construction.

Whether you're outfitting a new facility or upgrading an existing space, these versatile cabinets deliver functionality that adapts to your specific needs while maintaining the highest standards of durability and hygiene.

Design, Types & Specifications

When selecting a stainless steel rolling cabinet, understanding the various designs and specifications is crucial for finding the perfect match for your needs. These cabinets come in a wide range of configurations, each designed to address specific storage and workflow requirements.

Most folks I talk to are surprised by the variety of cabinet styles available. The all-drawer designs are perfect for organizing smaller tools and components - I've seen premium PROTO cabinets with up to 20 drawers providing a whopping 30,000 cubic inches of organized storage. If you need more flexibility, the drawer and door combinations like the Homak 72" RS Pro offer the best of both worlds - drawers for small items and cabinet spaces for bulkier equipment.

Need a workspace on the go? Workbench-top models feature a durable surface that creates an instant mobile workstation wherever you roll it. We've supplied these to several mortuary facilities where space is at a premium, and they've become essential multi-purpose stations.

The construction quality is where you really see the difference between professional and budget models. The thickness of the steel - measured in gauge - tells you a lot about durability. The lower the gauge number, the thicker the steel! For heavy-duty applications, look for 12-gauge steel that can support up to 1,900 pounds per shelf. Most commercial settings do well with 14-gauge, while standard industrial applications might use 16-gauge. The lighter 18-gauge works for basic applications where weight capacity isn't as critical.

As for security, I always recommend cabinets with 3-point locking systems to my clients. These secure the cabinet at multiple points with a single lock action - much more secure than the simple cam locks found on basic models. When you're storing valuable tools or sensitive materials, that extra security makes all the difference.

You can find detailed assembly instructions for many of our cabinet models in resources like this Assembled Dimensions PDF.

Standard Dimensions of a Stainless Steel Rolling Cabinet

Stainless steel rolling cabinets come in a range of standard dimensions to suit different space constraints and storage needs:

| Cabinet Type | Width Range | Depth Range | Height Range | Typical Drawer Count | Weight Capacity |

|---|---|---|---|---|---|

| Compact | 31"-41" | 18"-20" | 32"-40" | 4-11 | 600-1,200 lbs |

| Mid-Size | 42"-60" | 20"-24" | 34"-48" | 8-15 | 900-1,650 lbs |

| Heavy-Duty | 61"-84" | 24"-26" | 40"-72" | 12-20 | 1,500-3,600 lbs |

The wheels on these cabinets aren't just an afterthought - they're a critical component. Professional-grade stainless steel rolling cabinets typically feature 5" to 6" diameter caster wheels that can each support 600-660 pounds. Most designs use a combination of fixed and swivel casters (usually two of each) with locking mechanisms on at least two casters.

I remember installing cabinets at a mortuary in Memphis where the floors had several thresholds between rooms. We recommended models with 6" casters, and the staff later told me it was the best advice we gave them - those larger wheels roll smoothly over small obstacles that would stop smaller casters in their tracks.

Customization & Accessories

What really makes stainless steel rolling cabinets shine is how adaptable they are through customization and accessories. It's like getting a cabinet that grows with your needs!

While the classic brushed stainless finish is what most people picture, we've helped clients with custom finishes including powder-coated color options for departmental color-coding. One funeral home we worked with used different colored cabinets to instantly identify which department each belonged to - a small touch that made a big difference in their busy facility.

For clients working with chemicals, we recommend ventilated door and side panels to ensure proper airflow. Inside the drawers, customizable dividers and foam inserts keep tools organized and prevent damage - especially important for delicate instruments.

One of our most popular accessories is the pegboard attachment shown above. A funeral director in Dallas who purchased a customized cabinet from us shared: "The pegboard attachment has been a game-changer. We can hang our most frequently used instruments where they're immediately accessible, while keeping other supplies organized in the drawers below."

Other popular add-ons include non-slip drawer liners (a must for keeping tools from sliding around), additional shelves for cabinet sections, side-mounted tool holders, and even integrated power strips for charging electronic tools. Some of our mortuary clients add document holders to keep paperwork accessible but protected.

When selecting your stainless steel rolling cabinet, think beyond your immediate needs. The ability to add accessories later can significantly extend your investment's useful life. I always tell clients to imagine their workflow in five years - what might change, and how can their cabinet adapt?

For more specialized applications in medical settings, you might want to explore additional options in our guide to Stainless Steel Medical Cabinets.

The Stainless Edge: Benefits, Maintenance & Hygiene

Let's talk about why stainless steel rolling cabinets are worth every penny, despite costing more upfront than other options. There's a reason they're the go-to choice for demanding environments like morgues, hospitals, and industrial kitchens.

When I visit funeral homes to help them select equipment, I often point out that stainless steel isn't just about looking professional – it's about smart long-term investment. A properly maintained stainless steel rolling cabinet can serve your facility faithfully for decades, even in the toughest conditions.

The magic of stainless steel lies in its chromium content, which forms an invisible shield against corrosion. This self-healing layer is why these cabinets can handle constant exposure to moisture, chemicals, and cleaning agents without deteriorating. For mortuary settings where thorough disinfection is non-negotiable, this resistance is invaluable.

"We've had our stainless steel rolling cabinets for over 12 years now," a funeral director in Nashville told me recently. "Despite daily cleaning with hospital-grade disinfectants, they still look almost new. The powder-coated cabinets we had before started rusting within two years."

Beyond durability, the non-porous surface of stainless steel creates a naturally hygienic environment that doesn't harbor bacteria or absorb fluids – critical for medical settings and food preparation areas. This seamless, easy-to-clean surface helps maintain the strict sanitation standards required in funeral preparation rooms.

For facilities concerned with fire safety, stainless steel offers another advantage: it won't burn or release toxic fumes when exposed to heat. And for those with environmental priorities, stainless steel's 100% recyclability makes it a sustainable choice that aligns with modern waste reduction goals.

When compared to alternatives, stainless steel rolling cabinets consistently come out on top for long-term value:

| Feature | Stainless Steel | Powder-Coated Steel | Plastic |

|---|---|---|---|

| Corrosion Resistance | Excellent | Good (until coating is damaged) | Variable |

| Impact Resistance | Excellent | Good | Poor to Fair |

| Chemical Resistance | Excellent | Fair | Variable |

| Cleanability | Excellent | Good | Good |

| Longevity | Decades | 5-10 years typically | 3-7 years typically |

| Initial Cost | Highest | Medium | Lowest |

| Lifetime Value | Best | Good | Fair |

Caring for Your Cabinet

Taking care of your stainless steel rolling cabinet isn't complicated, but consistent maintenance ensures it will serve your facility for years to come. At American Mortuary Coolers, we recommend these simple practices to our clients:

For day-to-day cleaning, warm water with a mild detergent works perfectly. Always wipe in the direction of the grain – this prevents microscopic scratches that can dull the finish over time. After washing, rinse thoroughly and dry completely to prevent water spots, which can be stubborn to remove later.

Those pesky fingerprints that show up so clearly on stainless steel? A glass cleaner works wonders, or you can try one of the specialized stainless steel cleaners on the market. For tougher challenges like hard water deposits, a simple solution of one part vinegar to three parts water usually does the trick.

Don't forget about the moving parts! Quarterly lubrication of the casters prevents that annoying squeak that drives everyone crazy. While you're at it, check drawer slides, handles, and locks to make sure everything's working smoothly. These small maintenance steps can prevent bigger issues down the road.

"We've integrated cabinet maintenance into our monthly checklist," explains a laboratory manager from our Columbia, SC region. "Fifteen years later, our stainless steel rolling cabinets are still functioning perfectly and look almost new. That's a return on investment you can't ignore."

For mortuary environments specifically, we recommend a weekly deep cleaning protocol using hospital-grade disinfectants that are compatible with stainless steel. After disinfecting according to manufacturer instructions, remember to rinse thoroughly and dry completely – this step is crucial for maintaining that professional shine.

The latest research on corrosion resistance confirms what we've observed in practice: with proper care, stainless steel rolling cabinets maintain their integrity even in the challenging conditions of morgues and preparation rooms. This combination of durability and cleanability is why, despite the higher initial investment, our clients consistently choose stainless steel for their critical storage needs.

Buying Guide: Pricing, Brands, Warranty & Logistics

Ready to invest in a stainless steel rolling cabinet? Let me walk you through everything you need to know before making your purchase. I've helped hundreds of facilities find their perfect cabinet, and I've learned what matters most when it comes to price, brands, and those often-overlooked logistics details.

Price Range and Value Factors

When budgeting for your stainless steel rolling cabinet, expect to spend anywhere from $279 for a basic model to upwards of $5,300 for a premium industrial-grade unit. That's quite a range, right?

Think of it like buying a car – the price difference reflects what you're getting. A compact 31" cabinet might cost under $800, while a heavy-duty 72" model can easily exceed $4,000. What drives these price differences? Several important factors:

The thickness of the steel makes a huge difference – thicker steel (lower gauge number) can literally double the price. A cabinet with 12-gauge construction will cost significantly more than an 18-gauge model, but it might last twice as long in a demanding environment.

The number and quality of drawers also impacts price substantially. Those smooth-gliding, full-extension drawer slides that make accessing tools a dream? They're worth every penny but will increase your investment.

Leading Brands and Manufacturers

Over my years supplying stainless steel rolling cabinets to mortuaries and medical facilities, I've developed clear favorites among manufacturers:

Homak stands out for their exceptional construction quality and unique High Security Tubular Locking System. Their lifetime limited warranty speaks volumes about their confidence in their products.

Seville Classics offers excellent mid-range options with a practical UltraGuard fingerprint-resistant coating – a small feature that makes a big difference in maintaining a professional appearance.

Extreme Tools has captured the automotive market with their mag wheels supporting over 900 lbs each – perfect when you're storing heavy equipment that needs to remain mobile.

PROTO represents the premium end with industrial-grade cabinets featuring exceptional organization. Their 67" model offers an astounding 30,000+ cubic inches of storage.

Jamco specializes in heavy-duty industrial applications with impressive weight capacities up to 1,900 lbs per shelf.

Trinity provides versatility with sizes ranging from compact 31" models to substantial 72" workbenches with integrated features.

At American Mortuary Coolers, we're particularly selective about the stainless steel grade. For our mortuary clients, we insist on #304 stainless steel construction for its superior corrosion resistance – essential when dealing with the chemicals and cleaning protocols in funeral preparation.

Warranty and Support Considerations

The warranty on your stainless steel rolling cabinet tells you volumes about its expected lifespan. Standard warranties typically range from 1 to 5 years, but premium brands may offer 10-year or limited lifetime coverage. Some manufacturers are extraordinarily confident – Jamco, for instance, backs certain products with a remarkable 99-year limited warranty!

I always tell my clients to look beyond just the warranty duration. Check what's specifically covered – materials, workmanship, mechanical parts? Do casters and moving parts have different terms? Will they service it on-site, or do you need to ship it back (imagine shipping a 300-pound cabinet!)?

One of our mortuary directors shared a valuable lesson: "I initially focused just on price when buying our stainless steel rolling cabinets. After replacing a cheaper cabinet within three years, I understood the value of comprehensive warranty coverage. Our cabinets from American Mortuary Coolers have been trouble-free for seven years now."

Shipping, Delivery and Installation

These aren't lightweight items you can just toss in your trunk! The substantial weight of stainless steel rolling cabinets creates special logistics considerations that can surprise unprepared buyers.

Most cabinets ship as freight rather than parcel, with typical delivery times ranging from 10-15 business days for in-stock items. Be sure to ask about lift-gate service – this essential service (usually an additional $75-100) allows the freight carrier to lower your cabinet from the truck to ground level.

Consider whether you need inside delivery. Yes, it costs extra, but it prevents you from having to move a 300-600 lb cabinet yourself (and potentially injuring your back or damaging the cabinet).

Some cabinets arrive fully assembled, while others require partial or complete assembly. Factor in assembly time or professional installation costs when budgeting.

At American Mortuary Coolers, we understand the unique needs of mortuary facilities, which is why we provide direct delivery across the contiguous 48 states, with options for white-glove delivery and installation. Our technicians will position your cabinet, install accessories, and remove all packaging materials – letting you focus on serving families during difficult times.

Choosing the Right Stainless Steel Rolling Cabinet for Your Workspace

Finding your perfect stainless steel rolling cabinet means evaluating several workplace-specific factors:

First, be honest about your load capacity requirements. Assess the weight of items you'll store and choose a cabinet rated for at least 25% more than your expected maximum load. This buffer protects both your investment and your safety.

Your space constraints matter enormously. Measure your available space carefully, including clearance for drawer extension and door swing. I've seen too many facilities forget that drawers need space to open fully!

Don't overlook your flooring. Harder casters work beautifully on smooth concrete but may damage vinyl or wood flooring. Softer rubber casters are gentler on delicate flooring but don't roll as easily.

For environments storing valuable tools or sensitive materials, prioritize cabinets with robust 3-point locking systems rather than simple cam locks. The difference in security is substantial.

Environmental factors can make or break your cabinet's longevity. For humid environments or settings with chemical exposure, insist on #304 stainless steel rather than lower grades.

Think about future expandability – will your storage needs grow? Does the manufacturer offer compatible add-on components?

Finally, consider ergonomic factors. The height of work surfaces and placement of frequently accessed drawers should align with user height and typical workflows.

A pathology lab we work with in New York recently upgraded to custom stainless steel rolling cabinets designed specifically for their workflow. Their lab manager told me: "Having cabinets with the right height work surface and drawer configuration has reduced strain on our technicians and improved efficiency. The mobility allows us to reconfigure our lab as needed for different procedures."

For more information about equipment suppliers that might meet your specific needs, check out our article on Essential Morgue Equipment Suppliers or browse the RollCabs catalog for additional options.

Frequently Asked Questions about Stainless Steel Rolling Cabinets

How much weight can a typical cabinet handle?

When customers ask me about weight capacity, I always emphasize that not all stainless steel rolling cabinets are created equal. The weight capacity varies dramatically based on how they're built:

Entry-level cabinets typically support around 150-200 pounds per shelf or drawer, which works for basic supplies but not heavy tools. Mid-range models step up to 400-600 pounds per shelf, while those heavy-duty industrial beasts can handle an impressive 1,200-1,900 pounds per shelf.

Here's something many people overlook, though: your cabinet's total capacity is ultimately limited by those casters on the bottom. Most professional-grade cabinets have casters rated for 600-660 pounds each. Simple math tells us that gives you a maximum capacity of about 2,400-2,640 pounds total, even if the shelves themselves could handle more.

One of our industrial customers in Los Angeles learned this lesson the hard way: "We damaged a caster by overloading just one side of our cabinet. Now we're careful to distribute heavy items evenly throughout." Smart advice that can save you a repair bill!

What gauge of steel is best for harsh environments?

If you're working in environments with moisture, chemicals, or places that need frequent disinfecting (like our mortuary customers), I strongly recommend:

12 to 14 gauge #304 stainless steel for the cabinet body provides excellent durability against daily abuse. For drawers and shelves, 14 to 16 gauge usually offers the right balance of strength and weight. And if you're dealing with truly extreme conditions – think marine environments or heavy chemical exposure – consider upgrading to #316 stainless steel.

With gauge numbers, lower means thicker! While 18-gauge might be fine for a clean office environment, our mortuary cabinets use 14-gauge #304 stainless specifically because they need to withstand both bodily fluids and strong disinfectants while still looking professional for decades.

Do stainless steel rolling cabinets require special floor protection?

Your beautiful floors deserve some consideration when choosing a stainless steel rolling cabinet. Different flooring materials have different needs:

Vinyl and linoleum floors can develop permanent indentations under heavy cabinets, so softer rubber casters or caster cups are your friends here. For hardwood floors, polyurethane casters or caster cups prevent those heartbreaking scratches. Epoxy or sealed concrete? Standard hard casters work beautifully without extra protection. And if you're rolling over carpet, wider casters help prevent excessive compression.

One clever solution came from a funeral home director in Pittsburgh who told me: "We installed thin rubber track pathways in our preparation room. This protects our flooring while still letting our cabinets move freely between stations."

For facilities with uneven floors or thresholds between rooms, I usually suggest cabinets with larger 6-inch casters rather than standard 5-inch ones. That extra inch makes a surprising difference when rolling over small obstacles.

How do I know if I need a ventilated stainless steel cabinet?

Ventilated stainless steel rolling cabinets aren't for everyone, but they're absolutely essential in certain situations. You should consider them if you're:

Storing chemicals that release fumes, working in high-humidity environments where moisture could accumulate inside closed cabinets, needing air circulation around stored items, or if regulations require connection to building exhaust systems.

These specialized cabinets typically feature louvered vents or perforated panels that allow airflow while maintaining security. For laboratory or mortuary settings where chemicals are stored, ventilated cabinets that connect to building exhaust systems (delivering 75-150 CFM airflow) provide both safety and regulatory compliance.

What's the difference between #304 and #316 stainless steel?

This question comes up frequently when customers are comparing options. Both #304 and #316 are high-quality austenitic stainless steels, but they have important differences:

#304 Stainless Steel contains 18% chromium and 8% nickel, making it the most common grade for cabinets. It offers excellent corrosion resistance for most applications and serves beautifully in medical facilities, laboratories, and food service environments.

#316 Stainless Steel contains 16% chromium, 10% nickel, and adds 2% molybdenum. That molybdenum is the magic ingredient that provides superior resistance to chlorides and acids. We recommend this premium grade for marine environments, chemical laboratories, or facilities using particularly aggressive cleaning chemicals.

Be prepared for the price difference, though – #316 stainless steel cabinets typically cost 25-30% more than comparable #304 models. For most applications, including our mortuary settings, #304 provides the perfect balance of corrosion resistance and value.

How can I maximize the lifespan of my stainless steel rolling cabinet?

With proper care, your stainless steel rolling cabinet can easily provide 20+ years of service. Here's what I tell our customers:

Always clean with the grain using appropriate cleaners – this prevents scratches and preserves that beautiful finish. Set calendar reminders for quarterly maintenance to lubricate casters, check drawer slides, and inspect locks. Address small issues immediately before they become expensive problems.

Use drawer liners to protect interior surfaces from scratches and chemical exposure. Distribute weight evenly throughout the cabinet rather than loading up just one area. Keep your cabinet dry by wiping up spills right away and drying thoroughly after cleaning.

Finally, use the appropriate casters for your specific flooring type, and replace worn casters promptly – they're the literal foundation of your cabinet's mobility and stability.

These simple habits will ensure your investment continues to serve you beautifully for decades, even in the most demanding environments like our mortuary facilities.

Conclusion

Choosing the right stainless steel rolling cabinet is more than just a purchase—it's an investment in your workspace's efficiency, organization, and safety. Throughout this guide, we've walked through everything you need to know to make a smart choice that will serve you for years to come.

Here at American Mortuary Coolers, we've seen how the perfect storage solution can transform a workspace. Whether you're setting up a mortuary preparation room in rural Tennessee, a cutting-edge research lab in busy New York, or a manufacturing facility in Texas, a well-chosen stainless steel rolling cabinet pays dividends far beyond its initial cost.

I'd like to share a few key insights we've gathered from our years of experience:

Quality truly matters. We've heard from countless customers who initially went with lighter-duty cabinets only to find themselves shopping for replacements within a year or two. The difference between 18-gauge and 14-gauge stainless steel becomes crystal clear after a few months of daily use. Think of it as the difference between work boots from the dollar store versus a quality pair—one is an expense, the other an investment.

Consider the total cost of ownership, not just the price tag. One of our funeral director clients in Georgia summed it up perfectly: "I've had my stainless steel rolling cabinet for 15 years now. When I think about the three cheaper cabinets I replaced before this one, I should have just started with quality." A premium cabinet that gives you 20+ years of service offers substantially better value than replacing economy models every few years.

Don't overlook mobility features. The caster system is the unsung hero of any rolling cabinet. For most professional settings, 5-6" casters with at least two locking wheels provide that sweet spot of maneuverability and stability. As one of our laboratory clients told us, "Being able to easily move our supplies exactly where we need them has been a game-changer for our workflow."

Security protects your investment. Three-point locking systems are worth every penny compared to simple cam locks, especially when you're storing valuable tools or sensitive materials. One mortuary in Florida learned this lesson the hard way after a break-in targeted their less secure cabinets.

Regular maintenance extends lifespan. Simple habits like cleaning with the grain, lubricating moving parts quarterly, and addressing small issues promptly can add years to your cabinet's useful life. Think of it like changing the oil in your car—a little prevention goes a long way.

Before you make your final decision, take a moment to run through this mental checklist:

Have you measured your space, including room for drawer extension? Does the weight capacity meet or exceed what you'll actually store? Is the stainless steel grade appropriate for your environment? Does the drawer configuration match what you'll be storing? Are the casters suitable for your flooring? Do the security features match your needs? Is the warranty coverage adequate? Have you planned for delivery and installation?

Our team at American Mortuary Coolers specializes in providing customized stainless steel rolling cabinets for mortuary and medical environments across all regions of the United States. We understand that your storage needs are as unique as your facility, and we're here to help you find the perfect solution.

For more information about our custom mortuary equipment, including stainless steel rolling cabinets designed specifically for funeral homes and medical facilities, reach out to our friendly experts today. With direct delivery across the contiguous 48 states and decades of industry experience, we're ready to help you transform your workspace with the perfect stainless steel storage solution that combines durability, mobility, and security in one package.