Why the Right Stainless Steel Table Makes All the Difference

A stainless steel table is the gold standard for professional workspaces that demand durability, hygiene, and versatility. Whether you're setting up a mortuary prep room, commercial kitchen, or laboratory, these tables offer superior corrosion resistance and easy sanitization that other materials simply can't match.

Quick Answer for Stainless Steel Table Buyers:

- 304 stainless steel - Best for food service and humid environments

- 430 stainless steel - Budget option for dry, basic prep work

- 16-gauge thickness - Ideal balance of durability and cost

- Open base design - Easy cleaning underneath

- NSF certification - Required for commercial food handling

- Weight capacity - Ranges from 600-1,570 lbs depending construction

Over 500 units of stainless steel prep tables were purchased on Amazon last month alone, proving their popularity across industries. From 16-gauge commercial-grade tables supporting up to 750 lbs to custom units reaching 96 inches in length, these surfaces handle everything from light sandwich prep to heavy butchering tasks.

What sets quality stainless steel tables apart is their non-porous surface that resists stains, dents, and bacterial growth. Unlike wood or laminate alternatives, they won't absorb odors or harbor contaminants - critical factors in mortuary and medical environments where sanitation is paramount.

As we at American Mortuary Coolers with years of experience supplying mortuary equipment nationwide, we've seen how the right stainless steel table transforms workspace efficiency and hygiene standards. Our background in mortuary refrigeration has taught us that quality construction and proper material selection make the difference between equipment that lasts decades versus replacements every few years.

Stainless steel table terms to learn:

Types of Stainless Steel Tables Explained

Choosing the right stainless steel table starts with understanding how different designs serve different needs. Each style has its sweet spot where it really shines.

Open base tables feature exposed legs with crossbars for support, giving you easy access underneath for cleaning. The three-sided frame design means you can sit at them comfortably, and there's plenty of room to roll equipment underneath when not in use. They're also easier on your budget than enclosed alternatives.

Cabinet base tables turn your work surface into a storage powerhouse with sliding doors or drawers built right in. While they cost more upfront, they're brilliant space-savers that keep supplies dust-free and organized. Just remember they need more thorough cleaning protocols since you can't easily access all areas.

Tables with undershelves offer extra storage without fully boxing everything in. The adjustable versions give you flexibility as your needs change, though they require assembly rather than the rock-solid welded construction of fixed shelves.

Mobile tables with wheels are game-changers for flexible workspaces. Those 4-inch swivel casters (usually with brakes for safety) mean you can reconfigure your space on the fly. Food truck operators and caterers absolutely swear by these.

For tight spaces, folding tables and wall-mount tables work miracles. Folding units disappear when you need floor space, while wall-mounted versions give you a stable work surface without eating up precious square footage. Equipment stands deserve special mention too - these reinforced units handle the weight and vibration of mixers, slicers, and other heavy machinery.

Choosing a Stainless Steel Table for Commercial Use

Commercial environments demand bulletproof reliability from stainless steel tables.

Restaurants need NSF-certified tables with 16-gauge tops that can handle daily prep work. That non-porous surface becomes your best friend during health inspections - bacteria simply can't hide like it does in wood or plastic alternatives.

Laboratories often step up to 316L stainless steel because regular chemicals would eat through lesser materials. Many lab tables include integrated sinks with perfectly coved 5/8-inch radius corners that eliminate hard-to-clean spots.

Mortuaries demand the heavy-duty approach - we're talking 14-gauge tops that won't flinch under substantial loads. Custom heights matter here since different procedures require different working positions. At American Mortuary Coolers, we've perfected these custom solutions over years of serving funeral homes across the contiguous 48 states. You can learn more about specialized options in our guide to prep room tables.

Hospitals face constant disinfection challenges. Those sanitizers and cleaning chemicals would destroy most materials, but 304 stainless steel just shrugs them off day after day.

Choosing a Stainless Steel Table for Residential Use

Home applications focus more on looks and versatility. Kitchen islands with stainless tops bring that professional chef vibe to your cooking space. You can set hot pans directly on the surface without worry, and cleanup is genuinely effortless.

Garage workshops love stainless steel for its attitude toward oils, solvents, and temperature swings. Outdoor patios benefit hugely from stainless steel's weather resistance - no more worrying about mold, rot, or UV damage.

Hobby rooms appreciate the chemical resistance when craft projects involve adhesives, paints, or solvents. The smooth surface won't soak up spills or hold onto odors from different projects.

Key Features & Materials to Compare

Choosing the perfect stainless steel table becomes clearer once you understand what really matters for daily use.

Gauge thickness works backwards - the lower the number, the thicker the steel. An 18-gauge table (0.05 inches thick) works fine for making sandwiches, but it'll wobble under heavier tasks. Most commercial kitchens love 16-gauge (0.0625 inches) because it hits that sweet spot between strength and cost. When you need serious durability - like in mortuary work or heavy butchering - 14-gauge (0.0781 inches) becomes your best friend.

The alloy type makes or breaks your long-term satisfaction. 304 stainless steel contains chromium and nickel, creating beautiful corrosion resistance that handles humid environments and frequent cleaning. It's the workhorse of commercial kitchens and medical facilities. 430 stainless steel offers a budget-friendly alternative that works well in dry, controlled environments, though it's more prone to rust when things get wet. For ultimate chemical resistance, 316L stainless steel includes molybdenum, making it perfect for laboratories dealing with acids and harsh cleaning agents.

Surface finishes affect both looks and maintenance. A brushed finish hides inevitable scratches much better than a mirror polish. Matte finishes give you that modern, professional appearance while resisting fingerprints.

Edge styles and backsplashes make a real difference. Marine edges with raised lips contain spills beautifully, while bull nose edges eliminate sharp corners that can catch clothing or cause injuries. Backsplashes ranging from 1.5 to 10 inches protect your walls and make cleanup easier.

The construction method determines how your table arrives and performs. Fully welded tables provide maximum strength and rigidity - they're built to last decades. Knock-down designs ship easier and cost less but require assembly.

Quality tables include thoughtful details like bullet feet for leveling on uneven floors and hat channel reinforcement for added strength.

| Feature | 304 Stainless Steel | 430 Stainless Steel |

|---|---|---|

| Corrosion Resistance | Excellent in humid conditions | Good in dry environments |

| Cost | Higher initial investment | Budget-friendly option |

| Magnetic Properties | Non-magnetic | Magnetic |

| Best Uses | Food service, laboratories, humid environments | Basic prep work, dry storage |

| Durability | Superior long-term performance | Adequate for light-duty use |

304 vs. 430 Stainless Steel Table Comparison

304 stainless steel contains 18% chromium and 8% nickel, creating that non-magnetic, highly durable surface we recommend for most professional applications. The nickel content makes all the difference in corrosion resistance - it handles humidity, frequent washing, and even biological fluids we encounter in mortuary work.

430 stainless steel takes a different approach with 16% chromium but no nickel. This makes it magnetic and significantly less expensive upfront. In dry, controlled environments, it performs adequately. But expose it to regular moisture or cleaning chemicals, and you'll start seeing rust spots sooner than you'd like.

The cost difference tempts many buyers toward 430 steel. But consider this: replacing a rusted table costs more than buying quality the first time. In our experience supplying mortuary equipment nationwide, the facilities that choose 304 steel report better satisfaction and longer service life.

Humidity tolerance strongly favors 304 steel. Commercial kitchens with constant sanitization cycles need that extra protection. Mortuary environments, where we regularly deal with biological fluids and harsh cleaning protocols, particularly benefit from 304's superior durability.

At American Mortuary Coolers, we've seen how material choice affects long-term performance. That's why we typically recommend 304 stainless steel for our custom solutions - it simply performs better over the decades of service our customers expect.

Customization, Accessories & Add-Ons

Building the perfect stainless steel table means getting exactly what your workspace needs. Modern manufacturers understand that one size definitely doesn't fit all.

Custom dimensions go beyond standard depths of 24, 30, and 36 inches. Tables can stretch up to 96 inches in length for ambitious projects. Height matters more than you might think. The sweet spot for most people falls between 34 and 39 inches, but your needs might be different. Metro TableWorx offers six standard heights right out of the box.

Integrated sinks are game-changers. Single and double bowl options with smart 5/8-inch radius coved corners make cleaning easier than sharp zero-radius designs. No more bacteria hiding in impossible-to-reach corners. The seamless integration means fewer places for germs to set up shop.

Drawer systems bring organization right to your fingertips. Type 1 drawers give you stainless steel fronts that look professional, while Type 2 drawers go all-out with stainless steel fronts and sides.

Overshelves are like adding a second story to your workspace. Rear-mount versions keep supplies within reach but out of the way. In cramped spaces where every square inch counts, these vertical storage solutions are absolute lifesavers.

Productivity risers lift your equipment or supplies above the work surface, giving you more room underneath. The modular design means you can change things up as your needs evolve without buying a whole new table.

Details like kick plates and marine edges matter. Kick plates protect your investment from daily wear while making everything look finished and professional. Marine edges create helpful raised lips that contain spills - especially valuable in mortuary work where fluid control matters.

Mobility options give you flexibility when you need it. Four-inch diameter swivel casters with brakes mean your table can move when necessary but stay put when you're working. Leveling feet handle annoying uneven floors with 1.125 inches of adjustment range.

For mortuary professionals looking to optimize their prep areas, our detailed guide on Prep Room Tables dives deeper into workflow efficiency and specialized features.

Building a Stainless Steel Table That Fits Your Workflow

Creating your ideal stainless steel table starts with understanding how you actually work. Online configurators help you visualize exactly what you need before you buy.

Modular height systems like Metro TableWorx offer six different working heights, adjustable in the field without special tools. This means the same table works whether you're standing, sitting, or somewhere in between.

Crossbar positioning affects how you use your table daily. Center-mounted crossbars provide maximum strength for heavy loads. Rear-mounted crossbars give you better access for seated work or storing equipment underneath.

Foldable options solve the space puzzle for temporary setups or mobile operations. These tables fold completely flat for transport but give you full functionality when deployed.

The choice between fully welded and knock-down construction comes down to your priorities. Welded tables arrive ready to work but cost more to ship. Knock-down designs save on shipping costs but require some assembly time.

Maintenance, Certifications, Pricing & Top Brands

Taking care of your stainless steel table isn't complicated, but doing it right makes all the difference between a surface that looks professional for decades versus one that shows wear after just a few years.

Daily cleaning with mild detergent and warm water handles most situations perfectly. The key is avoiding harsh chemicals or abrasive scrubbers that can scratch the protective chromium layer that keeps your table rust-free.

Cleaning direction actually matters for brushed finishes. Always wipe with the grain direction, not against it. Cross-grain cleaning creates visible scratches that make your table look worn and unprofessional.

NSF certification appears as a simple marking on quality tables, but it represents rigorous testing for food safety standards. This certification ensures your table meets strict hygiene requirements for commercial food handling. While you don't legally need NSF certification for home use, it's a reliable indicator of quality construction and materials.

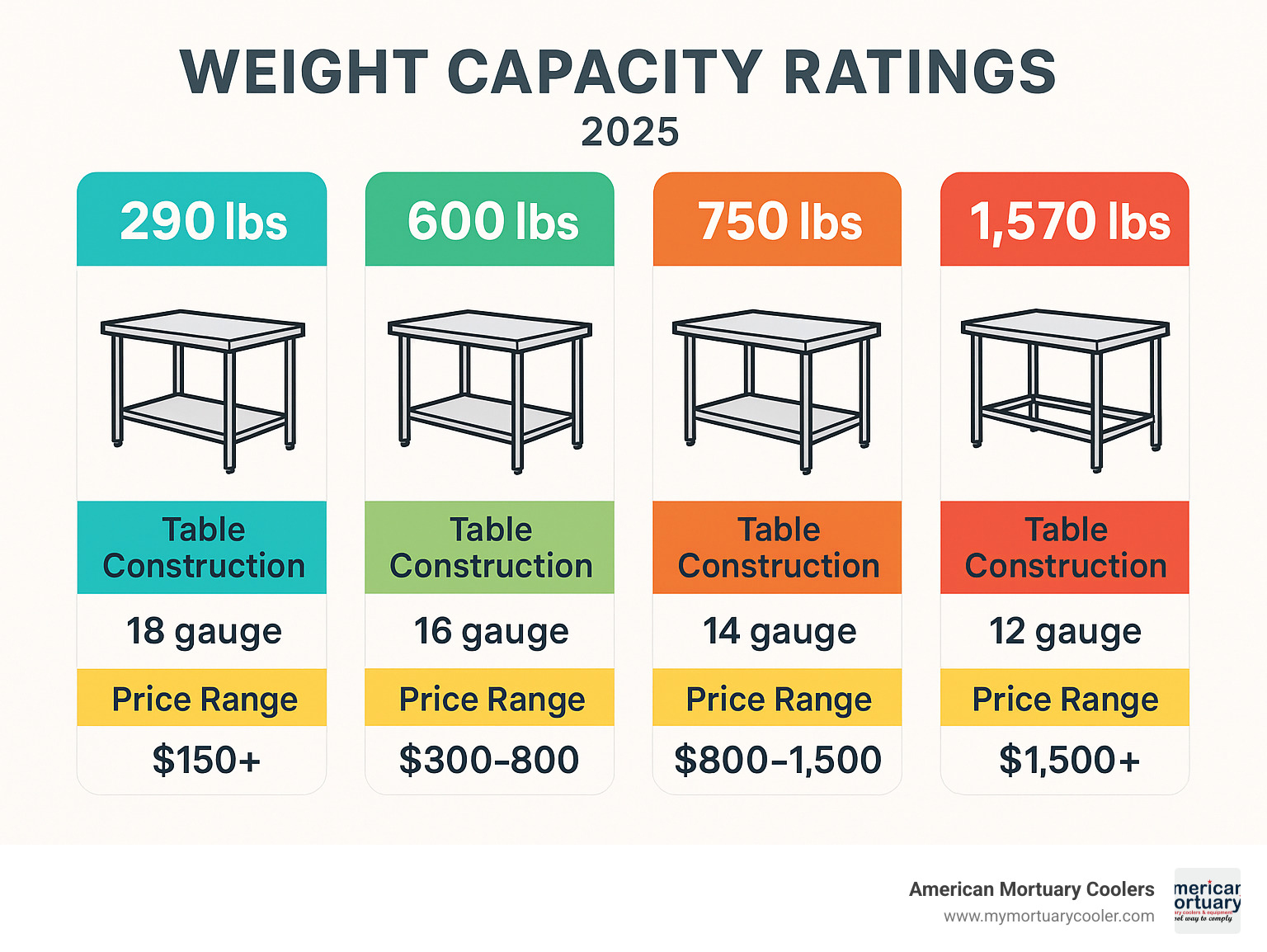

Weight capacity varies dramatically based on construction. Basic Uline tables handle 600 pounds comfortably, while their deluxe models support 750 pounds. Heavy-duty commercial tables with reinforced frames can handle over 1,570 pounds when properly constructed.

Pricing reflects quality in this market. Basic 18-gauge tables start around $150 for simple home use. Most commercial operations find their sweet spot with 16-gauge tables in the $300-800 range. Custom heavy-duty units can exceed $5,000, but these serve specialized applications like industrial food processing or mortuary work.

Warranty coverage typically ranges from one to five years, depending on the manufacturer's confidence in their construction quality.

The top brands each bring something different to the table. Metro excels at modular systems that adapt to changing needs. Gridmann focuses on NSF-certified commercial tables with reliable performance. Aero Manufacturing specializes in custom solutions for unique applications. Uline provides dependable standard models with consistent quality and nationwide availability.

Research from BlueScope Steel demonstrates the superior corrosion resistance that makes stainless steel tables such a smart long-term investment. The return on investment becomes clear when you consider that a quality table can serve faithfully for 20+ years with proper maintenance.

Keeping Your Stainless Steel Table Looking New

The secret to maintaining that showroom appearance isn't expensive products or complicated procedures - it's consistency and the right techniques.

Daily wipe-downs with mild detergent prevent the buildup of contaminants that cause staining or corrosion over time. A quick cleaning after each use takes less than a minute but prevents problems that could take hours to fix later.

Monthly polishing with appropriate stainless steel cleaners maintains the protective oxide layer and removes stubborn water spots that make surfaces look dull. Commercial stainless steel polish doesn't just restore shine - it actually provides additional corrosion protection that extends your table's life.

Sanitizer compatibility varies by product formulation. Most commercial sanitizers work safely with stainless steel, but chlorine-based products can cause pitting over time if used repeatedly. Always rinse thoroughly after sanitization to remove any residue.

Preventive care includes simple habits like removing spills promptly, avoiding harsh abrasives, and protecting the surface from impacts that could cause dents. These practices cost nothing but add years to your table's service life.

For mortuary-specific maintenance requirements where hygiene standards are absolutely critical, our Stainless Steel Prep Tables guide provides detailed protocols for maintaining the highest cleanliness standards in sensitive environments.

At American Mortuary Coolers, we've seen how proper maintenance transforms a good stainless steel table into a reliable workhorse that serves faithfully for decades. The small investment in proper care pays dividends in performance, appearance, and longevity.

How to Choose and Install the Right Stainless Steel Table for Your Space

Getting the right stainless steel table for your space isn't just about picking one that looks good - it's about creating a workspace that actually makes your job easier.

Start by measuring your footprint carefully, but don't just measure the table space itself. You need room for people to move around comfortably, doors to swing open, and equipment to slide in and out for cleaning. Nothing's more frustrating than finding your beautiful new table blocks access to your walk-in cooler or creates a traffic jam during busy periods.

Think about your workflow triangles - those invisible paths you walk dozens of times each day between prep areas, storage, and equipment. A properly positioned table should feel like it was always meant to be there, reducing unnecessary steps and creating natural work zones.

Height considerations matter more than most people realize. The standard 36-inch height works well for most standing tasks, but if you're doing detailed work or have team members of varying heights, custom heights between 34 and 39 inches can make a real difference. Some of our mortuary clients prefer slightly lower tables for better leverage during preparation procedures.

Don't forget about clearance for doors and equipment when planning your installation. Account for anything that swings, slides, or needs regular maintenance access.

Most stainless steel tables arrive as knock-down units that require assembly with basic tools - typically just a hex key and adjustable wrench. The process is straightforward, but make sure you have adequate space for assembly and a plan for moving the completed table into position.

Some installations may require anchoring to the floor or wall, particularly in high-traffic commercial environments or areas with specific building code requirements. Check your local regulations, especially for commercial installations where safety standards are more stringent.

Stainless Steel Table Selection Checklist

Choosing the perfect stainless steel table becomes much easier when you work through these key considerations systematically.

Space size determines your options more than any other factor. Measure not just the table footprint, but the entire work zone including user movement and equipment access.

Load requirements vary dramatically between applications. Light sandwich prep needs different support than heavy butchering or mortuary preparation work. Our 14-gauge tables handle the heaviest loads, while 16-gauge provides excellent durability for most commercial applications without the extra cost.

Mobility needs depend on how you'll use the space. Fixed tables provide maximum stability and often include useful features like undershelves and drawers. Mobile tables with casters offer flexibility but may sacrifice some storage options.

Storage needs should match your workflow patterns. Undershelves work well for frequently used items, while cabinet bases protect supplies from dust and provide a cleaner appearance. Overshelves maximize vertical space in compact areas.

Budget considerations extend beyond the initial purchase price. Factor in shipping costs, assembly time, and long-term maintenance when comparing options. A higher-quality table that lasts decades often provides better value than multiple replacements of cheaper alternatives.

At American Mortuary Coolers, we understand that every workspace has unique requirements. Whether you're setting up a new facility or upgrading existing equipment, the right stainless steel table forms the foundation of an efficient, hygienic workspace that serves you well for years to come.

Frequently Asked Questions about Stainless Steel Tables

Let's tackle the most common questions we hear from customers shopping for their perfect stainless steel table. These answers come from years of helping professionals across industries make the right choice.

What gauge should I pick for heavy-duty tasks?

When you're dealing with serious work that involves heavy loads or intense daily use, 14-gauge stainless steel is your best friend. At 0.0781 inches thick, this robust construction handles everything from butchering operations to supporting heavy equipment weighing up to 1,570 pounds.

Think of gauge like armor thickness - the lower the number, the thicker and stronger your table becomes. While 14-gauge costs more upfront, it's actually cheaper in the long run because you won't be replacing it every few years like you might with thinner alternatives.

For most commercial kitchens and prep areas, 16-gauge hits the sweet spot between durability and cost. It's thick enough to handle daily commercial use without breaking the bank. Save the 18-gauge for light residential tasks like sandwich making or craft projects.

When is 430 stainless acceptable instead of 304?

Here's the honest truth about 430 stainless steel - it's perfectly fine when your environment stays dry and you're not constantly washing and sanitizing surfaces. Think garage workshops, basic storage areas, or hobby rooms where you're not dealing with food or biological materials.

The key difference is that 430 stainless lacks the nickel content that gives 304 its superior corrosion resistance. In dry conditions, 430 performs admirably and saves you money. But the moment you introduce regular moisture, frequent cleaning, or any kind of food service work, you'll want to upgrade to 304 stainless steel.

We've seen too many customers try to save money with 430 in mortuary or restaurant applications, only to deal with rust spots and premature replacement costs later. For our mortuary clients especially, the superior chemical resistance of 304 steel is non-negotiable when dealing with embalming fluids and sanitizers.

Do I really need NSF certification for home use?

While NSF certification isn't legally required for your home kitchen or garage workshop, it's like buying a car with a five-star safety rating - you're getting quality assurance that benefits everyone.

NSF-certified stainless steel tables meet incredibly strict standards for materials, construction, and cleanability. These tables undergo rigorous testing to ensure they can handle commercial-grade sanitization and heavy use. Even if you're just using it for weekend barbecue prep, you're getting a table built to professional standards.

The price difference is usually modest, and you gain peace of mind knowing your table meets the same hygiene standards used in hospitals and commercial kitchens. Plus, if you ever decide to sell your home or upgrade your setup, that NSF marking adds value and credibility to your equipment.

Conclusion

Finding the perfect stainless steel table doesn't have to be overwhelming when you focus on what really matters for your specific needs. After reviewing all the options, materials, and features, most professionals find that 304 stainless steel with 16-gauge thickness hits that sweet spot between durability and cost-effectiveness.

The evidence is clear: investing in quality construction pays off in the long run. A well-built stainless steel table with proper NSF certification will serve you faithfully for decades, maintaining its appearance and hygiene standards through countless cleaning cycles and heavy use.

At American Mortuary Coolers, we've seen how the right equipment transforms a workspace. Our Tennessee-based team has been crafting custom stainless steel solutions that meet the exacting standards of mortuary professionals nationwide. We understand that in your line of work, there's no room for compromise on quality or reliability.

What sets our approach apart is the attention to heavy-gauge construction and precise fabrication details that matter in sensitive environments. When you're dealing with the dignity of families and the demands of professional practice, every weld, every finish, and every structural element needs to be perfect.

The longevity and hygiene benefits of quality stainless steel make it an investment rather than just a purchase. While you might pay more upfront compared to other materials, the years of reliable service, easy maintenance, and professional appearance deliver exceptional value over time.

Whether you need a standard prep table or require custom dimensions and specialized features, we deliver directly across the contiguous 48 states. Our nationwide service means you get the same quality craftsmanship and support regardless of your location.

Ready to upgrade your facility with equipment built to last? Explore our complete range of mortuary refrigeration solutions and find how American Mortuary Coolers can support your facility's unique requirements with the quality and service you deserve.