Why Electric Scissor Lifts Are Essential for Modern Facility Operations

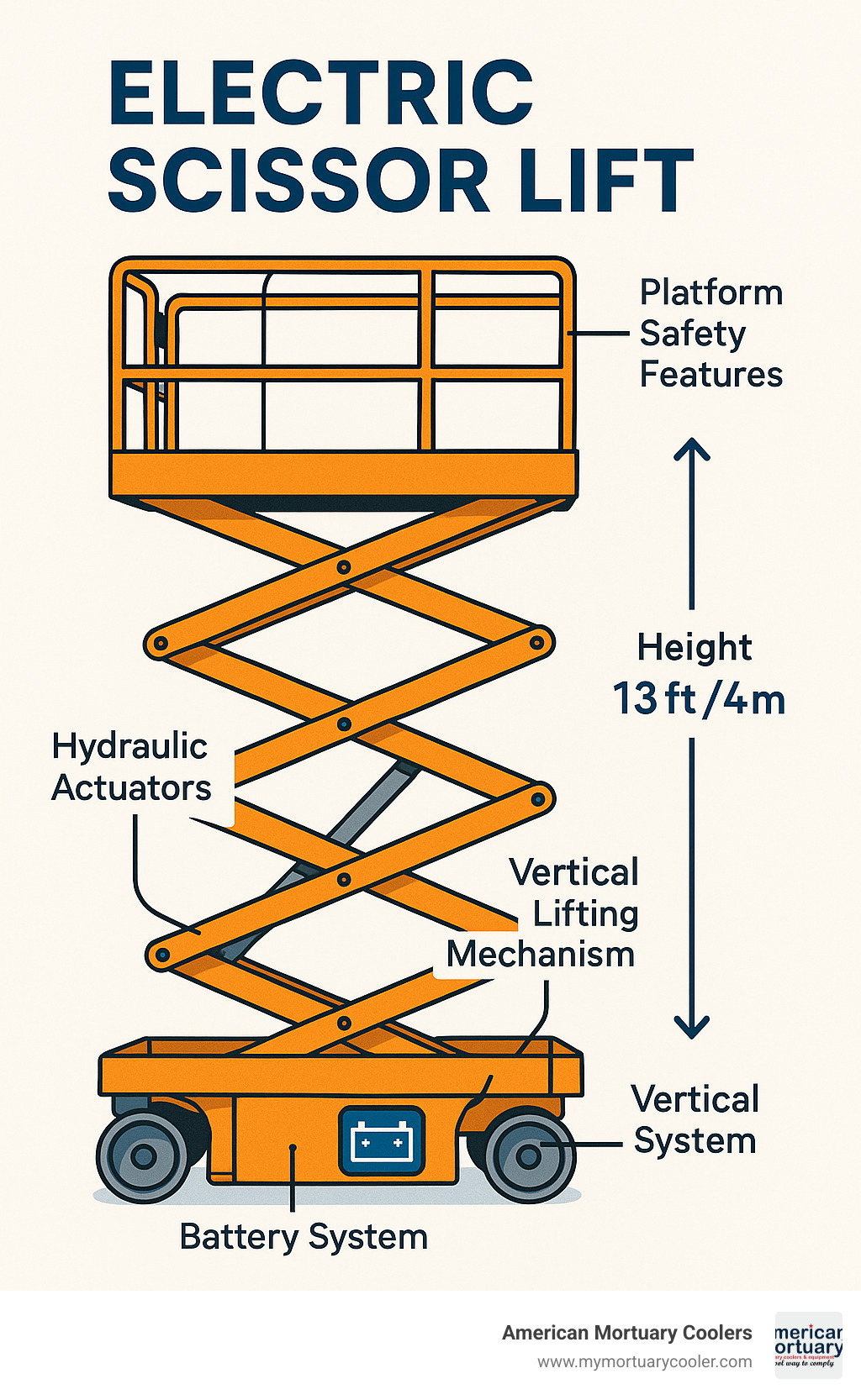

An electric scissor lift is a battery-powered aerial work platform that uses a scissor-like mechanism to raise workers and equipment vertically to liftd work areas. These emission-free lifts are becoming the preferred choice for indoor applications and environmentally sensitive work zones.

Quick Electric Scissor Lift Overview:

- Height Range: 4 meters (13 feet) to 18 meters (59 feet)

- Weight Capacity: 230 kg to 22,000 lbs depending on model

- Power Source: 24V DC battery systems with single-phase chargers

- Applications: Warehouse maintenance, construction, glass cleaning, cargo loading

- Key Benefits: Zero emissions, quiet operation, full-height driving capability

- Price Range: $2,800 to $6,800+ for new models

Electric scissor lifts solve critical challenges in modern facilities. Unlike diesel-powered alternatives, they produce zero in-use emissions and operate quietly - making them ideal for indoor work environments with noise restrictions. Their compact design allows passage through standard doorways while providing substantial platform workspace.

The versatility extends from routine maintenance tasks like lamp replacement to complex industrial applications. Major retailers like Home Depot offer various rental models, while specialized versions can handle everything from delicate laboratory work to heavy-duty operations with lifting capacities up to 10 metric tons.

Similar topics to electric scissor lift:

How an Electric Scissor Lift Works

The electric scissor lift operates like an accordion stretching upward. The shear-style arms fold and unfold in a diamond pattern, creating a stable platform that rises straight up while maintaining perfect balance.

The battery powertrain uses clean electric motors that draw power from industrial-grade batteries, typically running on 24V DC-drive systems. This means no diesel fumes, no hydraulic fluid leaks, and operation so quiet you can have a conversation while the lift runs.

When comparing hydraulic vs electric systems, electric drives only use power when actually lifting or lowering - not constantly running pumps like hydraulic systems. The control boxes house sophisticated electronics that manage everything from battery monitoring to precise speed control.

Key Components & Operation Cycle

The actuator transforms electrical energy into lifting power. These precision-engineered components work in harmony to raise platforms weighing thousands of pounds while keeping everything perfectly level.

Platform guardrails serve as both safety features and operational components. They automatically lock into position when the platform rises, creating a secure workspace that meets OSHA requirements.

The emergency stop button immediately halts all movement when pressed. The system won't restart until a trained operator manually resets it - a simple but effective safety measure.

Proportional controls provide finesse for precise work. These joystick-style controls respond to pressure applied - gentle touch for slow positioning, full pressure for maximum speed.

Scientific Edge of Pure-Electric Drives

The energy efficiency of electric scissor lifts is impressive. While diesel engines waste about 70% of their fuel as heat, electric motors convert roughly 90% of their energy into useful work.

Zero tailpipe emissions eliminates ventilation requirements and worker exposure to diesel fumes. You can operate an electric scissor lift in crowded warehouses, retail stores, or hospitals without air quality concerns.

The low noise operation transforms job sites. At under 70 decibels, these lifts are quieter than normal conversation, allowing easy worker communication without disturbing surrounding areas.

Regenerative lowering captures energy when the platform descends. The electric motors work in reverse, acting like generators that put energy back into the batteries, extending operating time while reducing component wear.

Main Types & Specifications of Electric Scissor Lifts

Electric scissor lifts come in varieties designed for virtually every job. From compact units for tight spaces to massive machines reaching impressive heights, there's an electric lift for every application.

Electric rough-terrain models combine clean electric operation with reinforced frames, knobby tires, and weather-sealed components for real construction sites.

Compact indoor units prioritize getting into tight spaces over raw lifting power. These nimble lifts squeeze between storage racks and through doorways that stop larger machines.

Self-propelled models offer the ability to drive around while fully liftd, eliminating the constant cycle of lowering, moving, and raising.

Push-around variants strip away complexity in favor of simplicity and affordability for manually positioned applications.

Mini lifts fill the gap between step ladders and full-size scissor lifts, reaching impressive heights while fitting in spaces larger machines cannot access.

| Model Type | Platform Height | Weight Capacity | Typical Applications |

|---|---|---|---|

| Mini Indoor | 13-19 ft | 500-800 lbs | Retail, light maintenance |

| Compact Indoor | 19-26 ft | 500-1000 lbs | Warehouse, HVAC work |

| Wide Indoor | 20-40 ft | 800-1500 lbs | Construction, heavy installation |

| Rough Terrain Electric | 25-60 ft | 1000-1500 lbs | Outdoor construction, tree work |

| Specialized Heavy-Duty | Variable | Up to 22,000 lbs | Industrial, mortuary applications |

Indoor Compact Electric Scissor Lift

Warehouse aisles present unique challenges that compact electric scissor lifts solve perfectly. Most compact indoor models measure less than 32 inches wide while providing adequate platform space for workers and tools.

The narrow turning radius allows these lifts to spin in place, making maneuvering in tight spaces effortless. The 19-ft class represents the sweet spot for indoor work, reaching high enough for most ceiling tasks while fitting through standard doorways.

Rough-Terrain Electric Scissor Lift

4x4 AC drive systems deliver surprising capability, climbing grades that challenge pickup trucks while maintaining smooth, quiet operation. Lithium packs are revolutionizing this market with faster charging, longer runtime, and consistent power output.

The 40-ft class rough-terrain electric scissor lifts reach working heights approaching 50 feet while carrying substantial loads, yet operate with whisper-quiet performance.

Push-Around & Stock-Picker Variants

Big-box retail environments have acceptd push-around electric scissor lifts for their balance of capability and cost-effectiveness. Facility maintenance teams appreciate the straightforward nature without complex drive systems.

Lightweight frames make these lifts surprisingly portable despite their capability, with many weighing less than 1,000 pounds for easy transport and positioning.

Choosing the Right Electric Scissor Lift for Your Job

Selecting the perfect electric scissor lift starts with understanding your specific needs.

Project height serves as your starting point. Platform height and working height are different - if you need to reach a 26-foot ceiling, you'll want a 20-foot platform height because working height includes your arm reach above the platform.

Rated load capacity requires honest calculation. Most electric scissor lifts handle 500 to 1,500 pounds safely, covering two workers plus reasonable equipment.

Platform size creates the trade-off between comfort and maneuverability. Larger platforms provide room for tools and comfortable work. Smaller platforms squeeze through tighter spaces.

Duty cycle matters significantly. Occasional light maintenance allows basic models, while eight-hour daily operation requires commercial-grade components and better cooling systems.

Charger voltage affects daily operations. Standard 110V chargers work anywhere, while 220V chargers need special outlets but charge faster.

Transport constraints become critical for multi-site operations. Measure doorways, truck beds, and storage spaces before selecting a model.

Application Checklist

HVAC installation work benefits from electric scissor lifts with generous platform space and solid positioning. Look for extendable platforms that provide extra reach without repositioning the base unit.

Lighting retrofit projects excel with lifts that drive at full height, allowing smooth movement from fixture to fixture without constant repositioning.

Cleanroom work demands specialized features like non-marking tires, sealed electrical components, and chemical-resistant materials. Some applications require stainless steel construction.

Construction finishing tasks often need lifts handling both indoor precision and outdoor durability.

Sustainability goals increasingly drive equipment choices. Electric lifts contribute to LEED certification points and help organizations meet carbon reduction targets.

Environmental & Cost Benefits

Lower operating costs make electric scissor lifts financially attractive. Electricity costs pennies compared to diesel fuel, and electric motors need minimal maintenance. Many operators report 50-70% lower operating costs.

Reduced diesel fumes eliminate health hazards and expensive ventilation requirements in enclosed spaces, especially important in hospitals, schools, or food processing facilities.

LEED credits for emission-free equipment help construction projects achieve green building certification.

The Used Tools for Sale Used Tools for Sale Tool Rental FAQs & Policies marketplace increasingly features electric models as organizations upgrade their fleets.

Safety Features, Regulations & Best Practices

Modern electric scissor lifts come packed with safety features, but they only work if you understand and follow proper procedures.

ANSI A92.20 standards govern every aspect of scissor lift design and operation in the United States. Every electric scissor lift sold must meet these requirements and display proper certification markings.

Fall-protection requirements vary depending on work type. OSHA generally requires fall protection for heights over 6 feet in construction and 4 feet in general industry applications.

Modern electric scissor lifts include built-in anchor points for safety harnesses. Premium models feature integrated fall-arrest systems that automatically stop falls.

Pothole guards protect the scissor mechanism from rocks, debris, and other materials that could jam the works, especially important for rough-terrain models.

Tilt sensors constantly monitor the lift's angle and shut everything down if things get too unstable. Advanced systems automatically adjust to keep platforms level on moderate slopes.

Platform load sensors prevent dangerous overloading by locking out controls and flashing warning lights when weight limits are exceeded.

Training cards or certifications are required for safe operation. Most rental companies include basic training with their service packages.

Daily Operator Inspection Routine

Starting with proper inspection prevents problems and ensures safety.

Battery condition checks should be first every morning. Look for terminal corrosion, check electrolyte levels for flooded batteries, and ensure charge indicators show full battery.

Tire inspection checks proper inflation, unusual wear patterns, and debris removal. Under-inflated tires affect stability and steering.

Emergency descent systems are your lifeline when things go wrong. Test backup systems according to manufacturer instructions - they should lower platforms smoothly even when main electrical systems fail.

Safety interlocks prevent operation when something isn't right. Check that guardrails latch properly, emergency stops work correctly, and all safety devices respond properly.

Maintenance & Care Tips

Charging cycles significantly impact battery life and performance. Follow manufacturer recommendations for when and how long to charge.

Electrolyte levels in flooded lead-acid batteries need regular monthly checking. Add distilled water when levels get low.

Scheduled service intervals typically fall between 150-250 operating hours, including safety system checks, electrical testing, and mechanical inspections.

Winter storage requires special attention in colder climates. Store batteries in warm, dry locations on trickle chargers to prevent freezing and sulfation.

Price Points, Rental Options & Leading Brands

When shopping for an electric scissor lift, prices range from $2,800 for basic push-around models to $68,000 for heavy-duty rough-terrain units with full features.

Most businesses find their sweet spot in the $15,000-$35,000 range for mid-range self-propelled indoor models offering reliability and features for regular commercial use.

Rental makes sense for short-term projects or seasonal work. Weekly rates typically run $120-$450, while daily rates fall between $90-$175.

The market is dominated by trusted names: Genie builds reputation on innovative battery technology and compact designs. JLG focuses on rugged construction and easy serviceability. Skyjack emphasizes simplicity and reliability.

Haulotte brings European perspective with unique bi-energy systems combining electric and diesel power for operational flexibility.

The most exciting development is lithium-powered models from manufacturers like DFLIFT, revolutionizing the industry with faster charging, longer runtime, and less maintenance than traditional lead-acid systems.

Prices vary significantly by region. The Provide Feedback Local store prices may vary… marketplace reflects these regional differences.

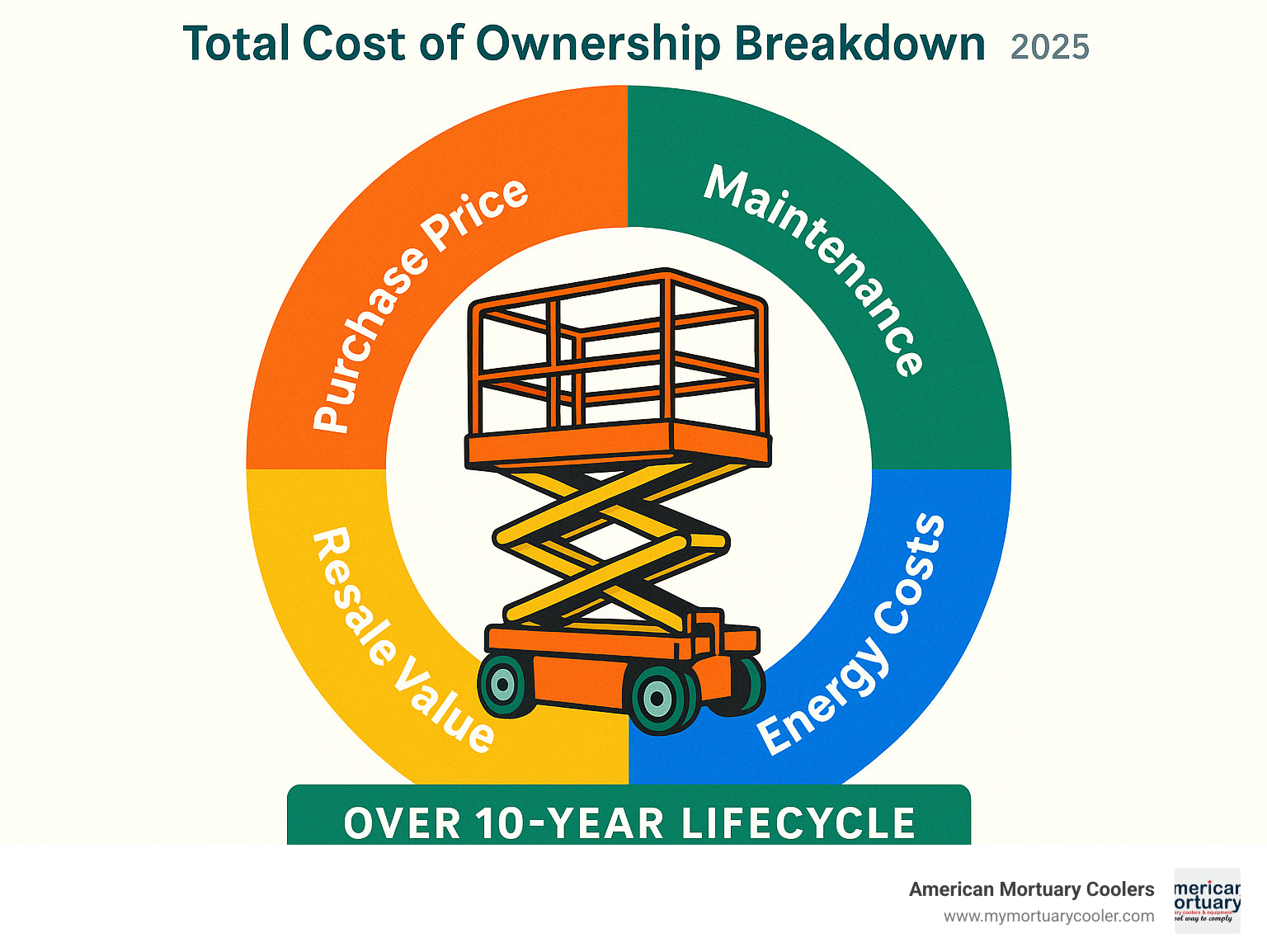

Budgeting for Total Cost of Ownership

Smart buyers look beyond sticker price to understand true ownership costs. The biggest ongoing expense is battery replacement. Traditional lead-acid batteries last 3-5 years, while lithium batteries continue 8-10 years.

Budget $2,000-$8,000 for battery replacement depending on lift size and battery technology. Lithium costs more upfront but longer lifespan often makes it the better investment.

Annual inspections are required by most jurisdictions and insurance companies, typically costing $300-$800 depending on lift complexity.

Well-maintained electric scissor lifts hold value remarkably well. Growing demand for emission-free equipment means quality brands retain 40-60% of original value after five years.

Financing programs from manufacturers and dealers spread costs over several years, often offering better terms than general business loans.

Frequently Asked Questions about Electric Scissor Lifts

What platform height range can I expect?

Electric scissor lifts offer incredible range for every job. Compact indoor models start at 10-13 feet and stretch to 19 feet, perfect for retail spaces and basic maintenance.

Mid-size units provide 20-33 feet of platform height - the construction workhorses. Large rough-terrain electric models reach 40-60 feet, with working heights touching 70 feet when factoring natural reach.

Platform height and working height are different. Add about 6 feet to platform height to determine actual reach. Most find the sweet spot between 19-26 feet.

How long do electric scissor lift batteries last per charge?

Most electric scissor lifts power through full 8-hour workdays under normal conditions. Compact indoor models with lead-acid batteries typically provide 6-10 hours of operation. Bigger units run 4-8 hours depending on workload.

Lithium-powered lifts are game-changers, often running 10-16 hours on single charges. Cold weather can reduce battery life 20-30%, and extreme heat isn't ideal either. Constant driving and repositioning drains batteries faster than stationary work.

Can I use an electric scissor lift outdoors in light rain?

Yes, with important caveats. Most electric scissor lifts handle light rain or damp conditions, especially with IP54 or higher protection ratings built to resist dust and water spray.

However, wet surfaces create slip hazards and affect traction, particularly with solid rubber tires. Standing water damages electrical components and creates shock hazards.

Never operate during thunderstorms or high winds. Most companies specify maximum wind speeds around 28 mph for safe operation. Rough-terrain electric models offer improved weather sealing, aggressive tread tires, and components rated for outdoor exposure.

Conclusion

The electric scissor lift industry is experiencing remarkable change. Environmental concerns and breakthrough battery technology are pushing these machines from "nice to have" to "must have" status across industries.

What makes electric scissor lifts compelling isn't just zero emissions - it's the combination of quiet operation, dramatically lower operating costs, and minimal maintenance needs. Your workers will thank you, your accountant will smile, and neighbors won't complain about noise.

Selecting the perfect electric scissor lift requires honest assessment of your needs. Platform height requirements, weight capacity, and working environment matter more than flashy unused features. A compact indoor model that fits through doorways beats a massive outdoor unit that sits unused.

Safety isn't negotiable - it's the foundation everything builds on. Proper training transforms equipment into reliable partners. Regular maintenance keeps partnerships strong. Following safety protocols ensures everyone goes home healthy.

The future is clear for aerial access equipment. Battery technology keeps improving, environmental regulations keep tightening, and electric scissor lifts keep getting more capable. Organizations investing in electric technology today position themselves for long-term success while creating better working conditions.

Whether you need standard lifts or custom solutions, success comes from working with people who understand both technology and your unique challenges. For specialized applications requiring custom solutions, explore our More info about custom mortuary coolers to see how we approach complex equipment design for demanding environments.

The future looks bright, quiet, and emission-free. Electric scissor lifts aren't just changing how we work at height - they're improving it in ways that matter to real people doing real jobs every day.