Why Body Carts Are Essential for Professional Operations

A body cart is a wheeled platform designed to safely transport and position heavy loads - from stripped vehicle shells in auto restoration shops to deceased individuals in funeral homes. These specialized carts eliminate the physical strain and safety risks of manual lifting while improving workflow efficiency.

Key Body Cart Types:

- Auto Body Carts - Support 2,000-3,000 lb vehicle frames during restoration

- Mortuary Body Carts - Transport deceased individuals with dignity and safety

- Parts Carts - Mobile supply stations for tools and materials

- Adjustable Models - Telescoping frames fit multiple vehicle sizes

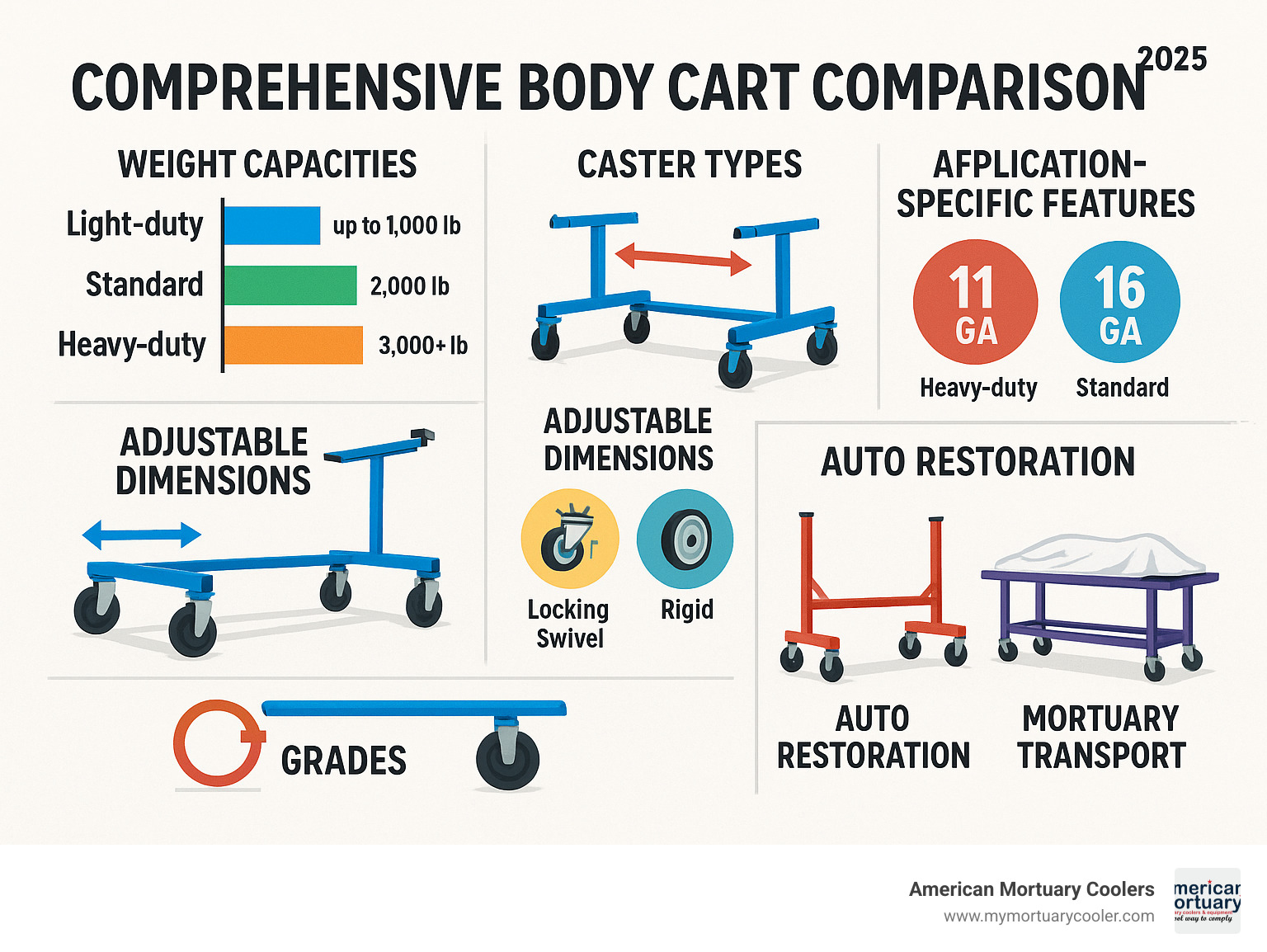

Common Weight Capacities:

- Light-duty: Up to 1,000 lbs

- Standard: 2,000 lbs capacity

- Heavy-duty: 3,000+ lbs capacity

Most professional body carts feature heavy-duty steel construction, locking swivel casters, and adjustable dimensions. The AutoTwirler Elite and Pro Series body carts are rated for up to 3,000 lbs with adjustable widths from 38" to 68", while the Summit Racing Heavy-Duty model offers 2,000 lb capacity.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral professionals select the right body cart and handling equipment for their specific needs.

Body cart further reading:

Body Cart Essentials: Definition, Uses & Key Benefits

Moving heavy objects safely shouldn't be a guessing game. Whether you're restoring a classic Mustang or managing operations in a funeral home, the right body cart transforms challenging tasks into manageable ones.

What Is a Body Cart?

A body cart is a heavy-duty wheeled platform designed to support, move, and position substantial loads with precision. In auto restoration, these carts cradle stripped vehicle shells during collision repair and restoration work. The robust construction typically features heavy-duty square tube steel frames that can handle serious weight while keeping everything stable.

The real genius lies in three key design principles: smart load distribution, reliable mobility, and flexible adjustability. Professional body carts spread weight evenly across multiple contact points, preventing stress concentrations that can damage both your cart and your project. The mobility comes from industrial-grade casters - usually 8" to 10" wheels with polyurethane-over-cast-iron construction that roll smoothly even under heavy loads.

Where Are Body Carts Used?

Body carts show up in more places than you might expect, each with their own specific needs.

Professional auto body shops rely on these carts to shuttle vehicle frames between work stations efficiently. The Innovative Bodyman Cart can supply two technicians at once, proving its worth in busy collision repair facilities.

DIY restoration garages love adjustable models like the Redline Engineering cart. It accommodates widths from 38-3/4" to 68-3/8" with a maximum length of about 142". That versatility means it works for everything from compact cars to full-size trucks.

Funeral preparation rooms need specialized mortuary carts designed for dignified, respectful transport. These often feature stainless steel construction for easy cleaning and quiet operation.

Manufacturing lines use body carts for moving work-in-process items, letting heavy assemblies glide smoothly between stations without needing crane assistance.

Why Choose a Body Cart Over Improvised Dollies?

The difference between a professional body cart and improvised solutions becomes clear once you start using them. Professional carts offer superior load balance through engineered contact points and adjustable supports. This prevents the tipping and sliding common with furniture dollies or makeshift platforms.

Floor-space savings represent another huge advantage. A well-designed body cart lets you store related components underneath - imagine storing a vehicle's chassis under the body cart while working on the shell above.

Safety improvements might be the most important benefit. Professional carts include locking casters to prevent unwanted movement during work, tie-down points for secure transport, and ergonomic heights that save your back.

Process repeatability ensures consistent results across multiple projects. With standardized cart dimensions and features, technicians develop muscle memory and workflows that improve both speed and quality over time.

Selecting the Ideal Body Cart for Your Project

Finding the perfect body cart feels like choosing the right tool for any big project - you want something that'll handle what you throw at it today while being flexible enough for tomorrow's challenges.

Core Specifications to Compare

Let's talk about what really matters when you're shopping for a body cart. Think of these specs as your shopping checklist - get these right, and you'll be happy with your purchase for years to come.

Weight capacity is where you absolutely can't compromise. Most heavy-duty auto body carts handle between 2,000 and 3,000 pounds, which includes your vehicle body plus any tools, parts, or accessories you'll pile on there. The Summit Racing Heavy-Duty model tops out at 2,000 pounds, while the AutoTwirler Elite and Pro series can handle up to 3,000 pounds. When in doubt, go bigger - you'll never regret having extra capacity.

Size flexibility can make or break your cart's usefulness. Fixed-width carts work great if you're always working on similar vehicles, but adjustable models give you options. The AutoTwirler Elite series expands from 38 inches to 65 inches wide, which means it'll handle everything from a compact car to a full-size pickup truck.

Height adjustment matters more than you might think. The Summit Racing cart adjusts from 19 to 20.5 inches, which might not sound like much, but that little bit of tweaking can save your back and make accessing different parts of your project much easier.

The build quality shows up in the steel construction and finish. Professional carts use heavy-duty square tubing with reinforcing where it counts, plus powder-coat finishes that resist rust and look professional.

Wheels make all the difference in how your cart actually performs. Most good carts use 8-inch or 10-inch wheels with polyurethane treads over cast-iron cores. Locking swivel casters on all four corners give you maximum control.

| Feature | Standard Cart | Elite Cart |

|---|---|---|

| Weight Capacity | 2,000 lbs | 3,000 lbs |

| Width Range | Fixed 60" | 38"-68" adjustable |

| Height Range | 19"-21" | 18"-24" |

| Wheel Size | 8" polyurethane | 10" heavy-duty |

| Price Range | $350-$600 | $1,200-$1,800 |

Standard vs Adjustable vs Model-Specific Body Carts

Here's where things get interesting - do you go with a standard cart that does one thing really well, an adjustable model that handles everything, or a specialized cart built for your specific ride?

Standard carts are the workhorses of the bunch. They're built with fixed dimensions that work great for common applications. The JEGS 555-81240 is a perfect example - it handles 2,000 pounds, comes apart without tools for storage, and just plain works. If you know exactly what you'll be using it for, a standard cart often gives you the best bang for your buck.

Adjustable carts are like the Swiss Army knives of the cart world. The AutoTwirler Elite series stretches from 38 to 65 inches wide with solid locking mechanisms that actually hold their position. Yes, they cost more upfront, but one cart that handles a Miata restoration and a Suburban repair project? That's compelling math, especially if storage space is tight.

Model-specific carts are the specialists. AutoTwirler makes dedicated Mustang and Mopar carts with mounting points and dimensions custom exactly to those platforms. They're less versatile, but if you're deep into a particular make, the fit and finish can be worth the trade-off.

For most restoration shops working on different projects, adjustable carts usually win out despite the higher price tag. The flexibility to handle multiple vehicle types with one cart simplifies your workflow and frees up storage space.

Body Cart vs Auto Rotisserie & Other Shop Carts

Let's clear up some confusion about when you'd choose a body cart versus other shop equipment. Each tool has its sweet spot, and understanding the differences helps you build the right setup.

Auto rotisseries give you that amazing 360-degree access for welding and bodywork that makes complex repairs actually manageable. But rotisseries need more setup time, more shop space, and a bigger investment. They're fantastic for frame-off restorations but overkill for many repair jobs.

Engine dollies are purpose-built for powertrain work, with adjustable arms and transmission support that make mechanical jobs much easier. While there's some overlap with body carts, dedicated engine dollies usually give you better ergonomics when you're wrestling with heavy engine components.

Parts carts like the Innovative Bodyman Cart solve a completely different problem - keeping your supplies organized and mobile. These specialized carts can supply two technicians at once and include features like barcode inventory tracking.

The real insight here is that successful shops often use multiple cart types rather than trying to make one cart do everything. A typical setup might include a body cart for the main shell, parts carts for supplies, and panel racks for components.

Using, Accessorizing & Maintaining Your Body Cart

Getting the most from your body cart isn't just about buying the right model - it's about using it safely, adding helpful accessories, and keeping it in top condition.

Best-Practice Workflow Tips

Before you even think about loading anything onto your body cart, take a moment for a quick safety check. Look over all the bolts to make sure they're tight, give each caster a spin to verify smooth operation, and test that the locking mechanisms actually lock. A loose bolt or sticky wheel can turn a routine job into a dangerous situation.

When it comes to load distribution, your cart has a sweet spot. Position heavy components over the main frame members, not hanging off the edges. Most carts are designed with the load centered between the main rails, so work with that design rather than against it.

Here's something that might seem obvious but gets forgotten: lock those casters before you start any serious work. The Innovative Bodyman Cart specifications specifically emphasize locking the 4" industrial casters when in use. It's amazing how much a cart can drift during a project, and that movement affects both safety and work quality.

If you're using a larger cart that can serve two technicians simultaneously, coordination becomes key. This prevents the awkward dance of two people reaching for the same tool at the same time.

Parts sequencing makes a huge difference in workflow efficiency. Organize your materials in the order you'll actually use them, with partially used items up front and backups behind. This simple system cuts down on search time.

Popular Accessories & Add-Ons

The beauty of modern body carts lies in their ability to grow with your needs through accessories. You don't need to buy everything at once - start with basics and add specialized items as your workflow develops.

Spray-gun holders protect expensive equipment while keeping it within easy reach. The Innovative system includes one spray gun holder standard, but you can add more if you work with multiple guns or coatings.

Organized storage transforms a basic cart into a mobile command center. The Innovative Bodyman Cart comes with an impressive array of storage options: 50 barcode tag holders for inventory tracking, multiple baskets in different sizes, and specialized holders for bottles, discs, and buffer pads.

Don't overlook trash management - a simple waste container prevents debris from accumulating on your work surface. This might seem minor, but it significantly improves both shop cleanliness and safety.

Hook systems handle the hanging items that every shop accumulates - hoses, cables, and lightweight tools. Shelf mats might be the most underrated accessory - they protect surfaces and prevent small parts from taking a dive to the floor.

The secret is matching accessories to your actual workflow rather than buying everything that looks cool. Start simple and add complexity as you find what would actually make your day easier.

Routine Maintenance & Storage

A well-maintained body cart can serve your shop for decades, but neglect will turn even the best cart into a frustrating liability. The good news is that maintenance isn't complicated - it just needs to be consistent.

Monthly bolt checks should become as routine as checking your tire pressure. Vibration and temperature changes naturally loosen connections over time. Focus on the caster mounting bolts and main frame connections first, since these handle the most stress.

Caster care keeps your cart rolling smoothly and protects your floors. Most industrial casters include grease fittings that need periodic attention. While you're at it, clean the wheels - debris buildup makes carts harder to push and can damage floor surfaces.

Keep an eye out for corrosion, especially if your shop is humid or you use water-based processes. The heavy-duty powder-coat finishes on professional carts provide excellent protection, but any chips or scratches need prompt attention to prevent rust from spreading.

Storage strategies depend on your cart type and shop layout. Some carts like the JEGS model break down quickly for compact storage when not in use - perfect for smaller shops. Others work better with vertical wall hanging.

For carts that see seasonal use, complete disassembly makes sense. Many are "designed for easy disassembly and storage" - a valuable feature when shop space is at a premium.

Scientific research on ergonomic tool use

Cost, Brands, Shipping & Assembly Insights

Shopping for a body cart means navigating a market with surprising price variations and hidden costs. Let me walk you through what you can expect to spend and how to avoid common purchasing mistakes.

Budget vs Premium Body Cart Models

The body cart market divides into three clear price tiers, each serving different needs and budgets.

Entry-level options under $400 include workhorses like the JEGS 555-81240 at $349.99. These carts deliver solid 2,000 lb capacity with basic steel construction and standard 8" casters. While they won't win any beauty contests, they get the job done for weekend warriors and occasional users. The trade-off is limited adjustability and basic features.

Mid-range elite models running $900-$1,500 represent the sweet spot for many professional shops. The AutoTwirler Elite series, priced between $1,351.36 and $1,514.86, adds the adjustable width mechanisms that make one cart handle everything from compact cars to full-size trucks. You're paying for versatility and the heavier construction that stands up to daily use.

Pro series carts above $1,900 cater to high-volume shops where downtime costs money. AutoTwirler Pro models range from $1,944.25 to $2,162.25, offering maximum adjustability and the heaviest construction available. These carts often pay for themselves through improved productivity in busy collision centers.

DIY lumber alternatives can slash costs dramatically. One clever builder documented creating a complete wood cart for approximately $135 in new materials, compared to $600+ for commercial equivalents. The catch? You need solid woodworking skills and shouldn't expect the same durability as professional steel models.

Most professional carts come with powder-coat finishes as standard, while raw steel options reduce costs but leave the finishing work to you. Given the time and materials needed for proper coating, the factory finish usually proves worthwhile.

Shipping, Assembly & Storage Tips

Freight classification can surprise first-time buyers with unexpected costs. Most professional body carts ship as "bolted kits" to reduce freight class and minimize shipping damage. The JEGS cart weighs in at 150 lbs, while larger adjustable models often exceed 200 lbs - enough to trigger freight shipping rather than standard parcel delivery.

Curbside delivery is standard for most carriers, which means you'll need a way to move that crated cart from the truck to your shop. Don't assume the driver will help - plan for this requirement, especially with the heavier professional models that arrive on pallets.

Assembly complexity varies dramatically between models. Basic carts might need only caster installation - a 30-minute job with basic tools. Adjustable models require careful alignment of telescoping mechanisms and can take 2-4 hours to assemble properly.

If you plan to transport loaded carts in trailers, tie-down considerations become critical. Use tie-down straps to secure the body to the dolly and also strap the dolly to the trailer floor. This double-securing approach prevents disasters during transport.

Shop floor footprint deserves careful measurement before ordering. Carts need clearance for caster swivel and loading access - the actual space requirement is larger than the cart's stated dimensions.

More info about pricing comparisons

Frequently Asked Questions About Body Carts

How do I calculate the weight capacity I really need?

Figuring out the right weight capacity for your body cart isn't just about looking up vehicle weights - you need to think like an engineer. Start with the basics: a stripped car body weighs anywhere from 500 pounds for a compact car to over 1,200 pounds for a full-size truck. But that's just the beginning.

Here's where most people make mistakes - they forget about everything else that goes on the cart. Those tools scattered around your workspace? They add up fast. Parts bins, welding equipment, even that coffee cup you always leave somewhere - it all counts toward your total load.

The golden rule is simple: double your expected weight. If you think you'll never exceed 1,000 pounds, get a cart rated for at least 2,000 pounds. This safety margin isn't just about preventing catastrophic failure - it's about handling the real world.

When you're pushing a loaded cart around corners or over that inevitable shop floor crack, dynamic forces can multiply the apparent weight significantly. Plus, carts that operate well below their maximum capacity simply last longer and work more smoothly.

Most professional body carts range from 2,000 to 3,000 pounds capacity for good reason. The 3,000-pound models provide that extra margin of safety that professional shops have learned to appreciate.

Can one body cart fit multiple vehicle types?

The short answer is yes, but with some important caveats. Adjustable body carts like the AutoTwirler Elite series can handle width variations from 38 inches up to 65 inches, which covers most passenger cars and light trucks you're likely to encounter.

But here's the reality check - "most" doesn't mean "all." That classic Cadillac with the boat-like proportions? It might push the limits. Modern trucks with aggressive fender flares? They could be a tight squeeze.

Length presents its own challenges. While carts like the Redline Engineering model stretch to about 142 inches, very long vehicles or those with extended components might not fit comfortably.

The height adjustment feature on quality carts helps accommodate different ground clearances and your preferred working height. Most adjustable models give you 4 to 6 inches of range, which handles the variations you'll see in typical automotive work.

If you're running a shop that specializes in one vehicle family - say, classic Mustangs - a model-specific cart might actually serve you better than a universal adjustable one. The specialized mounting points and optimized dimensions can make your work noticeably easier.

For shops handling everything from compact cars to pickup trucks, adjustable carts justify their higher price through pure versatility. One cart that handles 80% of your projects beats three specialized carts gathering dust.

What's the difference between polyurethane and pneumatic wheels on a body cart?

This choice comes down to your specific working conditions, and getting it wrong can make your life unnecessarily difficult. Polyurethane wheels are the standard on most professional body carts for several solid reasons.

These wheels combine a polyurethane tread with a cast-iron core, creating a wheel that rolls smoothly under heavy loads while protecting your floors. They resist cuts, chips, and the flat spots that can develop when carts sit loaded for extended periods. If you've got smooth concrete floors with a nice epoxy coating, polyurethane wheels are your best friend.

Pneumatic wheels tell a different story. They're essentially small tires that provide excellent shock absorption and handle uneven surfaces much better. One experienced user mentioned switching to pneumatic tires specifically for uneven ground, and the difference was immediately noticeable.

But pneumatic wheels come with trade-offs. They can puncture, they need periodic pressure checks, and they're generally not as durable under constant heavy loads. They're also typically more expensive to replace.

The research consistently shows that 8-inch or 10-inch polyurethane wheels represent the sweet spot for most indoor shop applications. They handle the weight, protect your floors, and keep rolling year after year with minimal maintenance.

Consider your specific situation honestly. If you're working on smooth shop floors, polyurethane wheels will serve you better. If you're dealing with cracked concrete, outdoor work, or frequently moving between different surface types, the extra cost and maintenance of pneumatic wheels might be worth it.

Conclusion & Next Steps

Choosing the right body cart can completely change how you approach your projects. Whether you're bringing a classic Mustang back to life in your garage or running a busy collision repair shop, the right cart makes everything easier, safer, and more efficient.

The research we've covered shows that professional-grade carts with 2,000-3,000 lb capacity really are worth the investment. You can save money with basic models, but the adjustable dimensions, heavy-duty construction, and smooth-rolling industrial casters on premium carts often pay for themselves through improved productivity and reduced back strain.

Here's what matters most when making your final decision: weight capacity should exceed your heaviest loads by at least 100%, adjustable models give you flexibility for different projects, and professional construction with powder-coat finishes will serve you for decades rather than years.

At American Mortuary Coolers, we've helped facilities across Tennessee, Georgia, Illinois, South Carolina, Texas, California, New York, and Pennsylvania select the right transport equipment for their specific needs. While our specialty is mortuary equipment, the principles of safe, efficient material handling apply whether you're moving vehicle bodies or serving funeral families with dignity.

Your next step depends on your situation. Auto restoration shops benefit most from adjustable carts like the AutoTwirler Elite series - they handle everything from compact cars to full-size trucks with one versatile platform. Funeral operations need specialized mortuary carts with stainless steel construction and quiet operation that maintains the respectful atmosphere families deserve.

DIY builders face an interesting choice. Building your own cart can save significant money if you have the skills and time, but commercial carts come with professional engineering, warranties, and proven reliability that's hard to match in a home workshop.

The beauty of investing in quality equipment is how it transforms your daily work experience. Instead of wrestling with inadequate tools or risking injury with improvised solutions, you'll have confidence that your body cart can handle whatever project comes next.

We understand that selecting specialized equipment involves more than just comparing specifications. It's about finding solutions that fit your workflow, meet safety requirements, and provide reliable service for years to come. Our experience with custom equipment design and direct delivery across the contiguous 48 states means we can help you find exactly what you need.

Whether you need help assessing your specific requirements, ensuring safety compliance, or exploring custom modifications, we're here to help you make the right choice for your operation.

More info about mortuary carts

Ready to upgrade your workflow with the right body cart solution? Reach out to discuss your specific needs - we'd love to help you find equipment that makes your work easier and safer.