Understanding Temperature Measurement with Thermocouples

18 inch thermocouples are specialized temperature sensors used in various heating applications where precise temperature monitoring at extended depths is required. Here's what you need to know:

| Feature | Description |

|---|---|

| Length | 18 inches (allows deep penetration into equipment) |

| Common Types | K, J, and T type (each with different temperature ranges) |

| Temperature Range | Up to 2300°F (1300°C) depending on type and sheath material |

| Popular Applications | Kilns, furnaces, water heaters, molten metal, HVAC systems |

| Price Range | $30-$300 depending on specifications |

| Sheath Materials | Stainless steel, Inconel 600, Cerite III (each with different benefits) |

When selecting an 18 inch thermocouple, you'll need to consider the specific temperature range of your application, the environment it will operate in (corrosive, high-temperature, etc.), and how it will be mounted. The right thermocouple ensures accurate temperature readings, which is critical for both safety and operational efficiency.

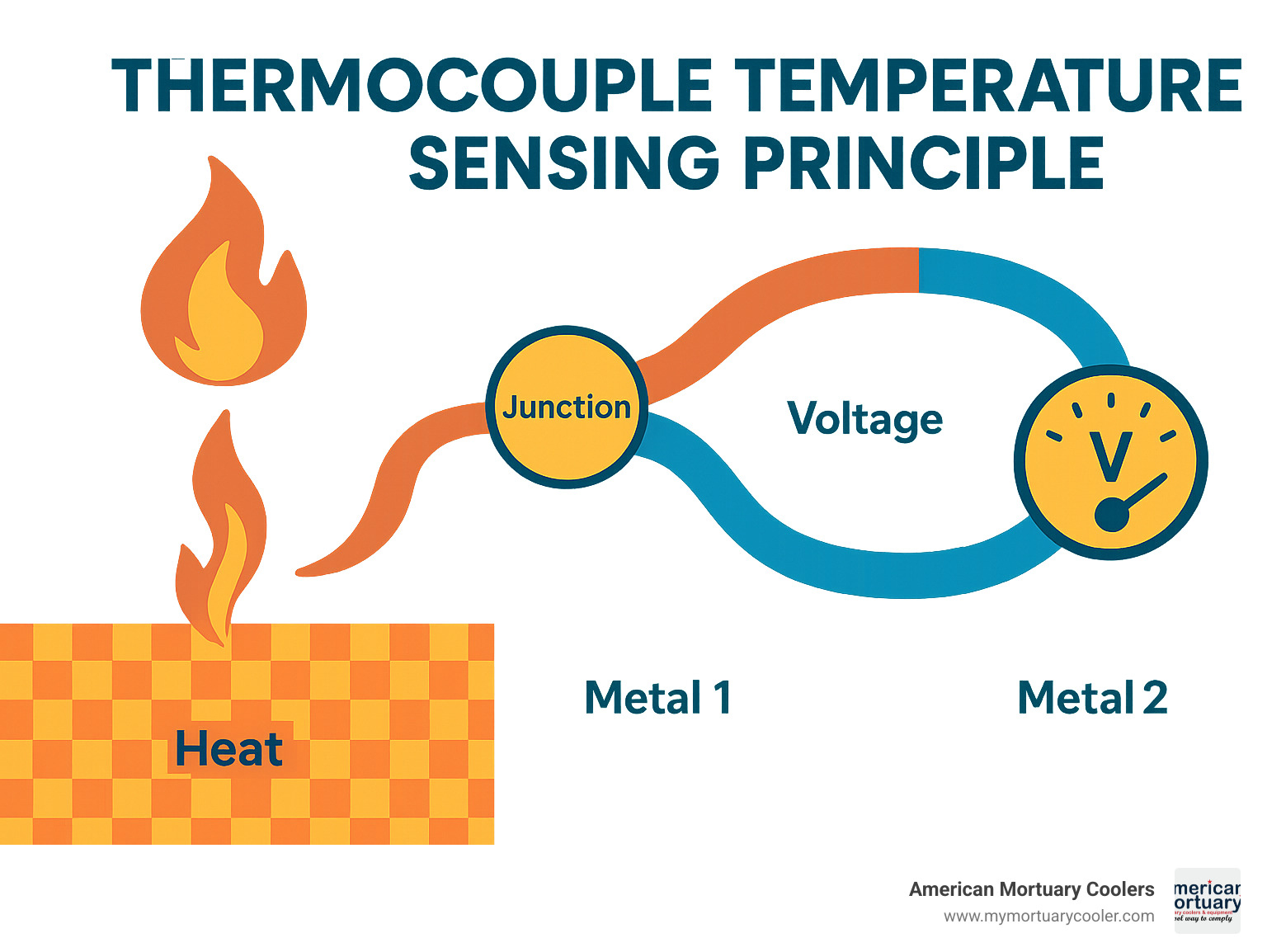

An 18 inch thermocouple works by generating a small voltage at the junction of two dissimilar metals, which varies with temperature. This simple yet effective design makes thermocouples reliable for a wide range of applications. The 18-inch length is particularly useful when you need to measure temperatures deep inside equipment or when the sensing element needs to be positioned away from mounting points.

I'm Mortuary Cooler, a national-level supplier of mortuary coolers with experience in temperature control systems including 18 inch thermocouples used in our cooling and heating equipment. My expertise comes from years of ensuring reliable temperature monitoring in critical environments.

18 inch thermocouple terms simplified:

What Is an 18 Inch Thermocouple and How Does It Work?

Ever wonder how your furnace knows when to turn on or off? That's where an 18 inch thermocouple comes in! This remarkable temperature sensor consists of two different metal wires joined at one end (the measuring junction) with the other end connected to your temperature measuring device. The name comes from its length—18 inches from tip to connection point—making it perfect for reaching deep into equipment where heat needs monitoring.

The magic behind thermocouples was finded back in 1821 by Thomas Johann Seebeck. When two different metals touch and heat is applied, they generate a small voltage that changes with temperature. This "Seebeck effect" creates a tiny electrical signal (usually around 30 millivolts) that your equipment converts into an accurate temperature reading.

Why 18 inches specifically? There are some practical reasons:

First, this length lets you measure temperatures deep inside furnaces and kilns where shorter sensors simply can't reach. Second, it provides a safe distance between the blazing hot measurement point and the cooler connection areas. And third, it helps you position the sensor correctly in large equipment where the measuring point sits far from access points.

At American Mortuary Coolers, we understand that precise temperature monitoring isn't just important—it's essential. Whether in our mortuary refrigeration systems or in industrial processes, knowing the exact temperature can make all the difference.

Key Applications for an 18 Inch Thermocouple

18 inch thermocouples show up in surprising places! In foundries and metal processing plants, these sensors reach deep into molten aluminum and zinc while keeping the connections safely away from extreme heat. Our CERITE III thermocouples with 18-inch hot legs feature special high-alumina protection tubes that won't get "wet" by molten metals—a crucial feature when you're dealing with 1200°F liquid metal!

In water heaters and boilers, the 18-inch length positions perfectly in pilot flames while routing safely to control systems. Many homeowners are familiar with universal replacement models like the White Rodgers H06E-18 and Honeywell 18-inch thermocouples designed specifically for these applications.

Glass and ceramic artists rely on these sensors in their kilns, where temperatures can reach a scorching 2300°F (1300°C). The extended length helps position the sensor at the perfect measurement point while keeping connections outside the heat zone.

Laboratory technicians and industrial oven operators appreciate how an 18 inch thermocouple can reach the center of larger ovens, providing readings away from walls and heating elements for more accurate results. Even commercial HVAC systems use these longer thermocouples to monitor combustion processes in larger heating units.

18 Inch Thermocouple Junction Styles

The way your 18 inch thermocouple's junction is made dramatically affects how it performs. Think of the junction as the "business end" of your sensor—it's where the temperature actually gets measured. There are three main styles:

Grounded Junctions connect the thermocouple wires directly to the inside wall of the metal sheath. This creates electrical continuity between the sensor and sheath, giving you faster response times—typically 3-5 times faster than ungrounded models. They're physically tougher too, making them popular in Type J and K industrial thermocouples. The downside? They can pick up electrical interference, which might be an issue in some settings.

Ungrounded Junctions keep the thermocouple isolated from the sheath with a layer of insulating material. Think of it as wearing gloves—you still feel the heat, but there's a barrier. This design protects against stray voltages and ground loops, making it ideal for electrically noisy environments or when measuring in conductive liquids. The trade-off is a slower response time, but for many applications, that's worth the electrical isolation.

Exposed Junctions extend beyond the protective sheath for direct contact with whatever you're measuring. These respond lightning-fast—up to 5-7 times quicker than ungrounded models—making them perfect for air and gas temperature measurements where every second counts. The drawback? They're more vulnerable to damage and corrosion since they lack the sheath's protection.

Choosing the right junction style for your 18 inch thermocouple depends on your specific needs. For kiln applications where quick response matters, a grounded Type K might be perfect. Working in an electrically noisy factory? An ungrounded model will serve you better by avoiding interference. And if you're measuring rapidly changing air temperatures, an exposed junction gives you the fastest readings.

Thermocouple Types, Sheath Materials & Temperature Limits

When you're looking for an 18 inch thermocouple, you'll quickly find that not all thermocouples are created equal. The magic happens in two key components: the type of metal wires used and the protective sheath that houses them. Let me walk you through the options in a way that makes sense.

Thermocouple Types

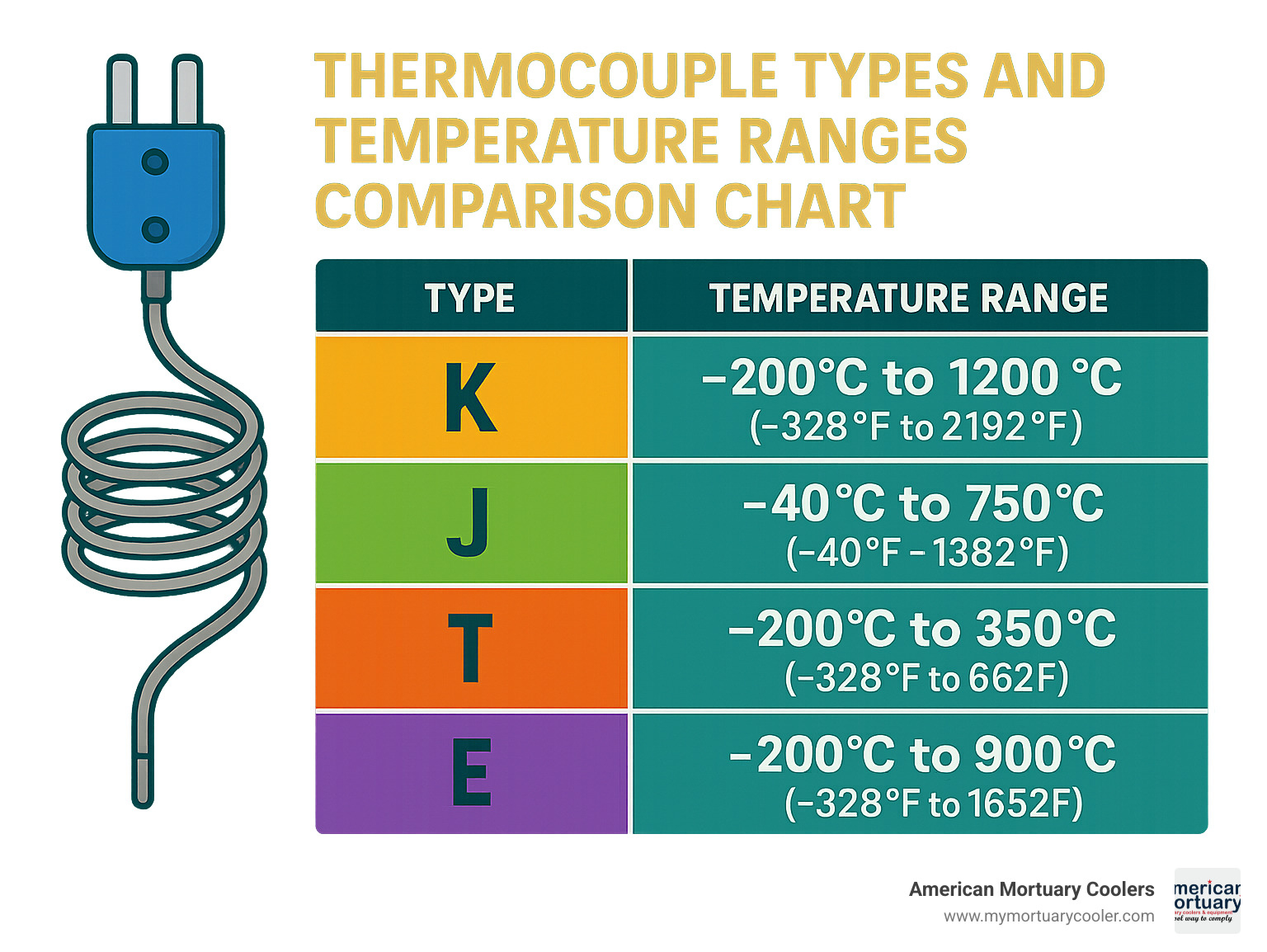

The Type K thermocouple is like the reliable family sedan of temperature sensors. Made from Chromel and Alumel metals, it handles temperatures from a frigid -328°F all the way up to a scorching 2462°F. You'll spot these easily by their yellow connectors. They're my go-to recommendation for most general applications because of their excellent oxidation resistance and consistent performance.

If you're working in more moderate heat, the Type J thermocouple might be your best friend. Using Iron and Constantan metals, these sensors work from -40°F up to 1382°F. While they can't handle the extreme temperatures of Type K, they actually give you a stronger signal per degree of temperature change, which can mean better sensitivity. Look for their black connectors when you're shopping.

For low-temperature specialists, nothing beats a Type T thermocouple. These Copper-Constantan sensors excel in the -328°F to 662°F range. They're particularly outstanding when working below freezing or in corrosive environments. Their blue connectors make them easy to identify, and their accuracy at lower temperatures is truly impressive.

Sheath Materials

The sheath is like your thermocouple's suit of armor, and choosing the right material makes all the difference in how long your sensor will last.

304 Stainless Steel sheaths are the workhorses of the industry. They're affordable, resist corrosion well, and can handle temperatures up to 1650°F. Their excellent mechanical strength means they can take a beating in industrial environments without failing. If you're on a budget but need something reliable, stainless is hard to beat.

When the heat really cranks up, Inconel 600 is worth the extra investment. This nickel-chromium alloy stands up to temperatures reaching 2000°F and resists oxidation beautifully. One of its hidden talents is bendability – you can shape it to a radius of 2.5 times the probe diameter without damage, making installation in tight spaces much easier.

For specialized applications like measuring molten metal temperatures, Cerite III ceramic sheaths are essential. Their high-alumina composition (85% alumina, 4% silica) creates a non-wetting surface that prevents molten metals from sticking. While they're more brittle than metal options, their chemical resistance is best for these challenging environments.

The 18 Inch Thermocouple Type Showdown

Let's be honest – choosing between thermocouple types can feel overwhelming. Here's how they stack up in real-world applications:

The 18 inch thermocouple Type K is your versatile all-star. It handles most high-temperature applications with ease, making it perfect for kilns, furnaces, and industrial processes. Price-wise, expect to pay between $30-$267 depending on specifications. For example, a K type with Inconel 600 sheath rated for 2000°F sits at the higher end of that range but delivers exceptional performance.

The 18 inch thermocouple Type J offers better sensitivity when you need more precise measurements. It's an economical choice for applications that don't push past 750°F, like HVAC systems and water heaters. Pricing runs similar to Type K, with a typical 1/4" × 18" probe with 72" leads costing around $267.

For specialty applications, especially those involving corrosive environments or lower temperatures, the 18 inch thermocouple Type T shines. Its copper component drives the price up (around $267 for a 1/4" × 18" probe with 72" leads), but the superior stability and accuracy are worth it when precision matters.

Sheath Material Selection Guide

Choosing the right sheath material isn't just about maximum temperature – it's about matching your specific environment.

Stainless steel sheaths offer the best bang for your buck in many applications. They stand up well to many chemicals, provide excellent mechanical strength, and are easy to maintain. I've found them ideal for general industrial use, steam applications, and food processing environments where cleanliness is important.

When temperatures climb, Inconel sheaths really earn their keep. Their superior performance in oxidizing environments and resistance to thermal cycling fatigue makes them the go-to choice for kilns, furnaces, and heat treatment ovens. Yes, they cost more upfront, but they'll outlast stainless in high-heat applications, saving you money in the long run.

For those dealing with molten metals, ceramic and Cerite sheaths are worth their weight in gold. Their non-wetting properties prevent molten aluminum or zinc from sticking to the probe, while their high-alumina content minimizes contamination. They're more fragile than metal options, but in foundry environments, nothing else will do.

When considering corrosion factors, sulfur-containing environments can attack stainless steel, while chloride environments may cause stress corrosion cracking. Reducing atmospheres like hydrogen can degrade certain sheaths, so matching your sheath to your specific environment is crucial.

In our work at American Mortuary Coolers, we've learned that even in refrigeration equipment, selecting the right thermocouple materials is essential for long-term reliability. The right 18 inch thermocouple with the proper sheath material ensures accurate temperature control year after year, which is something our customers truly appreciate.

Installing and Mounting an 18 Inch Thermocouple Assembly

Getting your 18 inch thermocouple properly installed isn't just about sticking it in place - it's an art that ensures you'll get accurate readings and years of reliable service. Think of it as finding the perfect home for your temperature sensor!

Common Mounting Methods

The way you mount your 18 inch thermocouple can make all the difference in how well it performs. Let's explore your options:

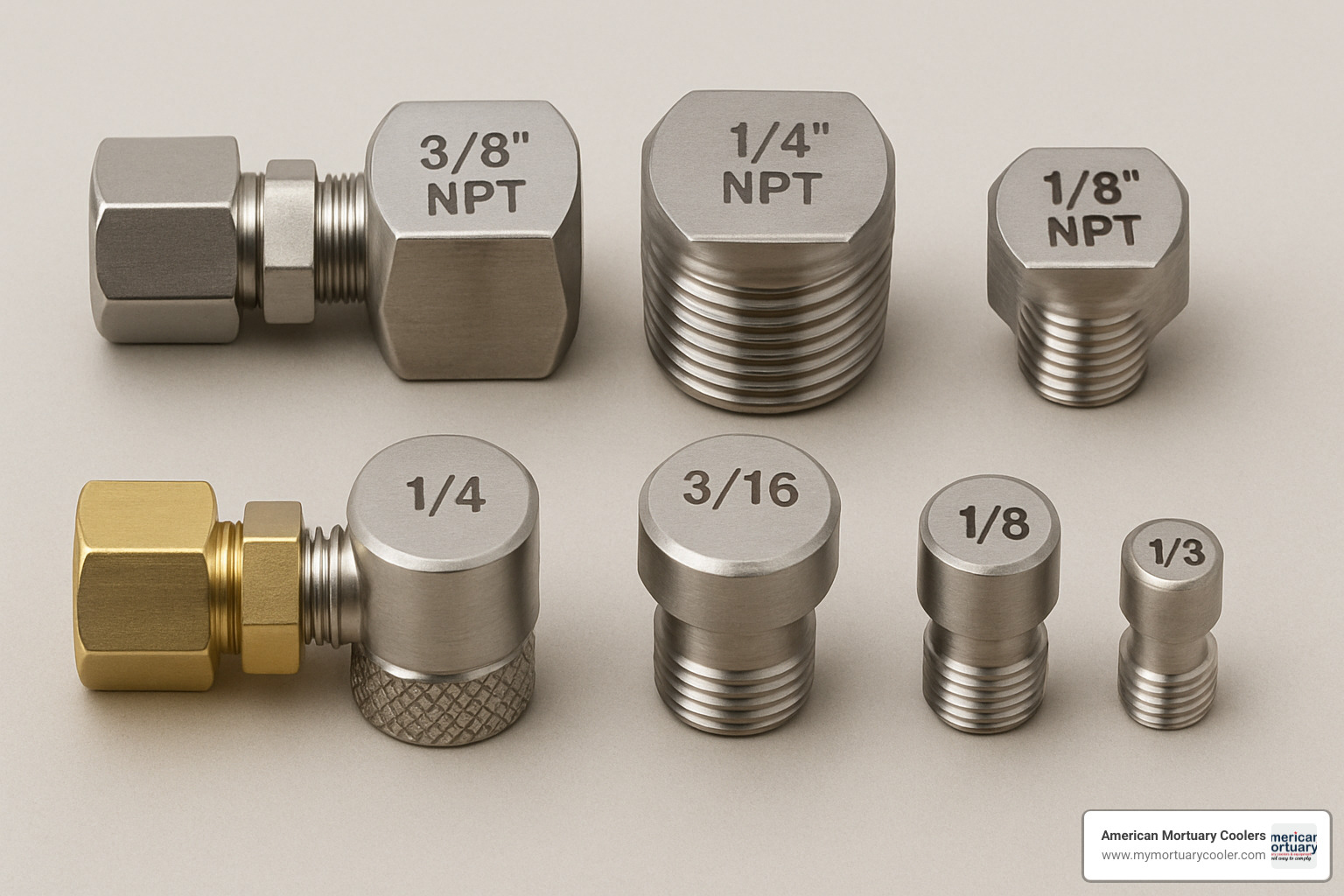

Threaded NPT Connections are the workhorses of industrial mounting. These threaded fittings (available in 1/8", 1/4", and 1/2" NPT sizes) create a nice, tight seal that keeps pressure where it belongs. They're perfect when you need to occasionally remove or replace your thermocouple without a major production. Many of our customers love the K type high-temperature models with 1/4" NPT adapters for their versatility.

When you need to dial in the exact position of your probe, Compression Fittings are your best friend. They let you adjust the insertion depth until it's just right, then lock it in place by tightening down on a ferrule. Just remember - once you've tightened that fitting, your thermocouple isn't going anywhere without replacing the ferrule!

For those tough environments where nothing but permanent will do, Weld-in Bushings provide the ultimate in pressure rating and durability. Of course, you'll need welding equipment and skills (or someone who has them), but the result is a rock-solid installation that stands up to almost anything.

Need quick access? Bayonet Adapters allow for speedy connection and disconnection with a simple twist. Their spring-loaded design ensures consistent contact with the surface being measured. While they're not typically pressure-tight, they're perfect for applications where you need frequent access.

And don't overlook Union Joints - especially handy in molten metal applications with CERITE III assemblies. These clever fittings let you replace just the "hot leg" of the thermocouple without disturbing all your carefully routed wiring. The 90° pipe union joints are particularly thoughtful as they prevent wire twisting during replacement.

Probe Diameter Considerations

Size matters when it comes to thermocouple probes! Your 18 inch thermocouple diameter affects three critical factors:

The slender 1/16" (1.6mm) probes respond almost instantly to temperature changes and can bend around tight corners, but they're more delicate and prone to damage. At the other end, 1/4" (6.4mm) probes are built like tanks - they'll survive rough handling but take longer to register temperature changes.

For many applications, the 1/8" (3.2mm) diameter hits the sweet spot - reasonably responsive while still being robust enough for industrial use.

In kilns, you'll often see specialty sizes like gauge 8 wire (0.128" or 3.25mm) that maximize durability while gauge 11 offers faster response times. It's all about finding the right balance for your specific needs.

Lead Lengths & Insulation Choices

Once your 18 inch thermocouple has sensed the temperature, those readings need to travel somewhere! That's where lead wires come in:

Most industrial applications use the standard 72" (6 foot) lead length, but we can provide longer leads for about $1 per additional foot. We've created custom lengths for all sorts of unique setups over the years.

The insulation protecting those leads is just as important as the length. Glass Braid insulation handles temperatures up to 900°F (482°C) while remaining flexible enough for most routing needs. For extra protection in harsh environments, Fiberglass with Stainless Steel Over-braid adds a layer of mechanical armor without sacrificing the temperature rating.

Working in milder conditions? PVC Insulation is an economical choice for temperatures up to 220°F (105°C) and offers good moisture resistance - perfect for HVAC systems and refrigeration equipment like our mortuary coolers. When chemicals are involved, PTFE (Teflon) insulation stands up to almost anything while handling temperatures up to 500°F (260°C).

Don't forget about the transition area where the high-temperature probe meets the extension wires. This junction typically can't handle more than 400°C (750°F), so position it accordingly!

Step-by-Step Installation for an 18 Inch Thermocouple

Let me walk you through installing your 18 inch thermocouple like a pro:

First, find the perfect spot for your measurement. The probe tip should be in the heart of what you're measuring, not touching walls or heating elements that might give false readings. Make sure the transition area and leads stay safely away from extreme heat.

Next, prepare your mounting connection. For threaded connections, use an appropriate thread sealant if needed. With compression fittings, check that the ferrule is facing the right direction. For welded connections, prepare your surfaces according to proper welding specs.

When you're ready to install the thermocouple, insert the probe to the proper depth and secure it. Tighten threaded connections to the right torque (not too tight, not too loose). For compression fittings, give the compression nut a firm tightening. Make sure the probe stays straight without any stress that could cause premature failure.

Now it's time to route those extension wires. Be gentle with the bends - maintain at least 2.5× the probe diameter for Inconel sheaths. Keep the wires away from high-voltage lines or strong electromagnetic fields that could interfere with your readings. Secure everything to prevent vibration damage, and use appropriate conduit where needed.

When connecting to your instrumentation, match the thermocouple type to the instrument input and observe proper polarity (those color codes are there for a reason!). Whether you're working with stripped leads or mini-plugs, make sure connections are secure and properly seated.

Finally, perform an initial verification. Power up the system and check for reasonable temperature readings based on what you know about your process. Verify that the readings respond appropriately when temperatures change.

At American Mortuary Coolers, we follow these same principles when installing temperature monitoring systems in our mortuary refrigeration units. Proper installation isn't just about accuracy - it's about peace of mind knowing your equipment is monitoring temperatures reliably day after day.

Selecting & Purchasing the Right 18 Inch Thermocouple

Shopping for an 18 inch thermocouple shouldn't feel like deciphering ancient hieroglyphics. Let me walk you through what really matters when you're looking for the perfect temperature sensor for your application.

Essential Selection Criteria

Think of choosing a thermocouple like buying a good pair of work boots – you need the right fit for the job at hand. First, consider the temperatures you'll be measuring. Type K thermocouples handle a broad range from -328°F to a whopping 2462°F, making them the Swiss Army knife of temperature sensing. If you're working with more moderate temperatures, Type J (-40°F to 1382°F) might be your best friend, while Type T shines in colder environments with its range of -328°F to 662°F.

Your working environment plays a huge role too. Got corrosive chemicals around? You'll need a sheath material that can take the abuse. Dealing with electrical equipment that creates interference? An ungrounded junction will keep your readings accurate. And if your equipment vibrates like a washing machine with an unbalanced load, you'll want something sturdy enough to handle the shake.

Response time is another critical factor. Think of it as the difference between instant and regular coffee – sometimes you need that reading right away! Smaller diameter probes with exposed or grounded junctions respond faster, while larger, ungrounded ones trade speed for durability.

The junction style – that's where the magic happens in your 18 inch thermocouple. Grounded junctions offer a good balance of response time and durability for most applications. Ungrounded junctions provide electrical isolation when you need it, and exposed junctions give you the fastest response but are more vulnerable to damage.

Don't overlook the importance of the sheath material. Stainless steel works well for general applications up to 1650°F, while Inconel 600 handles the heat up to 2000°F. For specialized applications like measuring molten metals, Cerite III is worth the investment.

Finally, consider how you'll connect your thermocouple to your equipment. Simple stripped leads give you flexibility at a lower cost, while mini-plugs make connection and disconnection a breeze. Need something more secure? Spade lugs or standard connectors like OSTW, LRTC, or SMPW will add about $3-$5 to your cost but might save you headaches down the road.

Budget vs. Premium: Price Ranges Explained

When it comes to 18 inch thermocouples, you'll find options across the price spectrum, each with its own set of trade-offs:

The economy range ($7-$30) includes basic replacement thermocouples like the White Rodgers H06E-18 at just $7.55. These are perfect for simple HVAC systems and water heaters but won't stand up to extreme conditions.

In the mid-range ($30-$100), you'll find industrial-grade sensors with better accuracy and durability. These workhorses offer various mounting options and good reliability for most industrial applications, like the K type high-temp thermocouple with mounting adapter starting at $30.

The premium range ($100-$300) is where you'll find the specialized performers. These high-precision thermocouples feature premium materials like Inconel 600 and can handle the most demanding environments. A Type J or K 1/4" × 18" probe with 72" leads will set you back about $267, but the performance justifies the price for critical applications.

What drives these price differences? Thermocouple type is a factor (K, J, or T), as is the sheath material (Inconel costs more than stainless steel). Diameter plays a role too, with larger diameters generally commanding higher prices. Specialized features like reinforced tips or bendable sections add to the cost, as do special terminations ($3-$5) and calibration certificates.

Good news on shipping: many suppliers offer free shipping on orders over $99, with standard shipping running about $9.95 for smaller orders. Items under 150 pounds typically ship via standard carriers, while heavier items ship freight with curbside delivery.

Add-Ons & Accessories

The right accessories can significantly extend the life and functionality of your 18 inch thermocouple. Ceramic protection sheaths are a must-have for gas or propane kiln environments, protecting your investment from harsh reducing atmospheres. The TC-K-KLNSH ceramic sheath, for example, is specifically designed for kiln thermocouples.

Quick-disconnect terminal heads are worth their weight in gold when it comes time for maintenance. These clever devices, common in CERITE III assemblies for molten metal applications, let you replace just the hot leg without disturbing your carefully routed wiring.

Need to extend your reach? Extension wire kits let you position your measuring instrument farther from the heat source. Just remember to match the wire type to your thermocouple type (K, J, or T) to maintain accuracy.

For applications where precision is paramount, calibration certificates provide documented verification of your thermocouple's accuracy. These certificates, traceable to national standards, are especially important for quality control applications.

Finally, mounting adapters give you flexibility in how you install your thermocouple. Available in various materials for different temperature ranges, options like 1/8" NPT, 1/4" NPT, and compression fittings let you adapt your sensor to your specific mounting needs.

At American Mortuary Coolers, we understand the importance of reliable temperature control across industries. While our mortuary refrigeration systems use specialized components, the principles of selecting the right temperature sensor apply whether you're monitoring a cremation retort or a pottery kiln. The right 18 inch thermocouple ensures your equipment operates safely and efficiently, day in and day out.

Maintenance, Replacement, Safety & Compliance

Taking care of your 18 inch thermocouple isn't just about getting accurate readings—it's about ensuring safety and extending the life of your investment. Let's talk about how to keep these temperature sensors working their best for years to come.

Lifetime Expectations and Maintenance Tips

How long should your 18 inch thermocouple last? Well, that depends on several factors. Higher temperatures will naturally shorten its lifespan—a thermocouple running near its maximum rated temperature might last months rather than years. Frequent heating and cooling cycles create thermal stress that ages components faster. And let's not forget environmental factors like corrosion or vibration that can take their toll.

Quality matters too. A premium thermocouple properly installed in a moderate environment might serve faithfully for 3-5 years, while the same sensor in harsh conditions might need replacement much sooner.

To get the most life from your sensor, make regular visual inspections part of your maintenance routine. Look for signs of corrosion, discoloration, or physical damage to the sheath and leads. A simple continuity test with a multimeter can tell you if the electrical path is still good. And don't forget to check those mounting connections—they can loosen over time with thermal cycling.

When readings start to drift or respond sluggishly to temperature changes, your thermocouple is telling you something. These are classic warning signs that replacement time is approaching. Don't wait for complete failure, especially in critical applications where accurate temperature control is essential for safety or product quality.

Replacing an 18 Inch Thermocouple Hot-Leg

In many industrial settings, especially those involving molten metals, thermocouples are designed with replaceable "hot legs" that make maintenance much simpler. Instead of replacing the entire assembly, you can just swap out the worn measuring portion.

When it's time for a hot-leg replacement, safety comes first. Make sure your system is powered down and cooled to a safe temperature. Appropriate protective gear isn't optional—it's essential, especially when working with equipment used for high-temperature applications.

The replacement process is straightforward if you take it step by step. First, locate the union joint (often a 90° pipe union) that connects the hot leg to the rest of the assembly. Once you've removed any insulation or protective covers, you can loosen the coupling nut and disconnect the old thermocouple. For CERITE III assemblies commonly used in molten metal applications, you'll unscrew the thermocouple from the union and disconnect the wires from the terminal head.

Installing the new hot leg is essentially the reverse process—insert the new 18 inch thermocouple, connect the wires (paying careful attention to correct polarity), and secure the union joint. This design is particularly clever for applications like aluminum foundries, where the hot leg ($56.80) can be replaced without disturbing the cold leg wiring.

Before putting everything back into service, double-check all connections and verify proper positioning. When you restart the system, monitor the readings closely to confirm everything is functioning correctly.

Handling and Bending Guidelines

One of the convenient features of metal-sheathed 18 inch thermocouples is that they can often be gently shaped to fit your installation. But there's a right way and a wrong way to do this.

The golden rule for bending Inconel sheaths is to maintain a minimum bend radius of at least 2.5 times the probe diameter. This means a 1/4" probe shouldn't be bent any tighter than a 5/8" radius curve. Bend gradually and evenly, using proper tools rather than forcing it by hand. And once you've made a bend, avoid straightening and re-bending—this work-hardens the metal and leads to breakage.

If you're working with ceramic-sheathed thermocouples, don't attempt bending at all—they're brittle and will snap. And whenever possible, try to do your bending before the initial installation rather than adjusting an already-installed probe.

Regulatory & Safety Considerations

Even something as seemingly simple as a temperature sensor comes with regulatory considerations. Some 18 inch thermocouples contain materials that require California Proposition 65 warnings, particularly those with lead in soldered connections or certain wire insulations. Manufacturers are required to provide appropriate warnings for affected products.

Electrical safety is another important consideration. If you're using grounded junction thermocouples, proper grounding practices are essential. In environments with high voltage or significant electrical noise, ungrounded junctions provide important isolation that can prevent measurement errors or equipment damage. When routing extension wires, keep them away from high-voltage sources and strong electromagnetic fields that could induce measurement errors.

Material compatibility matters too. Make sure your thermocouple materials won't react badly with the substances they'll contact. Some combinations can accelerate corrosion or even contaminate your process. And when mounting in dissimilar metals, consider the potential for galvanic corrosion.

Most manufacturers offer a one-year warranty against manufacturing defects, but this typically doesn't cover damage from improper installation or application. If you need to return an item, most suppliers require authorization within 30 days of delivery, with the actual return completed within 14 days of approval.

Frequently Asked Questions about 18 Inch Thermocouples

How often should I recalibrate an 18 inch thermocouple?

Recalibration schedules vary widely depending on your application. For critical processes where precise temperature control directly affects safety or product quality, quarterly or semi-annual calibration might be appropriate. Less demanding applications might do fine with annual checks.

High-temperature applications typically require more frequent verification because extreme heat accelerates drift. The best approach is to follow industry standards for your specific application while monitoring for drift between scheduled calibrations. If you notice increasing drift, that's a signal to shorten your calibration interval.

Can I bend an 18 inch Inconel-sheathed probe safely?

Yes, Inconel sheaths are designed to allow some flexibility, but there are important limitations. Always maintain that minimum bend radius of 2.5× the probe diameter. Make your bends gradually and evenly using the right tools—never force a sharp bend.

Avoid repeatedly bending the same section, and don't try to straighten a probe once it's been bent. Be aware that bending can slightly affect calibration in some cases, so verification after installation is a good practice.

What causes premature failure in high-temperature or corrosive baths?

Several culprits can lead to early thermocouple failure in demanding environments. Chemical attack on the sheath material is common in corrosive baths—that's why matching the right sheath material to your application is so important. Thermal shock from rapid temperature changes creates stresses that can crack sheaths or damage internal components.

Improper mounting that creates mechanical stress is another common issue, as is vibration fatigue in equipment with moving parts. The thermocouple junction itself can be "poisoned" by contamination that changes its electrical properties. In molten metal applications specifically, failure to use proper ceramic protection is a frequent cause of premature failure.

At American Mortuary Coolers, we understand the importance of reliable temperature monitoring. While our mortuary refrigeration systems use specialized temperature control components, we apply these same maintenance principles to ensure our cooling systems maintain precise temperatures year after year.

Conclusion & Next Steps

As we've journeyed through temperature sensing, it's clear that choosing the right 18 inch thermocouple isn't just a technical decision—it's an investment in your system's safety, efficiency, and reliability.

Throughout this guide, we've unpacked everything you need to know about these versatile temperature sensors. From the distinctive characteristics of Type K, J, and T thermocouples to the critical differences between sheath materials like stainless steel, high-performance Inconel 600, and specialized Cerite III for molten metals—each choice matters. We've walked through mounting options, junction styles, and lead configurations that can be custom to your specific needs.

The beauty of 18 inch thermocouples lies in their adaptability across industries. Whether you're firing ceramics in a kiln, managing molten metal temperatures, or maintaining precise control in industrial processes, your sensor's performance directly impacts your results.

For lasting performance in challenging environments, remember these key takeaways:

Match your materials to your environment—temperature extremes and corrosive conditions demand specific sheath materials. Choose the right diameter to balance quick response with sturdy construction. Install with care to prevent unnecessary stress on the probe. And perhaps most importantly, develop a regular maintenance routine that includes calibration checks.

Here at American Mortuary Coolers, we understand temperature control on a fundamental level. While our day-to-day focus is crafting custom mortuary refrigeration systems that we deliver across the contiguous 48 states, the principles of reliable temperature sensing are universal. When precision matters—whether keeping things cool or monitoring extreme heat—the fundamentals remain the same.

Your 18 inch thermocouple is more than just a component—it's the eyes and ears of your temperature control system. Choosing wisely means fewer replacements, more accurate readings, and ultimately, better results.

Looking for more insights on temperature control systems and related topics? Visit our blog for the latest insights from the team at American Mortuary Coolers. We're always happy to share what we've learned from our years in the temperature control business.