Optimizing Workplace Efficiency with Low Profile Scissor Lifts

A low profile scissor lift is a specialized lifting platform with an extremely low collapsed height (as little as 40mm/1.57 inches) that eliminates the need for pit installation while providing ergonomic height adjustment for materials handling.

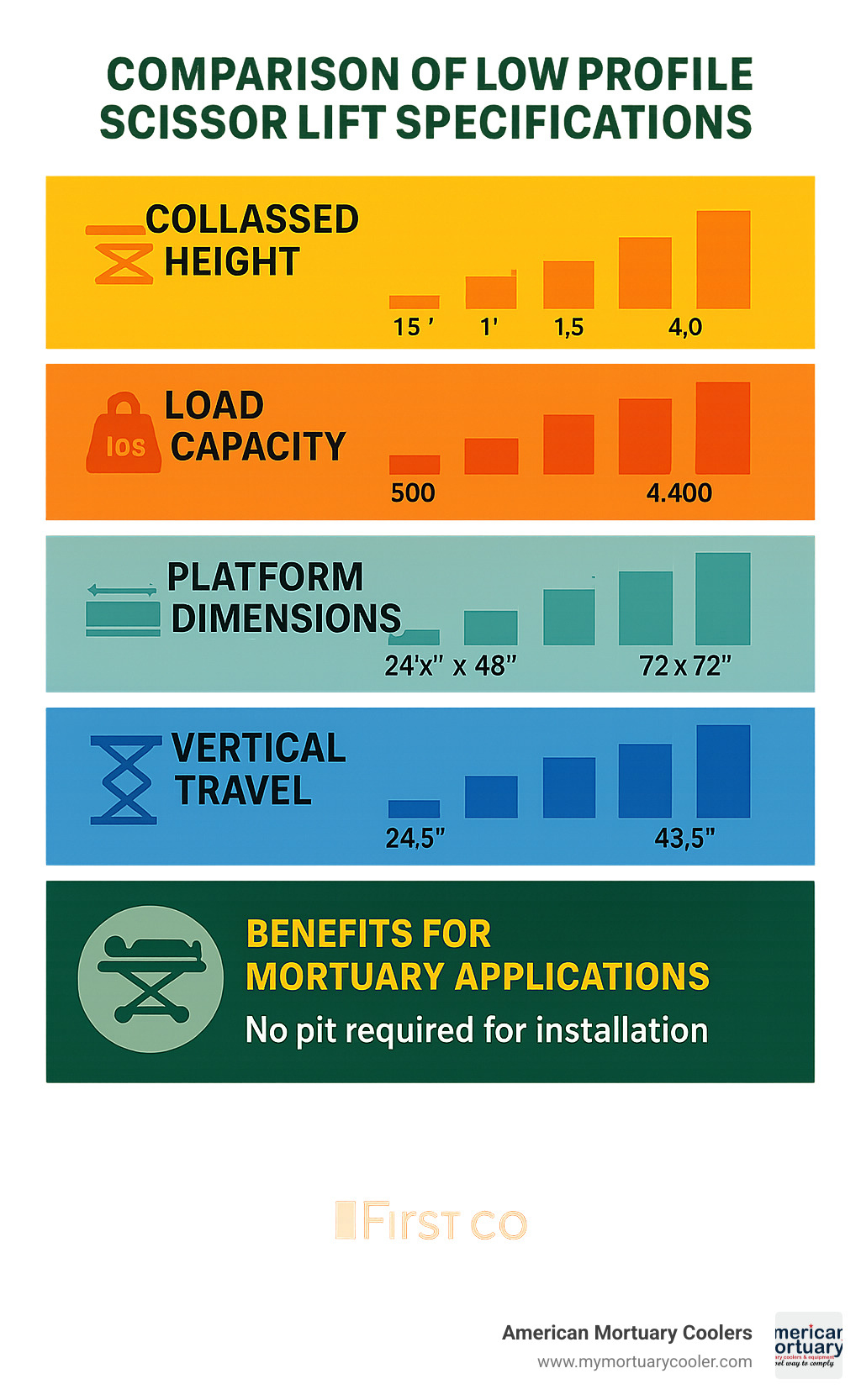

| Low Profile Scissor Lift Quick Facts |

|---|

| Collapsed Height: 40mm-100mm (1.57-4 inches) |

| Load Capacity: 500-4,400 lbs (227-1,996 kg) |

| Platform Sizes: 24"×48" to 72"×72" (610×1,220mm to 1,830×1,830mm) |

| Vertical Travel: 24.8"-43.3" (630-1,100mm) |

| Key Benefit: No pit required for installation |

Low profile scissor lifts solve a critical workplace challenge: how to efficiently load and unload materials without modifying your facility's floor. Unlike standard scissor lifts that require a recessed pit or ramp for access, these ultra-thin units can be loaded directly with pallet jacks, carts, or wheeled equipment.

Why businesses choose low profile scissor lifts:

- No pit installation – saves on construction costs and permits

- Improved ergonomics – reduces back strain by maintaining loads at optimal working heights

- Improved productivity – facilitates easier material handling and workflow

- Facility flexibility – ideal for leased premises where floor modifications are prohibited

- Versatile loading options – compatible with pallet jacks, carts, and wheeled equipment

For funeral homes specifically, these lifts provide crucial support for handling caskets and bodies with dignity and safety.

What Is a Low Profile Scissor Lift?

A low profile scissor lift is a specialized hydraulic lifting platform with an ultra-thin collapsed height of just 40 mm to 100 mm (1.57 to 4 inches). Unlike standard lifts, these allow you to roll equipment directly onto them from floor level—no pit digging or ramp building required.

What makes these lifts truly special is how they solve one of the biggest headaches in warehouse operations: moving materials efficiently without expensive facility modifications. Most comply with European safety standard EN 1570-1, ensuring they meet rigorous safety requirements.

| Feature | Standard Scissor Lift | Low Profile Scissor Lift |

|---|---|---|

| Collapsed Height | 8" to 12" (203-305 mm) | 1.57" to 4" (40-100 mm) |

| Installation | Requires pit or ramp | No pit required |

| Loading Method | Forklift primarily | Pallet jack, cart, or forklift |

| Platform Shapes | Typically rectangular | U-shaped, E-shaped, or solid |

| Initial Cost | Lower | Higher |

| Installation Cost | Higher (pit construction) | Lower (no modifications) |

| Typical Applications | Fixed workstations | Mobile loading, tight spaces |

| Facility Flexibility | Limited (permanent installation) | High (can be relocated) |

Low Profile Scissor Lift vs Standard Tables

The main difference between low profile scissor lifts and standard tables is their collapsed height. Standard tables typically stand 8 to 12 inches tall when collapsed, requiring a pit or ramp. Meanwhile, low profile models can be as thin as 1.57 inches (40 mm), allowing for smooth, direct floor-level access.

Despite their slim profile, these lifts offer impressive load capacities from 500 lbs for smaller units up to 4,400 lbs (2,000 kg) for heavy-duty models. Platform sizes range from compact 24"×48" (610×1,220 mm) tables to spacious 72"×72" (1,830×1,830 mm) platforms.

Ergonomic Benefits of a Low Profile Scissor Lift

The beauty of a low profile scissor lift lies in its ability to keep materials at just the right height for comfortable handling. This means significantly less bending, stretching, and awkward postures that lead to back injuries and muscle strains.

By maintaining loads at waist height—the ergonomic sweet spot—these lifts create a more comfortable working environment. OSHA recognizes proper lifting equipment as essential for preventing workplace injuries, and low profile scissor lifts directly address several key risk factors:

- Back strain prevention by eliminating repetitive bending and reaching

- Improved positioning with no handling materials below knee height

- Injury reduction by avoiding lifting heavy objects from floor level

- Better posture by eliminating awkward working positions

For funeral homes specifically, these ergonomic benefits translate to more dignified handling of deceased individuals and caskets with less physical strain.

Applications & Industry Use Cases

Low profile scissor lifts have found their way into numerous industries thanks to their floor-level access and versatility.

Warehousing and Distribution

In modern warehouses, these lifts make life easier by raising pallets to the right height for picking and packing. What makes them special is how a regular pallet jack can roll right onto them, even in facilities without loading docks.

Manufacturing and Assembly

Manufacturing teams use low profile scissor lifts to put components at the perfect working height, reducing fatigue and improving productivity throughout shifts.

Automotive Service

Mechanics use low-rise scissor lifts that sit just 3-4 inches off the ground, giving easy access to vehicle undercarriages without permanent pit installation.

Food and Pharmaceutical Processing

In clean environments, stainless steel low profile scissor lifts meet strict sanitation requirements while providing ergonomic benefits.

Mortuary and Funeral Services

These lifts transform funeral home operations by allowing dignified handling of deceased individuals and caskets, with smooth transitions between preparation areas, viewing rooms, and transport vehicles.

Loading Methods for Low Profile Units

What makes low profile scissor lifts truly versatile is their flexibility in loading methods:

Pallet Jack Loading

Standard hand pallet jacks can roll directly onto platforms with collapsed heights of just 3-4 inches—no pit installations or bulky ramps required.

Forklift Compatibility

Most low profile scissor lifts work perfectly with forklifts too, giving operations teams flexibility.

Cart and Wheeled Equipment Access

These lifts accommodate carts and wheeled equipment just as easily as palletized loads.

Specialized Platform Shapes

U-shaped platforms feature a 20.5" wide opening for narrow pallet jacks to access open-bottom pallets. E-shaped platforms offer a wider 27" center opening for standard pallet jacks. Solid platforms with ramps provide access for wheeled equipment.

Real-World Case Studies

Safetech LoLift Implementation

A mail sorting facility chose Safetech's LoLift with its ultra-low 40mm (1.57 inch) platform height because they couldn't modify their leased building. The pitless installation improved ergonomics without construction headaches.

EdmoLift U-Table in Warehouse Environment

A distribution center implemented EdmoLift's U-shaped low profile tables with an 80mm closed height. The U-shaped design allowed pallet jack operators to access open-bottom pallets directly, reducing forklift dependency in congested areas.

BendPak LR-10000 in Automotive Service

An auto service center installed BendPak's LR-10000 low-rise lifts, which collapse to approximately 4 inches. This gave technicians the ability to perform undercarriage work without permanent pit installations, maximizing facility flexibility.

Key Design Features, Safety & Options

Low profile scissor lifts feature thoughtfully engineered designs that transform workflow while prioritizing safety. Most models use electric/hydraulic systems with pressure-compensated flow dividers for smooth operation. The scissor mechanism provides stability while folding into an incredibly thin profile when lowered.

Many manufacturers have relocated the power unit off the main deck—a simple but brilliant move that helps achieve those ultra-low collapsed heights. Maintenance-friendly features include self-lubricated bushings at pivot points and hinged top designs for easy servicing.

Safety Features

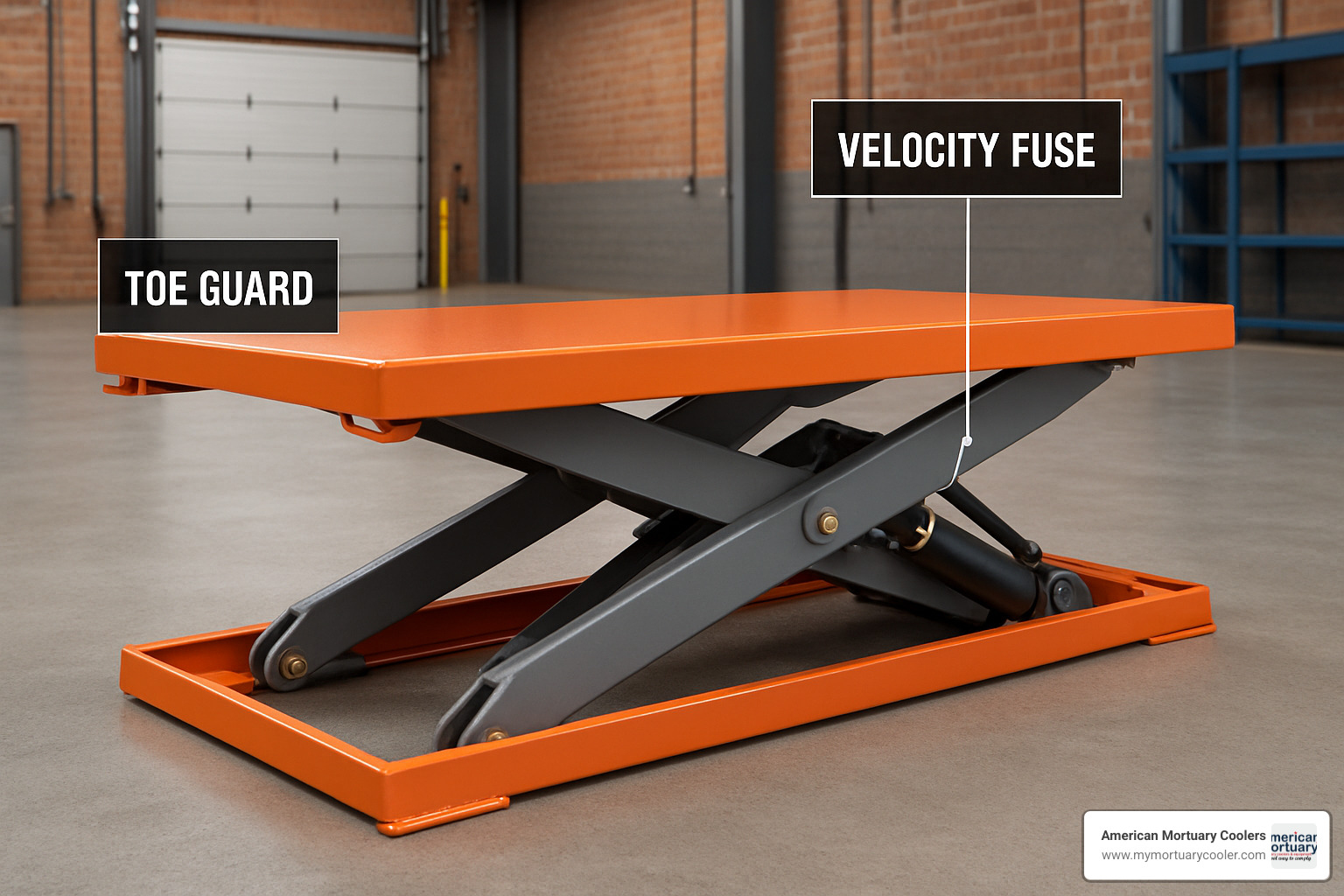

Safety is engineered into every aspect of low profile scissor lifts:

- Full-perimeter electric toe guards create a safety barrier, stopping the lift if they detect obstructions

- Dead-man controls require continuous operator input for movement

- Velocity fuses prevent uncontrolled descent even if a hydraulic line fails

- IP54-rated electrical systems protect against dust and water splashes

- 24V DC control units provide safer low-voltage operation

- Trap prevention bars stop descent if they detect obstructions underneath

Material Options

Your working environment dictates the materials needed:

- Standard steel construction serves most general industrial applications

- Stainless steel construction for food processing, pharmaceutical facilities, and medical settings including mortuary preparation rooms

- ATEX-rated components for environments with explosion risks

- Marine-grade aluminum for settings where weight and corrosion resistance matter

Low Profile Scissor Lift Safety Mechanisms

Multiple layers of protection ensure safe operation:

Hydraulic safety features:

- Hose burst valves prevent sudden descent if a line fails

- Pressure relief valves protect against overloading

- Flow control valves ensure controlled descent regardless of load weight

- Mechanical locks provide positive securing during maintenance

Electrical safety features:

- Emergency stop buttons for immediate shutdown

- Photo-eye protection systems scan for objects in the lift path

- Safety interlocks prevent operation unless all safety conditions are met

- Low-voltage controls minimize electrical hazards

Physical safety elements:

- Maintenance props physically support the lift during service

- Safety tape switches along platform edges detect obstructions

- ANSI/ALI-compliant locks meet stringent safety standards

- Encapsulated rollers prevent tipping

Customization & Accessories

Low profile scissor lifts can be customized with accessories for specific applications:

- Oversized platforms for larger loads like oversized caskets

- Rotating tops with auto-transition plates for precision positioning

- Foot pedals for hands-free operation

- Remote controls for operation from a safe distance

- Limit switches for predetermined stop positions

- Portable rollers for repositioning within your facility

- Weather-proof enclosures for outdoor or wash-down environments

- Non-slip platform treatments for wet environments

For mortuary clients across the country, these customization options create the perfect lift solution for each unique facility. More info about scissor lift maintenance

Selecting the Right Low Profile Scissor Lift & Cost Considerations

Finding the perfect low profile scissor lift for your needs is straightforward when you focus on what matters most for your operation.

Capacity Requirements

These specialized lifts offer quite a range—from lightweight 500 lb models to heavy-duty 4,400 lb workhorses. Take your heaviest load (including handling equipment weight), add about 25% as a safety buffer, and you've got your minimum capacity requirement.

Platform Dimensions

Platforms typically range from compact 24"×48" designs to expansive 72"×72" surfaces. Consider your typical loads and available floor space. For funeral homes, platform dimensions are particularly important when handling caskets of varying sizes.

Vertical Travel Requirements

Most low profile scissor lifts offer vertical travel between 24.8" and 43.3", perfect for bringing materials to a comfortable working height. Consider your operators' ergonomic needs and whether the lift needs to interface with fixed-height equipment.

Power Source Options

Your facility's infrastructure will determine the best power solution:

- Standard 460V three-phase power for industrial applications

- Alternative voltage options (208V, 230V) and single-phase configurations

- Battery-powered units for areas with limited power access or where mobility is important

- Pneumatic systems for environments where electrical components might pose hazards

Total Cost of Ownership

A quality low profile scissor lift typically costs between $3,000 and $10,000+ depending on capabilities and materials. Consider the complete picture:

- Initial purchase cost

- Lower installation costs compared to pit-mounted alternatives

- Ongoing operational expenses

- Maintenance requirements

- Expected lifespan (typically 10+ years with proper care)

For mortuary clients, ROI calculation should include the value of dignified handling, reduced physical strain on staff, and operational reliability.

Key Questions Before Purchase

Before making your final decision, consider:

- What exactly will you be lifting? (weight, dimensions, open-bottom pallets)

- Where will you be using the lift? (environment requirements)

- What safety standards apply to your industry?

- Who will maintain the equipment?

- When do you need it? (lead time considerations)

- Is your facility situation stable? (leased premises vs. owned)

Cost, Installation & ROI

The financial advantages of choosing a low profile scissor lift become clear when comparing installation scenarios:

Traditional pit-mounted lifts require:

- Concrete cutting and removal ($1,000-$3,000)

- Pit construction with drainage ($2,000-$5,000)

- Permits and inspections ($500-$1,500)

- Facility downtime during construction

In contrast, a low profile scissor lift simply needs a flat, level surface, an electrical connection, and basic floor anchoring—saving $3,500-$9,500 plus reduced disruption.

Ongoing operational costs include electricity consumption from 0.75kW-1.1kW motors during operation, hydraulic fluid replacement every 2,000-3,000 cycles or annually, and routine quarterly maintenance.

The real payoff comes in productivity benefits: reduced manual handling time, decreased injury risk, improved workflow efficiency, and minimized downtime compared to alternatives.

Maintenance & Long-Term Performance

Proper maintenance of your low profile scissor lift protects your investment and ensures safety. Think of it as preventive medicine—a little attention now prevents costly problems later.

Routine Inspection Schedule

Daily visual checks: Have operators look for hydraulic fluid leaks, test safety features, and ensure smooth operation without strange noises.

Monthly maintenance: Lubricate pivot points and hinges, check hydraulic fluid levels, inspect electrical connections, and test safety mechanisms.

Quarterly service: Perform thorough cleaning, inspect structural elements, and verify all bolts and connections remain tight.

Annual professional inspection: Complete hydraulic fluid change, comprehensive safety certification, and load testing.

Lubrication and Hydraulic Fluid Management

Always use the hydraulic fluid specified by your manufacturer. Replace it annually or after every 2,000-3,000 cycles. Even with self-lubricating bushings in modern lifts, don't skip monthly lubrication for other moving parts.

Cleaning Protocols

Different parts need different cleaning approaches:

- For platform surfaces, use cleaners appropriate to the material

- Clean hydraulic components with appropriate solvents and lint-free cloths, not pressure washers

- For electrical controls, use compressed air to remove dust and specialized electrical contact cleaners

Professional Servicing

Professional technicians bring specialized knowledge that complements your maintenance program. Their expertise helps spot subtle issues before they become major problems. Professional servicing also creates documentation that protects your warranty and demonstrates safety compliance.

Spare Parts Management

Keep critical components on hand to prevent small issues from causing major downtime:

- Hydraulic seals and O-rings

- Control switches and fuses

- Common fasteners specific to your model

Develop a relationship with your supplier for quick access to less common parts when needed.

Troubleshooting Common Issues

Uneven lifting: First check if your load is centered properly. If the problem persists with properly centered loads, you likely have air in the hydraulic system or worn bushings.

Oil leaks: Place clean paper under suspected areas overnight to pinpoint the source. Tightening fittings often solves minor leaks, while persistent issues usually indicate seals that need replacement.

Control problems: Start with the basics—check power source and connections before assuming more complex issues.

Compliance & Record Keeping

Maintain detailed service logs tracking every maintenance activity, part replacement, and observation. Document operator training thoroughly. Keep certification renewals on your calendar with plenty of advance notice.

For more detailed guidance, check out this helpful guide on scissor lift maintenance from our experts at American Mortuary Coolers.

Frequently Asked Questions about Low Profile Scissor Lifts

What is the typical load capacity and platform size range?

These versatile lifts come in a wide range of options to fit almost any need:

Load capacity ranges:

- Light-duty models: 500-1,000 lbs

- Medium-duty options: 1,000-2,000 lbs

- Heavy-duty models: 2,000-4,400 lbs

Platform sizes:

- Compact platforms: 24"×48"

- Standard sizes: 36"×48" to 48"×60"

- Large platforms: up to 72"×72"

Many suppliers offer custom sizing for unique situations often encountered in funeral service facilities.

How does a low profile design improve ergonomics compared to pit-mounted lifts?

The ergonomic advantages of low profile scissor lifts include:

- Flexibility: Unlike pit-mounted lifts permanently fixed in one location, low profile units can be repositioned as needs change

- Staff safety: No pit edges that can become trip hazards

- Easier maintenance: No confined space procedures required for servicing

- Facility adaptability: Can move with you when reconfiguring spaces or relocating

Are stainless steel or ATEX low profile models available for specialized environments?

Absolutely! For preparation rooms and specialized environments, modified versions are available:

Stainless steel models feature:

- 304 or 316 grade stainless steel construction

- Sealed bearings and smooth surfaces that prevent bacterial harboring

- Food-grade hydraulic fluids

- Closed heights as low as 85-105mm

ATEX-certified models provide:

- Explosion-proof electrical components

- Non-sparking materials

- Grounding systems to prevent static electricity buildup

While both options come at a premium price point, funeral home clients consistently find them worth the investment for peace of mind, compliance, and professional appearance.

Conclusion

Traditional scissor lifts often require expensive pit installations that can be a real headache for facility managers. Low profile scissor lifts offer a practical solution with collapsed heights as slim as 40mm (just 1.57 inches!), allowing you to roll equipment directly onto the platform without construction work.

What makes these lifts truly special is how they transform your workspace. Your team can say goodbye to awkward bending and stretching that leads to back injuries. Plus, when your workflow changes, you can simply relocate these lifts to where they're needed most.

Here at American Mortuary Coolers, we understand that funeral homes have unique needs beyond typical industrial applications. The equipment you use must not only be functional but also support the dignity of your work. That's why we've developed low profile scissor lift solutions specifically designed for the funeral industry—equipment that combines reliability with respectful handling.

We're proud to be based in Tennessee, but our reach extends nationwide. Whether you're in the Northeast, Southwest, or anywhere in between, we deliver our custom solutions directly to your doorstep. From New York to Los Angeles, Chicago to Dallas—we've got you covered across the contiguous United States.

Our team specializes in creating custom mortuary coolers and related equipment that truly meets your needs. Each low profile scissor lift we provide is carefully selected to match your specific requirements, ensuring smooth operations while honoring the solemn nature of your work.

Choosing the right equipment isn't just about efficiency—it's about caring for your staff too. By investing in a properly configured low profile scissor lift, you're creating a workspace that reduces physical strain and helps prevent injuries, allowing your team to focus on providing compassionate service to families.

Ready to explore how a custom low profile scissor lift could improve operations at your funeral home? Contact us at American Mortuary Coolers today. Our friendly experts will guide you through the options and help you find the perfect solution—one that improves both safety and dignity in your daily operations.