Understanding the Critical Role of Dead Body Preservation

When a loved one passes away, time stands still for the family—but not for natural processes. This is where a dead body morgue freezer becomes essential. These specialized units aren't just refrigerators; they're guardians of dignity during life's most sensitive transition.

A dead body morgue freezer maintains temperatures between -10°C and -20°C (-4°F to 14°F), creating an environment where decomposition slows dramatically. For funeral directors, medical examiners, and hospital staff, these units provide the precious gift of time—time for families to say goodbye, for medical examinations to be completed, or for funeral arrangements to be finalized.

| Feature | Details |

|---|---|

| Purpose | Preservation of human remains |

| Temperature Range | -10°C to -20°C (-4°F to 14°F) |

| Common Types | Single-body, multi-body (2-8), walk-in (5-50 bodies) |

| Key Materials | Stainless steel 304, polyurethane insulation |

| Standard Features | Digital temperature control, audio-visual alarms, seamless interiors |

| Typical Preservation Time | 6 hours to several weeks depending on temperature |

Beyond the technical specifications, these preservation systems serve a deeply human purpose. They prevent odor development, maintain the condition of remains for identification, and ensure the deceased remains in appropriate condition for viewing or scientific examination. They help maintain the final physical dignity of someone's father, mother, sister, or brother.

For funeral professionals balancing practical considerations with compassionate care, selecting the right unit involves thoughtful evaluation of capacity requirements, available space, and budget constraints. The goal remains consistent: providing reliable, respectful preservation that honors the deceased while supporting the bereaved.

I'm with American Mortuary Coolers, where we've spent years designing and delivering custom preservation solutions nationwide. We understand that behind every technical specification is a human story—which is why we approach each installation with both technical precision and genuine compassion.

You might also hear these units referred to by various industry terms including "mortuary refrigerator," "body box," "cadaver freezer," or "cold chamber." Whatever the terminology, their purpose remains constant: preserving dignity through proper care.

For those looking to learn more about the broader context of mortuary care, explore our resources on embalming supplies, connect with reputable mortuary equipment suppliers, or find options for larger facilities in our guide to walk-in body refrigerators.

What Is a Dead Body Morgue Freezer?

A dead body morgue freezer is specialized refrigeration equipment designed specifically for the preservation of human remains. Unlike your kitchen freezer, these units maintain precise low temperatures that significantly slow the natural decomposition process that begins immediately after death.

The primary purpose of these specialized units is preserving the deceased with dignity while awaiting identification, autopsy, funeral preparation, or final disposition. By maintaining temperatures well below standard refrigeration, these freezers effectively halt bacterial growth and enzymatic processes that lead to tissue breakdown.

"At American Mortuary Coolers, we understand that our freezers aren't just equipment—they're essential tools that provide families the time they need for proper goodbyes," says our head of product development. "Every unit we design focuses on both technical performance and the human element of afterlife care."

Depending on a facility's specific needs, dead body morgue freezers can preserve remains for periods ranging from a few days to several weeks. This extended preservation window becomes crucial for forensic investigations, when family members need to travel from distant locations, or when legal issues require delayed disposition.

Alternate Names You'll Hear in the Industry

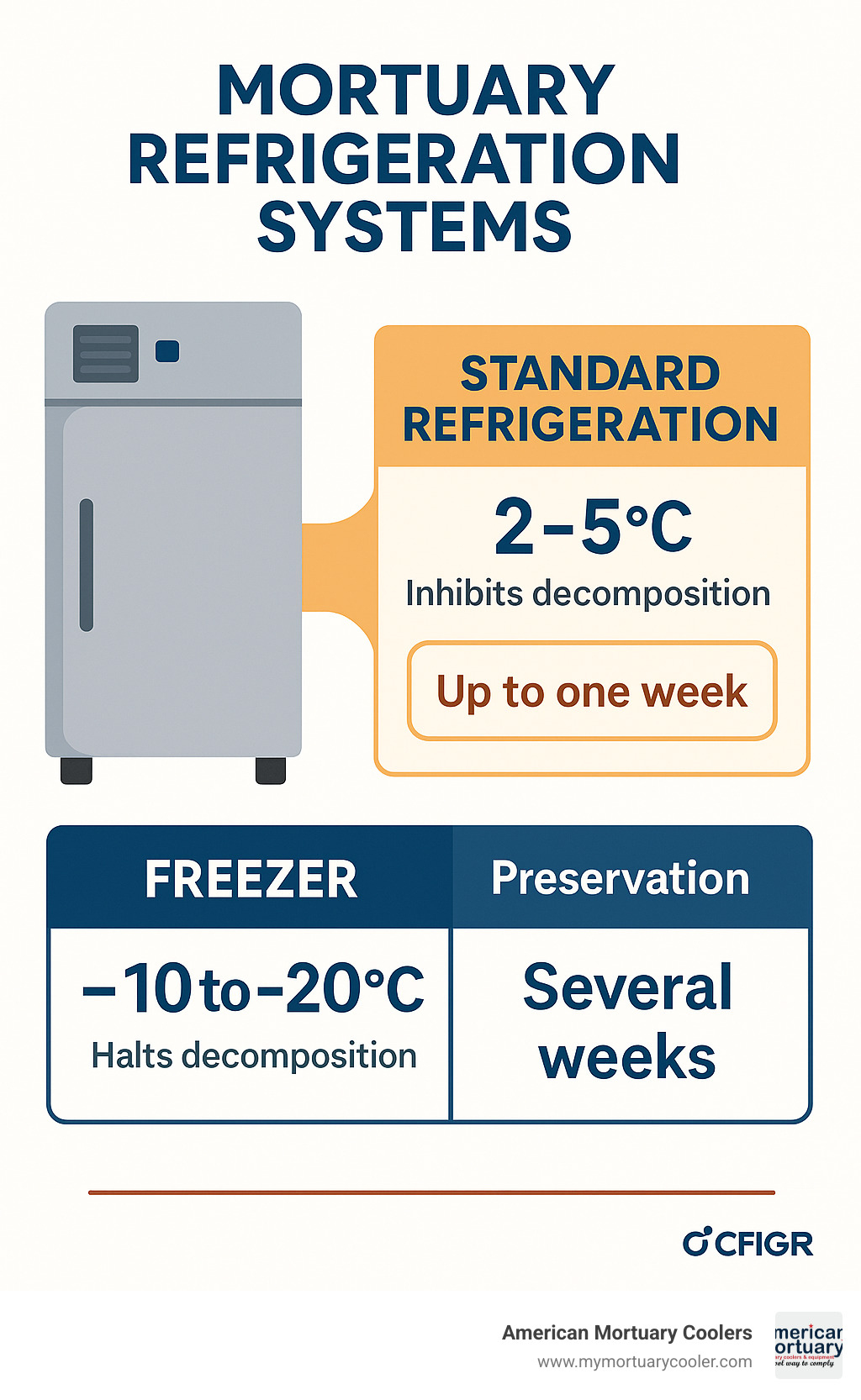

The funeral and medical industries use several terms when referring to dead body morgue freezers. You might hear them called mortuary refrigerators (though technically these operate at slightly higher temperatures of 2-4°C), body boxes (smaller, self-contained units for one to four bodies), cadaver freezers (common in medical and educational settings), cold chambers (typically walk-in units designed for multiple bodies), or mortuary cabinets (upright units with horizontal compartments).

These terms often overlap, and you'll find regional preferences dictate which terminology is most commonly used in different parts of the country. Understanding these variations helps when researching options or communicating with industry professionals.

How a Dead Body Morgue Freezer Preserves Tissue

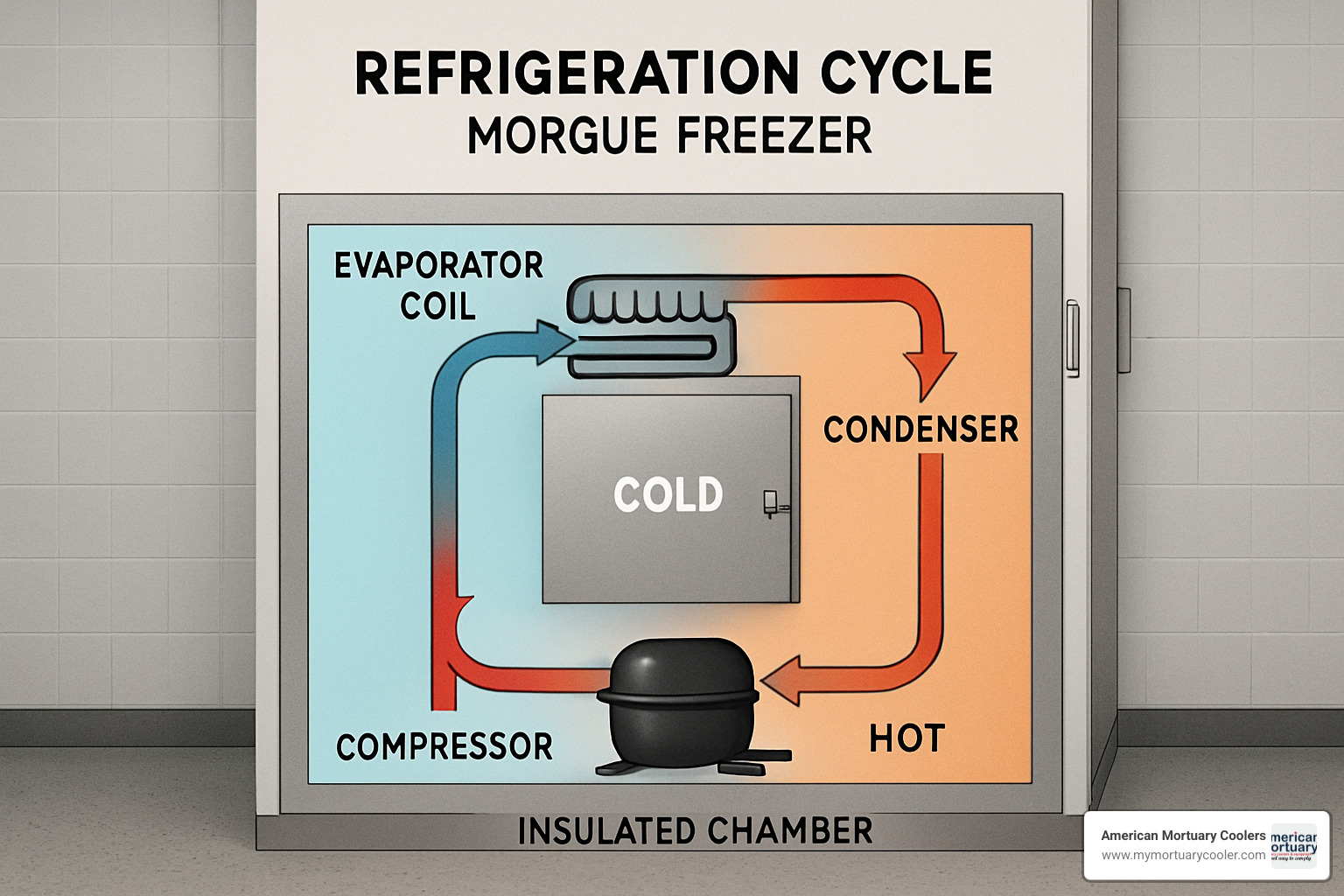

The science behind dead body morgue freezers isn't just about making things cold—it involves sophisticated refrigeration technology specifically calibrated for human tissue preservation.

The magic happens through several key components working in harmony. Evaporator coil systems inside the cabinet contain refrigerant that absorbs heat from the interior space. High-quality morgue freezers use what we call a "cold wall evaporator design" where 100% of the evaporator contacts the freezer walls, ensuring even cooling throughout—no hot spots or uneven preservation.

The compressor cycle serves as the heart of the system, pressurizing refrigerant gas and beginning the heat transfer process. Premium units use commercial-grade compressors designed for continuous duty, because reliability is non-negotiable when preserving human remains.

Most dead body morgue freezers maintain temperatures between -10°C and -20°C (14°F to -4°F). This range isn't arbitrary—it represents the sweet spot where bacterial growth halts, enzymatic processes slow significantly, and cell rupture due to ice crystal formation stays minimal. As our refrigeration experts often explain, "This temperature range represents the optimal balance between preservation effectiveness and energy consumption. Go warmer, and decomposition accelerates; go colder, and you face diminishing returns with substantially higher operating costs."

Modern units feature digital microprocessor controls for careful temperature regulation, ensuring remains stay in the best possible condition while minimizing energy use. Many advanced models include independent refrigeration systems for each chamber, allowing customized temperature settings and ensuring that a mechanical failure in one section doesn't compromise the entire unit.

For more detailed information about optimal temperatures, check out Morgue Freezer Temperature 101: How Cold is a Morgue Freezer.

Core Components & Materials Inside Every Unit

When we talk about what makes a dead body morgue freezer truly reliable, it all comes down to what's inside. At American Mortuary Coolers, we've spent years perfecting our designs based on real-world experience and feedback from funeral professionals across the country.

The heart of every quality morgue freezer starts with stainless steel 304 construction. This isn't your everyday stainless steel – it's medical-grade material specifically chosen for its remarkable ability to resist corrosion while standing up to years of cleaning with harsh disinfectants. The smooth, non-porous surface doesn't just look professional – it actively prevents bacteria from finding places to hide.

Keeping the cold in (and the heat out) is the job of high-density polyurethane foam insulation. This remarkable material is the unsung hero of energy efficiency in our units. According to scientific research on insulation R-value, PUF insulation delivers approximately R-7 per inch – substantially better thermal performance than most alternatives. This means consistent temperatures with less energy consumption.

"The difference between a good morgue freezer and a great one often comes down to the insulation quality," shares our lead engineer. "When a facility runs their unit 24/7/365, even small efficiency improvements translate to significant savings."

Temperature precision matters tremendously in our industry, which is why we incorporate digital microprocessor controllers that maintain temperatures within a single degree of your set point. Many of our models include data logging capabilities – increasingly important for regulatory compliance and quality assurance programs.

The humble door gasket might seem like a minor component, but these heavy-duty magnetic seals create the airtight environment necessary for temperature stability. We use specialized medical-grade materials that maintain flexibility even when temperatures plummet to -20°C, ensuring a perfect seal year after year.

For multi-body units, our independent refrigeration chambers represent a significant advancement over older designs. Each compartment functions with its own cooling system, allowing for individual temperature control when needed. This redundancy also means that if one section experiences an issue, the others continue operating normally – a crucial safeguard when preserving human remains.

Proper visibility is essential during transfers and inspections, which is why we integrate vapor-proof LED lighting in all our units. These energy-efficient fixtures are specifically engineered to function flawlessly in freezing environments while providing the illumination staff need to work safely and respectfully.

Hygiene & Contamination Prevention Features

When caring for the deceased, maintaining impeccable hygiene isn't just about regulations – it's about dignity and respect. Modern dead body morgue freezers incorporate thoughtful design elements that make sanitation simpler and more effective.

Seamless welded interiors represent a significant improvement over older mechanical joints. By eliminating the cracks and crevices where biological material could accumulate, these continuous surfaces create an environment that's genuinely cleanable. Our welding techniques ensure smooth transitions between surfaces – no rough edges or hidden corners.

Many of our premium models feature antimicrobial surface treatments that work continuously between cleanings. These specialized coatings use ion technology to actively inhibit bacterial growth on contact surfaces, providing an additional layer of protection for staff and remains.

"We design our units thinking about the people who clean them," explains our product development team. "Anything that makes that job easier or more effective is worth including."

Proper fluid management is essential in mortuary environments, which is why we incorporate strategically designed drain pans that channel any liquids away from storage areas while preventing cross-contamination. These systems include removable components for thorough cleaning – a small detail that makes a big difference for maintenance staff.

For facilities with improved biosecurity requirements, optional UV sterilization systems provide additional pathogen control during unoccupied periods. In walk-in units, we often include sloped interior floors that gently direct any fluids toward drains, eliminating pooling and potential contamination issues.

Energy & Safety Systems You Must Check

A dead body morgue freezer represents a significant investment, and smart buyers look beyond the purchase price to consider long-term operating costs and safety features. These systems directly impact your bottom line while protecting your staff and facility.

Low-ambient controls allow your refrigeration system to function efficiently even when environmental conditions fluctuate – particularly important for units installed in uncontrolled spaces or outdoor locations. This specialized technology adjusts operational parameters based on ambient conditions, maintaining optimal performance year-round.

Comprehensive multi-point alarm systems provide peace of mind through continuous monitoring. Modern systems include high/low temperature alerts with both visual and audible signals, door-ajar warnings to prevent temperature loss, and power failure notifications. Many of our models offer optional remote monitoring capabilities, allowing staff to receive alerts via text or email 24/7.

Staff safety is non-negotiable, which is why all walk-in units include OSHA-compliant release handles that allow anyone accidentally locked inside to exit immediately, even if the door is locked from the outside. This simple but critical feature has been mandatory for decades, but the quality and reliability of these mechanisms vary significantly between manufacturers.

Environmental responsibility matters too. Today's premium units use environmentally friendly refrigerants like R-134a or R-404A that comply with regulations while providing efficient cooling. The refrigerant choice affects not just environmental impact but also long-term serviceability as older formulations become increasingly restricted.

For facilities in areas prone to power outages, backup power compatibility is essential. Properly designed units can transition seamlessly to generator power without temperature fluctuations that could compromise preservation. We recommend discussing your backup power configuration with our team to ensure complete compatibility.

"When evaluating morgue freezers, think beyond the showroom appearance," advises our service director. "It's the systems you don't immediately see – the compressor quality, the control board reliability, the backup systems – that determine whether your unit will still be performing flawlessly a decade from now."

Types & Configurations of Morgue Freezers

When it comes to preserving the deceased with dignity, one size definitely doesn't fit all. The funeral industry offers a diverse range of dead body morgue freezer options to meet the unique needs of different facilities. From small funeral homes to major metropolitan hospitals, each organization has specific requirements that influence their ideal configuration.

At American Mortuary Coolers, we've seen how the right freezer makes all the difference in daily operations. Single-body units provide compact, plug-and-play solutions for smaller facilities with occasional needs. These self-contained units require minimal space while delivering reliable preservation when needed. They're perfect as backup systems or for facilities that rarely need extended preservation capabilities.

For those needing more capacity without sacrificing floor space, multi-tier cabinets offer an excellent middle ground. These vertical configurations house 2-8 horizontal compartments with individual access doors, making them incredibly space-efficient while maximizing storage capacity. The separate doors also help maintain temperature stability, as only one compartment is exposed during access.

Larger operations often gravitate toward walk-in freezers, which can accommodate anywhere from 5 to 50 bodies depending on the interior layout. These spacious units allow staff to enter the refrigerated environment, making body management more efficient for high-volume facilities. Though they require more significant installation efforts, they're the workhorses of busy medical examiners' offices and major funeral homes.

Roll-in units have become increasingly popular for their ergonomic advantages. With wide doors and gentle ramps, these freezers allow gurneys or trolleys to be rolled directly into the cooling space. This design eliminates the physical strain of transferring bodies, reducing staff injury risk while treating the deceased with greater dignity.

| Type | Capacity | Footprint | Best For | Installation Complexity |

|---|---|---|---|---|

| Single-Body | 1 | Small | Backup or occasional use | Low (plug & play) |

| Multi-Tier | 2-8 | Medium | Space-constrained facilities | Medium |

| Walk-In | 5-50 | Large | High-volume operations | High (often requires construction) |

| Mobile | 2-12 | Variable | Disaster response, multi-site service | Low (requires towing capability) |

"The configuration you choose should reflect both your current needs and where you'll be in five years," explains our design team at American Mortuary Coolers. "We often see facilities outgrow their initial units much faster than expected. Thinking ahead can save significant costs down the road."

For specialized needs, we also offer bariatric-specific models with reinforced trays and wider compartments. These thoughtfully designed units accommodate larger individuals with dignity – an increasingly important consideration in modern facilities. And for truly unique situations, our custom builds address unusual spaces or specialized applications that standard configurations simply can't handle.

Dead Body Morgue Freezer Options for Hospitals

Hospitals face unique challenges when selecting dead body morgue freezers. Their institutional setting, strict regulatory environment, and established workflows all influence the ideal preservation solution.

Many hospitals appreciate our plug-and-play body boxes that require only a standard electrical outlet. These self-contained units eliminate the need for specialized installation or drainage systems, making them perfect for smaller facilities or as supplemental capacity during unexpected surges.

Side-loading configurations have become the preferred choice for many hospital morgues. These designs align naturally with established transfer protocols, allowing bodies to be moved directly from gurneys to the refrigerated compartment with minimal lifting. This thoughtful design reduces staff strain while treating the deceased with appropriate care.

We've found that specialized stretcher trays make a world of difference in daily operations. Our hospital-oriented units feature reinforced, full-extension trays that glide smoothly even under load. This seemingly small detail significantly improves ergonomics for staff who manage multiple transfers daily.

Forward-thinking hospital administrators often select our modular expansion systems. These clever designs allow capacity to grow alongside the facility without requiring complete replacement. By adding compatible units over time, hospitals can scale their preservation capabilities in step with their overall growth.

For sophisticated facilities, we offer morgue freezers with building management system integration. These advanced units connect to centralized monitoring platforms for seamless temperature tracking, automated alarming, and optimized energy management – bringing mortuary operations into the modern era of facility management.

Dead Body Morgue Freezer Solutions for Disaster Response

When disaster strikes, preserving the deceased with dignity becomes an urgent logistical challenge. At American Mortuary Coolers, we've developed specialized dead body morgue freezer solutions that address these critical situations with compassion and efficiency.

Our mobile refrigeration units have become essential tools in emergency management. These trailer-mounted systems can be rapidly deployed to disaster sites, providing immediate preservation capacity without permanent infrastructure. Within hours of arrival, these units can be operational and preserving remains – a crucial capability when time is of the essence.

All our disaster response units feature generator-ready electrical systems. This thoughtful design ensures reliable operation even when local power infrastructure has been compromised. The compatible systems seamlessly transition between utility power and generator support without risking temperature fluctuations.

We've intentionally simplified setup procedures on our emergency units. The quick-deployment protocols allow personnel with minimal specialized training to make these systems operational. This practical approach recognizes that technical staff may be limited during crises, ensuring preservation capabilities aren't delayed by staffing constraints.

For large-scale events, our modular designs allow multiple units to link together, creating expanded capacity as needs evolve. This scalable approach has proven invaluable during pandemic surges and natural disasters when requirements can change rapidly and unpredictably.

The challenging environments often encountered during disaster response demand extra durability. Our ruggedized construction includes reinforced components and comprehensive weatherproofing to ensure reliable operation even in difficult conditions. From hurricane recovery efforts to temporary morgue expansions during COVID-19, these specialized units have helped communities manage overwhelming circumstances with dignity.

As noted by Polar Leasing, a provider of temporary refrigeration solutions, "The ability to quickly deploy appropriate refrigeration is often a critical factor in managing mass casualty events. Rental units specifically designed for mortuary use can bridge the gap until permanent solutions are established."

Critical Features to Compare Before You Buy

When it's time to select a dead body morgue freezer, you're making a significant investment in your facility's future. This isn't just another equipment purchase—it's a decision that impacts your daily operations, staff safety, and the dignity of those in your care.

Let's walk through the features that truly matter, so you can feel confident in your choice:

Temperature precision is your first priority. The best units maintain temperatures within ±1°C of your setpoint—not just in one spot, but throughout the entire chamber. Think of it as the difference between a basic home freezer that develops frost in corners and a precision instrument that keeps every inch at the perfect temperature.

"I've seen facilities struggle with units that swing 3-4 degrees in either direction," says our lead technician. "That kind of fluctuation accelerates tissue degradation and creates unnecessary stress for staff who constantly monitor readings."

Independent compressor systems are worth every penny in multi-compartment units. When each chamber has its own refrigeration system, you gain incredible flexibility and peace of mind. If one system needs maintenance, the others keep running—protecting the dignity of those in your care without interruption.

The body support systems might seem like a minor detail until you're using them daily. Premium trays glide smoothly even when fully loaded with 150kg or more, reducing staff strain and preventing those jarring moments when cheaper slides stick or catch. Your team will thank you for this feature every single day.

Loading assistance becomes increasingly important as our population changes. Features like reinforced ramps, properly designed lifts, and ergonomic transfer devices protect both your staff and the deceased from the risks of manual transfers. Some of our newest models include powered lift assistance specifically designed for bariatric cases—a thoughtful touch that shows respect for all individuals.

When comparing warranty coverage, look beyond the years to the specifics. Quality manufacturers stand behind their products with comprehensive protection: 15 years on structural elements like panels and doors, 5 years on mechanical components, and 1-2 years of labor coverage. If a supplier offers significantly less, it might signal their lack of confidence in their own equipment.

Financing options can transform how you approach this purchase. Rather than stretching your current budget or settling for less than ideal equipment, the right financing plan allows you to select the perfect unit while spreading costs over its useful life.

As noted in The Complete Guide to Comparing Mortuary Refrigeration Systems, "The sticker price is just the beginning of the story. Over a decade of operation, energy efficiency and reduced maintenance needs often make premium units the more economical choice."

Construction Materials & Durability Checklist

The materials used in your dead body morgue freezer tell a story about how long it will serve your facility and how well it will perform under pressure.

For exterior construction, you have meaningful choices. Fiberglass reinforced plastic (FRP) shines in outdoor settings where weather resistance matters. Powder-coated galvanized steel delivers solid performance for indoor units at a more accessible price point. For those seeking the ultimate in longevity and professional appearance, 304 stainless steel exteriors remain the gold standard—they'll look as good after a decade as they did on delivery day.

Inside is where material choices truly impact your daily experience. 304 stainless steel interiors aren't just about appearance—they create a non-porous surface that's easily sanitized and resistant to the harsh cleaning agents necessary in mortuary settings. Seamless construction eliminates those troublesome joints where fluids and contaminants could gather, while coved corners make thorough cleaning straightforward even during busy periods.

Don't overlook the door components that endure constant use. Heavy-duty hinges rated for 100,000+ cycles ensure smooth operation for years, while diamond-tread kick plates protect vulnerable lower door areas from damage during gurney transfers. The magnetic gaskets seem simple but play a crucial role—they need to maintain flexibility even at freezing temperatures to create a perfect seal every time.

"The difference between economy and premium units isn't always visible at first glance," shares our service department manager with a knowing smile. "But around year three, when economy units start showing wear and requiring frequent service calls, the wisdom of investing in quality materials becomes crystal clear."

Lighting systems need special consideration in cold environments. Vapor-proof LED fixtures provide reliable illumination where traditional lighting might fail, while exterior switches with indicator lights help staff confirm status at a glance. Automatic shut-off features prevent those energy-wasting situations where lights remain on unnecessarily.

Flooring considerations round out your durability assessment. Reinforced floors capable of supporting fully loaded gurneys prevent sagging and damage, while slip-resistant surfaces protect staff during transfers. If you need roll-in capability, integral ramps with proper slope and surface texture make the difference between smooth operations and daily frustrations.

Regulatory & Certification Must-Haves

In mortuary equipment, compliance isn't optional—it's essential for protecting your facility, your staff, and your reputation. When evaluating a dead body morgue freezer, ensure it meets these critical standards:

NSF Certification provides verification that your unit meets strict standards for materials, design, and construction. While originally focused on food service equipment, these certifications apply to mortuary refrigeration due to similar concerns about sanitation and public health. This third-party validation offers peace of mind that your equipment meets recognized industry benchmarks.

UL Listing focuses on electrical safety, confirming that components meet standards designed to reduce fire and electrical hazards. This certification is particularly important for equipment operating continuously in environments where staff might not always be present to respond to issues.

OSHA Compliance addresses workplace safety concerns, with particular emphasis on emergency release mechanisms in walk-in units. These features ensure that staff can exit immediately if accidentally enclosed, preventing potentially dangerous situations.

Different states have varying requirements for mortuary refrigeration, so confirming State Health Code Compatibility is essential before purchase. Our team at American Mortuary Coolers stays current with regulations nationwide, helping you steer these requirements with confidence.

The Energy Independence & Security Act established minimum efficiency standards for walk-in coolers and freezers. Compliance with these standards not only ensures legal operation but typically results in lower operating costs over the equipment's lifetime.

"I always tell our clients that regulatory compliance isn't about checking boxes—it's about creating a foundation of safety and reliability," explains our compliance officer. "When you choose properly certified equipment, you're investing in operational peace of mind."

At American Mortuary Coolers, we design and manufacture all our units to exceed these regulatory requirements. This attention to compliance simplifies your approval processes and provides confidence that your equipment will meet both current standards and anticipated future regulations.

Installation, Maintenance & Emerging Innovations

Proper installation and ongoing maintenance are critical to maximizing the lifespan and performance of your dead body morgue freezer. Additionally, staying informed about emerging technologies can help you make forward-thinking decisions when upgrading your equipment.

Installation Considerations:

Getting your morgue freezer installed correctly makes all the difference in how it performs over time. Think of it like building a house - the foundation matters tremendously.

First, you'll need to ensure your floor preparation is adequate. Most units require level, reinforced flooring that can support not just the empty unit but the combined weight when fully loaded. For larger walk-in freezers, we often recommend consulting with a structural engineer to verify your floor can handle the load.

Proper ventilation around your unit is non-negotiable. I've seen too many facilities try to squeeze units into tight spaces without adequate airflow. Your condensing unit needs to breathe - typically 12-18 inches of clearance around heat-rejection components. Without this, you're essentially asking your freezer to work in a sauna, dramatically shortening its lifespan.

"I once visited a funeral home where they'd tucked their unit into a closet with barely an inch of clearance," recalls our installation manager. "Their electric bill was through the roof, and the unit failed after just three years. Proper installation would have saved them thousands."

Your electrical service needs careful attention too. Many of our larger units require dedicated circuits or three-phase power. Having your electrician verify compatibility before delivery prevents the frustration of having your new equipment sitting unusable while electrical upgrades are made.

Don't overlook drainage planning. While our newer models feature self-contained condensate management, connecting to proper drainage prevents potential water damage and compliance headaches down the road.

Finally, measure your access routes carefully. Nothing's more frustrating than finding on delivery day that your unit won't fit through the hallway or doorway. For larger units, we can often coordinate partial assembly on-site, but knowing these challenges in advance makes installation day go smoothly.

Maintenance Best Practices:

Taking care of your dead body morgue freezer isn't complicated, but consistency is key. Think of it like maintaining your car - regular attention prevents unexpected breakdowns.

Daily monitoring is your first line of defense. A quick temperature check and visual inspection each morning can catch small issues before they become emergencies. Our newer models feature digital displays that make this process simple, but even older units should have functional thermometers that staff check regularly.

Your unit's defrost schedule plays a crucial role in maintaining efficiency. Ice buildup on evaporator coils acts like a blanket, making your unit work harder to maintain temperature. Most modern controllers allow customized defrost timing based on your specific usage patterns and ambient conditions.

Developing clear cleaning protocols keeps your unit sanitary and functional. We recommend a two-tier approach: daily wipe-downs of handles and frequently touched surfaces, combined with deeper cleaning on a scheduled basis. Always use cleaners approved for food-grade stainless steel to prevent corrosion or damage to your unit's surfaces.

Scheduling professional preventive maintenance is perhaps the most important step. Just like you wouldn't skip oil changes in your car, regular professional service (typically 2-4 times annually) keeps your freezer running at peak efficiency. Our technicians check refrigerant levels, test electrical components, and calibrate controllers during these visits.

As noted in Chilling Facts About Mortuary Coolers, "The mortuary refrigeration industry is experiencing rapid technological advancement driven by increased energy efficiency requirements and the digital change of facility management."

Extending Service Life of Your Dead Body Morgue Freezer

With proper care, a quality dead body morgue freezer from American Mortuary Coolers can serve your facility reliably for 15-20 years or more. Here's how to maximize your investment:

Pay special attention to your door gaskets. They're the unsung heroes of your freezer's efficiency. Clean them regularly with mild soap and water, and check for signs of wear like cracking, flattening, or reduced magnetic holding power. Replacing gaskets at the first sign of deterioration is far less expensive than dealing with the increased energy costs and potential temperature fluctuations.

Consider implementing data logging if your controller supports it. This valuable information helps identify subtle performance changes that might indicate developing issues. Many of our newer models include this feature standard, but retrofit options exist for older units.

"The most expensive service call is the one that could have been prevented," says our service department manager. "I've seen $15,000 repairs that started as $200 gasket replacements that nobody noticed needed attention."

Professional inspections provide peace of mind and catch issues invisible to the untrained eye. Our technicians bring specialized tools to check refrigerant pressure, test electrical components, assess compressor performance, and verify control system calibration. Think of these visits as an investment, not an expense.

Future Trends Worth Watching

The dead body morgue freezer industry continues to evolve with exciting innovations that promise better performance, efficiency, and environmental responsibility.

Eco-friendly refrigerants are becoming increasingly important as regulations phase out traditional options with high global warming potential. At American Mortuary Coolers, we're already transitioning to next-generation refrigerants that provide excellent cooling performance with dramatically reduced environmental impact.

The rise of smart IoT sensors is changing how facilities monitor their equipment. Internet-connected systems provide real-time alerts, remote temperature adjustment, and comprehensive data logging for both quality assurance and regulatory compliance. Imagine getting a text message if your unit's temperature begins to drift, long before it becomes a critical issue.

Modular panel systems represent another significant advancement. These innovative designs not only simplify installation but also allow for future expansion and provide superior energy efficiency through better insulation properties. For growing facilities, this modularity can be a game-changer.

Several exciting technologies are on the horizon, including solar-assisted cooling systems that incorporate renewable energy to offset consumption, particularly valuable for disaster response units. AI temperature prediction algorithms that learn usage patterns to optimize compressor cycles are beginning to appear in premium units. Even 3D-printed custom racks are becoming available, allowing for storage solutions precisely custom to your facility's unique needs.

"While the fundamental purpose of morgue freezers remains unchanged, how we achieve that purpose continues to advance through technological innovation," notes our research director. "Facilities planning equipment upgrades would be wise to consider these emerging technologies in their decision-making process."

At American Mortuary Coolers, we're committed to staying at the forefront of these innovations while maintaining the reliability and durability our customers depend on. After all, in our industry, dependable performance isn't just about convenience—it's about preserving dignity in the most challenging circumstances.

Frequently Asked Questions about Morgue Freezers

How long can a body stay in a morgue freezer?

When families ask me this question, I always emphasize that it depends on several important factors. A dead body morgue freezer operating at standard temperatures between -10°C and -20°C can preserve remains for several weeks to months with minimal deterioration.

I've worked with forensic facilities that maintain even lower temperatures (around -25°C to -30°C) when they need extended preservation that can last for many months. This is particularly important for unidentified remains or cases involving complex legal proceedings.

That said, I always remind our clients that freezing isn't meant to be permanent. Even in the best conditions, subtle changes will occur over time. I remember consulting with a county medical examiner who put it perfectly: "Freezing essentially presses pause on biological processes without stopping them completely. And how quickly cooling begins after death makes a tremendous difference in preservation quality."

For situations requiring truly extended preservation, I typically recommend consulting with a forensic specialist who can recommend specialized protocols custom to your specific needs.

What temperature range is standard for cadaver storage?

Over my years in the industry, I've seen consistent standards emerge for dead body morgue freezer temperature ranges based on preservation needs:

For short-term storage (typically 3-10 days), standard refrigeration between 2°C and 4°C (35°F to 39°F) is usually sufficient. This is what many funeral homes use when preparation will happen relatively quickly.

Medium-term storage calls for true freezer conditions between -10°C and -20°C (14°F to -4°F). This is the most common range we install in our morgue freezers at American Mortuary Coolers, as it provides weeks of reliable preservation for most situations.

For specialized long-term needs, particularly in forensic or research settings, deep freezing between -25°C and -30°C (-13°F to -22°F) provides extended preservation capabilities.

The quality units we build maintain temperatures within ±1°C of the setpoint, ensuring consistent conditions throughout the preservation period. As I often tell our clients, "Your temperature choice isn't just about how long you'll store remains—it's about the specific purpose of preservation." A body awaiting identification requires different conditions than one being prepared for a funeral service later in the week.

Are morgue freezers energy efficient compared to regular freezers?

This is a question I hear frequently from facility managers concerned about operating costs. The truth is that dead body morgue freezers have a different efficiency profile than standard commercial freezers for several important reasons.

First, the insulation quality makes a significant difference. The units we build at American Mortuary Coolers feature premium insulation with R-values between 25-30 for walls, substantially better than many standard commercial freezers. This superior insulation pays dividends in energy retention.

The usage pattern also works in favor of morgue freezers. Unlike food service freezers that might be opened dozens of times daily, morgue units experience fewer door openings and maintain more stable thermal loads. I've seen this translate to meaningful efficiency gains in real-world operation.

There is a tradeoff, however. Morgue freezers prioritize absolutely precise temperature control over maximum efficiency. Sometimes maintaining exact conditions requires additional energy, but it's essential for proper preservation.

Size also matters significantly. The larger walk-in units we install generally achieve better efficiency per cubic foot than smaller compartmentalized units, simply due to favorable surface-area-to-volume ratios. It's basic thermodynamics at work.

I'm proud to say that today's well-designed dead body morgue freezers typically consume 30-50% less energy than models from just 20 years ago. This improvement comes from advances in insulation technology, more efficient compressors, and sophisticated digital controls.

When helping clients evaluate energy efficiency, I always encourage them to look beyond the specifications on paper. "Your facility's ambient conditions and specific usage patterns matter tremendously," I explain. "The unit that's most efficient in a lab test might not deliver the best performance in your unique environment."

Conclusion

Selecting the right dead body morgue freezer is one of the most important decisions any funeral home, hospital, or forensic facility will make. These aren't just mechanical units that keep things cold – they provide families with precious time for meaningful goodbyes, support your staff's commitment to dignified care, and keep you on the right side of regulatory requirements.

Here at American Mortuary Coolers, we've built our reputation by listening to what funeral professionals actually need, then crafting custom, durable solutions that address those specific challenges. One thing that sets us apart is our nationwide delivery network – we ensure that clients across all 48 contiguous states receive properly installed, fully operational equipment without the headaches that come with third-party shipping arrangements.

When you're weighing your options for a new morgue freezer, keep these essential considerations in mind:

Capacity Planning: Think beyond your current needs to what your facility might require 3-5 years from now. The most expensive morgue freezer is the one you outgrow too quickly.

Quality Construction: The difference between economy and premium units becomes dramatically apparent around year five. Investing in quality materials and components now means reliable service for decades.

Regulatory Compliance: Peace of mind comes from knowing your equipment exceeds all applicable standards – not just meets minimum requirements.

Energy Efficiency: The purchase price is just the beginning. A well-designed unit with proper insulation and modern components will deliver significant savings over its lifetime.

Support and Service: Even the best equipment eventually needs maintenance. Choose a provider who answers the phone when you call and has technicians who understand the unique demands of mortuary refrigeration.

The preservation of human remains is a profound responsibility that touches families at their most vulnerable moments. By selecting a thoughtfully designed and expertly manufactured dead body morgue freezer, you demonstrate your unwavering commitment to excellence in every aspect of your professional practice.

We'd welcome the opportunity to discuss your facility's specific needs. With locations across the country—including Johnson City TN, Atlanta GA, Chicago IL, Columbia SC, Dallas TX, Los Angeles, New York NY, and Pittsburgh PA—we've positioned ourselves to provide responsive, personalized service throughout the United States.

For more information about our leading morgue coolers and to discuss how we can help with your specific preservation needs, please visit More info about our leading morgue coolers.