When Your Cooling System Fails: Understanding Emergency Cold Storage

Emergency cold storage solutions provide immediate refrigeration when your primary cooling systems fail or when unexpected situations demand rapid temperature control. These mobile, temporary units maintain critical temperatures for perishable goods, vaccines, and other temperature-sensitive materials during power outages, equipment breakdowns, or disaster situations.

Key Emergency Cold Storage Solutions:

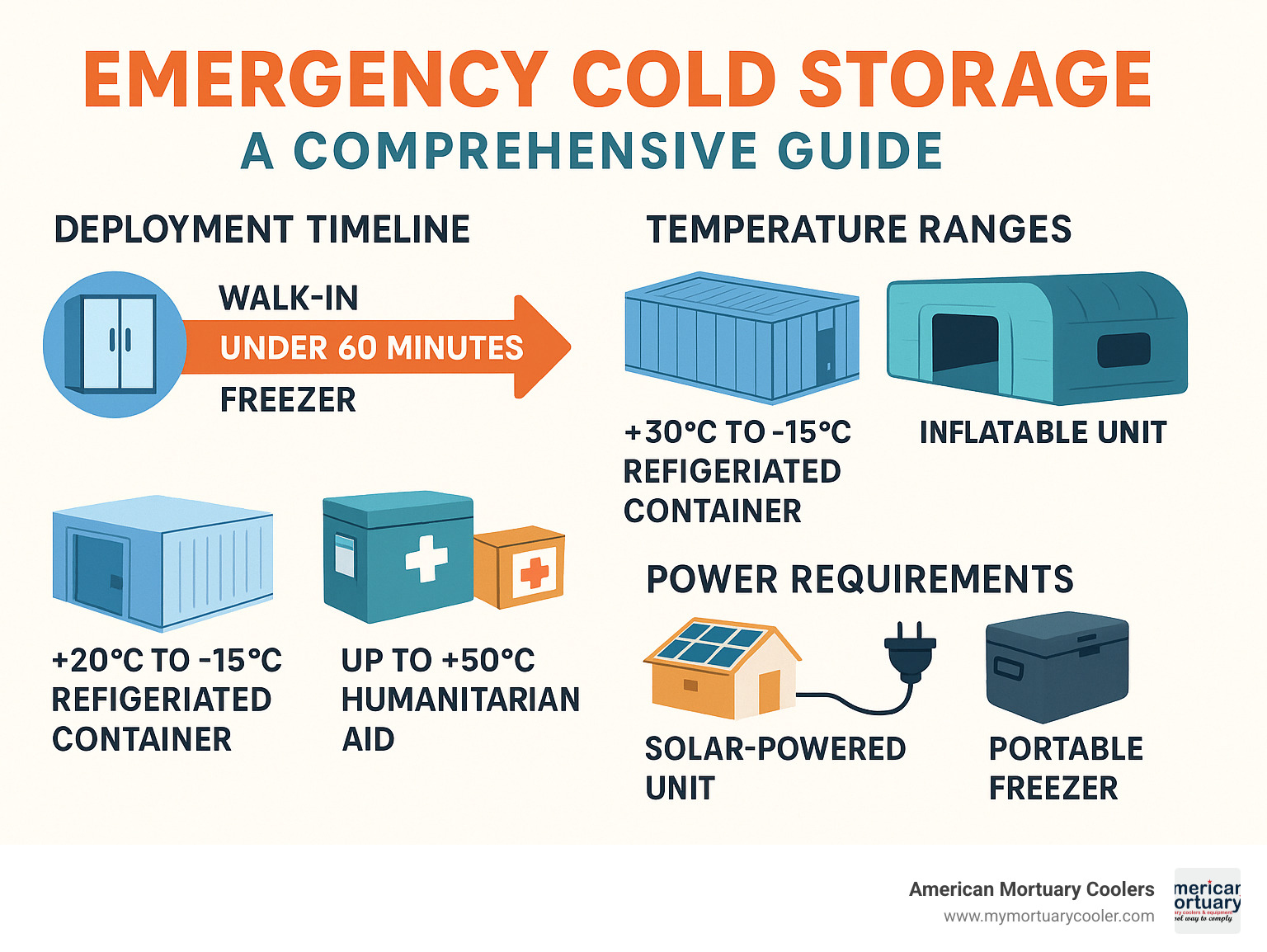

- Walk-in coolers and freezers - Portable units that can be deployed in under 60 minutes

- Refrigerated containers - 10ft, 20ft, and 40ft units with temperature ranges from +30°C to -35°C

- Inflatable cold storage - Rapid-deploy units for disaster relief and humanitarian aid

- Solar-powered units - Off-grid solutions that can store up to 25,000 meals

- Portable freezers - Plug-and-play units operating on standard 110V outlets

The demand for emergency cold storage is rapidly increasing due to rising natural disasters attributed to global warming. Modern units can maintain interior temperatures from +2°C to +15°C even in ambient conditions up to +50°C, with some portable units maintaining temperatures between 0°F and 50°F.

Whether you're facing a sudden equipment failure, preparing for seasonal demand surges, or responding to natural disasters, having access to reliable emergency cold storage can mean the difference between maintaining operations and losing valuable inventory.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with experience in providing emergency cold storage solutions for funeral homes and healthcare facilities. My expertise spans custom-built refrigeration systems designed to meet critical temperature requirements when primary cooling systems fail or when rapid deployment is essential.

Emergency cold storage vocab to learn:

Emergency Cold Storage 101: Definition, Importance, When It's Needed

When your main cooling system goes down, emergency cold storage becomes your lifeline. These temporary refrigeration solutions jump into action when your primary systems fail or when unexpected situations demand immediate temperature control. Think of them as your cooling insurance policy - there when you need them most.

The science behind effective cold storage is simple yet powerful. When you lower the temperature, you dramatically slow down the chemical reactions that cause deterioration. Scientific research on archival cold storage shows that proper cold storage environments can extend the life of materials by hundreds of years, especially for items where deterioration is starting to occur.

This principle works whether you're preserving vaccines, keeping food fresh, or maintaining sensitive biological materials. The colder it gets, the slower things break down - it's nature's pause button.

So when do you need emergency cold storage? Equipment failure is the most common culprit - imagine your walk-in cooler's compressor failing on your busiest day. Natural disasters like storms or floods knock out power for days. Humanitarian aid operations rely on emergency cooling for food and medical supplies during disaster relief. Sometimes it's seasonal surges where regular storage can't handle peak demand.

The Rising Need for Resilient Cooling

The demand for emergency cold storage in humanitarian and disaster relief work climbs every year. With more natural disasters linked to global warming, organizations are recognizing how critical backup cooling systems are.

Our supply chains have become fragile. One failure - power grid issues, equipment breakdown, or transportation problems - can ripple through entire networks, spoiling millions of dollars worth of temperature-sensitive goods.

FEMA statistics show that communities with robust emergency infrastructure, including backup cooling capabilities, recover faster from disasters and experience less economic loss.

Critical First 48 Hours

The first 48 hours after an emergency are make-or-break for maintaining the cold chain. Everything happens fast with no room for mistakes.

Food safety deteriorates within hours once refrigeration fails. Vaccine viability is even more critical - many vaccines are permanently ruined by temperature swings outside their safe range. Morgue capacity becomes serious during mass casualty events when facilities need immediate refrigerated storage expansion.

This is why organizations have developed solar-powered cold-storage containers that can store up to 25,000 ready-to-eat meals, ensuring communities have safe food during those critical first 48 hours.

Solutions, Deployment & Innovations

When disaster strikes, you need emergency cold storage solutions that work fast and reliably. Today's options range from simple plug-and-play units to sophisticated solar-powered systems operating completely off-grid.

Walk-in coolers and freezers remain the backbone of emergency cooling. Modern versions deploy in under 60 minutes and maintain temperatures from +2°C to +15°C even in +50°C ambient conditions. Weatherproof designs work anywhere, with customization for unusual spaces.

Portable freezers handle smaller emergencies, maintaining 0°F to 50°F temperatures on standard 110V power. Temperature displays on front and back make monitoring easy from any angle.

Refrigerated containers bring serious capacity in 10ft, 20ft, and 40ft sizes. In cooler mode: +30°C to -10°C. Freezer mode: -10°C to -35°C. A 40-footer provides nearly 38 feet of internal storage space.

Inflatable cold storage deploys in under 60 minutes and operates off-grid in harsh conditions, designed specifically for disaster relief and humanitarian aid.

Solar-powered units represent sustainable emergency cooling. Organizations like Abound Food Care developed solar containers storing up to 25,000 ready-to-eat meals without grid power or fuel.

Hybrid electric systems reduce costs and emissions while meeting sustainability goals and providing reliable emergency cooling.

| Feature | Walk-in Coolers | Refrigerated Containers |

|---|---|---|

| Deployment Time | Under 60 minutes | 2-4 hours |

| Power Requirements | 110V-460V options | 420V/460V 3-phase |

| Temperature Range | 0°F to 50°F | -31°F to 86°F |

| Mobility | Moderate | High |

| Capacity | Customizable | Fixed sizes |

| Setup Complexity | Low | Moderate |

Emergency Cold Storage Deployment Timeline

Speed matters when cooling fails. Understanding realistic timelines helps planning and expectation setting.

Same-day deployment works for portable freezers on 110V power and small walk-in units with standard connections. Local inventory means hours to deployment.

24-48 hour deployment covers custom walk-in coolers and refrigerated containers needing proper electrical setup, plus transport from regional depots.

3-7 day deployment applies to large custom installations requiring site preparation or specialized temperature requirements.

Smart organizations maintain standby rental agreements guaranteeing immediate deployment when primary refrigeration fails.

Future-Ready Tech: Solar & IoT

The future of emergency cold storage gets smarter and more sustainable yearly. Solar-powered refrigeration eliminates power concerns when electrical grids fail for days.

IoT integration brings remote monitoring with real-time temperature alerts and predictive analytics spotting potential failures before they happen. Battery backup technology maintains precise temperature control for extended periods without external power.

According to scientific research on off-grid refrigeration, advances in energy-efficient compressors enable critical temperature maintenance in challenging conditions, particularly valuable for disaster relief where power sources are unreliable.

Key Considerations & Best Practices

Successful emergency cold storage deployments require understanding specific needs and planning ahead. Making the right choices quickly can save thousands in spoiled inventory.

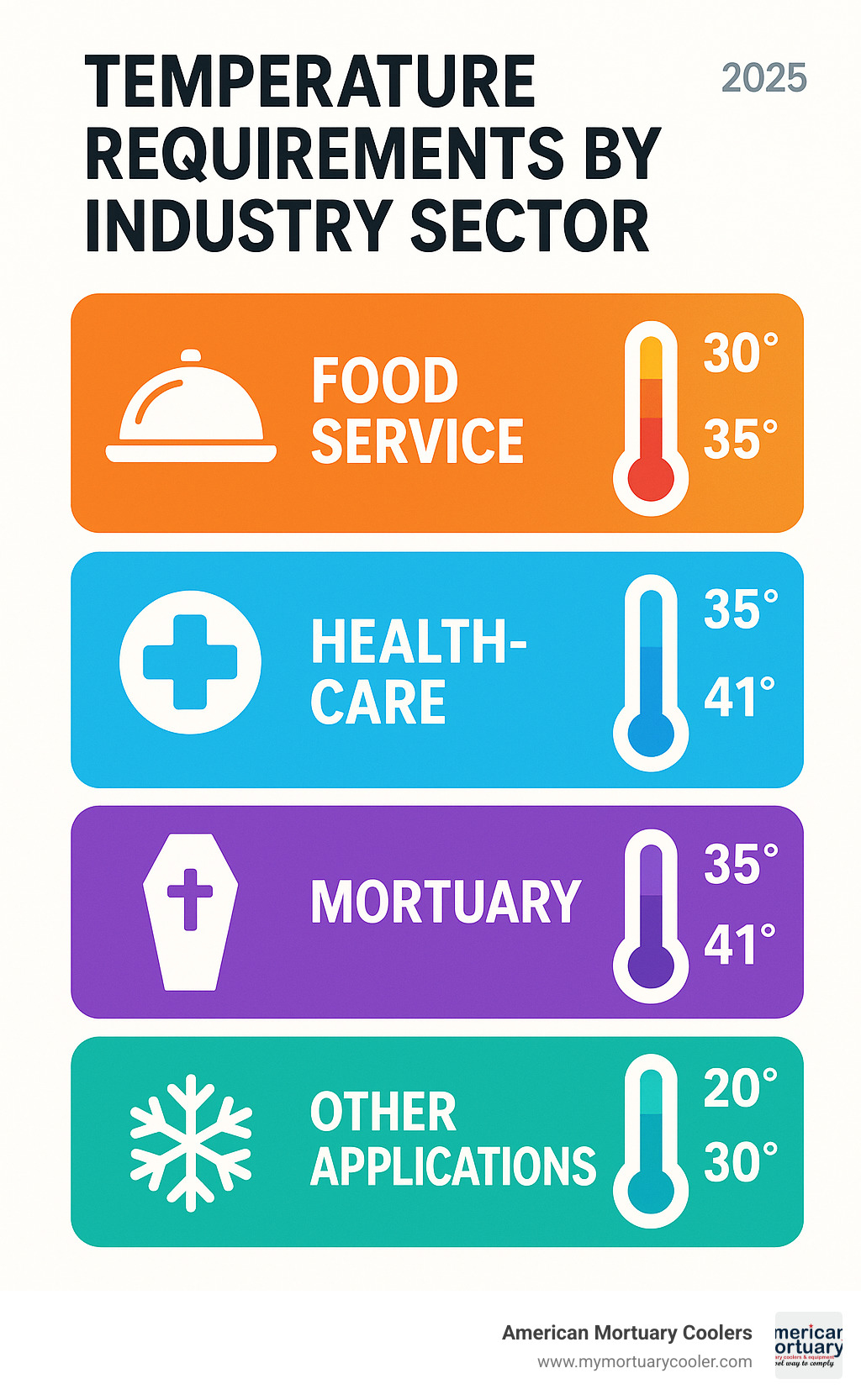

Temperature requirements vary dramatically. Food storage needs 32°F to 40°F refrigeration and 0°F to -10°F freezing. Pharmaceuticals demand precise ranges like 36°F to 46°F. Mortuary applications require 35°F to 38°F, while archival storage ranges from 40°F down below 0°F.

Capacity planning often underestimates needs. Calculate current inventory plus packaging inefficiencies and surge situations. Plan for 20-30% more capacity than immediate needs - better too much space than spoiled inventory.

Power reliability becomes critical during emergencies. Standard connections work for most situations - 110V for small units, 220V to 460V for larger systems. Generator backup isn't optional for extended outages. Solar systems work off-grid, while hybrid systems combine multiple sources for maximum reliability.

Regulatory compliance can't be ignored during emergencies. Food service needs HACCP compliance, pharmaceuticals fall under FDA regulations, healthcare considers HIPAA requirements, plus local health department rules for temporary installations.

Rental versus purchase depends on frequency and cash flow. Rentals eliminate upfront costs and scale based on demand. Costs depend on size, temperature requirements, duration, delivery distance, and installation complexity.

Emergency Cold Storage Safety Checklist

Safety protocols become more important under pressure. Temperature monitoring needs redundant sensors with automated alarms and data loggers for compliance documentation.

Inventory management requires discipline during chaos. FEFO rotation prevents waste, clear labeling with dates and requirements, plus detailed logs for tracking and compliance.

Sanitation procedures can't be shortcuts. Establish cleaning schedules with food-safe products, separate equipment for different zones, and document everything for compliance.

Emergency protocols should be written and practiced beforehand. Train staff on backup power activation, establish communication protocols for alarms, and create contingency plans for equipment failure.

Choosing the Right Unit & Provider

The provider matters as much as equipment. Thorough site surveys assess space, access routes, electrical capacity, site conditions, and regulations. Avoid providers who quote without seeing your site.

Service contracts become lifelines during extended deployments. Look for 24/7 support, rapid response times, preventive maintenance, and clear escalation procedures.

Uptime guarantees separate professionals from equipment renters. The best companies provide service level agreements because temperature excursions cost more than rental fees.

For more info about cold storage safe practices, working with experienced providers who understand your industry makes emergencies manageable situations.

Industries, Use Cases & Best Practices

When equipment fails at critical moments, emergency cold storage becomes essential across industries. Different sectors face unique challenges but share the absolute need to keep things cold when everything goes wrong.

Food service operations face equipment failures during peak periods. Walk-in coolers and freezers become lifesavers when losing inventory means losing money and reputation. Smart operators plan with flexible rental agreements for holiday rushes or kitchen renovations.

Healthcare and pharmaceutical facilities operate under strict rules. Storing vaccines, blood products, or medications requires pharmaceutical-grade units with redundant systems and precise monitoring. Temperature excursions can be life-or-death situations.

Event planners need reliable refrigeration for outdoor festivals and corporate gatherings. Portable units work perfectly, placed exactly where needed and scaled to crowd size.

Floriculture businesses face timing pressures - broken coolers during Valentine's week spell disaster. Agricultural operations have similar pressures during harvest seasons.

Disaster relief represents the most critical application. When emergencies strike, communities need food distribution and medical supply preservation. Solar-powered units revolutionized this field, operating off-grid when traditional power fails.

At American Mortuary Coolers, we understand funeral homes and medical examiners' specialized needs. Mass casualty events, equipment breakdowns, or renovations require immediate solutions. Our custom mortuary coolers use UL-approved components meeting industry standards. Learn more at morgue coolers.

Museums and archives require precise environmental control for preserving documents, artifacts, and photographs. Cold storage can add centuries to irreplaceable historical items.

Breweries and wineries depend on emergency cooling for fermentation control and product storage. With thousands of gallons at stake, backup cooling is essential insurance.

Case Study Snapshots

During wildfire emergencies, solar-powered containers stored meals for displaced families, running off-grid for weeks. A major hospital's pharmacy renovation threatened vaccine storage - portable pharmaceutical units delivered within 24 hours maintained perfect control throughout construction. One resort restaurant exceeded storage capacity by 40% during peak season - modular walk-in coolers solved the problem with flexible rental terms.

Innovation Outlook Inside Each Sector

The future looks electric and smart. Industries switch to electric-powered temporary cold storage for sustainability goals while cutting costs. Modular scalability changes capacity planning - start small, expand as needed. Smart monitoring through IoT sensors provides remote temperature monitoring, automated alerts, and predictive maintenance, reducing failure risks before they happen.

Frequently Asked Questions about Emergency Cold Storage

When facing cooling emergencies, you have questions. We've helped organizations steer these challenges for years - here are the most common concerns.

How much power do emergency units require?

Emergency cold storage power requirements depend on what you're cooling and space size. Like choosing between a desk fan and whole-house AC - bigger jobs need more power.

Small portable units plug into standard 110V outlets, drawing 15-20 amps. Perfect for keeping vaccines or food cold temporarily.

Walk-in coolers require 220V single-phase or 460V three-phase power, pulling 25-50 amps. These need qualified electrician setup - not wall outlet jobs.

Large refrigerated containers need 420V or 460V three-phase at 25 amps, though some adapt to 240V three-phase at 50 amps with special adapters.

Generator backup requires 10-50 kilowatts depending on unit size. Always use licensed electrical contractors for anything beyond basic 110V connections.

What rental costs should I expect versus building permanent space?

Emergency cold storage rentals often make more financial sense than permanent construction, especially for temporary needs.

Rental costs vary significantly. Small units run $200-800 monthly, while large containers cost $1,500-4,000 monthly. Pricing depends on size, duration, temperature requirements, delivery distance, and power complexity.

Compare to permanent construction at $150-300 per square foot, and rentals become attractive. One customer saved $10,000 using refrigerated container rental versus building permanent capacity.

Rentals include maintenance, repairs, and 24/7 support. With permanent installations, ongoing costs are yours. Longer terms offer better rates - negotiate upfront if you need units for months.

How do I maintain product safety during transport and setup?

Maintaining product safety during emergency cold storage deployment requires solid planning and careful execution.

Before units arrive, have a game plan. Identify temporary storage for critical items - backup coolers or ice solutions. List temperature-sensitive products for prioritization. Train teams beforehand, not during emergencies.

During transport, time is critical. Use insulated containers for important items. Keep portable monitors with everything. Plan moves to minimize room temperature exposure with backup cooling ready.

During setup, let units reach target temperature and stabilize before loading. Use multiple sensors to verify operation. Load temperature-sensitive items first, working systematically through inventory.

Once running, don't assume everything's fine. Set redundant monitoring with automated alerts. Check regularly with visual inspections and keep detailed temperature logs for regulatory compliance.

Conclusion

When your cooling system fails at 2 AM on a busy weekend, or when a natural disaster knocks out power for days, emergency cold storage becomes your lifeline. It's not just about having backup equipment sitting around - it's about protecting everything that matters to your business and community.

We've seen how the right emergency cooling solution can save the day. Whether it's a solar-powered container keeping 25,000 meals fresh in a disaster zone, or a portable freezer maintaining life-saving vaccines during a power outage, these systems step up when we need them most.

The secret to success isn't just having great equipment - it's being prepared before disaster strikes. Smart organizations don't wait for emergencies to start thinking about backup cooling. They partner with experienced providers, establish rental agreements, and create response plans that can be activated immediately when primary systems fail.

Climate change is making emergency preparedness more important than ever. With more frequent storms, longer power outages, and increasingly fragile supply chains, having reliable backup cooling isn't a luxury anymore - it's essential for staying in business.

At American Mortuary Coolers, we've spent years helping funeral homes and healthcare facilities across the contiguous 48 states prepare for the unexpected. Our custom, rapidly deployable solutions are designed with one goal in mind: keeping your operations running when everything else stops working.

What excites us most is where this industry is heading. Solar power is making units completely independent of the grid. IoT sensors are providing real-time monitoring from anywhere. Eco-friendly refrigerants are making systems more efficient and sustainable. The future of emergency cold storage is getting brighter, smarter, and more reliable every year.

The bottom line is simple: hope for the best, but plan for the worst. Whether you choose rental agreements, purchase portable units, or establish partnerships with deployment specialists, having a solid emergency cooling plan can mean the difference between a minor hiccup and a major catastrophe.

Don't wait until you're in crisis mode to start thinking about backup cooling. Take time now to assess your needs, explore your options, and build relationships with providers who understand your industry. When emergency strikes - and it will - you'll be ready.

For more information about custom mortuary cooling solutions and emergency cold storage options, explore our morgue coolers and find how we can help protect your most critical assets when primary systems fail.