Finding the Right Walk-In Cooling Solution for Your Needs

A walk in refrigeration unit is a large-scale cooling system designed to maintain specific temperatures in an enclosed space big enough for people to enter. These units are essential for businesses that need to preserve perishable items in bulk quantities.

Quick Guide to Walk-In Refrigeration Units:

| Feature | Description |

|---|---|

| Types | Remote, Self-contained, Top-mount, Side-mount, Penthouse |

| Temperature Range | +35°F to +45°F (coolers), -10°F to 0°F (freezers) |

| Typical Sizes | From 36 sq. ft. (6'x6') to 1,600+ sq. ft. (40'x40') |

| BTU Requirements | 4,986-6,540 BTU/h (6'x6' cooler), 7,980-10,310 BTU/h (10'x10' freezer) |

| Lifespan | 15+ years with proper maintenance |

Walk-in refrigeration units come in various configurations to suit different business needs. The right unit depends on your space constraints, temperature requirements, and budget considerations. Most importantly, selecting the correct size and refrigeration capacity ensures efficient operation and prevents equipment failure.

Key factors to consider include:

- Where heat will be discharged (inside or outside your building)

- How much interior space you can sacrifice for the evaporator

- Whether you need a cooler (+35°F to +45°F) or freezer (-10°F or lower)

- The expected product load and door traffic

- Installation environment (indoor vs. outdoor)

My name is Mortuary Cooler, and I've specialized in national-level walk in refrigeration unit supply for funeral homes and mortuaries. With years of experience providing custom cooling solutions, I understand the unique requirements for preserving dignity through reliable refrigeration technology.

Simple guide to walk in refrigeration unit:

What Is a Walk In Refrigeration Unit?

Picture walking into a giant refrigerator where you can stroll around and organize your temperature-sensitive items with room to spare. That's exactly what a walk in refrigeration unit is – a spacious, insulated room equipped with cooling technology that's large enough for people to enter and move around in.

Unlike your standard kitchen refrigerator (what we call reach-ins), these units offer significant storage capacity for businesses needing to keep large quantities of perishable items fresh. Think of it as the difference between a closet and a bedroom – both store things, but one gives you space to move around.

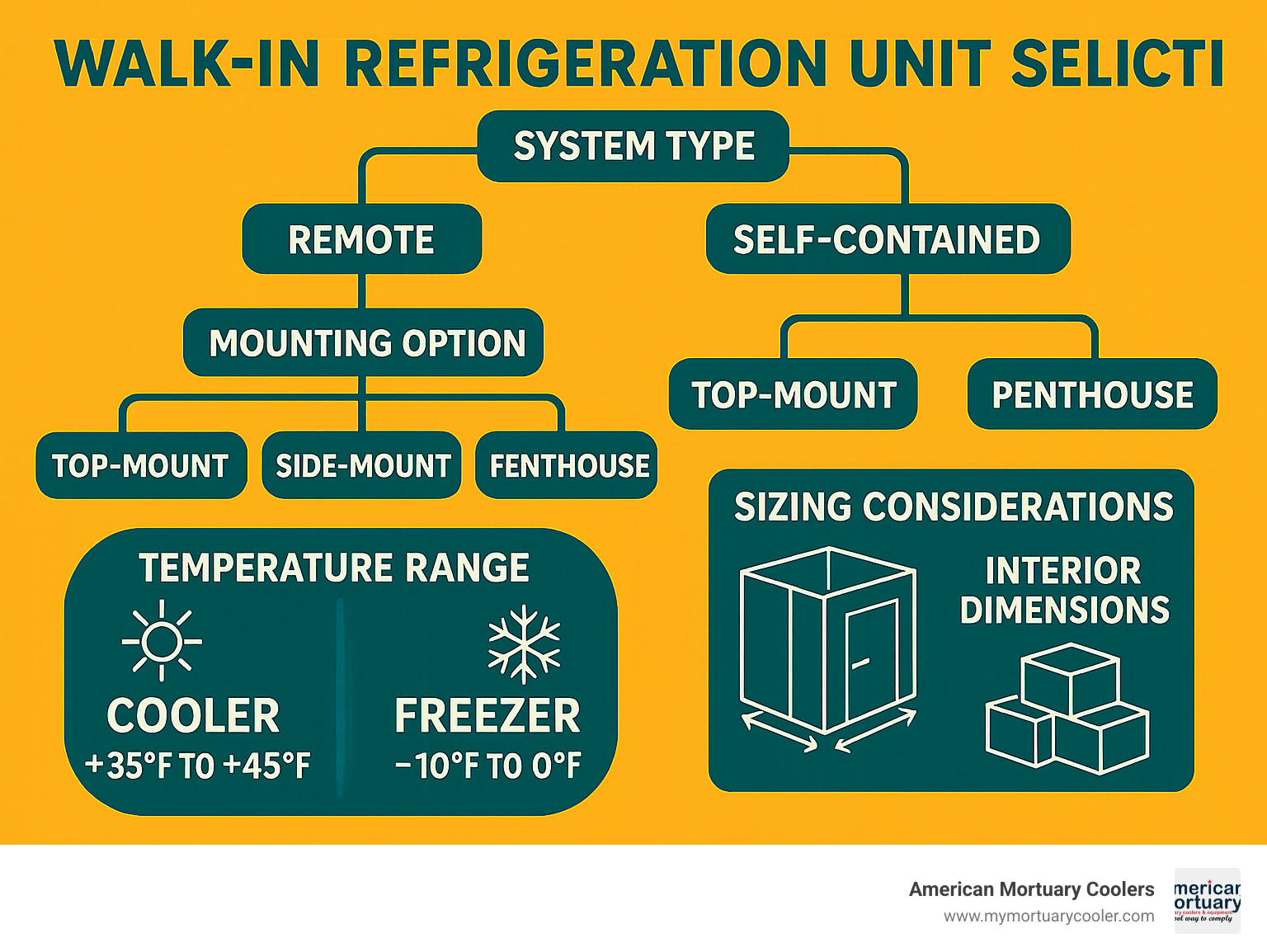

Most walk in refrigeration units operate within specific temperature ranges. Coolers typically maintain temperatures between +35°F and +45°F, while freezers run colder at -10°F to 0°F. For specialized needs, some units can go as low as -30°F or as high as +86°F in dual-temperature applications.

Size-wise, these units start at a cozy 36 square feet (about 6' x 6') and can expand to warehouse dimensions exceeding 1,600 square feet (40' x 40'). This versatility makes them valuable across numerous industries:

"Having a reliable walk-in cooler changed everything for our funeral home," shares one of our longtime clients. "The precise temperature control gives families peace of mind knowing their loved ones are being cared for with dignity."

These units serve diverse needs across industries:

Foodservice establishments rely on walk-ins to keep ingredients fresh and prepared foods safe. Floral shops use them to extend the life and beauty of their arrangements. Pharmaceutical facilities store temperature-sensitive medications and supplies. Mortuary settings (our specialty at American Mortuary Coolers) require specialized units for respectful preservation. Warehouses use industrial-sized units for bulk storage, while dual-temp applications serve businesses needing flexibility between cooling and freezing.

The Science Behind Large-Scale Cooling

Every walk in refrigeration unit operates using the same fundamental refrigeration cycle that powers your home refrigerator, just on a larger scale. This process involves four key components working together:

The compressor acts as the heart of the system, pressurizing refrigerant gas and raising its temperature. This hot gas moves to the condenser, which releases heat outside the unit and converts the refrigerant to liquid form. Next, the expansion valve reduces pressure in the liquid refrigerant, causing it to rapidly cool. Finally, the evaporator allows the cold refrigerant to absorb heat from inside the walk-in as it evaporates back into gas form.

This continuous cycle effectively transfers heat from inside to outside, maintaining your desired temperature consistently.

Proper insulation is crucial for efficiency. Modern walk-in panels use advanced polyurethane or polyisocyanurate foam with impressive R-values (thermal resistance ratings) between R-25 and R-32 for 4-inch panels. The higher the R-value, the better the insulation performance.

For outdoor units, fiberglass construction offers remarkable advantages. According to scientific research on thermal conductivity, "Fiberglass has a thermal conductivity of only 0.04 BTUs compared to metal," resulting in better energy efficiency and reduced operating costs over the unit's lifetime.

Types of Walk-In Refrigeration Systems

Choosing the right walk in refrigeration unit is a bit like finding the perfect pair of shoes - it needs to fit your space, meet your needs, and feel comfortable with your budget. Let's explore the main types of systems that keep these giant coolers running smoothly.

When I visit clients to discuss their refrigeration needs, the first question I typically ask is: "Where do you want the heat to go?" This simple question helps determine whether a remote or self-contained system makes more sense for their situation.

Remote vs. Self-Contained at a Glance

Remote systems are like having your furnace in the basement while the vents are upstairs. The noisy, heat-generating parts (the condensing unit with compressor and condenser) live somewhere else - often outside your building or tucked away in a mechanical room. Meanwhile, only the quiet cooling component (evaporator) stays inside your walk-in.

"Remote systems are the least expensive to purchase initially," I often explain to clients, "but may cost more overall depending on installer rates and parts costs."

Self-contained systems, on the other hand, are the all-in-one solution. Everything is packaged together, making installation simpler, but they discharge heat into the surrounding area (which might increase your air conditioning costs).

Here's how they stack up against each other:

| Feature | Remote Systems | Self-Contained Systems |

|---|---|---|

| Heat Discharge | Outside building | Inside building |

| Installation Complexity | Higher (requires technician) | Lower (often pre-assembled) |

| Initial Cost | Lower purchase price | Higher purchase price |

| Operating Noise | Lower inside building | Higher inside building |

| Interior Space Impact | Minimal | Reduces usable space |

| Maintenance Access | Separate locations | Single location |

Picking the Best Mounting Style

Once you've decided between remote and self-contained, the next question becomes: "Where should we put the cooling unit?" This is where mounting styles come into play.

Top-mount systems hang from the ceiling inside your walk-in. They're popular and cost-effective, but they do steal some of your headroom and might make you duck if you're tall. Many of our mortuary clients prefer these when ceiling height isn't an issue.

Side-mount units attach to a wall inside the walk-in. You'll keep your full ceiling height (great for taller staff), but you'll sacrifice some wall space that could otherwise hold shelving. I've found these work well in buildings with lower ceilings.

Penthouse systems sit proudly on top of your walk-in roof. While initially more expensive, they preserve 100% of your interior space. As one restaurant owner who installed multiple walk-ins told me, "We found that penthouse systems, while seemingly pricier upfront, proved less expensive over the lifetime because they save interior space and come factory assembled."

Saddle-mount units straddle the wall, with one foot inside and one outside, giving you a compromise between side-mount and remote systems.

For outdoor applications, especially in harsh weather areas, fiberglass construction offers exceptional durability. "Our units have been tested above 175°F for sun resistance and can handle roof snow loads up to 100 lbs per square foot," is a feature we're particularly proud of at American Mortuary Coolers.

Many clients also appreciate our pre-assembled remote systems that arrive factory-assembled and pre-charged with refrigerant. This reduces on-site installation time and minimizes the chance of errors, often making them more cost-effective than field-assembled systems when you factor in labor costs.

How to Size and Specify Your Walk In Refrigeration Unit

Getting the size right for your walk in refrigeration unit is like finding the perfect pair of shoes - too small and you'll be uncomfortable, too large and you'll waste money. Proper sizing ensures your unit runs efficiently while keeping your products at just the right temperature.

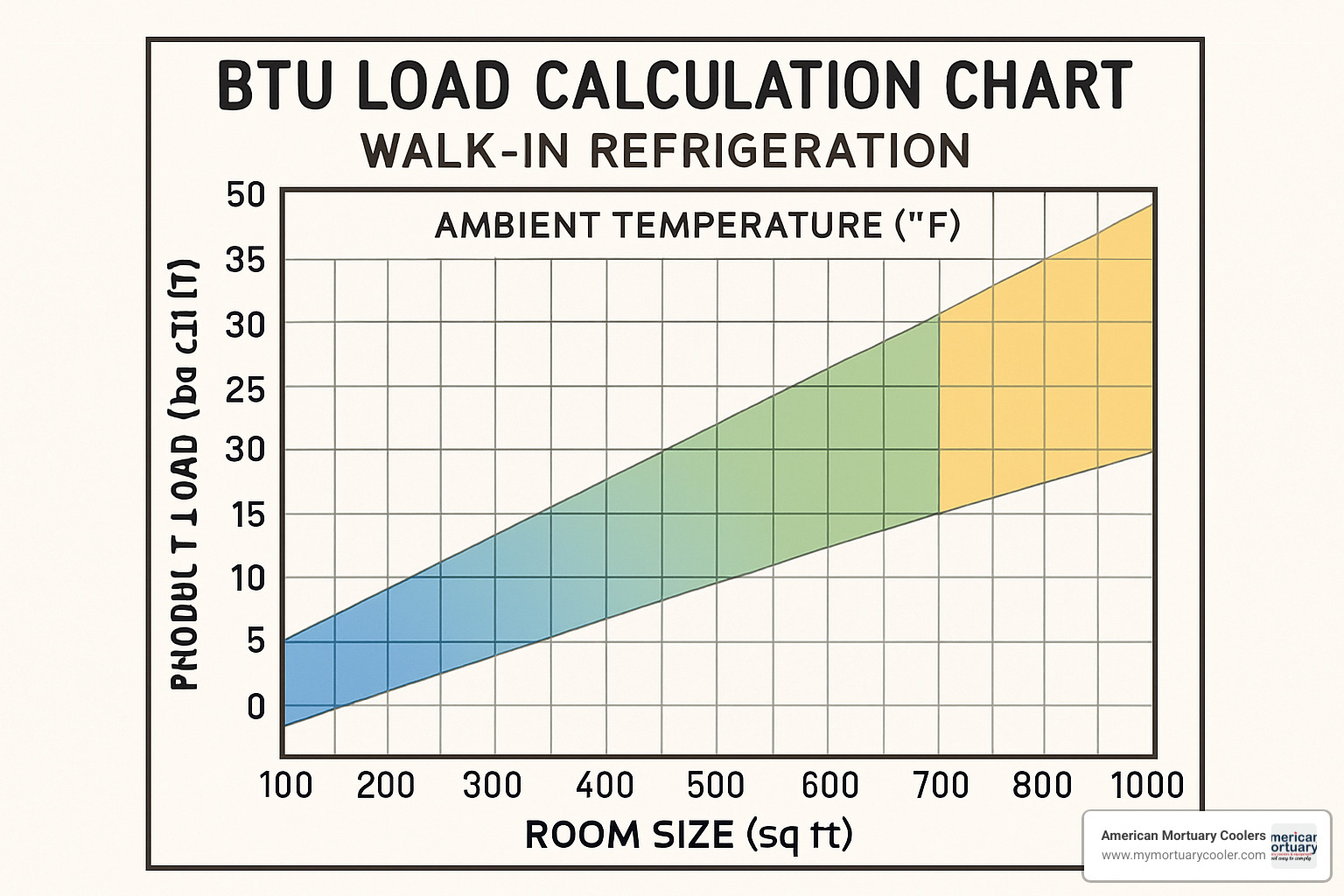

When calculating the refrigeration capacity needed, we measure in BTU/h (British Thermal Units per hour) - essentially how much heat the system can remove hourly. After years in the business, I've seen how several key factors impact your BTU requirements:

The dimensions of your room are just the starting point. Your desired temperature, the surrounding conditions, insulation quality, and how much product you're storing all play crucial roles. Even seemingly small details like how often people open the door or how many lights you have inside can significantly affect your needs.

For a quick reference, most 6' x 6' coolers running at 35°F need about 4,986 BTU/h for standard use, or 6,540 BTU/h if you're planning heavy usage. Step up to an 8' x 10' cooler, and you're looking at roughly 7,934 BTU/h for normal operations. Freezers require more cooling power - a 10' x 10' freezer at 0°F typically needs 7,980 BTU/h, or 10,310 BTU/h for heavy use.

"I've seen too many customers trying to save money with an undersized unit," one of our technicians recently told me. "They end up spending more on repairs and higher energy bills because the system never stops running. It's like trying to cool your house with a window AC unit when you really need central air."

Five-Step Load Calculation Checklist

To get your sizing right, follow this straightforward process:

Room Data: Start with the basics - measure your space dimensions carefully and decide on your target temperature. Consider whether your unit will be indoors or exposed to outdoor conditions.

Insulation Data: The R-value of your insulation makes a huge difference. Higher values mean better insulation, which reduces the workload on your refrigeration system. Note the construction materials and expected exterior temperatures on all sides.

Infiltration Data: Every time that door opens, cold air escapes and warm air rushes in. Be realistic about door usage and consider whether you'll use strip curtains or air curtains to minimize infiltration.

Product Data: What are you storing, how much of it, and at what temperature does it arrive? A mortuary cooler receiving room-temperature items requires more cooling capacity than one receiving pre-cooled items. How quickly do you need to pull down the temperature?

Miscellaneous Data: Don't forget the little things that add up - people working inside generate heat, as do lights and any equipment operating in the space.

One funeral director in Tennessee told us, "When we replaced our old cooler, I spent extra time documenting our actual usage patterns. Your team helped me calculate the perfect size, and we've saved about 15% on our electricity bill compared to our previous unit while maintaining more consistent temperatures."

Most manufacturers (including us at American Mortuary Coolers) offer sizing calculators to help with these calculations. The Heatcraft Quick BTUH Load Calculation Chart is particularly helpful for getting ballpark figures.

Common Sizing Mistakes to Avoid

Through decades of experience, we've identified four critical sizing mistakes that can cause headaches down the road:

Undersizing is perhaps the most common error. An undersized unit will run constantly, struggling to reach target temperatures during busy periods. This strains the system, increases energy costs, and often leads to premature failure.

Oversizing isn't much better. While it might seem like "more cooling is better," an oversized system cycles on and off too frequently, reducing efficiency and potentially shortening compressor life - not to mention wasting your money upfront.

Ignoring ambient heat can lead to unpleasant surprises, especially for units located outdoors or in warm environments like kitchens. Your system needs to be sized to handle the hottest days, not just average conditions.

Forgetting future growth is a mistake we see often. It's better to have some extra capacity than to outgrow your unit in a year or two. Consider your business plans and allow room for expansion.

"We had a client in Florida who initially wanted the smallest possible unit to save on costs," our installation manager recalled. "After discussing their five-year growth plans, they opted for a slightly larger model. Three years later, they called to thank us because their business had grown exactly as projected, and their cooler still had plenty of capacity."

Proper sizing isn't just about comfort—it's about dignity in our industry. A properly sized walk in refrigeration unit ensures consistent preservation while maximizing energy efficiency. Need more specific guidance for your situation? Check out our detailed information about walk-in sizing for deeper insights into getting this crucial decision right.

Buying Checklist: Features, Efficiency & Compliance

Shopping for a walk in refrigeration unit can feel overwhelming with all the options out there. Trust me, I've helped hundreds of customers through this process, and having a checklist makes all the difference in finding the perfect match for your needs.

Let's start with the building blocks of any quality walk-in unit - the panels themselves. You'll want insulated panels with at least R-25 value for coolers and R-32 for freezers. These panels typically range from 4 to 6 inches thick, with thicker panels providing better insulation but taking up more space. Most of our clients love the durability of stucco-embossed galvalume, though stainless steel offers a premium look, and fiberglass is fantastic for outdoor applications. The best panels feature tongue-and-groove designs with cam-lock fasteners that create those tight seals you need for efficiency.

Door hardware might seem like a small detail, but it makes a huge difference in daily operation. Self-closing hinges and automatic door closers are worth every penny - they prevent those "oops, someone left the door open" moments that waste energy. Magnetic gaskets and positive door seals keep the cold air where it belongs, and interior safety releases are absolutely non-negotiable for preventing accidental entrapment. Many of our mortuary clients also opt for kick plates to protect doors from gurneys and strip curtains for additional energy savings.

"When I installed my first walk-in at my funeral home, I skimped on the door hardware," one of our Tennessee clients told me. "Big mistake! I ended up replacing everything within a year. Get the good stuff from the start."

Floor options vary based on your needs. Standard aluminum floor panels handle up to 600 lbs per square foot, but if you're using pallet jacks or forklifts, you'll need reinforced flooring. Some installations can use existing concrete floors with proper thermal breaks, which can save on costs.

Don't overlook the vapor barrier - it's the unsung hero preventing moisture infiltration that can degrade your insulation over time. A continuous vapor barrier throughout the structure is essential for long-term performance.

Modern refrigeration systems use eco-friendly refrigerants like R-448A and R-290, which are not only better for the environment but also comply with EPA and DOE regulations. If you're in California, be aware of Proposition 65 warnings regarding potential chemical exposure - you can find more information at http://www.P65Warnings.ca.gov.

The brains of your system - the monitoring controls - deserve careful consideration. Digital LED thermometers provide at-a-glance temperature readings, while alarm systems alert you to any temperature deviations before they become problems. Smart defrost controls that operate based on actual need rather than timed cycles can significantly reduce energy consumption.

Cooler vs. Freezer—Which Do You Need?

The choice between a cooler and freezer comes down to your specific preservation needs.

Walk-in coolers maintain temperatures between +35°F and +45°F and typically feature 4-inch panels with R-25 insulation. They come with standard door hardware (no heaters needed) and generally cost less to operate than freezers. We recommend coolers for most mortuary applications because they provide ideal conditions for dignified preservation while minimizing tissue dehydration.

Walk-in freezers maintain temperatures between -10°F and 0°F and require at least 4-inch thick panels with R-32 insulation. Unlike coolers, freezers need door heaters to prevent gasket freezing and heated pressure relief vents to equalize pressure. Floor insulation is absolutely critical in freezer applications. While they cost more to operate, freezers are necessary for long-term preservation needs.

"In our mortuary facilities across Tennessee and Georgia, we typically recommend coolers rather than freezers," explains our regional specialist. "The standard +35°F to +45°F range is ideal for dignified preservation while minimizing tissue dehydration."

Energy & Environmental Upgrades

Today's walk in refrigeration unit options include several energy-saving features that can significantly reduce your operating costs:

High-efficiency EC motors use up to 70% less energy than standard motors, while LED lighting not only consumes less power but also generates less heat inside your unit. Variable-speed compressors adjust output based on actual demand rather than cycling on and off, and newer A2L refrigerants have lower Global Warming Potential while still complying with the AIM Act.

Many of our clients have taken advantage of utility company rebates for energy-efficient equipment. One Chicago customer shared, "When we upgraded our facility with EC motors and LED lighting, we saw a 30% reduction in our monthly energy bills. The utility rebates covered about 20% of the upgrade costs, making the ROI even more attractive."

These upgrades aren't just good for your wallet – they're good for the planet too. If your business has sustainability goals, these energy-efficient options can help you meet them while providing the reliable cooling you need.

For more information about walk-in cooler panels and options, check out our detailed guide: Everything You Need to Know About Walk-In Cooler Panels.

Installation, Maintenance & Total Cost Insights

When it comes time to install your walk in refrigeration unit, proper planning makes all the difference between years of trouble-free operation and constant headaches. Think of it as building a foundation for your business's cold storage needs.

Site Preparation starts with a solid foundation—literally. You'll need a level concrete slab or reinforced floor that can handle the weight of your unit plus everything you'll store inside. Don't forget about drainage for condensate removal; nobody wants puddles forming around their expensive refrigeration system!

"We once had a client who skipped proper drainage installation," shares our Tennessee installation manager. "Six months later, they were dealing with mold issues that could have been easily avoided with a simple drain slope."

Make sure you have enough ceiling clearance if you're going with a top-mounted unit, and leave plenty of breathing room around outdoor condensing units—they need proper airflow to function efficiently.

Installation Requirements typically involve several professionals working together. Most units require 208-230V power, with larger systems sometimes needing 3-phase power. You'll want a licensed refrigeration technician to handle refrigerant charging (it's actually required by law), a qualified electrician for safe electrical connections, and proper ventilation planning for heat dissipation.

With regular care, your walk in refrigeration unit can provide reliable service for 15+ years. Maintenance isn't complicated, but it is essential—regular cleaning of condenser and evaporator coils, checking door gaskets and hinges for wear, monitoring refrigerant levels, lubricating moving parts, and keeping those drain lines clear. Many of our clients establish a maintenance calendar to ensure nothing gets overlooked.

When budgeting for your refrigeration investment, consider the complete picture. Initial purchase prices typically range from $5,000 for small basic units to $30,000+ for larger custom solutions. Installation costs add another $2,000 to $10,000 depending on complexity. Remember to factor in ongoing expenses like electricity (which varies by size, usage patterns, and local utility rates) and maintenance contracts ($500-$2,000 annually).

"We understand that this represents a significant investment for most businesses," notes our finance team leader. "That's why we offer 100% financing options for qualified customers. You can start benefiting from improved refrigeration immediately while spreading the cost over time."

Warranty coverage is another important consideration. New units typically include comprehensive protection—many manufacturers offer 1-year parts and labor warranties, with panel warranties extending up to 15 years. Used equipment, while less expensive upfront, often comes with limited or no warranty coverage.

Need your unit quickly? Standard "quick-ship" models can be deployed faster, while custom solutions take longer but offer custom features for your specific needs.

Choosing the Right Walk In Refrigeration Unit for Your Industry

Different industries have unique refrigeration requirements, and at American Mortuary Coolers, we understand these nuances better than most.

Foodservice operations need heavy-duty flooring that can handle the constant movement of carts and racks, NSF certification for food safety compliance, and multiple shelving tiers for organized storage of ingredients and prepared items.

Mortuary facilities require specialized considerations that we've perfected over decades. Our mortuary units feature carefully designed racking systems for dignified body storage, precise temperature control for optimal preservation, whisper-quiet operation for respectful environments, and backup power systems to ensure uninterrupted operation even during emergencies.

Floral businesses benefit from higher humidity controls to prevent wilting, glass display doors for customer viewing, and specialized shelving designed for delicate arrangements.

The biotech and pharmaceutical industries depend on validated temperature monitoring systems, redundant refrigeration for critical samples, and sophisticated alarm systems with remote notification capabilities.

Craft breweries need specialized keg racking systems, precise temperature control for optimal serving conditions, and wider doors to accommodate keg movement.

Outdoor kiosks require weather-resistant construction, improved insulation for extreme temperatures, and security features for unattended operation.

"Each industry has its own language when it comes to refrigeration," explains our design team leader. "At American Mortuary Coolers, we've spent years learning the specific needs of the funeral industry to ensure our units provide dignified preservation under all circumstances."

Troubleshooting Your Walk In Refrigeration Unit

Even well-maintained units occasionally need attention. Knowing how to address common issues can save you time, money, and potentially prevent product loss.

Temperature fluctuations are often the first sign something's amiss. Start by checking thermostat settings and calibration, then inspect door gaskets to ensure they're creating a proper seal. Make sure there's adequate airflow around both evaporator and condenser coils, and verify that refrigerant levels are correct.

Ice build-up typically points to defrost cycle issues. Check the settings, inspect door gaskets and hinges for damage, verify that drain lines are clear and properly sloped, and ensure humidity control is functioning as intended.

Seeing unusually high energy bills? Clean those condenser and evaporator coils, check for air leaks around doors and panel joints, verify the refrigerant charge is correct, and consider upgrading to more energy-efficient components if your unit is older.

Door gasket wear is normal but needs attention. Regular inspection and cleaning extend gasket life, but prompt replacement of damaged gaskets is essential for maintaining temperature integrity. Proper door adjustment ensures even contact around the entire perimeter.

When you encounter alarm codes, document the specific code, research its meaning in your manual, contact manufacturer support if needed, and schedule professional service for complex issues.

"Last winter, a funeral home in North Carolina called us in a panic because their unit was struggling to maintain temperature," recalls our service coordinator. "Our technician finded that snow had blocked the condenser's airflow. A simple cleaning resolved the issue and restored proper operation—crisis averted!"

Frequently Asked Questions about Walk-In Refrigeration Units

How long does a walk-in refrigeration unit last?

With proper care and attention, a quality walk in refrigeration unit can be your faithful cooling companion for 15 years or more. Think of it as two separate parts working together - the refrigeration system (compressor, evaporator, and related components) typically serves you well for 7-10 years, while those sturdy insulated panels can stand strong for 20+ years.

"We have clients in the Pittsburgh area still using panels we installed over 20 years ago," our installation supervisor often tells new customers with a smile. "The secret isn't really a secret at all - regular maintenance and addressing small issues before they become big problems."

The longevity of your unit largely depends on how well you maintain it. Simple practices like keeping coils clean, ensuring proper refrigerant levels, and lubricating moving parts can add years to your investment. Think of it like regular oil changes for your car - a little preventive care goes a long way.

Can I install a unit outdoors without a roof overhang?

Absolutely! But you'll need a specialized outdoor walk in refrigeration unit designed to brave the elements. These weather-warriors come equipped with features that standard indoor units simply don't have.

Outdoor units typically feature weatherproof roof caps and sealed seams to keep rain and moisture out. Their exteriors are finished with UV-resistant materials to prevent sun damage, while improved insulation helps them maintain temperatures despite whatever Mother Nature throws their way. The refrigeration components themselves are specially designed to withstand outdoor conditions, and proper drainage systems prevent water accumulation.

Fiberglass-constructed units are particularly well-suited for outdoor installation. These hardy structures can handle extreme temperatures, heavy precipitation, and even salt exposure in coastal areas. Some of our outdoor units have been tested to withstand scorching temperatures above 175°F and impressive snow loads up to 100 pounds per square foot.

"For our Los Angeles clients, we recommend units with UV-resistant exteriors and improved insulation to handle the heat," explains our Pacific Region manager. "Meanwhile, our Rocky Mountain customers need units that can handle heavy snow loads and dramatic temperature swings from day to night."

What warranties should I look for on panels and compressors?

When investing in a walk in refrigeration unit, the warranty is your safety net. Here's what to look for in quality coverage:

For the panels, which form the structure of your unit, expect 10-15 years of protection against manufacturing defects. Doors, with their moving parts and regular use, typically come with 1-5 year warranties covering hardware and components. A quality compressor—the heart of your cooling system—should be backed by at least a 5-year warranty. Other refrigeration components generally carry 1-year parts warranties, and installation labor is typically covered for the first year.

Many manufacturers offer extended warranties for additional peace of mind, though these come at an extra cost. Always take time to read the fine print carefully—warranty terms often include maintenance requirements that, if not followed, could void your coverage.

"We stand behind our products with some of the best warranties in the industry," our warranty department proudly states. "Our standard 15-year panel warranty, 5-year door and floor warranty, and 1-year parts and labor warranty give our customers confidence that we'll be there for them long after installation day."

At American Mortuary Coolers, we understand that reliability isn't just about convenience—it's essential for the dignified services you provide. That's why we focus on building units that last and backing them with warranties you can count on.

Conclusion

Choosing the right walk in refrigeration unit isn't just about buying equipment—it's about making a smart investment in your business's future. After exploring all the options, features, and considerations, you're now equipped to make a decision that will serve your needs for years to come.

As you prepare to take the next step, keep these three important considerations in mind:

First, create a comprehensive budget that goes beyond the sticker price. Remember to include installation costs, expected monthly energy consumption, and regular maintenance expenses. This total cost of ownership approach helps prevent unwelcome surprises down the road.

Second, don't go it alone. Professional consultation can save you thousands in the long run by helping you avoid common pitfalls. Our refrigeration specialists understand the unique challenges of temperature-controlled storage and can guide you toward the perfect solution.

Finally, think about where your business will be in five years, not just today. The right walk in refrigeration unit should accommodate your growth plans, whether that means selecting a slightly larger unit now or ensuring your system can be expanded later.

"When we installed our first walk-in cooler, we underestimated how quickly our business would grow," shares one of our long-term clients in Chicago. "Three years later, we had to replace it entirely—an expensive lesson in forward thinking."

At American Mortuary Coolers, we've spent years perfecting our approach to refrigeration solutions for the funeral industry. Our team serves clients from coast to coast, with a presence in Johnson City TN, Atlanta GA, Chicago IL, Columbia SC, Dallas TX, Los Angeles, New York NY, Pittsburgh PA, and beyond.

We understand that mortuary refrigeration isn't just about technical specifications—it's about providing dignified care with reliable equipment. Our custom-built solutions are designed specifically for your facility's needs and delivered directly to your location, eliminating middlemen and ensuring quality control from our workshop to your doorstep.

Whether you're opening a new facility or upgrading existing equipment, we're here to help. For personalized assistance in finding the perfect refrigeration solution for your specific needs, contact our team today. We'll guide you through every step of the process, from initial sizing to final installation.