Essential Tools for Medical Cast Removal

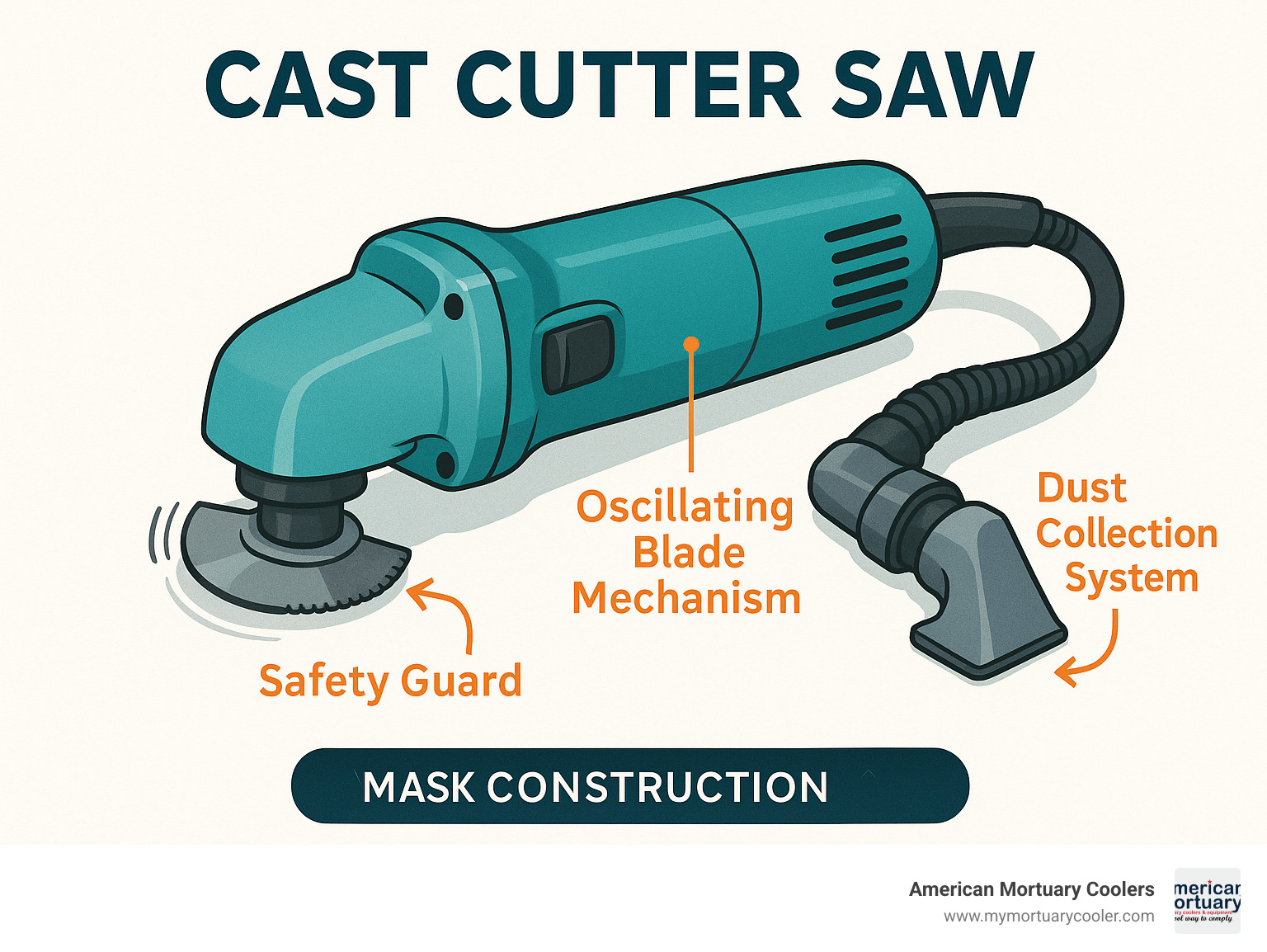

A cast cutter saw is a specialized medical device that uses a rapidly oscillating blade to cut through plaster or fiberglass casts without harming the skin underneath.

If you're looking for quick information about cast cutter saws, here's what you need to know:

| Feature | Description |

|---|---|

| Purpose | Safely removes orthopedic casts without injuring skin |

| How it works | Blade oscillates (not rotates) at 11,000+ movements per minute |

| Safety mechanism | Oscillation moves skin with blade, preventing cuts |

| Types | Corded electric, cordless, pediatric, vacuum-integrated |

| Price range | $800-$2,500 for professional models |

| Common brands | Stryker, DeSoutter, BSN, Oscimed |

The cast cutter saw is an essential tool in orthopedic care that often causes anxiety in patients despite its remarkable safety record. When you see or hear a cast cutter saw in action, it seems intimidating - the noise, vibration, and appearance suggest danger. However, the ingenious design makes them incredibly safe, with complications occurring in less than 1% of cases.

Unlike regular saws that rotate continuously, cast cutter saws oscillate rapidly back and forth. This oscillating action is what makes them safe - the blade moves too quickly to cut soft tissue, which simply vibrates with the blade rather than being cut.

I'm Mortuary Cooler, a national-level supplier of mortuary equipment including specialized tools like the cast cutter saw used in both medical and forensic settings.

Basic cast cutter saw terms:

Understanding Cast Cutter Saws

When you hear the whirring sound of a cast cutter saw in an orthopedic clinic, it's natural to feel nervous. But this remarkable medical tool represents one of medicine's clever solutions: how do you cut through something as hard as plaster without harming the skin beneath it?

These specialized tools work using an oscillating motor that moves the blade back and forth at mind-boggling speeds—typically over 11,000 oscillations per minute. That's so fast your eye can't even track the movement!

The story of the cast cutter saw begins in 1945 when surgeon Homer H. Stryker patented the first plaster cast cutter. Before this invention, removing casts was often nerve-wracking, involving dangerous cutting shears that risked patient injury. While Neil McKay later patented cast cutting shears in 1950 as a mechanical alternative, Stryker's oscillating saw quickly became the preferred choice.

What Exactly Is a Cast Cutter Saw?

A cast cutter saw is a specialized medical device designed specifically for removing orthopedic casts made of plaster or fiberglass. Unlike regular saws, it features a small, circular blade that oscillates rather than spinning continuously.

These devices serve as standard equipment in orthopedic clinics, emergency departments, and sports medicine facilities. Some patients with long-term casting needs might encounter portable versions during home health visits.

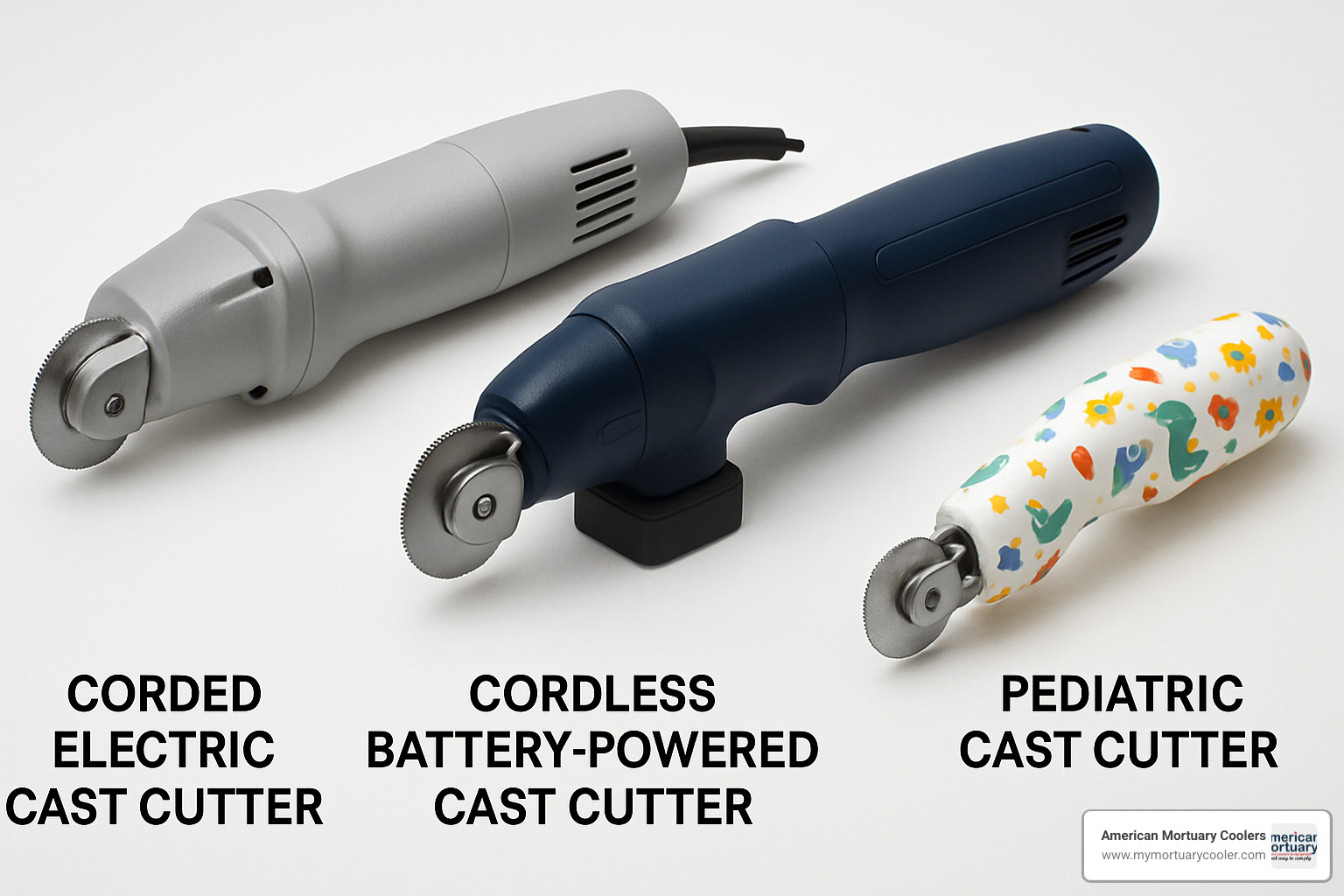

Cast cutter saws come in various configurations—from corded electric models to battery-operated versions for portability. There are even specially designed pediatric units with reduced noise levels to help ease children's anxiety.

How a Cast Cutter Saw Works vs. a Regular Saw

The fundamental difference between a cast cutter saw and a regular saw lies in how the blade moves.

A regular saw uses a continuous cutting action that will cut through anything in its path, including skin. That's definitely not what you want when removing a cast!

In contrast, a cast cutter's blade oscillates rapidly back and forth through a tiny arc. When this high-speed oscillating blade touches something soft and flexible like skin, the skin simply vibrates along with the blade rather than being cut. It's almost like the skin "dances" with the blade.

However, hard materials like plaster or fiberglass can't flex with the blade's rapid movement. Instead, these rigid materials get gradually worn away by the blade's teeth through repeated abrasion.

Evolution & Main Types of Cast Cutter Saws

Since Dr. Stryker's invention, cast cutter saws have evolved considerably. Today's market offers several distinct types:

Corded Electric Cast Saws serve as the reliable workhorses of orthopedic clinics, delivering consistent power without battery limitations.

Cordless Lithium-Ion Models offer mobility and convenience, making them perfect for home health visits or facilities where power outlets are inconveniently located.

Pediatric Quiet Units are specially designed with reduced noise levels (some as quiet as 40 dB) to minimize anxiety in younger patients.

Vacuum-Integrated Systems capture dust during cutting through built-in HEPA filtration systems.

Manual Cast Cutting Shears continue to serve as backup options and can be useful in settings without electricity.

Safety & Clinical Considerations

When it comes to cast cutter saws, safety isn't just a feature—it's the fundamental design principle. Despite their intimidating appearance and sound, these specialized tools are engineered with multiple safeguards to protect patients during cast removal.

Studies have recorded temperatures exceeding 101°C (214°F) during the removal of fiberglass casts with cast cutter saws. This heat potential highlights why proper technique and equipment selection matter so much in clinical settings.

Modern cast removal approaches focus on several key safety elements: properly positioned blade guards, careful temperature monitoring, HEPA vacuum systems for dust capture, awareness of high-risk areas, and the critical use of cast spreaders to safely separate the cast after cutting.

Built-in Safety Features That Protect Patients

Today's cast cutter saws incorporate thoughtful safety features specifically designed with patient protection in mind.

Quality cast saw blades feature relatively dull teeth compared to traditional cutting tools—a deliberate design choice that reduces laceration risk while remaining effective against rigid cast materials. Most models include protective guards extending beyond the blade's teeth, creating a physical barrier between the cutting edge and the patient's skin.

Advanced models take safety further with pressure-sensitive switches that automatically stop blade oscillation if excessive force is applied. The ergonomic grips and balanced weight distribution allow for precise control, reducing the chance of slips or unintended contact.

Many cast cutter saws now feature adjustable speed controls, letting clinicians select lower, safer speeds for delicate areas. Some premium models even include heat dissipation features or temperature monitoring to prevent thermal injuries.

Common Risks & How to Avoid Them

Despite their safety-focused design, cast cutter saws still present certain risks that require proper training and technique to address.

Thermal burns represent one of the most common concerns, especially with fiberglass casts. Smart clinicians avoid burns by using intermittent cutting with cooling periods, applying gentler pressure, using coolant spray for fiberglass casts, and selecting lower oscillation speeds when working in sensitive areas.

Skin abrasions and lacerations typically occur over bony prominences where skin lies close to the cast surface. Experienced technicians prevent these by avoiding prolonged blade contact over these areas and using a cast spreader immediately after creating an initial cut.

Cast Cutter Saw Use in Orthopedics vs. Autopsy/Pathology

While the term "cast cutter saw" typically refers to tools used in orthopedic settings, similar oscillating saw technology appears in forensic and pathology applications, though with important differences.

The orthopedic cast removal saws most people encounter are designed primarily for plaster and fiberglass removal with patient safety as the priority. They feature safety guards and dull-edge blades specifically to protect living tissue. These tools typically operate at lower power settings (110-210W) and include dust collection systems for clinical cleanliness.

By contrast, autopsy and pathology bone saws are engineered for cutting through bone and tissue in post-mortem examinations. These tools typically have higher power ratings (often 500W+) for cutting dense bone and may include specialized blades for specific procedures.

At American Mortuary Coolers, we understand both applications well. The key difference is the priority: orthopedic cast cutter saws focus on patient safety and comfort, while pathology saws prioritize precision cutting of dense tissues in post-mortem examinations.

For those interested in specialized pathology tools, our More info about mortuary tools resource provides additional information.

How to Choose the Best Cast Cutter Saw

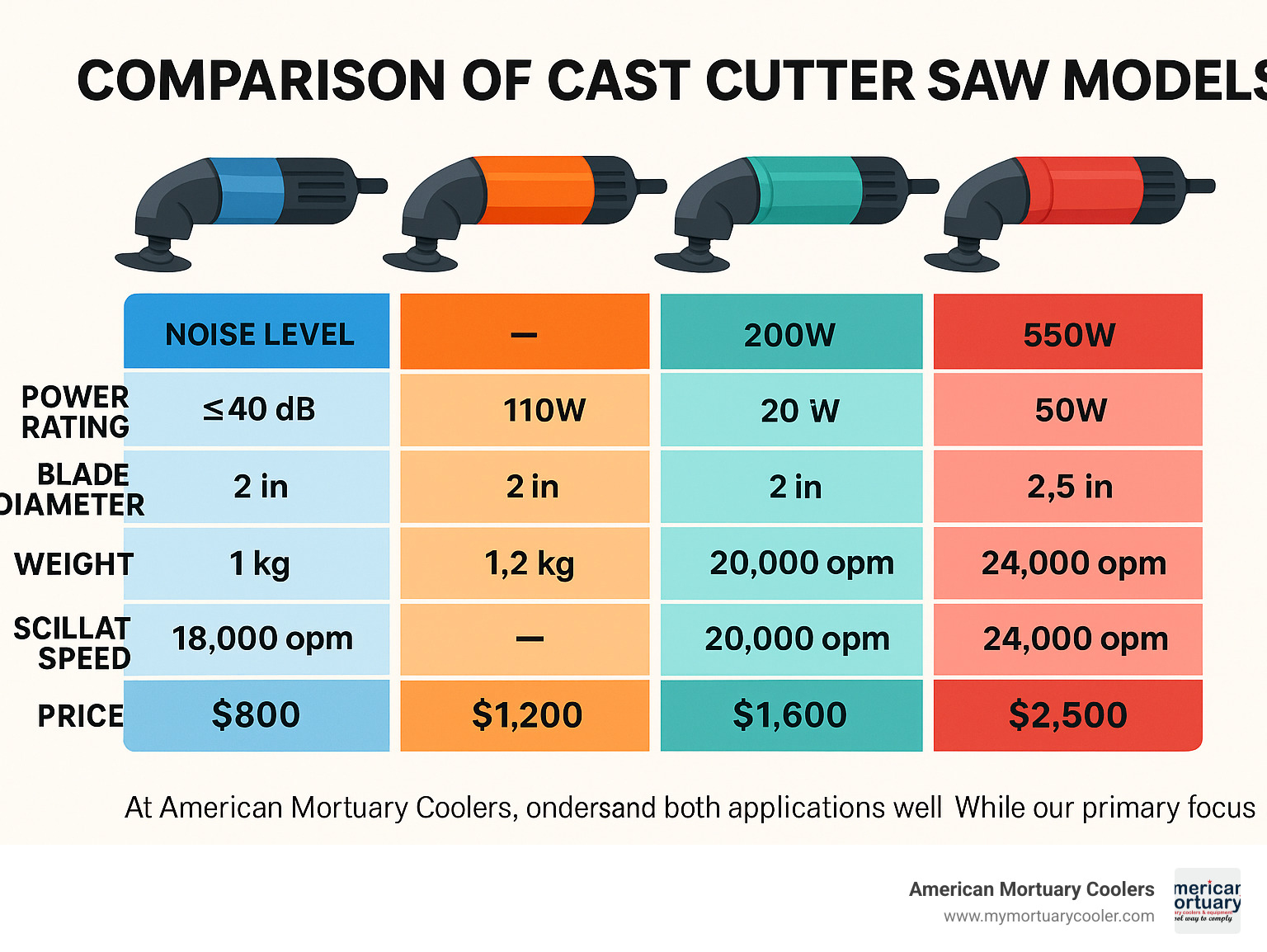

Finding the perfect cast cutter saw for your facility doesn't have to be overwhelming. With prices ranging from $800 for basic models to $2,500+ for premium systems, you'll want to make sure you're investing in the right tool for your specific needs.

When shopping for a cast cutter saw, pay attention to these key specs: noise level (particularly important in pediatric settings, where premium models operate at ≤40 dB), power ratings (typically 110W-500W), blade size (most standard blades measure 2-2.5 inches in diameter), weight (lighter models around 1kg save your wrists during busy days), and oscillation speed (higher-end models offer variable speeds up to 24,000 oscillations per minute).

Matching a Cast Cutter Saw to Your Setting

The right cast cutter saw depends largely on where you'll be using it. In a busy outpatient orthopedic clinic, durability is non-negotiable. These high-volume settings benefit from reliable corded models like the DeSoutter CleanCast™ CSB-100A or BSN Hex-Drive systems.

Emergency departments need versatility above all else. When you never know what's coming through the door, a cast cutter saw with quick-change blade capabilities like the Stryker 940 makes all the difference.

For sports medicine and field applications, think portable and rugged. Your cast cutter saw needs to travel well and perform reliably outside the clinical setting.

When working with children, an ultra-quiet pediatric specialty saw (≤40 dB) like the DeSoutter CSP-201 can transform a potentially frightening experience into a manageable one.

Leading Brands & Flagship Models

Several manufacturers have established themselves as leaders in the cast cutter saw market, each with standout models worth considering.

Stryker, the original pioneer in cast saw technology, set the gold standard with their legendary 940 Cast Cutter. Though officially discontinued, this workhorse earned such a devoted following that replacement parts remain available through third-party suppliers.

DeSoutter Medical offers premium options like their CleanCast™ CSB-100A Cordless High-Power System with integrated vacuum and the CSP-201 Pediatric Cast Saw System specifically designed for younger patients.

BSN Medical features the innovative Hex-Drive Cast Cutter with a clever blade system that extends blade life by 50% through six rotation positions.

Oscimed specializes in user comfort with models like the ultra-quiet Ergo II, the compact Oscimed 2000, and the Oscimed PSV II with integrated HEPA filtration vacuum system.

Key Components & Must-Have Accessories

A cast cutter saw is only as good as its complete system. Beyond the saw itself, several essential components and accessories ensure optimal performance and safety.

Specialized blades make a surprising difference in your daily work. Hex-drive blades offer 50% longer life by allowing rotation to six different positions as sections wear down.

Vacuum systems protect both patients and staff from harmful dust. Whether integrated or attachable, look for HEPA filters that capture 99.97% of particles as small as 0.3 microns.

A good cast spreader is absolutely essential for safely separating the cast after cutting. This simple tool dramatically reduces the risk of skin injury during final removal.

Ownership Essentials: Maintenance, Accessories & Costs

Bringing a cast cutter saw into your facility is a bit like adopting a pet – the initial purchase is just the beginning of your relationship. To get the most value from this essential tool, you'll need to understand its care requirements, accessory needs, and the full financial picture of ownership.

When shopping for a professional-grade cast cutter saw, expect to invest anywhere from $800 for a basic model to $2,500 for a premium system with all the bells and whistles. But remember, that sticker price is just one piece of the ownership puzzle.

Routine Care & Troubleshooting

Keeping your cast cutter saw in tip-top shape doesn't require advanced mechanical skills – just consistent attention to a few basics:

After each patient, take a moment to wipe down the exterior with an approved disinfectant and remove any cast debris from the blade. This five-minute routine prevents buildup that could affect performance.

On a weekly basis, check the blade's condition for any signs of dulling or damage. This is also a good time to check that the blade guard is properly aligned and that all controls work smoothly.

Monthly maintenance gets a bit more involved. Replace HEPA filters according to how frequently you use the saw – busy clinics might need monthly replacements, while occasional users can stretch this to quarterly.

When troubles arise, they're usually straightforward to solve. If your saw won't start, check the power connection or battery charge. Excessive vibration typically points to a blade issue, while overheating often means it's time to clean ventilation openings.

Total Cost of Ownership

Understanding what your cast cutter saw will cost over its lifetime helps prevent budget surprises and makes it easier to determine when an upgrade makes financial sense.

Beyond the initial purchase price of $800-$2,500, budget for $200-$500 in essential accessories like additional blades, cast spreaders, and perhaps a storage solution.

The day-to-day expenses add up over time. Replacement blades run $20-$50 each and might last anywhere from 100 uses (for budget models) to 800 uses (for premium blades). HEPA filters ($30-$80) typically need replacement every 1-3 months depending on your volume.

For cordless models, factor in battery replacement every 2-3 years at $100-$300. Professional servicing runs $150-$300 annually and is well worth it for preventive maintenance.

Most quality cast cutter saws have a lifespan of 5-10 years with proper care. Some manufacturers offer trade-in programs when you're ready to upgrade, and leasing options ($50-$200 monthly) might make sense if you prefer predictable payments.

Are There Alternatives to a Cast Cutter Saw?

While the oscillating cast cutter saw has become the gold standard for cast removal, several alternatives exist for specific situations:

Cast cutting shears offer a completely manual approach with no power requirements. They're silent and potentially less intimidating for extremely anxious patients, but they require significant hand strength and work much slower.

Some clinics repurpose oscillating multi-tools with medical blades as a budget-friendly option. While these cost less upfront, they typically lack medical-specific safety features.

For simple plaster casts, cast immersion and unwrapping eliminates cutting entirely. This zero-risk approach involves softening the cast in water until it can be unwrapped.

For those interested in exploring these alternatives further, resources like "Do You Know How to Safely Remove a Cast Easily?" provide valuable insights.

Training, Best Practices & Advanced Tips

Learning to use a cast cutter saw properly is a journey that combines technical skill with patient care. In professional healthcare settings, proper training isn't optional—it's essential for everyone's safety and peace of mind. Most facilities now require formal certification that includes both classroom learning and hands-on practice.

For pediatric patients, the experience deserves special attention. Children are often terrified by the noise and appearance of the cast cutter saw, but simple desensitization techniques work wonders. Letting kids touch and examine the unpowered equipment beforehand, using colorful distraction techniques during the procedure, and choosing quieter pediatric models can transform the experience.

Step-by-Step Guide to Using a Cast Cutter Saw

Using a cast cutter saw effectively combines art and science. The process begins well before you make the first cut:

Start by explaining the procedure to your patient in reassuring terms. Many people have never experienced cast removal and expect pain, so take a moment to explain that the saw's special design prevents it from cutting skin.

Position your patient comfortably with their cast well-supported. Before powering up, inspect your equipment thoroughly and don your personal protective gear. If your system has vacuum collection, activate it to keep dust at bay.

When you're ready to cut, hold the saw firmly in your dominant hand while supporting the cast with your other hand. Always power on the saw before making contact with the cast, then apply the blade at a 90-degree angle using light, gentle pressure.

The most effective technique isn't cutting straight through but using what professionals call the "score-and-spread" method. Make a controlled score along your planned cutting line, then create a parallel cut if needed. Use a cast spreader to gently separate these scored sections rather than cutting deeply in one pass.

Once you've scored all necessary lines, power off the saw and use cast spreaders to gently separate the halves. Remove the cast carefully, watching for any places where bandages might be stuck, and inspect the skin thoroughly.

Teaching Safe Technique: From Rookie to Pro

Mastering the cast cutter saw follows a natural progression that transforms cautious beginners into confident experts:

For beginners, the focus is on fundamentals—proper hand positioning, basic saw control, and following safety protocols religiously. Practice on empty cast materials or training models builds muscle memory without risk.

As intermediate skills develop, practitioners begin working more efficiently while maintaining safety standards. This stage involves practice on various cast types and body locations, learning to adapt techniques for different patient needs.

Advanced practitioners demonstrate consistent, efficient removal with minimal supervision. They handle complex or challenging cases with confidence, often train others, and regularly refresh their skills.

Beyond Medicine: Non-medical Uses of a Cast Cutter Saw

The remarkable precision of a cast cutter saw makes it valuable far beyond the medical setting. With appropriate blades and safety precautions, these specialized tools excel at a surprising variety of creative and practical tasks.

Plastic sheet trimming becomes remarkably precise with a cast saw's oscillating action. The controlled cutting motion produces clean edges in acrylic and other plastic sheets.

For artisans working with small metal tubing, a cast saw fitted with metal-cutting blades creates cleaner cuts in brass, aluminum, and copper than many rotary alternatives.

The hobby and craft community has adopted these tools for everything from intricate model building to custom jewelry fabrication and detailed woodworking on small pieces.

Frequently Asked Questions about Cast Cutter Saws

Why doesn't a cast cutter saw hurt the skin?

One of the most fascinating things about a cast cutter saw is that despite its intimidating appearance and sound, it's remarkably gentle on skin. This isn't magic—it's physics!

Unlike regular saws that rotate continuously, a cast cutter saw oscillates back and forth at incredible speeds—over 11,000 times per minute. When this rapidly vibrating blade touches your skin, something wonderful happens: your skin's natural elasticity allows it to simply vibrate along with the blade rather than being cut.

Imagine pressing a vibrating toothbrush against a bowl of Jell-O. The Jell-O just wiggles in response, right? Your skin reacts similarly to the cast saw's blade. Meanwhile, the rigid cast material can't flex with these rapid movements, so it gradually gets worn away by the blade's teeth.

That's why patients typically feel only a tickling vibration and slight warmth rather than pain. However, improper technique, pressing too hard, or holding the blade in one spot too long can still cause skin irritation or heat buildup.

How long does it take to remove a fiberglass leg cast?

In experienced hands with a well-maintained cast cutter saw, removing a standard fiberglass leg cast typically takes just 3-5 minutes. That said, the actual time can vary depending on several factors.

A full-leg cast that extends from toe to groin might take 5-10 minutes to remove safely. Thicker casts or those with reinforced areas around fracture sites naturally take longer to cut through. And patient factors matter too—children, anxious patients, or those with sensitive skin often need a slower approach.

The entire appointment usually lasts 15-20 minutes, which includes preparation time, the actual cutting, cleaning the skin afterward, and assessing how well healing has progressed.

What maintenance does a cordless cast cutter require?

Like any precision medical tool, a cordless cast cutter saw needs regular TLC to keep it running safely and effectively.

After each use, it's important to remove and clean the blade according to the manufacturer's instructions—usually a quick wipe-down with an approved disinfectant. The exterior surfaces should be cleaned as well, and if you won't be using the device for a while, it's best to remove the battery.

Battery care is particularly crucial for cordless models. Different manufacturers have specific charging recommendations. Generally, storing batteries at room temperature will extend their life. Most batteries will need replacement after about 300-500 charge cycles, typically around the 2-3 year mark.

Monthly maintenance should include checking that the blade guard is properly aligned and secure, cleaning any dust from motor vents, verifying all switches work properly, and lubricating moving parts according to manufacturer specifications.

With proper care, most cordless cast cutters will serve reliably for 5+ years in standard clinical settings.

Conclusion

Choosing the right cast cutter saw isn't just about finding a tool—it's about ensuring patient comfort, clinical efficiency, and ultimately, better healing outcomes. Throughout our journey exploring these fascinating devices, we've seen how their ingenious oscillating technology keeps patients safe while efficiently removing even the toughest casts.

When you're in the market for a cast cutter saw, the sticker price ($800-$2,500) tells only part of the story. The true value comes from considering the complete picture: ongoing maintenance needs, blade replacements, filter changes, and potential service requirements. With proper care and technique, these remarkable tools deliver complications in less than 1% of procedures.

At American Mortuary Coolers, we understand specialized equipment. While our primary focus is creating durable, custom mortuary refrigeration solutions for clients across the lower 48 states from our Tennessee headquarters, we appreciate that many funeral professionals interact with medical facilities where tools like cast cutter saws play a vital role.

The principles that guide our approach to mortuary equipment translate perfectly to cast removal. Whether it's durability that stands the test of time, customization that meets your specific clinical needs, or service that goes the extra mile—quality always matters most when health outcomes are on the line.

Finding your perfect cast cutter saw means balancing power requirements, safety features, ergonomic design, and budget realities. By understanding the technology behind these tools, investing in proper staff training, and maintaining your equipment with care, you'll create better experiences for both patients and providers.

For those interested in exploring other specialized equipment solutions, our more detailed information about morgue coolers showcases our commitment to quality across all our product lines.