Why Personal Refrigerated Cooling Systems Are Revolutionizing Hot Weather Work

PERSON REFRIGERATED COOLING SYSTEM- technology represents a breakthrough in wearable climate control, using miniature vapor-compression refrigeration to provide targeted cooling for individuals working in extreme heat conditions.

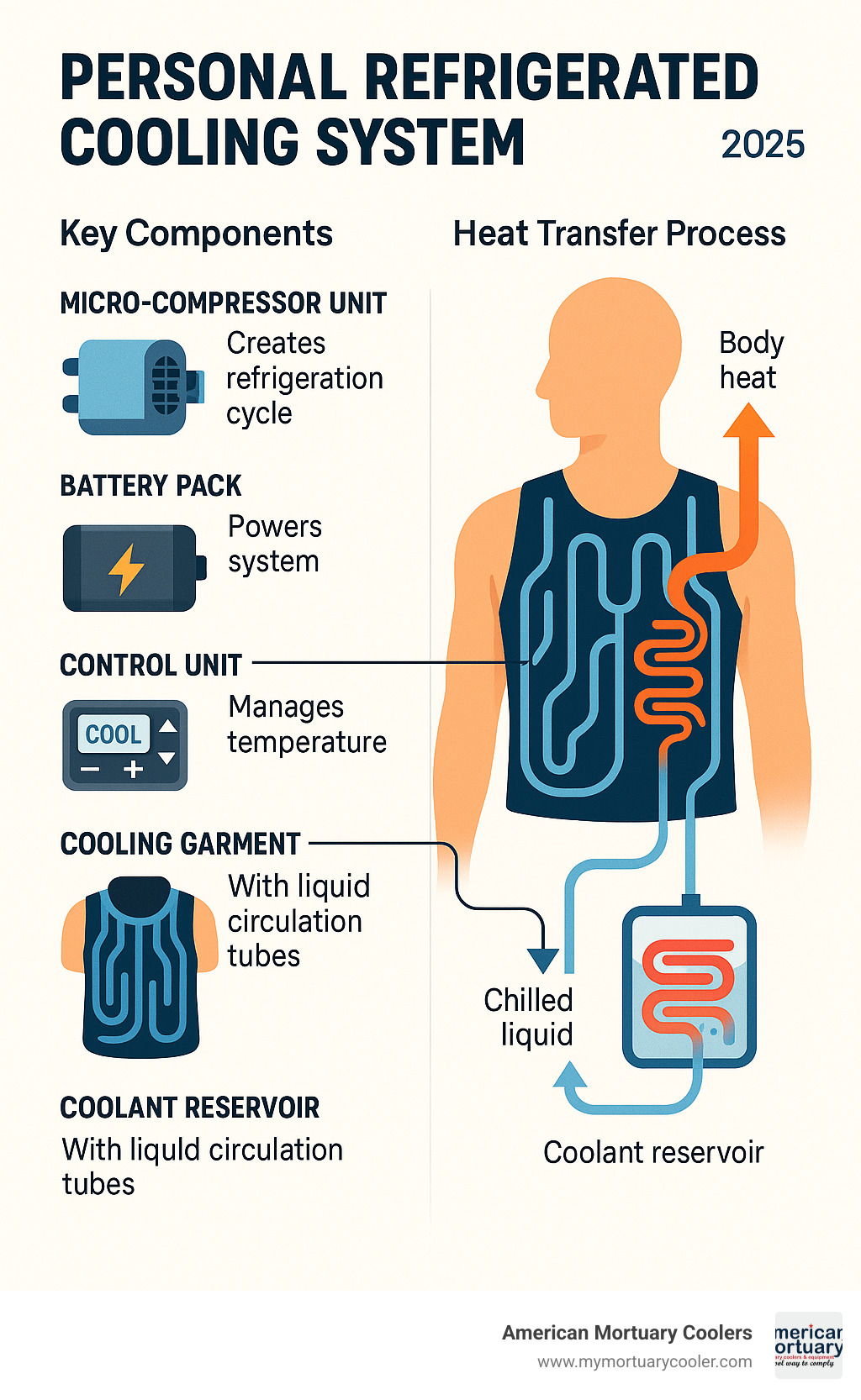

Key Components:

- Micro-compressor unit - Creates refrigeration cycle

- Cooling garment - Distributes chilled liquid across body

- Battery pack - Powers system for 2-8 hours

- Control unit - Manages temperature and safety functions

- Coolant reservoir - Circulates chilled fluid through garment

These systems evolved from military and aerospace applications where astronauts and pilots needed reliable cooling in confined spaces. Unlike traditional ice-based cooling vests that lose effectiveness as ice melts, refrigerated systems maintain consistent temperatures.

The technology works by:

- Compressing refrigerant to create cooling effect

- Circulating chilled liquid through tubes in a wearable garment

- Absorbing body heat and returning warm liquid to be re-cooled

- Maintaining target temperatures regardless of ambient conditions

I'm Mortuary Cooler, a national level mortuary cooler supplier with experience in refrigeration systems including PERSON REFRIGERATED COOLING SYSTEM- applications for medical and mortuary professionals.

PERSON REFRIGERATED COOLING SYSTEM- word roundup:

What Is a Personal Refrigerated Cooling System?

A PERSON REFRIGERATED COOLING SYSTEM- is your personal air conditioner that you can wear. It uses the same basic principles as your home refrigerator, just shrunk down to fit in a backpack or vest.

A tiny compressor creates a cooling effect by compressing and expanding refrigerant. This chilled liquid flows through small tubes woven into a special cooling garment that wraps around your body. The micro-compressor does the heavy lifting, while liquid circuits carry the cold exactly where you need it most.

Unlike ice packs that turn into warm, soggy messes after an hour, a PERSON REFRIGERATED COOLING SYSTEM- keeps working at the same temperature all day long. According to scientific research on sub-ambient passive cooling, these systems can achieve temperatures below the surrounding air temperature while staying energy efficient.

The applications include welders working next to blazing hot metal, race car drivers in cockpits that feel like ovens, surgeons in heavy sterile gowns, and construction workers under the summer sun.

Origins and Evolution

The story of personal cooling starts in space. Back in the 1960s, astronaut suits needed to keep people comfortable in the vacuum of space, where temperatures can swing from blazing hot to freezing cold in minutes.

Military pilots faced similar challenges in their cockpits, especially during long missions in hot climates. Those early systems were bulky but proved the concept worked.

COMPCOOLER has been refining this military-grade technology for over 15 years, taking those original astronaut and pilot cooling solutions and making them practical for everyday use.

ChillOut Systems represents the newest generation of this technology, bringing "active driver cooling technology into the 21st century" with systems that never run out of cooling power because they use continuous refrigeration rather than ice.

PERSON REFRIGERATED COOLING SYSTEM- Components & Operation

A PERSON REFRIGERATED COOLING SYSTEM- works like a tiny refrigerator you can wear. At the heart sits the micro-compressor - a miniature powerhouse that creates refrigeration. Companies like Aspen Systems produce over 100,000 of these annually, making it possible to pack serious cooling power into something the size of a shoebox.

The condenser uses small fans to blow away hot air generated during cooling. The evaporator absorbs heat from the cooling liquid that flows through your garment. A circulation pump keeps chilled liquid moving through tubes in your cooling vest. The coolant reservoir stores this liquid, while the battery pack typically delivers 12V/20A power. The control unit manages temperature preferences and safety functions.

When comparing vapor-compression systems to thermoelectric alternatives:

| Feature | Vapor-Compression | Thermoelectric |

|---|---|---|

| Cooling Capacity | 200-400W | 50-150W |

| Efficiency (COP) | 2.0-4.0 | 0.5-1.0 |

| Temperature Range | -20°F to +40°F | +20°F to +60°F |

| Power Consumption | Lower per watt of cooling | Higher per watt of cooling |

The vapor-compression approach wins for serious cooling applications requiring reliable performance in extreme conditions.

Core Cycle Inside a PERSON REFRIGERATED COOLING SYSTEM-

The refrigeration cycle follows four stages that repeat continuously. Compression starts when the micro-compressor squeezes gaseous refrigerant, increasing temperature and pressure. Condensation follows as hot, pressurized gas flows through the condenser and releases heat to surrounding air, changing into high-pressure liquid.

Expansion occurs when liquid refrigerant rushes through a tiny expansion valve, causing sudden pressure drop that chills the refrigerant. Evaporation completes the cycle as cold refrigerant absorbs heat from your circulating coolant liquid, turning back into gas.

The Coefficient of Performance (COP) typically ranges from 2.0 to 4.0, meaning you get 2-4 watts of cooling for every watt of electrical power consumed.

Smart Controls in a PERSON REFRIGERATED COOLING SYSTEM-

Modern units pack impressive intelligence into compact designs. Temperature management uses digital thermostats for precise control, with some units offering multiple cooling zones. Systems automatically adjust based on ambient conditions.

Safety systems include compressor protection preventing overheating damage, low battery warnings, pressure relief valves, and leak detection sensors. The user interface features LED displays showing temperature and battery status, with push-button controls for easy adjustment.

IoT integration enables supervisors to monitor worker safety in real-time, tracking both system performance and worker comfort levels in high-risk environments.

For professionals working in temperature-critical environments, our comprehensive guide to mortuary cold storage options explores how professional refrigeration systems achieve exact temperature control.

Benefits, Use Cases, and Limitations

A PERSON REFRIGERATED COOLING SYSTEM- offers significant advantages over traditional cooling methods. The energy savings are substantial - instead of cooling entire buildings, you're only cooling one person. Targeted comfort happens right where you need it most, against your skin.

For occupational safety, these systems prevent heat stress, which kills more workers than lightning, tornadoes, and hurricanes combined. When wearing heavy protective gear that traps body heat, personal cooling prevents heat exhaustion and heat stroke.

Unlike ice vests that gradually warm up, refrigerated systems deliver consistent performance throughout their entire run time.

Motorsports represents one of the most demanding applications. Racing drivers deal with cockpit temperatures hitting 140°F or higher. ChillOut Systems designed iceless coolers specifically for this challenge, providing continuous cooling without weight penalties.

In medical settings, surgical teams working under hot operating room lights benefit enormously. Systems don't interfere with sterile procedures but help maintain focus during long operations.

HAZMAT response teams face extreme conditions in chemical protective suits that trap heat. Industrial workers - especially welders and foundry workers exposed to radiant heat - use these systems to stay productive and safe.

Limitations include weight and bulk - even compact units add 5 to 15 pounds to your gear. Battery life limits operation to 2-8 hours depending on capacity and cooling demands. Maintenance requirements include regular filter changes, leak checks, and occasional professional service. The cost factor ranges from $1,100 to nearly $4,000 depending on features.

For technical details about vapor-compression fundamentals, ASHRAE provides comprehensive resources.

Application Spotlight: Mortuary & Medical Settings

The funeral industry and medical field present unique cooling challenges where PERSON REFRIGERATED COOLING SYSTEM- technology excels.

Mobile morgue operations during disasters require temporary cooling solutions. Funeral home preparation rooms can get uncomfortably warm - embalmers performing detailed restoration work need comfort and focus. Transport operations involve moving between hot outdoor temperatures and cold storage areas.

At American Mortuary Coolers, our experience with body fridges and mortuary refrigerators has taught us that comfortable professionals do better work.

In medical applications, surgical teams working under intense operating room lights face heat buildup affecting performance. Laboratory technicians working with temperature-sensitive samples benefit from personal cooling while protecting valuable materials.

Application Spotlight: Outdoor Workers & Athletes

Construction crews, farm workers, and athletes represent huge markets for personal cooling technology.

The construction industry benefits from reduced heat-related injuries and worker compensation claims. Extended safe working hours during summer months keep projects on schedule.

Agricultural applications include field workers during harvest seasons, greenhouse operations exceeding 100°F, and livestock handlers in hot barns.

Professional racing drivers were early adopters. Race car cockpits combine engine heat, safety gear, and confined spaces creating brutal conditions. Modern racing cooling systems integrate with safety equipment and keep cockpit temperatures 20-30 degrees cooler.

Hydration integration addresses two needs simultaneously. COMPCOOLER offers hydration bladders in 2.5L and 4.0L capacities that work with their cooling systems.

Selecting & Maintaining Your System

Picking the right PERSON REFRIGERATED COOLING SYSTEM- requires matching your specific work conditions and cooling needs.

Consider cooling capacity first. Most systems come in 200W and 400W sizes. 200W units work for office workers or light outdoor tasks, while 400W systems handle heavy-duty work like welding or construction in extreme heat.

Power source options include 12V DC power for trucks, 24V commercial vehicle power, or standard wall outlets. Battery-powered units provide freedom to move but need recharging every few hours.

Portability matters - backpack-style systems work for mobile workers, while larger stationary units with long cooling hoses suit fixed workstations. Weight typically adds 5-15 pounds to your gear.

Look for proper certifications like CE, FCC, UL, and ISO9001 registration for safety and quality assurance.

Checklist Before Buying a PERSON REFRIGERATED COOLING SYSTEM-

Temperature targets determine system requirements. Some systems cool 40 degrees below ambient temperature, others are more modest.

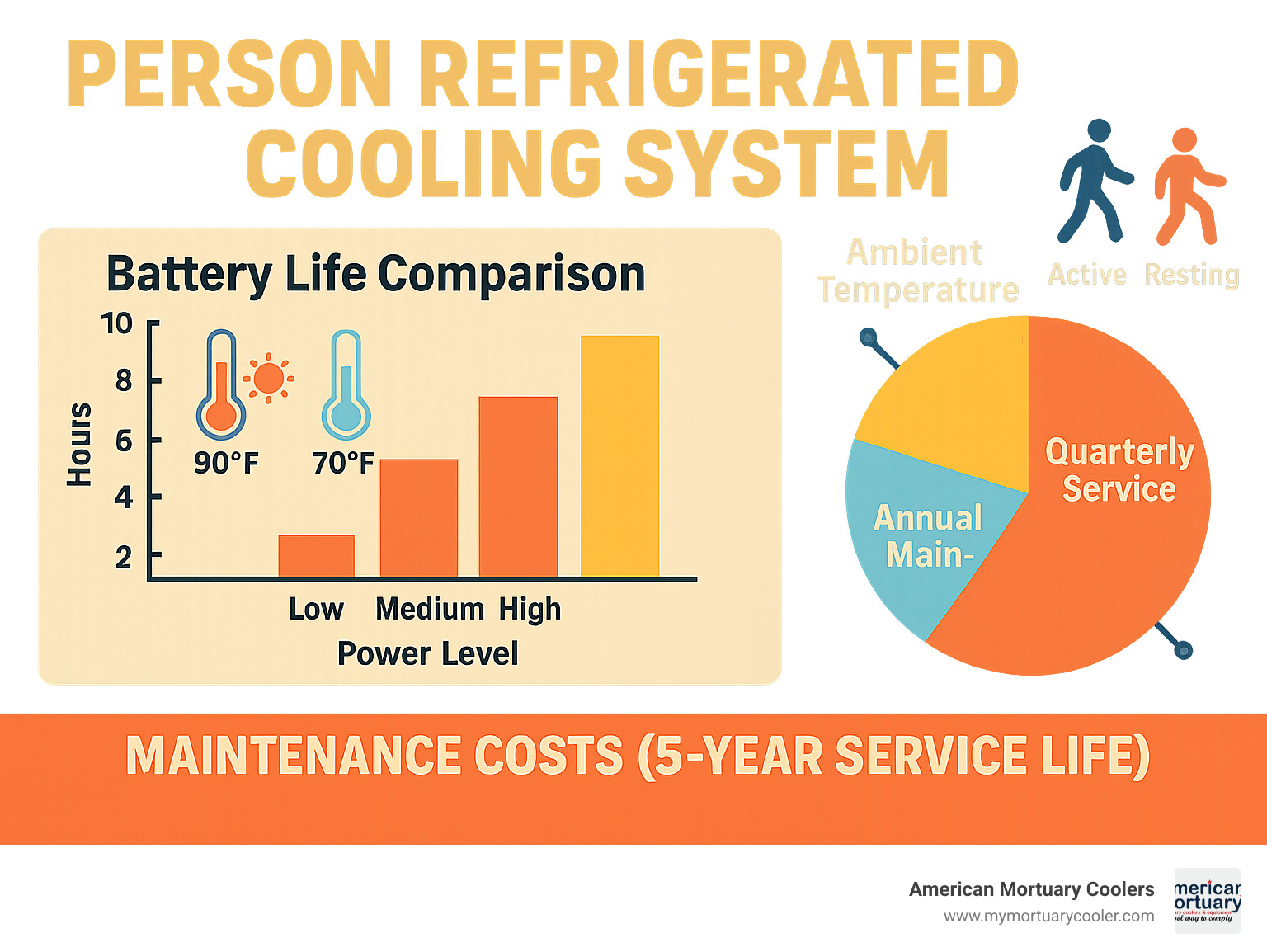

Runtime requirements determine battery needs. All-day cooling requires multiple battery packs or plug-in capability. Most batteries last 2-8 hours depending on workload.

Integration with existing gear is often overlooked. Will your cooling vest fit under safety equipment? Can the control unit attach to your tool belt?

Warranty coverage indicates manufacturer confidence. Look for comprehensive warranties from established companies.

For detailed guidance, our comprehensive guide to comparing mortuary refrigeration systems provides evaluation frameworks.

Routine Service & After-Sales Support

PERSON REFRIGERATED COOLING SYSTEM- maintenance isn't complicated but is absolutely necessary.

Monthly check-ups should include inspecting tubing and connections for wear, checking battery charge, ensuring cooling garment cleanliness, and testing controls.

Quarterly maintenance involves cleaning condenser coils, replacing dirty air filters, checking electrical connections, and testing safety systems.

Annual service includes leak testing the refrigerant system, checking compressor oil levels, replacing wear items, and recalibrating temperature sensors.

Keep spare parts including extra batteries, air filters, fuses, and cleaning supplies. Professional users should have backup cooling garment tubes.

Professional service support matters when problems arise. Choose manufacturers providing good technical support and accessible service centers.

For maintenance principles, our complete guide to walk-in mortuary refrigerator specifications covers approaches applying to all refrigeration equipment.

Frequently Asked Questions about Personal Refrigerated Cooling

How long can a PERSON REFRIGERATED COOLING SYSTEM- run on battery?

Most PERSON REFRIGERATED COOLING SYSTEM- units run 2-8 hours on single battery charge, depending on conditions.

200W systems in moderate conditions provide 6-8 hours of reliable cooling, sipping power gently for lighter work or all-day coverage.

400W systems for extreme heat deliver 2-4 hours of runtime, working harder to maintain cooling in serious conditions.

Factors affecting battery life include higher ambient temperatures requiring overtime work, physical activity generating more body heat, system efficiency varying between models, and battery condition degrading over time.

Smart users keep spare batteries and rotate them during long shifts. Many systems offer vehicle DC power connections for workers near trucks with 12V power.

Are the refrigerants used safe for wearers and the environment?

Modern PERSON REFRIGERATED COOLING SYSTEM- manufacturers use safe, environmentally responsible refrigerants.

Most systems use R-134a with zero ozone depletion potential and relatively low global warming potential - the same refrigerant in millions of car air conditioners.

R-410A offers similar environmental benefits. Cutting-edge systems use natural refrigerants like CO2 (R-744) with zero ozone depletion potential and global warming potential of just 1.

Safety features include sealed systems with no user-serviceable refrigerant components, leak detection sensors for automatic shutdown, pressure relief valves preventing over-pressurization, and FDA approval standards for body-contact materials.

Personal cooling systems contain less than one pound of refrigerant - minimal amounts compared to home air conditioners.

Can these systems integrate with protective or athletic gear?

Absolutely. Manufacturers design systems specifically for specialized equipment integration.

Protective equipment integration includes HAZMAT suits where traditional cooling is impossible, firefighter gear with heat-resistant cooling garments, military applications compatible with body armor, and medical PPE maintaining sterile procedures.

Athletic applications feature racing suits with SFI safety ratings and ultra-lightweight designs, cycling gear focusing on aerodynamics, and running equipment prioritizing movement freedom.

Engineering solutions include flexible tubing moving naturally with your body, quick-disconnect fittings for rapid equipment changes, compact control units staying out of the way, and multiple mounting options accommodating different configurations.

At American Mortuary Coolers, our experience with mortuary refrigeration systems has taught us that the best cooling technology works seamlessly with existing equipment and procedures.

Conclusion

PERSON REFRIGERATED COOLING SYSTEM- technology has evolved from specialized astronaut and military equipment into practical, life-saving technology keeping workers safe in challenging conditions.

The future brings exciting developments. Magnetic refrigeration using magnetocaloric materials could create cooling without traditional refrigerants, offering better efficiency and less environmental impact. Elastocaloric refrigeration uses shape-memory alloys creating cooling through mechanical deformation, enabling incredibly compact systems.

Improved materials science means tomorrow's systems will be smaller, lighter, and more powerful. Smart integration with IoT connectivity and AI-driven controls will enable predictive maintenance, automatic condition adjustment, and seamless workplace safety integration.

Sustainability goals drive innovation across industries. Personal cooling systems offer smart solutions - maintaining worker safety and comfort while using far less energy than air conditioning entire buildings.

At American Mortuary Coolers, we've seen how critical precise temperature control is in professional environments. Our experience designing custom mortuary coolers across Tennessee, Georgia, Illinois, South Carolina, Texas, California, New York, and Pennsylvania has taught us that cooling technology isn't just about comfort - it's about safety, efficiency, and getting the job done right.

Whether working in hot foundries, responding to HAZMAT emergencies, or performing delicate mortuary preparation work, reliable performance, energy efficiency, and user safety must work together creating solutions that make real differences.

Investment in PERSON REFRIGERATED COOLING SYSTEM- technology pays for itself through improved worker safety, fewer heat-related incidents, and maintained productivity when temperatures rise. As technology advances, we expect more innovative applications protecting workers while supporting environmental goals.

These systems represent more than cooling technology - they're about caring for people doing difficult, important work in challenging conditions. That's something we understand deeply, and why we're excited about where this technology goes next.

For more information about our comprehensive cooling solutions, visit our website to explore how we can help with your specific refrigeration needs.