Understanding PIMS: The Data Backbone of Modern Operations

PIMS stands for multiple systems across different industries, but they all share one common goal: managing critical information to improve operations and decision-making.

Quick PIMS Overview:

- Process Information Management System - Collects real-time data from manufacturing and industrial processes

- Pennsylvania Information Management System - Tracks student data across all PA school districts

- Pittsburgh Institute of Mortuary Science - Educational institution for funeral service professionals

- Plasma Instrument for Magnetic Sounding - NASA sensor on Europa Clipper mission

- Python Image Sequence - Software library for scientific video analysis

The most common use of PIMS refers to Process Information Management Systems - powerful platforms that collect, store, and analyze data from industrial equipment like sensors, controllers, and automation systems. These systems help companies monitor everything from temperature and pressure in manufacturing plants to student performance in educational institutions.

Whether you're tracking fermentation in a bioprocessing facility, monitoring plasma around Jupiter's moon Europa, or managing student records across Pennsylvania's 500+ school districts, PIMS provides the data foundation that drives better decisions and improved outcomes.

As American Mortuary Coolers, we've worked with funeral homes nationwide to integrate reliable refrigeration systems that connect seamlessly with facility management platforms. Understanding how different PIMS solutions work helps mortuary professionals make informed decisions about equipment that supports their data tracking and operational needs.

PIMS Across Industries: From Process Data to Plasma Sensors

Here's something fascinating: PIMS isn't just one thing. The same basic idea - managing information to make better decisions - shows up in completely different industries, from factory floors to NASA missions.

| System Type | Data Focus | Real-Time Requirements | Primary Users |

|---|---|---|---|

| PIMS | Process variables, equipment status | High (milliseconds) | Plant operators, engineers |

| MES | Production orders, batch records | Medium (minutes) | Production managers |

| ERP | Business transactions, inventory | Low (hours/days) | Executive management |

Think of it this way: whether you're tracking temperature in a pharmaceutical plant or monitoring student progress across Pennsylvania schools, you need reliable systems to collect, store, and make sense of your data. That's where PIMS comes in.

PIMS in Manufacturing & Process Industries

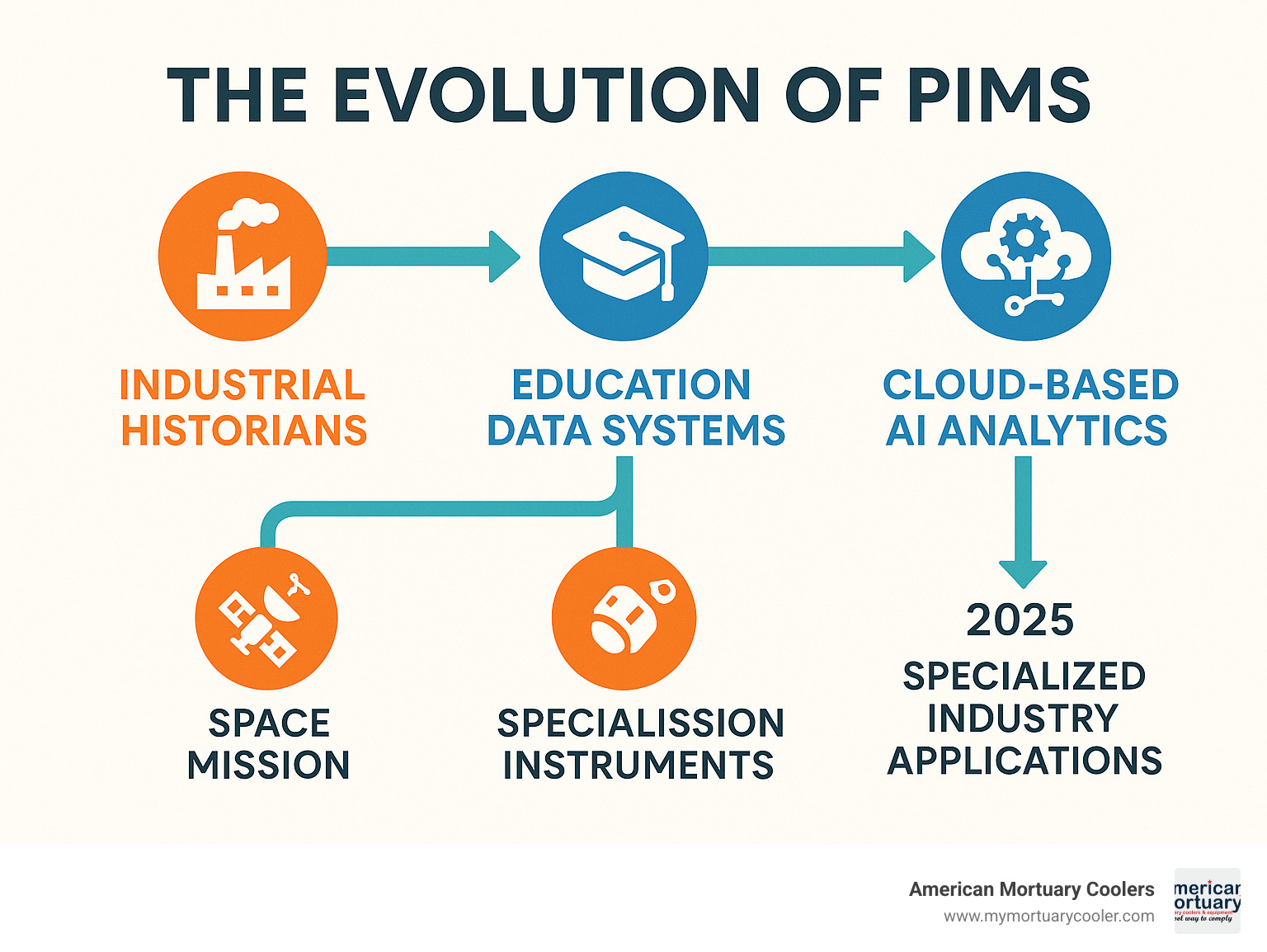

In manufacturing, Process Information Management Systems act like the brain of industrial operations. These systems started as simple data recorders back in the 1970s, but they've evolved into sophisticated platforms that can handle massive amounts of high-speed data.

Modern industrial PIMS work hand-in-hand with other systems you might recognize: SCADA systems for real-time monitoring, DCS platforms for process control, and LIMS for quality testing data. It's like having a team where everyone speaks the same language.

Take bioprocessing, for example. PIMS constantly monitor critical factors like fermentation temperature, pH levels, and dissolved oxygen. They track how well cells are growing and how much nutrients they're consuming in bioreactors. This helps ensure everything runs smoothly during complex purification steps like chromatography and filtration.

For companies dealing with FDA or EPA regulations, PIMS provide the detailed audit trails and access controls that inspectors want to see. Having solid data integrity and traceability can literally make or break a regulatory inspection.

PIMS in Education, Healthcare, and Space Missions

Now here's where it gets interesting - PIMS shows up in some pretty unexpected places.

Pennsylvania's schools use their Information Management System to track student data across more than 500 school districts statewide. It helps schools meet federal reporting requirements under the Every Student Succeeds Act while keeping student information private and secure.

The Pittsburgh Institute of Mortuary Science has kept their tuition stable for five straight years while maintaining small class sizes - under 30 students online and a 17:1 ratio in classrooms. Their information systems track student progress through more than 500 campus embalmings completed annually, ensuring everyone gets the hands-on training they need.

Out in space, NASA's Europa Clipper mission uses a Plasma Instrument for Magnetic Sounding with four specialized sensors to measure plasma around Jupiter's moon Europa. This data helps correct magnetometer readings so scientists can learn more about Europa's hidden ocean beneath the ice.

Even privacy advocates use PIMS concepts. Ontario's Privacy and Information Management Taskforce helps school boards steer complex privacy laws - showing how these systems extend beyond just collecting data to protecting it too.

At American Mortuary Coolers, we understand how important reliable data systems are for funeral homes. That's why our custom refrigeration solutions are designed to integrate smoothly with facility management platforms, giving you the operational visibility you need while maintaining the reliability your families depend on.

Inside a Process Information Management System (PIMS) – Architecture & Integration

Think of a PIMS like the nervous system of a modern facility - it needs to collect information from everywhere, process it quickly, and deliver insights where they're needed most. Understanding how these systems work under the hood helps explain why they're so valuable across industries, from manufacturing plants to funeral homes.

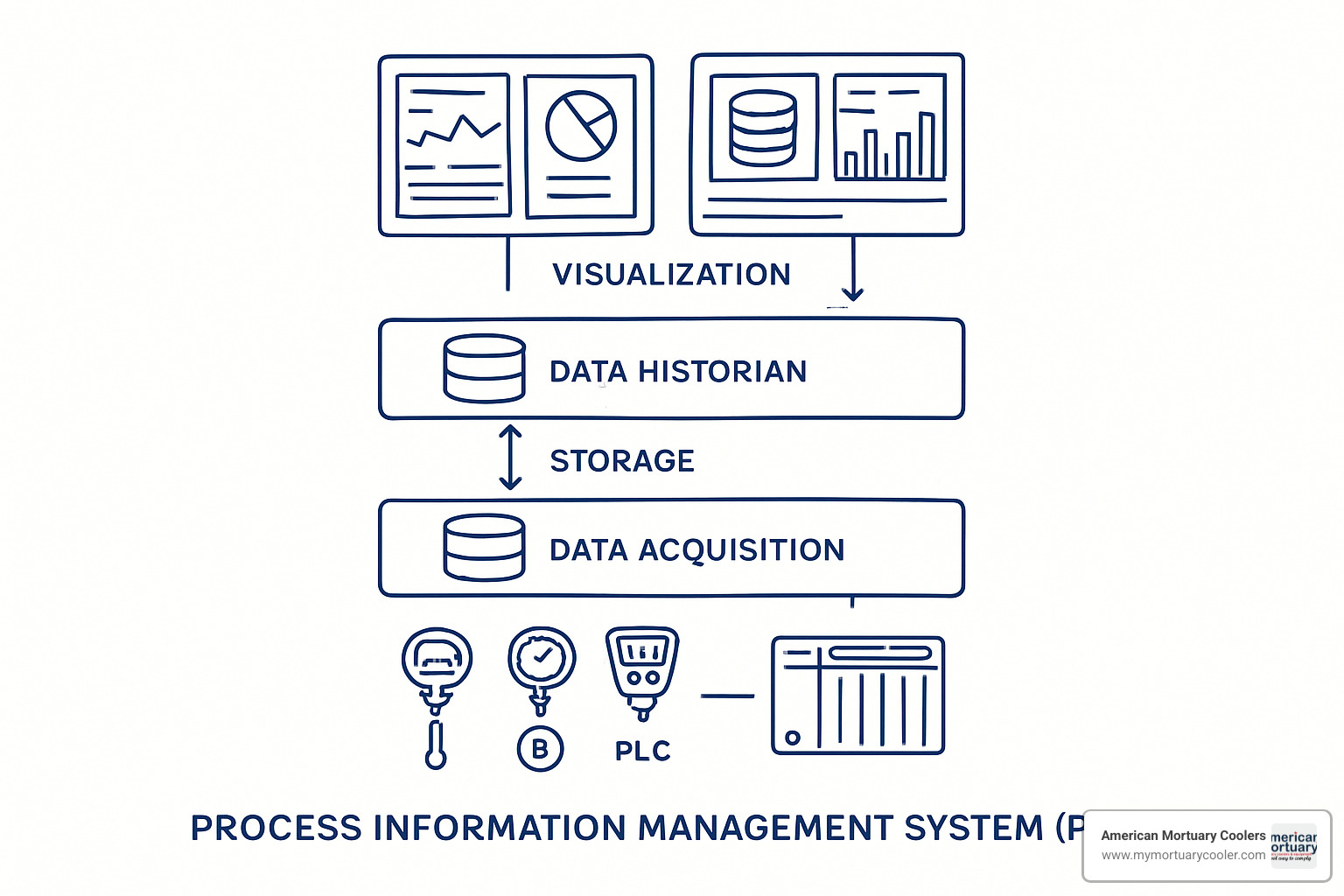

The magic happens through several layers working together seamlessly. Raw data flows in from sensors and equipment, gets processed and stored, then transforms into the dashboards and reports that help people make better decisions.

Key Components and Architecture

Every PIMS starts with data collectors - the digital ears that listen to everything happening in your facility. These collectors speak multiple languages, connecting to PLCs, DCS systems, SCADA networks, and individual sensors. Modern collectors use standardized protocols like OPC-UA, which means they can talk to equipment from different manufacturers without missing a beat.

The real-time historians form the memory center of any PIMS. These specialized databases store time-series data with incredible precision - we're talking microsecond timestamps that can track thousands of data points updating multiple times per second. Unlike regular databases, historians are built specifically for this high-speed, high-volume data storage.

Data storage in modern PIMS gets more sophisticated every year. The best systems use hybrid approaches that combine traditional relational databases for structured information with NoSQL systems for everything else. This flexibility means your PIMS can store numerical sensor readings alongside equipment maintenance photos or operator notes.

Visualization and analytics tools turn all that raw data into something useful. Real-time dashboards show what's happening right now, while trend analysis helps spot patterns over time. Advanced PIMS include predictive analytics that can warn you about potential equipment failures before they happen.

Security and audit systems keep everything locked down and traceable. Role-based access controls ensure people only see what they need to see, while comprehensive audit trails track every data change - crucial for regulatory compliance in industries like pharmaceuticals or funeral services.

Integration with SCADA, DCS, LIMS & ERP

The real power of PIMS comes from playing well with other systems. Modern platforms use middleware connectors and REST APIs to create smooth data flows between operational and business systems.

SCADA integration creates a perfect partnership - SCADA systems excel at real-time control but struggle with long-term data storage, while PIMS provide the historical context that helps operators understand patterns and trends. Together, they give you both immediate control and long-term perspective.

DCS connectivity goes deeper than just collecting process variables. The best integrations capture control actions and operator interventions, creating a complete picture of how processes behave under different conditions. This detailed record proves invaluable for troubleshooting and optimization.

LIMS integration automatically flows laboratory data into your PIMS, connecting quality measurements with the process conditions that created them. This correlation is particularly valuable in pharmaceutical manufacturing and food processing, where quality and process parameters must align perfectly.

ERP connections bridge the gap between operations and business systems. Production data, energy consumption figures, and quality metrics flow from PIMS into business systems, enabling accurate cost accounting and performance reporting that actually reflects what's happening on the floor.

At American Mortuary Coolers, we've seen how important these integrations are for funeral homes managing multiple refrigeration units and tracking critical parameters. Our systems connect seamlessly with facility management platforms, giving funeral directors the data visibility they need for smooth operations. More info about mortuary supplies shows how the right equipment integration makes all the difference in professional funeral service delivery.

Benefits, Applications & Vendor Landscape

When organizations implement a PIMS, they're not just buying software - they're investing in a change that touches every aspect of their operations. The results speak for themselves, with companies across industries reporting dramatic improvements that go straight to their bottom line.

Tangible Benefits for Process Industries

The most compelling benefit of PIMS implementation is the immediate boost to Overall Equipment Effectiveness (OEE). Most companies see their equipment utilization improve by 10-15% within the first year, simply because they finally have visibility into what's actually happening on their production floor.

Predictive maintenance becomes a game-changer when your PIMS starts analyzing equipment vibration patterns, temperature fluctuations, and performance trends. Instead of waiting for expensive breakdowns, you can schedule maintenance when it's convenient. Many facilities cut their unplanned downtime in half using this approach.

Energy optimization often surprises facility managers with quick wins. When you can see exactly which processes are energy hogs and when they're running inefficiently, those 5-10% energy cost reductions start adding up fast. One chemical plant we know identified a pump that was running unnecessarily during off-peak hours - a simple fix that saved thousands annually.

Quality control gets boostd when laboratory data flows automatically into your PIMS. You can correlate quality measurements with process conditions in real-time, catching problems before they become expensive batch losses or customer complaints.

For regulatory compliance, automated data collection and audit trails turn what used to be nightmare inspections into routine paperwork. Whether you're dealing with FDA 21 CFR Part 11 requirements or ISO standards, having comprehensive records at your fingertips makes compliance much less stressful.

Real-World Applications & Case Studies

The versatility of PIMS really shines when you see how different industries adapt the technology to solve their unique challenges.

In pharmaceutical manufacturing, bioprocessing facilities rely on PIMS to monitor fermentation parameters with incredible precision. Research shows these systems excel at tracking critical variables like temperature, pH, and dissolved oxygen - the difference between a successful batch and a costly failure.

Cold chain management has evolved significantly with specialized PIMS solutions. Companies like Pimware offer sophisticated temperature monitoring systems that don't just track conditions - they actually calculate remaining product shelf life during transit. Their Starter Kit, priced at $165 with 4 tags, a remote control, and USB reader, shows how accessible this technology has become.

Logistics operations demonstrate the scalability of PIMS technology. PIMS Inc., with over three decades of experience, routinely manages projects involving hundreds of mailers with more than 2,000 packages each. This kind of complex distribution operation would be impossible without robust information management systems.

Even space exploration relies on PIMS technology. NASA's Europa Clipper mission uses a specialized PIMS to measure plasma characteristics around Jupiter's moon Europa - proving these systems work even in the most extreme environments imaginable.

Success stories keep rolling in from every sector: oil and gas companies reducing operational costs by 15% through better asset utilization, food processing plants achieving 99.9% traceability for recall management, pharmaceutical manufacturers cutting batch release time by 40%, chemical plants improving safety response time by 60%, and utilities boosting power generation efficiency by 8%.

The vendor landscape includes established players like OSIsoft PI (now part of AVEVA), Aspen IP.21, and Wonderware Historian, alongside emerging open-source solutions. Each platform brings unique strengths depending on your industry requirements and integration needs.

At American Mortuary Coolers, we see how these same principles apply to funeral home operations. Understanding PIMS concepts helps mortuary professionals select refrigeration equipment that integrates seamlessly with their facility management systems, providing the operational visibility that modern funeral homes need. Scientific research on PIMS analytics continues advancing the field, benefiting industries from manufacturing to mortuary services.

Implementation Challenges, Security & Future Trends

Implementing a PIMS can transform your operations, but it's not always smooth sailing. After working with facilities nationwide, we've seen what works and what doesn't. The good news? Most challenges are predictable and manageable with the right approach.

Deployment Pitfalls and How to Overcome Them

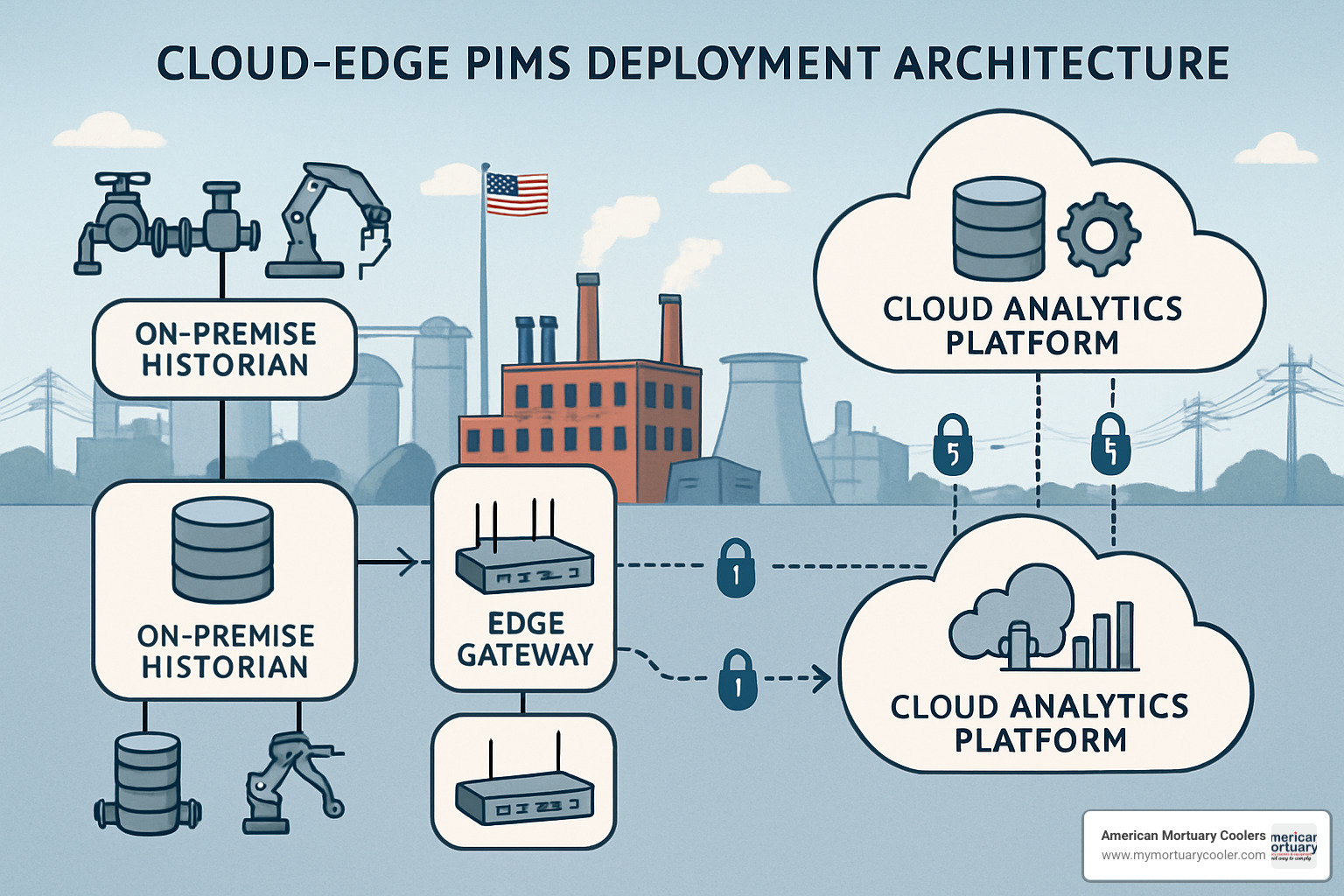

Legacy systems cause the biggest headaches during PIMS implementation. You might have equipment from the 1980s that speaks a completely different language than modern systems. The solution isn't replacing everything - it's using protocol converters and edge gateways that act like translators between old and new technology.

Data quality problems can sink even the best PIMS project. When sensors drift out of calibration or network connections get flaky, you end up with garbage data that leads to bad decisions. Smart implementations build in data validation rules and automated quality checks from day one.

Getting people to actually use the system presents another common challenge. You can have the most sophisticated PIMS in the world, but if operators ignore it or don't trust it, you've wasted your investment. Successful projects focus heavily on training and showing people how the system makes their jobs easier, not harder.

Scope creep kills budgets and timelines. What starts as a simple monitoring project suddenly becomes a complete facility overhaul. The best approach is starting small with your most critical processes, proving value, then expanding gradually.

Stakeholder buy-in makes or breaks PIMS projects. You need support from both the C-suite and the shop floor. Management wants ROI numbers, while operators want systems that actually help them do their jobs better. Clear communication about realistic benefits keeps everyone aligned.

Security & Compliance Considerations

Security isn't optional when your PIMS connects to networks and cloud systems. Modern facilities face real threats from cyberattacks, and operational data is increasingly valuable to bad actors.

Network protection starts with proper firewalls and network segmentation. Your PIMS shouldn't sit on the same network as your email system. VPNs provide secure remote access while keeping unauthorized users out.

Access controls ensure people only see data they need for their jobs. Role-based permissions mean a maintenance technician can't access financial data, while executives can't accidentally change process setpoints. Multi-factor authentication adds another security layer.

Data encryption protects information both when it's stored and when it's moving between systems. This is especially important for sensitive operational data that could reveal competitive advantages.

Audit trails track every system access and data change. These logs support both security monitoring and regulatory compliance - you can prove who accessed what data and when.

Backup and disaster recovery plans ensure your PIMS can recover quickly from failures or security incidents. Regular testing of these plans prevents nasty surprises during real emergencies.

For mortuary facilities, security is particularly critical given the sensitive nature of the information involved. Our refrigeration systems support encrypted communications and secure data logging to protect facility operations. More info about morgue refrigerators.

What's Next: Cloud, IoT & AI-Driven PIMS

The future of PIMS is getting exciting. New technologies are making these systems smarter, more responsive, and easier to use.

Edge computing brings analytics closer to your equipment. Instead of sending all data to the cloud for processing, edge devices can make decisions locally. This means faster response times and systems that work even when internet connections fail.

IoT sensors are revolutionizing data collection. Wireless sensors can monitor equipment that was previously impossible to instrument. Battery-powered devices can track vibration, temperature, and other conditions in places where running cables wasn't practical.

Artificial intelligence is changing how PIMS analyze data. Machine learning algorithms can spot patterns in historical data that humans would never notice. These AI systems can predict equipment failures weeks in advance or automatically optimize process parameters.

Digital twins create virtual copies of physical processes using PIMS data. These models let you test different operating scenarios without affecting real production. You can answer "what if" questions safely and find optimal operating conditions.

Augmented reality overlays PIMS data onto real equipment through smart glasses or mobile devices. Technicians can see live data, maintenance history, and troubleshooting guides while looking at actual equipment.

Self-healing systems represent the ultimate goal - PIMS that can fix problems automatically. These systems can restart failed services, switch to backup equipment, or alert the right people based on predefined rules.

These advances point toward PIMS that don't just collect data but actively participate in running your facility. The systems of tomorrow will be more like digital partners than passive monitoring tools.

FAQs & Next Steps

If you've made it this far, you probably have some burning questions about PIMS. Don't worry - we get asked about these systems all the time, especially from funeral directors trying to figure out how all this technical stuff applies to their operations.

Let's clear up the confusion with straight answers to the questions that matter most.

What does PIMS stand for and where is it used?

Here's the thing about PIMS - it's like asking what "Smith" means. There are a lot of different Smiths out there, and they're all doing different things.

Process Information Management Systems are the workhorses of industrial facilities. You'll find them in manufacturing plants, oil refineries, pharmaceutical companies, food processing facilities, and power plants. Basically, anywhere people need to keep track of what their equipment is doing minute by minute.

The Pennsylvania Information Management System handles student data for over 500 school districts across the state. That's a lot of report cards and test scores to keep organized.

The Pittsburgh Institute of Mortuary Science has been training funeral service professionals for more than 80 years. With over 500 embalmings completed on campus each year, they know a thing or two about hands-on education.

NASA's Plasma Instrument for Magnetic Sounding is currently flying toward Jupiter's moon Europa, measuring plasma conditions in space. Talk about working in extreme environments.

And there's the Python Image Sequence library for folks doing scientific video analysis - because sometimes you need to turn video into data.

The common thread? All these systems manage critical information to help people make better decisions, whether that's running a chemical plant or tracking student progress.

How is a PIMS different from MES or ERP?

Think of it like this: PIMS is your facility's nervous system, MES is the brain coordinating activities, and ERP is the memory keeping track of the big picture.

PIMS lives in the moment. It's watching every sensor, every temperature reading, every pressure gauge - sometimes thousands of times per second. When something goes wrong at 2:47 PM, PIMS knows exactly what happened and when.

MES (Manufacturing Execution Systems) thinks in terms of batches and production runs. It knows which products are being made, who's making them, and what materials are being used. It's more concerned with "Did we make 1,000 widgets today?" than "What was the temperature in reactor 3 at 2:47 PM?"

ERP (Enterprise Resource Planning) thinks in terms of weeks and months. It handles purchase orders, inventory, accounting, and planning. It cares about whether you made money this quarter, not whether the temperature spiked for 30 seconds yesterday.

These systems work together beautifully. PIMS provides the real-time foundation, MES coordinates the work, and ERP manages the business side.

How long does it take to deploy a PIMS successfully?

The honest answer? It depends on how ambitious you are right out of the gate.

If you're starting simple - maybe monitoring one process area with basic data collection - you're looking at 3 to 6 months. This gives you time to get the hardware installed, configure the software, train your team, and work out the inevitable bugs.

Medium-complexity projects with multiple process areas and some advanced analytics typically take 6 to 18 months. You're dealing with more integration points, more stakeholders, and more opportunities for things to get complicated.

Enterprise-wide deployments can stretch 12 to 36 months or even longer. When you're connecting dozens of systems across multiple facilities, things get complex quickly.

The secret to success? Start small and prove value first. The most successful PIMS projects we've seen begin with a focused pilot, demonstrate clear benefits, then expand systematically. It's like renovating a house - you don't tear down all the walls on day one.

Key factors that speed things up include having clear requirements from the start, strong support from both management and operators, an experienced implementation team, and realistic expectations about timelines.

At American Mortuary Coolers, we've learned these same lessons apply to mortuary refrigeration systems. Whether you're managing a single funeral home or facilities across multiple states, starting with your core needs and building from there leads to better long-term results.

Our custom solutions are designed to integrate smoothly with whatever facility management systems you're already using. From our Tennessee headquarters, we deliver reliable refrigeration equipment that grows with your needs while maintaining the data integrity that modern funeral homes require.

American Mortuary Coolers delivers durable, custom refrigeration solutions that integrate smoothly with facility data systems—learn how we streamline mortuary operations in our Comprehensive Solutions for Mortuary Needs.

The world of PIMS keeps evolving as new technologies emerge and industries find innovative applications. Whether you're tracking plasma around Jupiter's moons, managing student data across Pennsylvania, or monitoring refrigeration systems in funeral homes, the principle stays the same: better information leads to better decisions and better outcomes.