Finding the Right Trolley with Lift for Your Needs

For those looking for a quick answer about trolley with lift options:

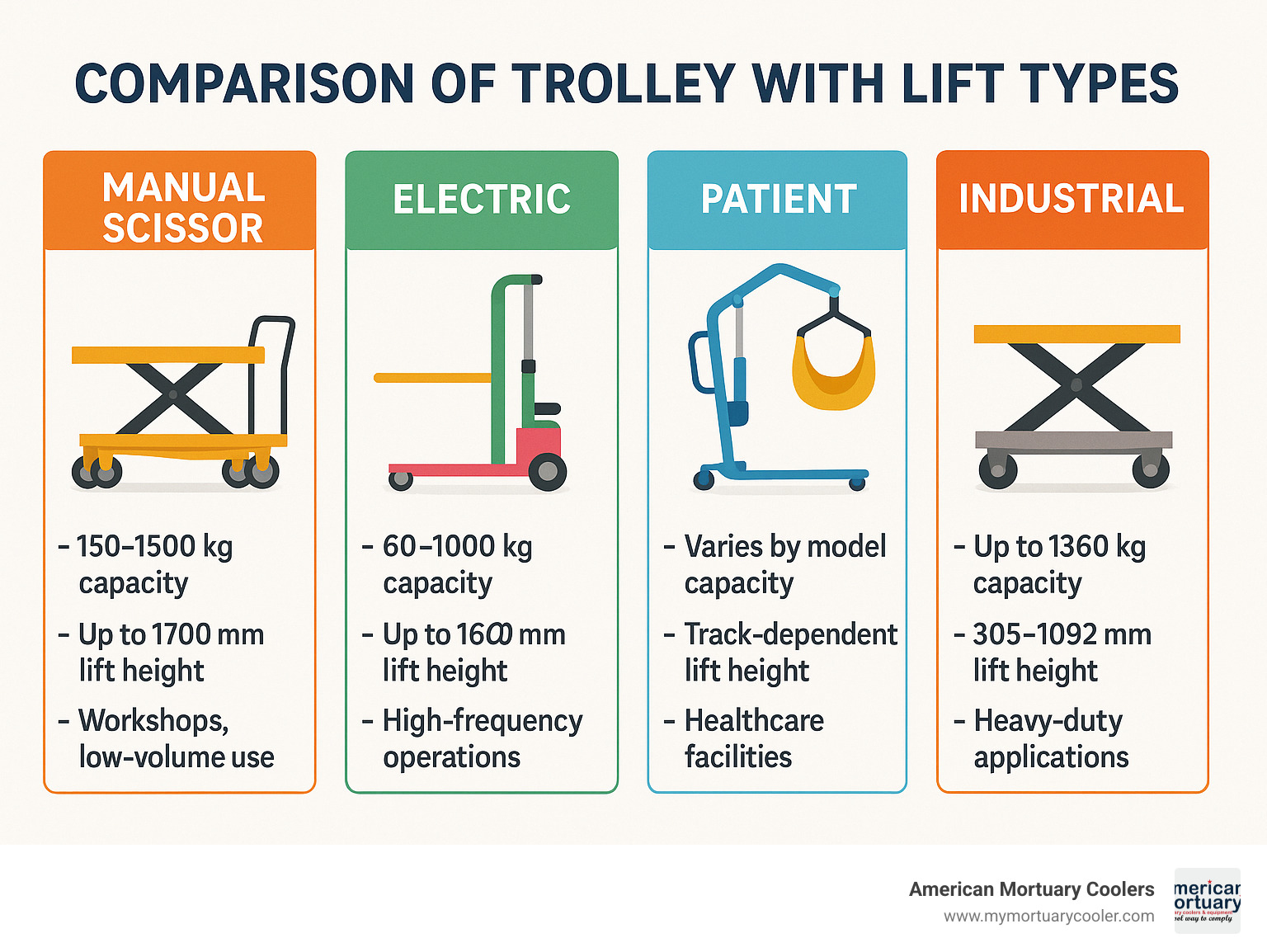

| Type | Capacity Range | Lift Height | Best For |

|---|---|---|---|

| Manual Scissor | 150-1500 kg | Up to 1700 mm | Workshops, low-volume use |

| Electric | 60-1000 kg | Up to 1600 mm | High-frequency operations |

| Patient | Varies by model | Track-dependent | Healthcare facilities |

| Industrial | Up to 1360 kg (3,000 lbs) | 305-1092 mm | Heavy-duty applications |

A trolley with lift combines mobility with vertical lifting capability, creating an essential tool for efficient material handling across numerous industries. These versatile devices eliminate the need for manual lifting, reducing workplace injuries while increasing productivity. Whether you're moving heavy components in a factory, transferring patients in a healthcare facility, or handling deceased individuals in a funeral home, the right lifting trolley can transform your workflow.

The value of these tools extends beyond just lifting capacity - they bring ergonomic benefits that protect staff from strain injuries, improve workplace efficiency, and often provide substantial return on investment through reduced labor costs and increased throughput.

I'm Mortuary Cooler, a specialist in mortuary equipment including trolleys with lift designed for funeral home applications. Having worked with numerous funeral directors to implement efficient body handling systems, I understand how the right trolley with lift can dramatically improve workflow while maintaining dignity in care.

What Is a Trolley with Lift & How Does It Work?

A trolley with lift is essentially your workplace superhero - a mobile platform with the power to move up and down while carrying your heavy loads. Unlike regular trolleys that only roll horizontally, these versatile tools combine the best of both worlds: the mobility of a cart with the vertical lifting capability of a hoist.

Think of it as eliminating the middleman in your workflow. As John Davis, a logistics consultant we partner with at American Mortuary Coolers, puts it: "The beauty of a well-designed trolley with lift is that it eliminates multiple handling steps. Instead of lifting an item onto a cart, moving it, then lifting it again to place it on a shelf or workstation, you simply load once, transport, lift to the required height, and slide it into place."

These handy devices typically work through one of several clever mechanisms. Mechanical scissor lifts use an expanding X-shaped structure that stretches upward when compressed horizontally. Hydraulic systems harness fluid pressure to extend cylinders that raise your platform smoothly. Linear actuators employ electric motors that transform spinning motion into straight-line movement, while pneumatic systems use compressed air to generate lifting power.

Depending on your needs, lifting heights vary dramatically - from just a few inches to over five and a half feet in some industrial models!

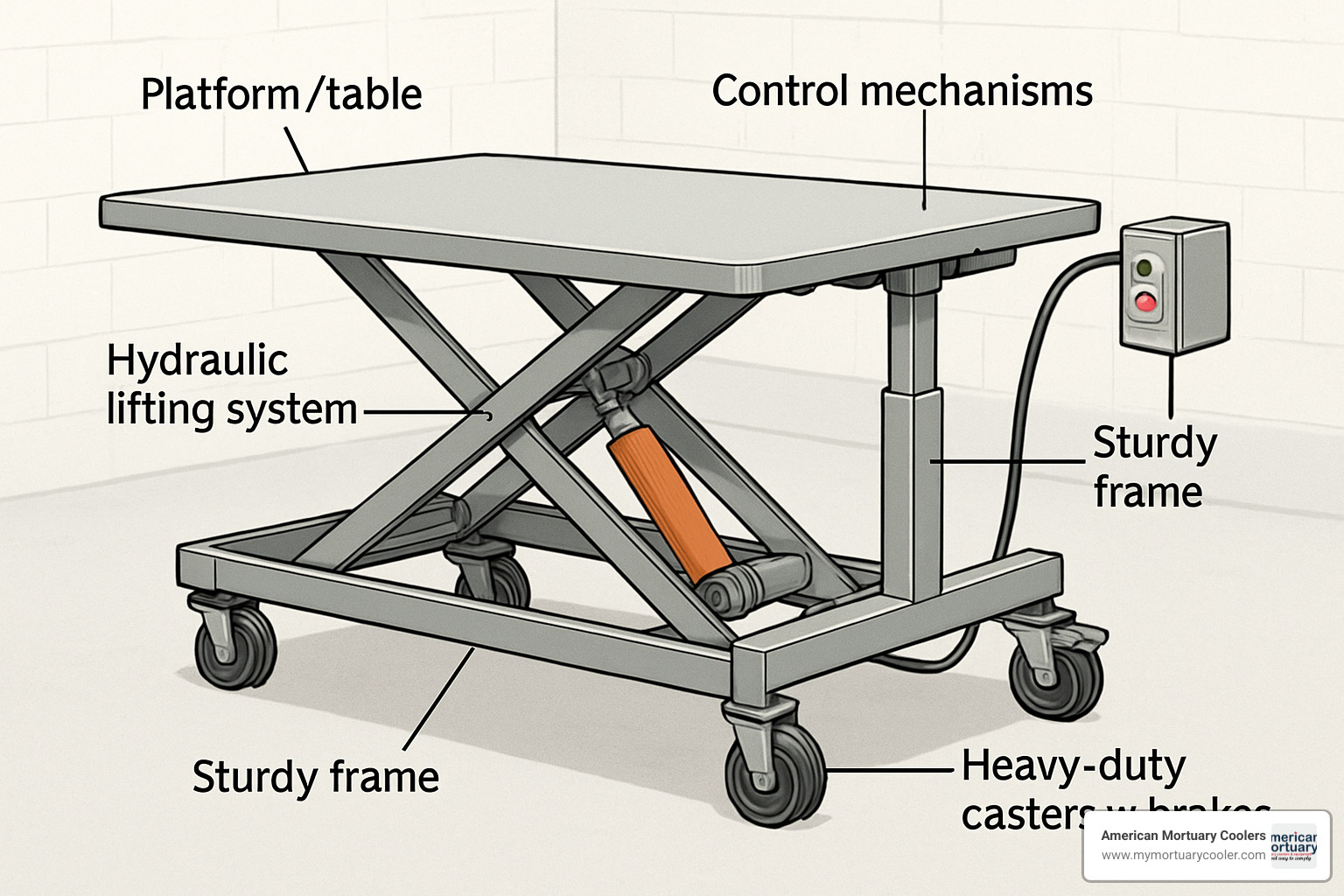

Anatomy of a Modern Trolley with Lift

Just like the human body, a trolley with lift has several vital components working together in harmony:

The platform or table serves as the workhorse, bearing the weight of whatever you need to move. This rests atop a sturdy frame - the skeleton that holds everything together.

Casters or wheels provide mobility, typically heavy-duty with braking capabilities so your trolley stays put during lifting operations. No runaway carts here!

At the heart of every lifting trolley is its lifting mechanism - whether it's a hydraulic cylinder pushing upward, an electric motor driving a gearbox, or mechanical linkages creating leverage.

Controls might be as simple as a foot pedal or hand pump, or as sophisticated as electronic buttons and switches. And don't forget the safety features - overload protection valves, emergency stops, and anti-drop mechanisms that prevent accidents.

Quality models like the Wulfs Custom Welding Lift Table Trolley System feature sealed ball bearings for buttery-smooth movement and precision-engineered lifting components. Many even incorporate sealed and bolted ball transfers that can be easily replaced if damaged - a thoughtful nod to real-world maintenance needs.

How the Lift Mechanism Generates Vertical Motion

The magic behind the up-and-down movement varies depending on your trolley with lift type:

With manual hydraulic systems, you become the power source. Each pump of the foot pedal or hand lever pressurizes hydraulic fluid in a closed system. This forces fluid into a cylinder, extending the piston rod and raising your platform. When you're ready to lower, a release valve allows controlled descent as fluid returns to its reservoir. Simple, reliable, and surprisingly effective!

Electric lift systems take the muscle work out of the equation. A battery-powered motor (usually 12V or 24V) drives either a hydraulic pump or a lead screw mechanism. With just the push of a button on a control pendant, the motor springs to life, generating the force needed to raise your platform. The TAWI Lightweight Lifting Trolley, for example, achieves a lifting speed of 125 mm per second and can complete about 100 lifts of 60 kg by 1 meter on a single battery charge.

Mechanical scissor systems employ a clever scissor-like linkage that expands vertically when compressed horizontally, often powered by a screw mechanism or hydraulic pressure.

Regardless of the system, safety is built in. Protection valves and mechanical stops prevent overextension, while anti-drop mechanisms ensure your load stays put even if power or hydraulic pressure is lost. It's engineering peace of mind, one lift at a time.

Comparing the 4 Main Types of Trolleys with Lift

Shopping for a trolley with lift can feel overwhelming with so many options out there. Let me walk you through the four main types you'll encounter, highlighting what makes each one special and where they truly shine. Think of this as your friendly guide to finding the perfect lifting partner for your specific needs.

Manual Scissor Trolley with Lift

The manual scissor lift trolley is the workhorse of the lifting world – simple, reliable, and wonderfully straightforward. These budget-friendly options work through good old-fashioned elbow grease, using a foot pedal or hand pump to activate the hydraulic system.

These trolleys typically handle anywhere from 150 kg for lighter models up to an impressive 1500 kg for heavy-duty versions, with maximum lift heights reaching up to 1700 mm. Price-wise, you're looking at $300 on the low end to about $2,000 for premium models with higher capacities.

I remember chatting with a warehouse manager in Tennessee who summed it up perfectly: "Our manual scissor trolleys are perfect for our small parts department. We only need to adjust height a few times per shift, and the staff appreciates how simple they are to maintain."

These manual workhorses really shine in places where electrical power isn't readily available or might even be a hazard. Think outdoor construction sites, areas with flammable materials, or small workshops where lifting needs are occasional rather than constant.

Electric Trolley with Lift

When you're ready to step up your lifting game, electric trolleys with lift bring power to your fingertips – literally! With simple push-button controls, these battery-powered assistants take the strain off your body and speed up operations.

These models typically handle between 60 kg and 1000 kg, with lift heights comparable to their manual cousins at up to 1600 mm. The convenience comes at a higher price point, usually between $1,500 and $6,000, but the productivity gains often justify the investment.

The Lightweight trolleys from TAWI are perfect examples – weighing just 35 kg while lifting up to 60 kg. Their 12V batteries power approximately 100 one-meter lifts per charge, making them perfect for retail and light industrial settings.

Sarah Thompson, an ergonomics specialist who's consulted with us at American Mortuary Coolers, puts it well: "Electric models change the game when you're doing repeated lifts throughout the day. The reduction in physical strain translates directly to fewer injuries and higher productivity."

These powered helpers are particularly valuable in environments requiring frequent height adjustments – think busy warehouses, production lines, and retail stockrooms where staff are constantly moving items between different heights.

Patient Lift Trolley with Lift

Patient lift trolleys represent specialized engineering with a heart. Designed specifically for healthcare environments, these systems prioritize gentle, dignified transfers for people with mobility limitations.

Unlike their industrial cousins, patient lift trolleys focus on moderate weight capacities (typically 150-250 kg) with features specifically designed for human comfort and dignity. They often integrate with ceiling track systems or come as portable gantry units, compatible with various slings and harnesses.

The Handicare Portable Ceiling Lift Trolley (MPN 360655) shows the specialized nature of these systems, designed as a replacement part for specific ceiling lift models (AP-300, AP-450, P-440, P-600). These sophisticated systems generally cost between $2,000 and $10,000+, reflecting their specialized nature.

At American Mortuary Coolers, we understand that many of the same principles apply to the respectful handling of deceased individuals in funeral homes and mortuaries – dignity in movement never stops being important.

Industrial Heavy-Duty Trolley with Lift

When serious lifting power meets precision control, you're looking at industrial heavy-duty lift trolleys – the powerhouses of the lifting world. These robust systems handle the heaviest loads in demanding environments where failure isn't an option.

Industrial trolleys with lift typically manage between 800 kg to well over 3,000 kg (6,600+ lbs), with lift heights ranging from 300 mm to 1100 mm. Their sophisticated construction and capabilities put them in the $5,000-$20,000+ price range, but for operations moving heavy items regularly, they're worth every penny.

The Wulfs Custom Welding Lift Table Trolley System exemplifies this category beautifully. With its 3,000 lbs capacity and integrated ball transfer table, it allows precise positioning adjustments – two inches side-to-side and twelve inches front-to-rear – making it perfect for applications where exact placement is as important as lifting power.

In our work at American Mortuary Coolers, we've found that specialized heavy-duty trolleys with lifts designed specifically for mortuary applications provide both the strength and respectful handling capabilities that funeral professionals need. These specialized tools become indispensable for facilities managing daily transfers with dignity and efficiency.

Where a Trolley with Lift Shines: Industries & Use Cases

A trolley with lift is like that versatile friend who somehow fits perfectly into any social gathering. These practical workhorses have found their way into countless industries, making work easier, safer, and more efficient wherever they go. Let's take a look at how different sectors are putting these handy tools to work.

Manufacturing

Walk into any modern manufacturing facility and you'll likely spot several lifting trolleys in action. They're the unsung heroes of production floors, moving components between workstations while keeping everything at just the right height for workers.

"Before we got our lifting trolleys, our team was constantly bending, stretching, and straining to position parts," says a production manager at an automotive plant. "Now we bring the work to the perfect height instead of forcing our bodies to adapt."

The innovative UNI-TROLL Trolley system showcases this adaptability perfectly. Designed to carry three 600 x 400 mm ISO modular boxes per shelf level, it helps manufacturing teams maximize both space and efficiency on busy production floors.

Warehousing & Logistics

In the world of warehousing, trolleys with lift have become as essential as the shelves themselves. Order pickers use them to access products at various heights, loading dock teams rely on them for vehicle loading, and inventory specialists count on them for efficient stock rotation.

A logistics manager from Atlanta who partners with American Mortuary Coolers for specialized transport shared: "Our electric scissor lift trolleys have transformed our order fulfillment process. Pickers can now bring the trolley to optimal working height rather than constantly bending and reaching, cutting our fulfillment time by nearly 20%."

Healthcare

Hospitals and clinics depend on specialized lifting trolleys that go far beyond patient transfers. Medical teams use them for positioning sensitive equipment, moving supplies throughout facilities, supporting maintenance operations, and even creating adjustable workstations in laboratories.

The healthcare environment demands equipment that's quiet, maneuverable in tight spaces, and easy to sanitize – requirements that well-designed lifting trolleys meet with ease.

Funeral Industry & Mortuary Services

In the funeral industry, trolleys with lift serve a particularly meaningful purpose. These specialized tools provide dignified transfer of deceased individuals, proper positioning during preparation procedures, and efficient movement between different areas of funeral homes.

At American Mortuary Coolers, we understand the unique needs of funeral professionals. That's why we've developed custom-designed trolleys with lift features specifically engineered for mortuary applications. Our solutions prioritize respectful handling while ensuring staff can work efficiently and safely across our service regions in the Southeast, Southwest, and Midwest.

Retail & E-commerce

From the stockroom to the sales floor, retail environments benefit tremendously from the flexibility of lifting trolleys. Staff use them to restock shelves at various heights, set up displays, transport merchandise, and fulfill online orders.

Modern retail-friendly options like the TAWI Lightweight Lifting Trolley weigh just 35 kg, making them perfect for navigating busy store aisles while still providing impressive lifting capability.

Real-World Wins from Deploying a Trolley with Lift

The impact of introducing trolleys with lift to a workplace is often remarkable:

A Chicago distribution center cut labor hours for stock rotation by 30% after bringing in electric lift trolleys, allowing the same staff to handle increased volume during busy seasons.

One funeral home in our Southeast service region saw workplace injuries drop by 75% after introducing our specialized mortuary trolleys with lift features. This dramatic improvement meant fewer lost workdays and reduced worker's compensation claims.

An e-commerce fulfillment center in Dallas boosted their picks per hour by 22% by switching from standard carts to electric lift trolleys – a direct result of reducing the physical strain on workers who no longer needed to constantly bend and reach.

The UNI-TROLL system helped one customer increase their usable storage space by 15% within the same physical footprint simply by making better use of vertical space.

Standard Capacities & Lift Heights You'll See on the Market

When shopping for a trolley with lift, you'll find they generally fall into a few standard categories:

Light-Duty (150-300 kg) models typically lift between 210 mm and 1000 mm. These are perfect for retail environments, light manufacturing, and office settings. Both manual scissor lifts up to 150 kg and electric models up to 300 kg fall into this category.

Medium-Duty (300-500 kg) options usually offer lift heights from 300 mm to 1500 mm. Warehouses, distribution centers, and general manufacturing facilities favor these more robust models with their larger platforms and improved stability features.

Heavy-Duty (800-1500 kg) trolleys provide lift heights from 400 mm to 1700 mm. Industrial manufacturing, heavy logistics operations, and specialized sectors rely on these workhorses with their reinforced structures and powerful lift mechanisms.

Specialized solutions, like those we provide at American Mortuary Coolers for funeral homes, are designed around specific industry needs. These often feature proprietary systems built for particular workflows, with capacities and features custom to unique applications.

Manual vs Electric: Choosing & Cost Considerations for Your Trolley with Lift

When you're in the market for a trolley with lift, one of the biggest decisions you'll face is whether to go manual or electric. It's a bit like choosing between a manual and automatic car - each has its place depending on your specific needs.

Initial Investment

Let's talk money first, since that's often what gets the conversation started. Manual scissor lift trolleys are the budget-friendly option, typically ranging from $300 to $2,000 depending on how robust you need them to be. On the other hand, electric lift trolleys will set you back anywhere from $1,500 to $6,000 or more for models with all the bells and whistles.

As Sarah, our procurement specialist at American Mortuary Coolers, often tells clients: "The sticker price is just one piece of the puzzle. Think about how many times a day you'll be raising and lowering that platform. Your back might thank you for spending a bit more upfront."

Operational Considerations

Before you make your decision, take a moment to consider your day-to-day operations:

How often will you be adjusting heights? If you're only making a few adjustments per hour, a manual model might serve you perfectly well. But if your team is constantly raising and lowering loads, electric models start looking like a much better investment for preventing fatigue.

Where will you be using it? Manual models shine in outdoor settings or areas where electrical components might be problematic. They're also great in places where you don't have reliable access to charging stations.

What about your workspace layout? In tight quarters, the typically more compact manual models might steer better. In open spaces, the slightly bulkier electric models won't cause any issues.

And don't forget about power access. If your facility doesn't have convenient places to plug in, you'll either need to create a charging station or stick with manual options.

Total Cost of Ownership Analysis

Looking at the bigger picture reveals some interesting insights:

Manual trolleys with lift win on simplicity - no batteries to replace, no charging needed, and generally fewer things that can break down. However, they introduce hidden costs through operator fatigue and the potential for strain injuries when used frequently.

Electric trolleys with lift require more upfront investment and some ongoing costs like battery replacements every few years. But they more than make up for it in reduced physical strain, higher productivity, and happier employees when used in the right settings.

When a Manual Trolley with Lift Makes Sense

Manual models are still the right choice in many scenarios. They're perfect for low-volume operations where lifting happens just a few times per day. If you're working with tight budget constraints, they'll get the job done without breaking the bank.

They also shine in outdoor environments or places where electrical components might be problematic. Many of our funeral home clients in rural areas prefer manual models as backup units since they're always ready to go, even during power outages.

One funeral director in our Southwest Region recently told us, "We went with manual trolleys in our preparation room because we only need to adjust heights a few times per day, and we wanted something simple that all our staff could use without special training."

Why Upgrade to an Electric Trolley with Lift

Electric models really prove their worth in certain scenarios. If your team is performing high-frequency lifting operations, the reduced physical strain can prevent fatigue and injuries. They're also ideal when ergonomic concerns are a top priority in your workplace safety program.

Many of our clients appreciate the consistent lifting speed that electric models provide, especially when standardizing processes across multiple locations. And in today's challenging labor market, anything that makes physical jobs less demanding is a major plus.

The TAWI Lightweight Lifting Trolley is a perfect example of these benefits in action. On a single battery charge, it can perform about 100 lifts of 1 meter each while maintaining a steady lifting speed of 125 mm/s. For busy operations, that kind of reliable performance translates directly to getting more done with less strain.

At American Mortuary Coolers, we've helped countless funeral homes find the perfect balance between budget and functionality. Whether you're looking for something simple and reliable or need a powered solution for busier facilities, we'll help you find the right trolley with lift for your specific needs.

Safety, Maintenance & Future-Proof Features

When you invest in a trolley with lift, you're not just buying equipment—you're investing in workplace safety and efficiency. Let's explore how to keep your lifting trolley running smoothly for years to come, with insights we've gained from working with funeral homes across the country.

Essential Safety Features

Today's lifting trolleys come packed with safety features that protect both operators and valuable loads. At American Mortuary Coolers, we've seen how these features prevent accidents and build operator confidence.

Good braking systems are your first line of defense. Look for total-stop brakes that lock wheels securely during lifting operations, preventing those heart-stopping moments when equipment shifts unexpectedly. Some electric models even feature automatic braking when the handle is released—a small feature that can prevent big accidents.

Overload protection is another non-negotiable safety element. Quality hydraulic systems include pressure relief valves that simply refuse to lift beyond rated capacity. More advanced electric models might include sensors that cut power automatically when detecting excess weight, often with warning lights or sounds to alert operators.

"I remember visiting a funeral home where a director had injured his back trying to lift a trolley that was stuck under too much weight," shares our safety coordinator. "Good overload indicators would have prevented weeks of pain and staff shortages."

Anti-drop protection provides peace of mind when loads are suspended. Look for mechanical safety stops, anti-drop plates, and hydraulic check valves that keep platforms stable even if something goes wrong with the primary lifting system.

For electric models, emergency stop buttons should be prominent and easy to reach. And regardless of trolley type, proper guards around pinch points will protect fingers and hands during operation.

IP Ratings and Environmental Protection

If you're considering an electric trolley with lift for environments with moisture or dust, pay attention to IP (Ingress Protection) ratings. An IP54 rating works fine for standard indoor settings, while IP65 offers protection in washdown areas. For particularly harsh environments, IP67 models provide protection even against temporary water immersion—though they'll cost more.

We often recommend higher IP-rated models for preparation rooms in funeral homes, where cleaning procedures can involve significant moisture.

Daily & Annual Maintenance Checklist

A well-maintained trolley with lift will serve you faithfully for years. Here's what we recommend to our customers:

Start each day with quick visual checks—look for hydraulic leaks, test lifting functions, and examine wheels for debris. For electric models, check battery levels before starting work. These five-minute inspections can prevent hours of downtime later.

Monthly, take time to lubricate moving parts according to your manufacturer's guidelines. Inspect structural components more carefully and verify that all safety features work correctly. Check hydraulic fluid levels and condition—dark or cloudy fluid often signals problems brewing.

Annual service should be more comprehensive. Have hydraulic systems thoroughly inspected and fluids replaced if needed. Examine all structural welds and connection points for signs of fatigue. For electric models, have the electrical system professionally assessed. This is also the time to replace worn components before they fail.

"Maintenance records aren't just paperwork," our service manager often tells customers. "They're your protection against liability and your roadmap for equipment longevity." Keep detailed logs of all service, both for regulatory compliance and to track patterns that might indicate developing issues.

Battery Care for Electric Models

If you've invested in an electric trolley with lift, proper battery care will significantly extend its useful life. Many industrial batteries perform best when fully discharged before recharging, though this varies by battery type.

Temperature matters enormously for battery health. Extreme heat or cold can dramatically reduce capacity and lifespan. Store and charge your equipment in climate-controlled areas when possible.

Plan for regular battery testing and replacement. Most industrial batteries need replacement every 2-3 years, even with perfect care. Budget for this expense as part of your total cost of ownership.

The TAWI Lightweight Lifting Trolley uses a 2 × 12V 7Ah battery system delivering approximately 100 lifts per charge. Understanding your model's specific performance helps you plan daily workflows without unexpected power losses.

Emerging Trends to Watch

The world of trolley with lift technology continues to evolve in exciting ways. Some advanced models now incorporate self-driving capabilities—imagine equipment that follows predetermined routes or responds to voice commands, freeing staff for more skilled tasks.

Smart sensors and Internet of Things (IoT) integration are changing maintenance from reactive to predictive. These systems collect usage data and can alert you to potential issues before failures occur.

Modular attachment systems represent another significant advancement. These adaptable platforms can quickly transform to handle different load types, increasing versatility and return on investment.

Sustainability has become a major focus, with manufacturers using eco-friendly materials and design processes that reduce environmental impact while often improving durability. At American Mortuary Coolers, we've acceptd this trend in our own manufacturing.

Improved ergonomics make modern lifting trolleys more intuitive to operate, reducing training requirements and operator fatigue. These human-centered design improvements often translate directly to increased productivity and reduced workplace injuries.

In the funeral industry, we're particularly interested in how these innovations can improve dignity in handling while maintaining the reliability that funeral directors depend on every day. After all, when you're caring for someone's loved one, equipment failure simply isn't an option.

Frequently Asked Questions about Trolleys with Lift

How do I size a trolley with lift for my load?

Choosing the right trolley with lift isn't just about matching numbers on a spec sheet—it's about finding equipment that truly fits your daily operations.

When sizing your trolley, start by determining your maximum load weight, including any containers or packaging that will ride along. Then, add a safety buffer of about 20-25%—this isn't just cautious, it's smart business. A trolley rated for 500 kg when you regularly move 450 kg items leaves very little room for error.

Platform dimensions matter just as much as weight capacity. I've visited countless facilities where teams purchased adequately strong trolleys only to find their oddly-shaped loads couldn't sit properly on the platform.

"Nearly half our customers initially focus solely on weight ratings," shares Mark, our lead engineer at American Mortuary Coolers. "But in practice, it's often the platform size and maximum lift height that determine whether the equipment truly serves their needs."

Don't forget to evaluate your space constraints too. A larger platform provides stability but might be challenging to maneuver in tight corridors or crowded workspaces.

For specialized industries like funeral services, we always recommend speaking with experts who understand your unique requirements. That's why American Mortuary Coolers provides customized solutions custom to the specific needs of funeral homes throughout our service regions.

What safety certifications should I look for?

Safety isn't optional when it comes to lifting equipment, and the right certifications provide peace of mind that your trolley with lift meets established standards.

If you're in North America, look for equipment that complies with ANSI/ITSDF B56.5 standards for powered industrial trucks. Electric models should carry UL or CSA electrical system certifications, confirming they've been tested for electrical safety. OSHA compliance documentation is also essential for workplace equipment.

European facilities should seek the CE marking, which indicates conformity with EU health, safety, and environmental protection standards. EN 1570 compliance applies specifically to lifting tables, while ISO 3691 covers powered industrial trucks.

Beyond formal certifications, check for practical safety features that protect your team daily: clearly marked load capacities, emergency lowering mechanisms that work even during power failures, and overload protection systems that prevent dangerous lifting attempts.

At American Mortuary Coolers, we understand that safety is particularly important in the funeral industry, where dignity in handling is paramount. That's why all our equipment meets or exceeds relevant safety standards, giving our clients confidence whether they're in Tennessee, Georgia, Illinois, or anywhere else we serve.

Are there ergonomic or sustainability benefits?

The ergonomic advantages of a well-designed trolley with lift transform how people work—and how they feel at the end of their shift.

By bringing work to the ideal height, these trolleys virtually eliminate the need to bend repeatedly or reach awkwardly for items. This isn't just about comfort; it's about preventing injuries that can change lives. When surfaces match in height, items can be slid rather than lifted, dramatically reducing strain on backs and shoulders.

"We worked with a funeral home in Georgia that reported a 70% decrease in staff complaints about back discomfort after introducing height-adjustable trolleys," notes our customer success manager. "Their team could position deceased individuals at the perfect working height for preparation procedures, reducing physical strain during what's already emotionally demanding work."

The adjustability also means workers of different heights can all work comfortably with the same equipment—a significant advantage in today's diverse workforce.

From a sustainability perspective, modern trolleys with lift contribute meaningfully to greener operations. Quality models often remain in service for over a decade with proper maintenance, reducing manufacturing demand and associated environmental impacts. Many electric models now incorporate energy recovery during lowering operations, capturing and reusing power that would otherwise be wasted.

The UNI-TROLL system exemplifies this forward-thinking approach, with design principles explicitly aligned with UN Sustainable Development Goals throughout the supply chain.

Perhaps most importantly, these trolleys optimize space utilization by enabling vertical storage and movement, allowing facilities to make better use of their existing footprint rather than expanding—a considerable sustainability win in both construction materials saved and land preserved.

Conclusion

Choosing the perfect trolley with lift isn't just about picking equipment—it's about changing how your team works. From simple manual scissor lifts that shine in occasional-use settings to sophisticated electric models that power through high-volume operations, there's a solution waiting to match your specific challenges.

Here at American Mortuary Coolers, we've seen how the right equipment makes all the difference. Our years serving funeral homes across Tennessee, Georgia, Illinois, New York, Texas and beyond have taught us an important lesson: personalized solutions deliver the greatest value. Whether you're carefully handling sensitive items in healthcare, managing warehouse inventory, or providing dignified care in a funeral home, your lifting trolley choice matters deeply.

What we've learned matters most when selecting your trolley with lift:

Finding the perfect match between trolley type and your specific needs should be your first priority. Consider how often you'll use it, what you'll be lifting, and where you'll be using it. The difference between an occasional-use manual model and a hardworking electric version can dramatically impact your daily operations.

Looking beyond the price tag reveals the true value. When you factor in the operational benefits, ongoing maintenance, and expected service life, sometimes the more expensive option actually costs less in the long run. Our customers often tell us the productivity gains alone justify upgrading to premium models.

Safety features aren't optional extras—they're essential protections. Never compromise on overload protection, anti-drop mechanisms, and reliable braking systems. These features protect both your team and the items being transported.

A simple maintenance routine can add years to your equipment's life. Just like changing the oil in your car, regular care of your trolley with lift prevents costly breakdowns and extends its useful service. We recommend creating a simple maintenance calendar to keep everything running smoothly.

The ergonomic benefits often surprise our customers most. The right lifting trolley doesn't just move things—it protects your team from strain injuries while naturally improving productivity. Many clients report this as the most valuable benefit over time.

For specialized funeral industry applications, American Mortuary Coolers offers custom-built solutions with the durability and respectful functionality needed for dignified handling. We deliver directly to all 48 contiguous states, ensuring that funeral homes nationwide can access the equipment they need to serve their communities with care and efficiency.

The ideal trolley with lift isn't necessarily the one with the highest price tag or the longest feature list—it's the one that solves your specific challenges while providing reliable service for years to come. It's about finding that perfect balance between functionality, durability, and value.

For more information about specialized lifting solutions for the funeral industry, take a look at our resources on reliable mortuary hydraulic body lifts or visit your one-stop shop for mortuary coolers.