Why Cart Trays Are Essential for Professional Operations

A cart tray is a portable platform or container designed to organize, transport, and secure items on wheeled carts across various professional environments. Cart trays serve multiple critical functions:

- Transport: Move equipment, supplies, or materials safely between locations

- Organization: Keep items contained and prevent spills or loss during movement

- Efficiency: Reduce handling time and improve workflow in busy facilities

- Safety: Provide secure storage with features like raised edges and locking mechanisms

- Hygiene: Offer easy-to-clean surfaces that meet sanitation standards

Cart trays are widely used across industries including healthcare, foodservice, laboratories, retail, and mortuary services. They range from simple plastic organizers to sophisticated insulated systems with temperature control capabilities.

The mortuary industry particularly benefits from specialized cart trays designed for secure transport of sensitive materials. According to research data, professional-grade cart trays like the Cambro TDCR12 can handle substantial loads (up to 90 lbs) while maintaining NSF sanitation compliance - critical factors for funeral homes and morgues.

"This humble plastic tray is one of the items most requested by Montessori teachers!" - a testament to how essential these simple tools become across professional settings.

As American Mortuary Coolers, a national-level mortuary cooler supplier, we've seen how the right cart tray can transform operational efficiency in funeral homes and morgues. Our experience working with funeral directors across Tennessee, Atlanta, Chicago, and beyond has shown that choosing quality cart trays directly impacts both staff productivity and service reliability.

Must-know cart tray terms:

What Is a Cart Tray and Why Every Facility Needs One

Think of a cart tray as the unsung hero of professional facilities. It's essentially a specialized platform that turns any wheeled cart into a powerhouse of organization and efficiency. Whether you're running a mortuary, hospital, laboratory, or warehouse, these trays solve problems you didn't even know you had.

Here's what makes cart trays so valuable: they create mobile workstations that follow your staff around. No more endless trips back to the supply room or fumbling with loose items that slide around during transport. Everything stays exactly where it should be.

In mortuary work, this reliability becomes absolutely critical. When you're handling sensitive materials or working with grieving families, the last thing you need is equipment failure or disorganization. A quality cart tray ensures that your tools, supplies, and materials move safely from one location to another.

The sanitation aspect can't be overstated either. Professional cart trays are built with smooth, non-porous surfaces that clean easily and resist bacterial growth. This isn't just convenient – it's essential for meeting health department standards and maintaining the dignity that funeral service requires.

What really sets these systems apart is their thoughtful design. Features like raised perimeter edges contain spills before they become problems. Heavy-duty materials handle the weight of equipment without warping or cracking. And mobility features like quality casters make transport smooth and quiet – important when moving through facilities where families may be present.

The numbers don't lie about their importance. Professional facilities across the country have invested heavily in cart tray systems, with warehouses dedicating hundreds of thousands of square feet just to meet demand. This widespread adoption reflects a simple truth: when you find a tool that genuinely makes work easier and safer, you stick with it.

At American Mortuary Coolers, we've seen how the right cart tray can transform a funeral home's daily operations. It's one of those investments that pays for itself through improved efficiency and reduced stress on your staff.

Types of Cart Trays and Their Industry Applications

Choosing the right cart tray isn't a one-size-fits-all decision. Different industries have developed specialized solutions that address their unique challenges, from maintaining sterile conditions in hospitals to protecting sensitive electronics in retail environments.

The beauty of modern cart tray design lies in how manufacturers have fine-tuned these systems for specific applications. What works perfectly in a busy restaurant kitchen might be completely wrong for a laboratory handling biological specimens.

Mortuary & Laboratory Cart Tray Options

When you're working with body trays and cadaver trays, there's no room for compromise on materials or construction. These cart trays are almost exclusively built from stainless steel - and for good reason. The easy cleaning properties and secure transport features aren't just conveniences; they're essential for maintaining the dignity and safety that these environments demand.

Specimen trays take a slightly different approach, often incorporating compartmentalization to prevent any possibility of cross-contamination. We've seen funeral homes make the switch from improvised transport solutions to proper stainless steel cart trays, and the difference is immediately obvious. Fewer spills, easier cleaning, and most importantly, the peace of mind that comes from knowing you're using equipment designed specifically for these sensitive applications.

The stainless steel construction isn't just about looking professional. These surfaces can handle the aggressive cleaning chemicals required in mortuary and laboratory settings while maintaining their integrity year after year.

Utility & Service Carts

Workshop environments need cart trays that can handle serious weight while staying organized. Take the UCA1500 Utility Cart Tray - it supports up to 80 pounds while providing integrated cable management features. This makes it perfect for hauling audio-visual equipment or electronic devices without creating a tangled mess of cords.

The lockable casters on these utility trays might seem like a small detail, but they're crucial when you need your mobile workstation to stay put. Many models include clever storage solutions like handle-mounted bags with multiple pockets, essentially creating a workshop that rolls wherever you need it.

These aren't just trays with wheels - they're complete mobile workstations designed to adapt to whatever task you're tackling.

Specialized Healthcare Trays

Healthcare facilities have pushed cart tray innovation in fascinating directions. Insulated trays and denested carts for meal delivery have become incredibly sophisticated. Aladdin Temp-Rite's denested insulated tray transport carts come in 12 and 20 tray capacities, and they're engineered to reduce meal delivery errors while maintaining food quality.

The individual tray suspension systems and formed-in tray retainers might sound like engineering overkill, but they solve real problems. When you're navigating busy hospital corridors, those perimeter shoulders that prevent trays from sliding during transport become essential safety features.

Patient and staff safety drives every design decision in these specialized healthcare trays, from temperature retention to secure containment during transport.

Storage & Transport Trays

The newest frontier in cart tray design focuses on creating true mobile workstations. Anti-static materials protect sensitive devices, while specialized mounting systems can transform ordinary shopping carts into secure mobile offices.

Compucart trays, which have been 100% made in America since 1995, demonstrate this evolution perfectly. They can convert any standard shopping cart into a workstation for tablets, laptops, and other electronic devices. The theft-deterrent features and anti-static materials show how cart tray innovation continues expanding into applications nobody imagined just a few years ago.

These storage and transport trays prove that the humble cart tray has evolved far beyond simple containment - they're now sophisticated tools for device and sample protection in our increasingly mobile work environments.

Construction Materials & Key Features to Look For

The materials used in cart tray construction directly impact durability, hygiene, and operational lifespan. Understanding these materials helps ensure you select trays that will perform reliably in your specific environment.

Stainless steel remains the gold standard for mortuary and healthcare applications. Its non-porous surface resists bacterial growth while standing up to aggressive cleaning chemicals. The research shows that stainless steel construction with reinforced bead welding provides the heavy-duty performance needed in demanding environments.

Polypropylene (PP#5) offers excellent chemical resistance and is both PVC-free and BPA-free, making it ideal for applications where food safety or chemical compatibility is important. This material is particularly popular in educational and food service applications.

Aluminum provides an excellent strength-to-weight ratio, making it perfect for applications where the cart tray needs to be both durable and lightweight. Aluminum construction is often found in utility carts where mobility is prioritized.

ABS plastic offers impact resistance and easy cleaning while remaining cost-effective for high-volume applications. Many commercial cart trays use ABS construction with specialized coatings to improve durability.

Key features to prioritize include:

- Reinforced bead welding for joints that won't fail under load

- Rust-resistant coatings that extend operational life

- Swivel casters with at least two locking wheels

- Effective braking systems for safety during loading and unloading

- Perimeter shoulders or raised edges to contain contents during transport

The Cambro TDCR12, with its 90-pound capacity and NSF listing, demonstrates how proper material selection and construction techniques create cart trays that perform reliably for years.

Insulated Tray Carts: Keeping Contents Safe and Secure

When temperature matters, insulated cart trays become absolutely essential. These specialized systems do more than just transport items - they create a protective environment that maintains proper temperatures whether you're moving meals through hospital corridors or transporting temperature-sensitive specimens in a mortuary setting.

The magic happens in the insulation design itself. Quality insulated carts can maintain proper temperatures for several hours, giving staff the flexibility to make efficient batch deliveries without constantly worrying about temperature loss. This isn't just convenient - it's often a safety requirement.

Perimeter bumpers serve double duty on these carts. They protect the cart from damage when navigating tight doorways and corners, but they also shield walls and equipment from dings and scratches. Anyone who's tried to maneuver a fully loaded cart through a busy facility knows how valuable this protection becomes.

The secure transport features make all the difference during actual use. Secure latching systems prevent accidental opening during transport - imagine the chaos if a cart full of meal trays suddenly opened while going around a corner! Individual tray suspension and formed-in retainers keep contents from shifting around, maintaining both temperature and presentation quality throughout the journey.

Hospital and mortuary corridors present unique challenges for cart navigation. These environments demand carts that steer smoothly while maintaining their protective function. The research shows that well-designed systems like Aladdin Temp-Rite carts handle these demands effectively, with features specifically engineered for professional healthcare environments.

Scientific research on temperature control and safety dives deeper into how proper insulation design directly impacts safety and quality retention during transport - essential reading for anyone responsible for temperature-sensitive transport operations.

Safety, Ergonomics & Maintenance Best Practices

When you're moving heavy equipment or sensitive materials day after day, the last thing you want is a cart tray that fights you every step of the way. That's why worker safety and ergonomic design should be your top priorities when selecting cart trays for your facility.

The best cart trays feel natural to use. Push/pull handles positioned at comfortable heights make all the difference during long shifts. Heavy-duty casters that roll smoothly reduce the effort needed to steer tight corners and doorways. When your staff isn't struggling with equipment, they can focus on providing the compassionate service families deserve.

Non-marking bumpers serve a dual purpose - they protect your walls and equipment from damage while giving operators a clear sense of the cart's boundaries. This is especially important in funeral homes where maintaining a pristine environment is essential for families' peace of mind.

Load distribution isn't just about following rules - it's about preventing accidents. That 80-pound capacity limit on utility cart trays exists for good reason. Exceeding weight limits can cause structural failure or tipping, potentially injuring staff or damaging sensitive equipment. Even weight distribution across the tray surface prevents dangerous tipping during transport.

Proper maintenance keeps your cart trays safe and extends their working life significantly. NSF guidelines provide the roadmap for effective cleaning and sanitation in commercial environments. The key is understanding which cleaning chemicals work effectively without damaging your specific cart tray materials.

Stainless steel trays can handle aggressive disinfectants, while plastic components may require gentler approaches. Regular inspection of casters, handles, and structural components helps you catch potential problems before they become safety hazards. Those lockable casters should engage firmly every time, and swivel mechanisms should move freely without excessive wobbling.

For comprehensive information about maintaining hygienic conditions in mortuary environments, see our guide on morgue storage solutions.

A well-maintained cart tray isn't just equipment - it's an investment in your staff's safety and your facility's professional reputation. When families are going through difficult times, they notice when everything runs smoothly and professionally.

Cost, Customization & Leading Brands

When it comes to cart tray pricing, you'll find options that range from budget-friendly to premium professional-grade systems. The key is understanding what you're getting for your investment and how it matches your facility's needs.

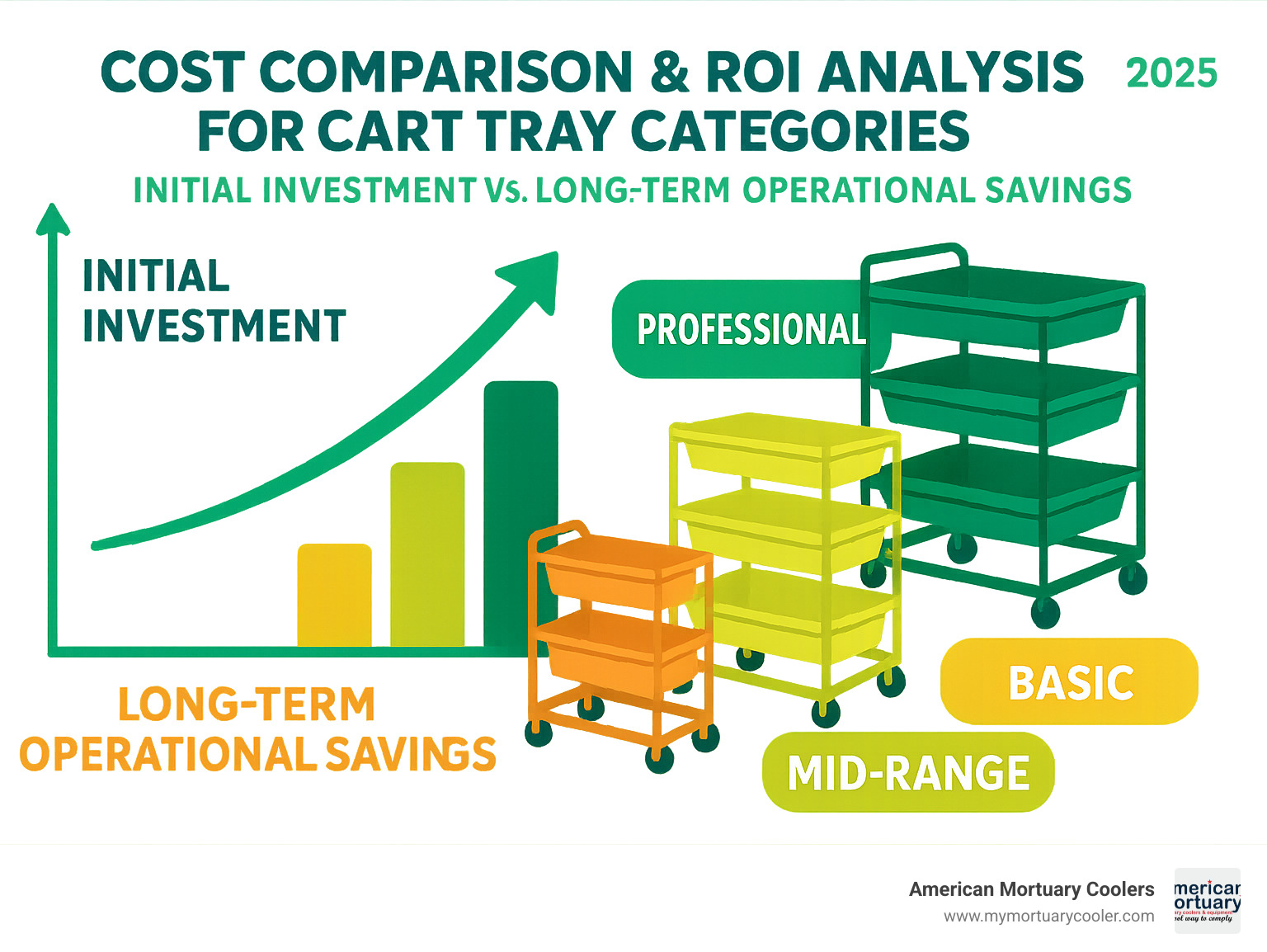

Basic utility trays start around $15-50 for simple plastic construction. These work well for light-duty applications where you need basic organization without breaking the budget. Mid-range options in the $50-200 range typically offer better materials, higher capacity ratings, and the kind of durability that handles daily use without constant replacement.

For specialized applications like insulated transport or heavy-duty mortuary use, professional-grade systems can range from $200-1000+. While that might seem steep, we've seen how investing in quality cart trays actually saves money over time through reduced maintenance costs and improved operational efficiency.

At American Mortuary Coolers, we understand that every funeral home has unique needs. That's why our custom solutions often include color options to match your facility's aesthetics, tray dividers for better organization, and locking lids when security is a concern.

The accessories that really make a difference include removable dividers for flexible organization, locking mechanisms for security, and custom drainage systems that make cleaning a breeze. We also offer specialized mounting hardware for unique applications, color-coding systems for department identification, and anti-static treatments when you're working with sensitive electronics.

Innovation in cart tray design is moving toward modularity - systems that let you reconfigure as your needs change. Smart features like RFID tracking and integrated temperature monitoring are starting to appear in high-end systems, particularly for healthcare and pharmaceutical applications.

It's worth noting that even consumer-grade options are gaining popularity. The Mainstays 3-Tier Plastic Multi-Purpose Rolling Laundry Cart has over 1,200 reviews and sits in more than 100 people's carts, showing how versatile cart solutions are finding their way into all kinds of applications beyond traditional commercial use.

Frequently Asked Questions about Cart Trays

What size cart tray is right for my operation?

Choosing the right cart tray size feels overwhelming at first, but it comes down to two simple questions: what are you moving, and where are you moving it?

Start by measuring your largest items. In our experience working with funeral homes across Tennessee and beyond, we've learned that most facilities need trays that handle their biggest specimens while still fitting through standard doorways. Those 32-36 inch doorways are your limiting factor in most buildings.

The Cambro TDCR12 gives you a good reference point with dimensions of 38 1/8" x 22 3/4" x 41 1/4". This size works well for most mortuary operations because it balances capacity with maneuverability - you can carry what you need without getting stuck in tight corners.

Load rating matters just as much as size. Here's a simple rule we share with our clients: calculate your heaviest typical load, then add 25% to that number. This safety buffer prevents overloading and accounts for those times when weight isn't distributed perfectly. A cart tray that's stressed to its limits won't last long, and nobody wants equipment failing during critical operations.

How do I clean and sanitize a cart tray safely?

Cleaning your cart tray properly isn't just about making it look good - it's about maintaining the health standards your facility depends on. The approach depends entirely on what your tray is made from.

Stainless steel trays can handle the aggressive disinfectants common in mortuary work. These materials were chosen specifically because they won't break down under harsh cleaning chemicals. Plastic trays need gentler treatment to prevent cracking or clouding that can harbor bacteria.

Always gear up first. Gloves and eye protection aren't optional when you're working with cleaning chemicals. We've seen too many avoidable injuries from splashes or skin contact with disinfectants.

The cleaning process itself is straightforward: clear everything out, remove visible debris, apply your cleaning solution, wait for the recommended contact time, then rinse thoroughly. NSF-listed cart trays come with specific instructions that keep you compliant with health department standards. Following these procedures protects both your staff and your facility's operating license.

Are cart trays compatible with existing carts or dollies?

Most cart trays are designed to work with standard equipment, but checking compatibility before you buy saves headaches later. The good news is that manufacturers generally stick to common sizing standards.

Standard shopping carts with child seats work with most retail-style trays. Utility carts often use standardized mounting systems that make swapping trays relatively simple. But "standard" doesn't mean universal - always measure your existing equipment and compare it to the tray specifications.

Retrofit kits can bridge the gap when your existing cart doesn't quite match your new tray. Universal mounting hardware adapts most trays to different cart configurations, though some unique setups need custom solutions.

When you're unsure, measure twice and buy once. Most manufacturers provide compatibility charts or can recommend mounting solutions for your specific setup. At American Mortuary Coolers, we often help customers work through compatibility questions because getting it right the first time saves everyone time and money.

Conclusion

Choosing the right cart tray doesn't have to be overwhelming. After years of helping funeral homes and morgues across the country, we've learned that the best cart tray is simply the one that makes your daily work easier and safer.

The research we've covered shows that quality cart trays genuinely improve how facilities operate. Your staff will feel less strain, your workflows will run smoother, and you'll spend less time worrying about spills or equipment failures. That's not marketing speak - it's what we see every day in the field.

When you're making your selection, focus on the basics first. Material compatibility with your cleaning products matters more than fancy features. Load capacity should handle your heaviest typical loads with room to spare. Quality casters and ergonomic handles will save your staff's backs over the long haul. Secure containment and stability prevent the accidents nobody wants to deal with.

Don't forget about compliance requirements either. NSF, FDA, and other industry standards exist for good reasons, and staying compliant protects both your facility and the families you serve.

At American Mortuary Coolers, we've seen every kind of facility setup imaginable across the contiguous 48 states. What works perfectly in a small-town funeral home might not suit a busy urban mortuary. That's why we focus on understanding your specific needs rather than pushing one-size-fits-all solutions.

The cart tray industry keeps evolving too. Anti-static materials, temperature control systems, and other innovations solve real problems that facilities face every day. But remember - the fanciest cart tray in the world won't help if it doesn't match how your team actually works.

Whether you're moving sensitive materials, organizing medical supplies, or creating mobile workstations, investing in the right cart tray system pays for itself through improved efficiency and fewer headaches. Your future self will thank you for taking the time to choose wisely.

For comprehensive information about how cart trays work alongside cooling systems and other mortuary equipment, check out our mortuary coolers guide.

The bottom line? Get a cart tray that fits your space, handles your loads, and stands up to your daily routine. Everything else is just details. Take your time, consider where your facility might grow, and invest in equipment that'll still be serving you well years from now.